Article Contents

Industry Insight: Neon Led Flexible

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the demand for versatile, energy-efficient, and visually impactful solutions. Flexible LED neon lighting has rapidly emerged as a pivotal technology within this evolution, moving far beyond its decorative origins to become a strategic asset for architects, facility managers, and lighting specifiers. Its unique combination of bendable form, consistent linear illumination, and robust performance addresses critical challenges in modern commercial environments – from defining dynamic retail displays and hospitality ambiance to providing highly visible, code-compliant safety egress pathways and industrial zone marking in warehouses and manufacturing facilities. Crucially, the adoption of these systems in professional settings hinges on demonstrable safety and reliability, making adherence to stringent international standards like ETL certification for the North American market and CE marking for Europe non-negotiable prerequisites, not optional extras. These certifications provide the essential assurance that flexible neon products meet rigorous electrical safety, performance, and environmental requirements for demanding 24/7 commercial and industrial operations.

Beauty STC Manufacturing Co., Ltd. stands at the forefront of this advancement. Established in 1998, we have dedicated over two decades to pioneering high-performance LED lighting solutions engineered specifically for professional applications. Our deep-rooted expertise in optical design, thermal management, and robust construction protocols ensures our flexible LED neon systems deliver not only exceptional aesthetic quality and design flexibility but also the unwavering durability, long-term lumen maintenance, and certified safety demanded by commercial and industrial clients worldwide. We understand that in these settings, lighting is infrastructure – it must perform flawlessly, reduce operational costs, and integrate seamlessly into complex building systems, which is why Beauty STC remains committed to innovation grounded in real-world engineering rigor and global compliance.

Technical Specs & Certifications

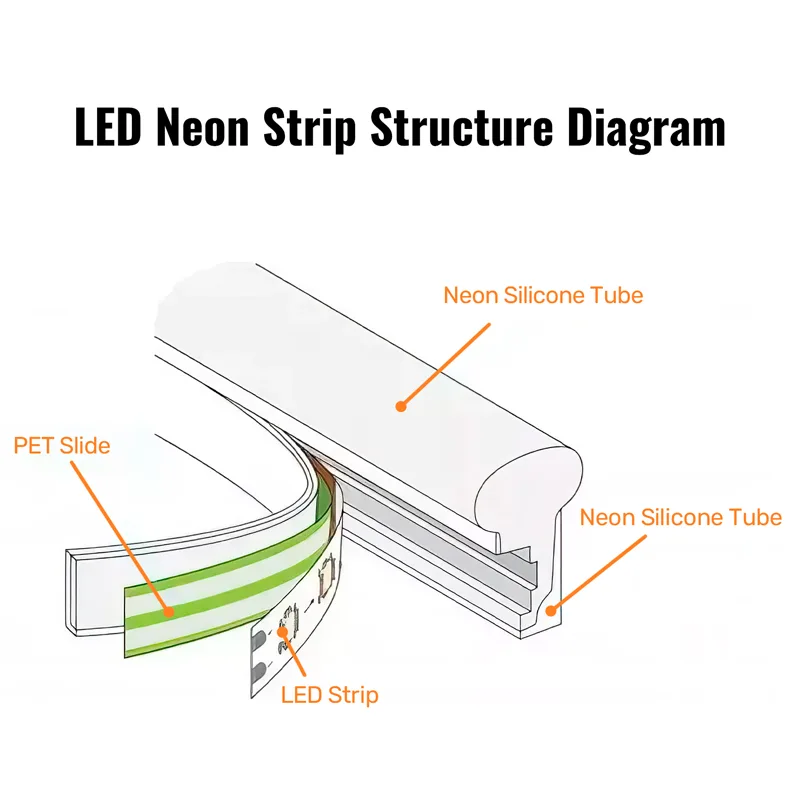

The Neon LED Flexible lighting product line from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial applications. Designed to replicate the soft, continuous glow of traditional neon while offering the efficiency and durability of modern LED technology, this flexible strip delivers exceptional photometric performance and build quality.

