Article Contents

Industry Insight: Neon Flex Led Strip

Introduction & Market Demand

The Evolution of Neon Flex in Commercial Lighting

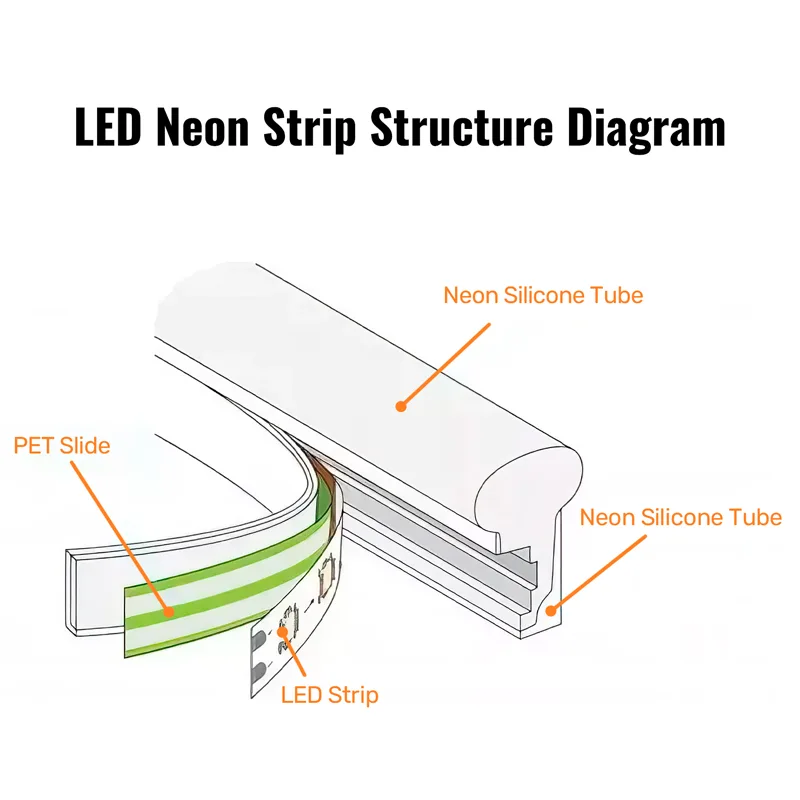

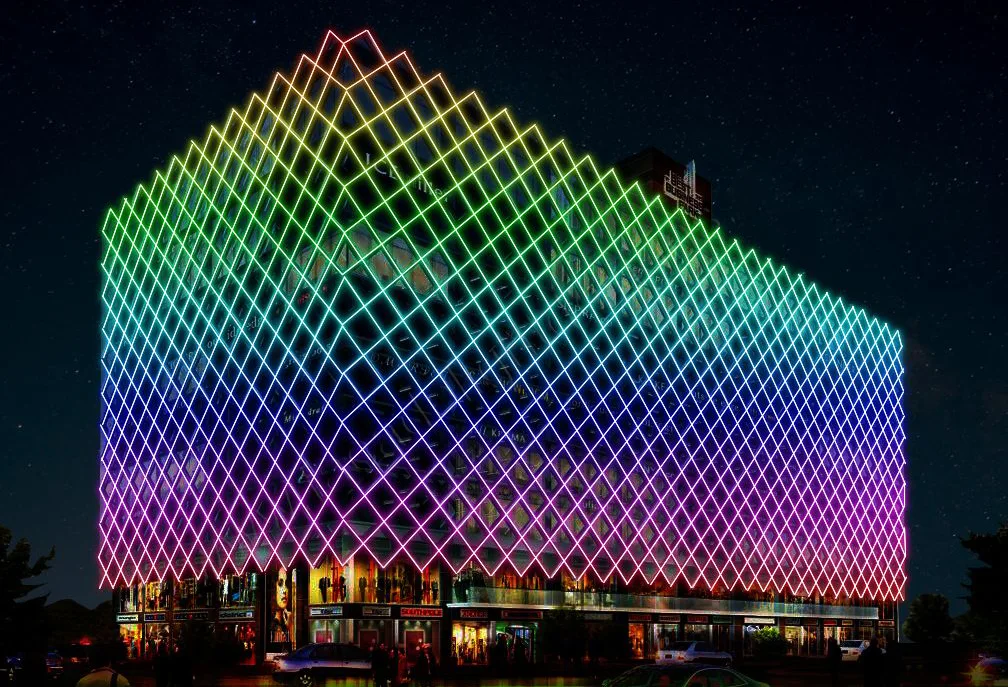

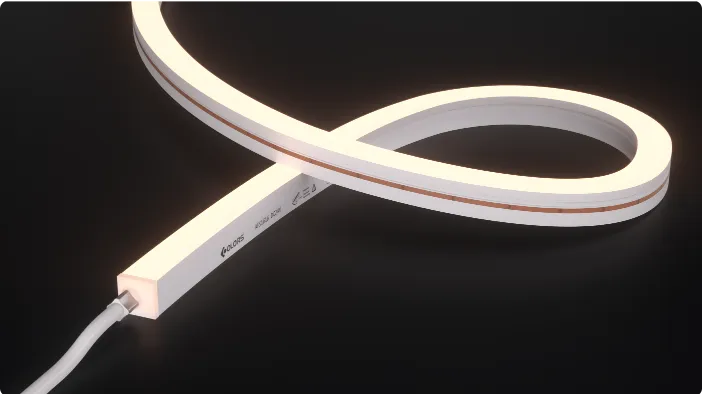

Neon flex LED strip technology has transcended its decorative origins to become a critical component in modern commercial and industrial lighting applications. Architects and project managers increasingly specify these flexible, energy-efficient solutions for retail storefronts, architectural accents, wayfinding signage, and outdoor installations—where traditional neon glass tubes pose safety risks, high maintenance costs, and design limitations. Unlike conventional neon, LED neon flex delivers consistent color uniformity, 50%+ energy savings, and zero mercury content while maintaining the same visual impact. Its bendable form factor enables intricate designs without rigid constraints, making it indispensable for contemporary projects requiring both aesthetics and functionality.

Why Certification Compliance is Non-Negotiable for Global Importers

For distributors and contractors sourcing neon flex for Western markets, compliance with regional safety and performance standards is not optional—it is a regulatory and commercial imperative. Uncertified products risk customs rejection, legal penalties, and catastrophic liability issues. A single failed inspection due to non-compliant electrical components can delay projects by weeks, incur costly rework, and damage long-term client relationships.

| Parameter | Industry Requirement | Beauty STC Specification |

|---|---|---|

| Safety Certifications | Mandatory for market access (UL/ETL for North America, CE for Europe) | ETL (USA/Canada), TUV CE (Europe) certified |

| IP Rating | IP65 for outdoor exposure, IP67 for submerged/wet locations | IP65 (standard), IP67 (customizable) |

| Color Rendering Index (CRI) | ≥90 for accurate color representation in retail/architectural spaces | Standard 90+ CRI across all products |