In terms of efficiency, the Neon LED Flexible series achieves a luminous efficacy of up to 120 lumens per watt, depending on color temperature and density configuration. This high lumen-to-watt ratio ensures energy-efficient operation without compromising brightness, making it ideal for long-duration installations where power consumption and thermal management are critical.

Color rendering is a key strength of this product. All variants in the Neon LED Flexible range feature a Color Rendering Index (CRI) greater than 90, with some models reaching CRI 95. This ensures accurate and vibrant color reproduction, essential for applications in retail displays, architectural accent lighting, hospitality environments, and art installations where true-to-life color representation is paramount.

Regarding environmental protection, Beauty STC offers multiple IP rating options to suit diverse installation conditions. The standard version is rated IP65, providing protection against dust and low-pressure water jets, making it suitable for indoor and semi-outdoor use. For fully outdoor or high-moisture environments such as signage, façade lighting, or under-cabinet kitchen applications, an IP67-rated version is available, offering complete dust tightness and temporary immersion resistance up to 1 meter for 30 minutes. The silicone overmolding used in higher IP-rated models ensures long-term durability, UV resistance, and consistent optical clarity.

Beauty (STC) Manufacturing Co., Ltd. maintains stringent quality control throughout production, using high-grade SMD LEDs, precision-flexible PCBs, and robust silicone encapsulation. Each batch undergoes rigorous testing for color consistency, thermal performance, and electrical safety, ensuring long operational life—typically rated at 50,000 hours (L70). The company’s adherence to international standards including CE, RoHS, and UL certifications underscores its commitment to safety, reliability, and environmental responsibility.

Overall, Beauty STC’s Neon LED Flexible strips combine high efficiency, excellent color fidelity, and superior ingress protection, making them a trusted choice for designers and contractors seeking premium-quality, durable, and visually consistent LED lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED production capacity, specifically engineered to support high-volume, high-quality output for global markets. This strategically located factory leverages Jiangmen’s strong industrial ecosystem and logistics advantages within the Pearl River Delta region. Central to its operations is a dedicated surface mount technology (SMT) production line equipped with state-of-the-art Yamaha YS series placement machines. These machines feature high-speed, high-precision nozzles capable of handling ultra-small 0201 and 0402 LED components alongside larger drivers and connectors, ensuring consistent placement accuracy essential for reliable flexible LED products. The SMT lines operate with automated optical inspection (AOI) systems integrated directly into the workflow, enabling real-time defect detection and immediate process correction to maintain stringent quality standards before products proceed to subsequent stages.

Rigorous reliability testing is a cornerstone of the Jiangmen factory’s quality control protocol, with aging tests forming a critical phase for all LED products, particularly the neon flexible line. Every batch of neon LED flexible strips undergoes a mandatory 72-hour continuous aging process under controlled thermal and electrical conditions that simulate extended operational life. This occurs in dedicated environmental chambers where products operate at rated voltage while temperature sensors monitor thermal performance across the strip length. Any units exhibiting lumen depreciation beyond specified thresholds, color shift, or failure during this extended burn-in are automatically rejected, ensuring only units meeting Beauty STC’s durability benchmarks reach customers. This systematic aging verification is non-negotiable for both standard and custom OEM orders.

The factory possesses comprehensive OEM capability specifically tailored for neon LED flexible products, making it a preferred partner for brands requiring customized solutions. This capability spans the entire product lifecycle from initial concept to finished goods. Engineering teams collaborate closely with clients to develop bespoke specifications including unique color temperatures, special RGBW or tunable white configurations, custom silicone diffuser profiles and colors, specific cut lengths, connector types, and voltage requirements. The Jiangmen facility supports full vertical integration for these custom orders, handling everything from specialized PCB design and SMT assembly of client-specific component layouts, through silicone extrusion and overmolding for the neon-like appearance, to final aging, testing, and packaging under the client’s branding. This includes managing client-supplied components if required and adhering strictly to confidential manufacturing agreements, all while maintaining compliance with international safety standards such as UL, CE, and RoHS through in-house testing labs and certified processes. The combination of advanced SMT, uncompromising aging validation, and deep OEM customization expertise positions the Jiangmen factory as a robust manufacturing hub for sophisticated neon flexible LED solutions.

Application Scenarios

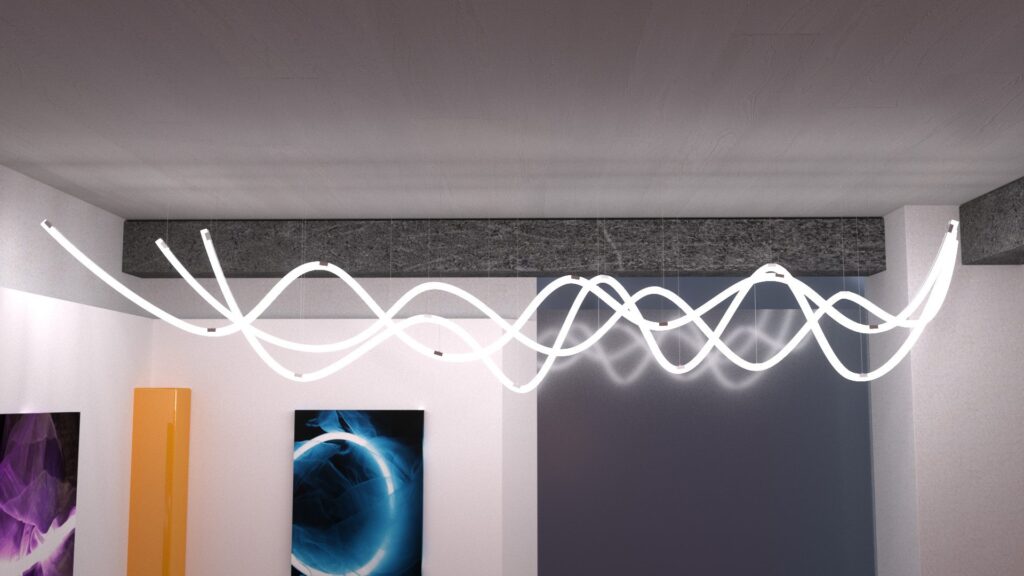

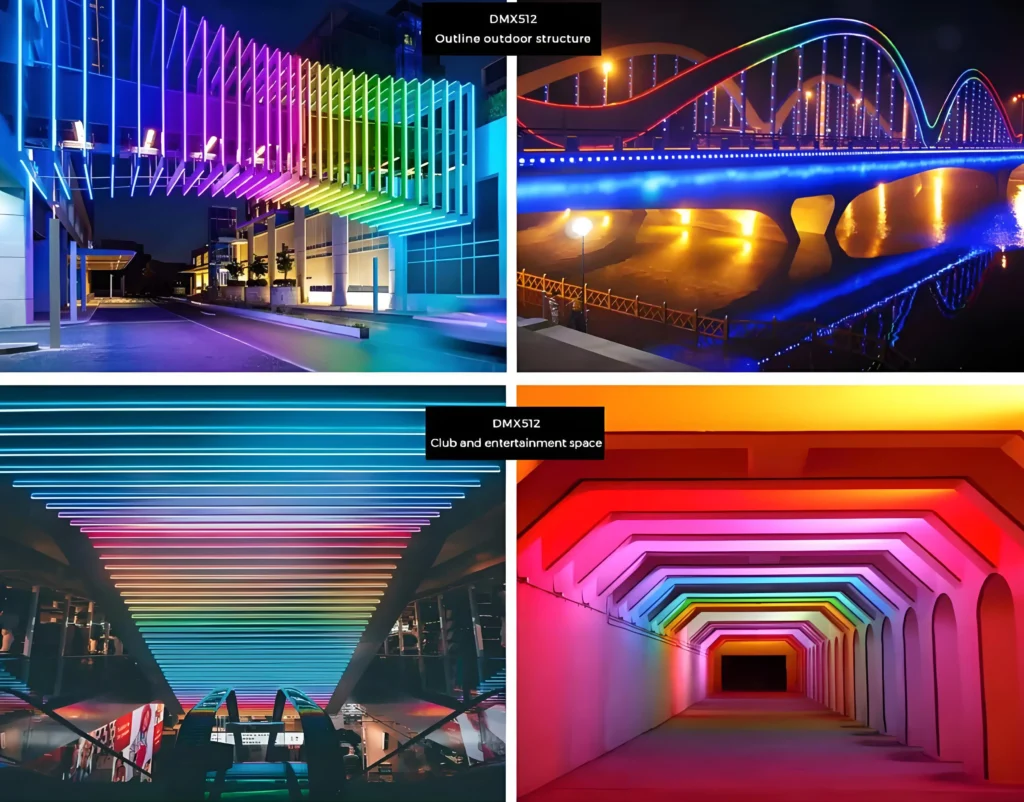

Neon LED flexible lighting is a versatile and energy-efficient solution suitable for a wide range of commercial and hospitality environments. Its flexibility, vibrant color options, and ability to create custom shapes make it ideal for accentuating architectural features and enhancing ambiance.

In hotels, neon LED flexible strips are commonly used in lobbies, reception areas, guest corridors, and around mirrors or headboards in guest rooms. They are particularly effective for branding elements such as hotel logos, backlit signage, and decorative features in bars or lounges. The soft, diffused glow contributes to a modern and inviting atmosphere, enhancing the overall guest experience.

Malls benefit from neon LED flexible lighting in storefront signage, promotional displays, and feature walls. The lighting can be customized into creative shapes and animated effects to attract shoppers and highlight key areas such as entrances, food courts, or seasonal installations. Its durability and low maintenance make it ideal for high-traffic environments that require long operational hours.

In office settings, neon LED flexible strips are best used in reception areas, conference rooms, and break rooms to add a touch of modern design. They can outline ceiling coves, under-cabinet areas, or stair edges for both aesthetic and functional lighting. While not typically used for task lighting, they enhance spatial perception and contribute to a dynamic, contemporary work environment.