| Voltage Options | Regional compatibility (e.g., 12V/24V DC, 120VAC) | Configurable for 12V, 24V DC, or 120VAC to meet local grid standards |

| Maximum Continuous Run Length | Varies by voltage; 164ft (50m) for 120VAC systems | Up to 164ft continuous run (120VAC models) |

These certifications validate rigorous testing of thermal management, electrical safety, and durability—critical for installations in high-traffic commercial environments. Beauty STC’s ETL and TUV CE certifications are not merely stickers; they represent documented proof that every batch undergoes third-party validation for fire resistance, electrical integrity, and environmental resilience.

25+ Years of Manufacturing Excellence for Global Projects

Founded in 1998, Beauty (STC) Manufacturing Co., Ltd. operates from Jiangmen, Guangdong—a hub for precision LED manufacturing—and has supplied certified lighting solutions to 50+ countries worldwide. Our production facility adheres to ISO 9001 quality management principles, with every neon flex product traceable from raw materials to final testing. Unlike commodity suppliers, we specialize in OEM/ODM services that balance customization with compliance:

Custom Specifications: Tailored color temperatures (2700K–6500K), beam angles, and cut lengths without compromising certification integrity.

End-to-End Traceability: Batch-specific documentation for ETL/CE compliance, including material safety data sheets (MSDS) and RoHS reports.

Global Logistics Experience: Streamlined export processes for EU, North American, and Asian markets, with packaging compliant with destination-country labeling requirements.

As stated in our core principles—“Be a responsible enterprise, Be a caring person”—we prioritize ethical manufacturing and technical transparency. This commitment ensures that distributors receive not just products, but reliable, future-proof solutions that meet the exacting demands of commercial lighting projects.