For successful installation, ensure the surface is clean, dry, and free of dust or grease to promote strong adhesion of the backing tape. Use aluminum mounting channels where possible to protect the strip, improve heat dissipation, and provide a clean, professional finish. Avoid sharp bends—follow the manufacturer’s minimum bend radius to prevent damage. Always calculate the total power load and use an appropriate driver or power supply, preferably with a slight overhead capacity. For outdoor or high-humidity areas, use only IP65 or higher rated strips and protect connections with silicone sealant or waterproof enclosures. Finally, test the lighting before finalizing the installation to verify color consistency and brightness across the entire run.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s advanced neon LED flexible solutions engineered for superior performance and design versatility. Our cutting-edge flexible neon strips deliver vibrant, uniform illumination with exceptional bendability down to tight radii, enabling seamless integration into complex architectural curves, custom signage, and dynamic retail displays without compromising brightness or color consistency. We utilize high-density SMD LEDs and premium silicone encapsulation to ensure weather-resistant durability, consistent lumen output, and long-lasting operation even in demanding environments.

Partner with Beauty STC to leverage our engineering expertise in customizing length, color temperature, voltage, and IP ratings specifically for your application requirements. Our dedicated technical team provides full support from prototype development through to bulk production, ensuring your project meets exact specifications while maintaining energy efficiency and regulatory compliance.

Elevate your next project with reliable, high-quality flexible neon LED technology built to exceed industry standards. Contact our lighting solutions manager directly at [email protected] to discuss your custom requirements and receive expert guidance tailored to your vision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.