Contact our engineering team for technical specifications, compliance documentation, or OEM project consultations: [email protected] | +86-13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Factory-direct data sheet – Neon Flex LED Strip

1. Key Photometric & Electrical Parameters

| Parameter (24 V side-bend profile, 10 × 20 mm) | Beauty STC Certified Range | Notes on Measurement Method |

|---|---|---|

| Luminous efficacy | 110–125 lm/W @ 25 °C | Integrating-sphere, 2 m sample, IES LM-79-19 |

| CRI | Ra ≥ 90 (R9 ≥ 60) | 3000 K & 4000 K bins, IES LM-79 |

| Lumen maintenance | L₇₀B₁₀ ≥ 54 000 h | TM-21 projection @ 55 °C T-point |

| Power draw | 8 W/m (±5 %) | 24 VDC regulated source, 2 m run |

| Binning tolerance | ≤ 3 SDCM | MacAdam ellipse, 1/8th step |

| Flicker | PstLM ≤ 0.2, SVM ≤ 0.4 | IEC TR 61547-1:2020 |

| Max continuous run | 20 m (single-feed) | 2.5 mm² Cu bus, <5 % V-drop |

| Operating window | –40 °C to +60 °C / 10–90 % RH | IEC 62031 |

2. Ingress & Mechanical Protection

| IP Grade | Construction Detail | Test Report |

|---|---|---|

| IP67 | Extruded UV-stabilised silicone jacket, 2-shot over-mould on end-caps | IEC 60598-2-20, 1 m immersion 30 min |

| IK06 | 10 × 20 mm profile, 1.2 mm Al-backing strip optional | EN 62262 impact test |

| UV rating | ΔE < 2 after 1000 h Q-SUN 340 nm | ISO 4892-2 |

3. PCB & Component Engineering

Why consistency matters in long-run neon flex

Copper weight: 2 oz (70 µm) rolled annealed Cu for 30 % lower voltage drop versus 1 oz market average.

LED pitch: 60 LEDs/m on 3-in-1 SMD 2835, optical centre-line held to ±0.2 mm by punched register holes—eliminates “dotting” when bent.

Bin-on-reel: Every 5 m section is cut from the same wavelength & flux bin; barcode links to raw-data file kept 5 years for OEM traceability.

Solder mask & overlay: White high-reflectance mask (ε ≥ 0.85) plus 25 µm CTI-600 overlay for 4 kV dielectric—passes UL 8750.

Thermal interface: 3 W/m·K silicone bed between PCB and outer jacket; keeps T-junction ≤ 85 °C at 45 °C ambient.

4. Certification & Regulatory Matrix

| Market | Standard | Beauty STC Status |

|---|---|---|

| USA / Canada | UL 2108, UL 879 (Sign) | ETL cETL listed, file 5021056 |

| Europe | EN 60598-2-20, EN 62031, EN 55015 | TUV SUD CE + RoHS + REACH |

| UK | UKCA 2020 | Completed 2023 |

| Marine | IEC 60092-306 | Component approved (DNV pending) |

| Fire | UL 94 V-0 (PCB & jacket) | Third-party witness tested |

5. Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic Market (typical) | Beauty STC Certified | Impact on Project |

|---|---|---|---|

| Luminous efficacy | 75–90 lm/W | 110–125 lm/W | 30 % fewer watts → lower driver count |

| CRI | Ra 80–85, R9 10–20 | Ra ≥ 90, R9 ≥ 60 | Meets museum & retail colour fidelity |

| IP rating | IP65 (glue-fill only) | IP67 (full silicone extrusion) | Survives high-pressure wash |

| PCB copper | 1 oz (35 µm) | 2 oz (70 µm) | 20 m runs vs 5 m before re-feed |

| Binning | 5–7 SDCM | ≤ 3 SDCM | Visually uniform façade lines |

| Lifetime claim | L₅₀ 25 000 h (no report) | L₇₀ 54 000 h (TM-21) | Reduces maintenance cycles |

| Certifications | Self-declared CE | ETL + TUV CE | Passes AHJ inspection first time |

| Warranty | 2 years | 5 years (OEM) | Cash-flow protection for installers |

6. Production Controls That Deliver Above-Spec Product

- 100 % hi-pot & ground bond at 1.5 kVAC / 25 A on every finished metre.

- AOI & solder-paste SPI after SMT to keep voids < 10 %.

- Climate-cycle burn-in: 2 h @ –40 °C ⇄ 2 h @ +85 °C, 5 cycles, powered—catches latent solder cracks.

- Integrating-sphere sampling every 200 m—data auto-uploaded to MES; if lm/W drifts >3 % the reel is quarantined.

- RoHS & REACH batch tests quarterly by SGS; certificates archived 10 years for OEM trace-back.

7. OEM / ODM Flexibility

Jacket colour, CCT (2200–6500 K), CRI (Ra 80–97), voltage (12 V, 24 V, 36 V, 48 V), and cross-section (8×16 mm, 10×20 mm, 12×22 mm) configurable within 3 weeks.

PCB length can be supplied in 10 mm increments up to 50 m continuous; laser-marked with customer part number and sequential metre mark.

Private-label sleeve & reel artwork—MOQ 500 m.

Established 1998, Beauty (STC) Manufacturing Co., Ltd exports to 50+ countries under ETL & TUV CE listings. For datasheet packages or project submittals, email [email protected] or call +86-13902885704.

Factory Tour: Manufacturing Excellence

Precision Manufacturing Process & Industrial-Grade Quality Control

Since 1998, Beauty STC Lighting has maintained a vertically integrated production facility in Jiangmen’s High-tech Industrial Zone. Our manufacturing process follows rigorous international quality standards, with every stage—from component sourcing to final assembly—subject to stringent quality control protocols. All products undergo ETL and TUV CE certification testing to meet North American and European safety standards.

Automated SMT Production Line

Our Jiangmen facility operates a fully automated surface-mount technology (SMT) production line featuring high-speed placement machines with 0201 component capability. The line includes:

Precision stencil printing with automated optical inspection (AOI)

Reflow soldering with controlled thermal profiles (per IPC-J-STD-001)

In-line AOI for solder joint integrity checks

This ensures consistent solder joint quality and minimizes human error, critical for maintaining reliability in continuous LED strip configurations. All processes comply with RoHS 2.0 and REACH environmental standards.

Rigorous Aging & Burn-In Testing

All neon flex units undergo a 72-hour continuous burn-in process under controlled conditions (40°C ambient temperature). During this phase, we monitor:

Luminous flux stability

Voltage drop across the strip

Color consistency (Δu’v’ ≤ 0.003)

Thermal performance at maximum load

This process identifies latent defects before shipment, ensuring products meet IEC 62717 standards for long-term operational stability. Thermal cycling tests simulate real-world environmental stressors, validating performance across -20°C to 60°C operating ranges.

Comprehensive QC Protocols

Quality control is embedded at every production stage. Key validation tests include:

| Test Parameter | Standard | Acceptance Criteria |

|---|---|---|

| IP Rating | IEC 60529 | IP65: 6.3mm nozzle spray (10 min); IP67: 1m immersion (30 min) |

| Electrical Safety | IEC 60598-1 | 1500V AC dielectric strength test (1 min) |

| Color Consistency | IEC 62717 | Δu’v’ ≤ 0.003 |

| Lumen Output | LM-79 | ±5% of nominal value |

| CRI | IES LM-79 | Ra ≥ 90 (for high-CRI variants) |

Tailored OEM/ODM Solutions

With 26+ years of manufacturing expertise, Beauty STC provides full OEM/ODM capabilities for global clients. All custom configurations undergo the same ETL and TUV CE certification testing as standard products, ensuring compliance with North American and European safety standards for any project requirement.

| Customization Parameter | Available Options |

|---|---|

| Length | 0.5m to 15m continuous (voltage drop optimized) |

| CCT Range | 2700K to 6500K (standard options: 3000K, 4000K, 5000K) |

| CRI Options | Ra 80, Ra 90+ |

| Diffuser Profile | Round, square, or custom extruded profiles |

| IP Rating | IP65 (dust/water-resistant), IP67 (submersible) |

| Packaging | Custom branding, anti-static reels, retail-ready boxes |

Our engineering team collaborates directly with clients to optimize PCB layouts, thermal management solutions, and optical performance. All designs undergo finite element analysis (FEA) for thermal efficiency and mechanical durability before mass production. For technical specifications or custom project consultations, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for Factory-Certified Neon Flex LED Strip

ETL/TUV-CE listed, engineered since 1998

1. Hospitality & Retail – First-Impression Lighting

| Zone | Typical Spec (Beauty STC PN: NF-SB-24V-10W) | Mounting Note for Contractors |

|---|---|---|

| Hotel porte-cochère | 24 V, 10 W/m, 3000 K, IP67, >90 CRI | Continuous 5 m reels on 3 mm aluminum tab; silicone-end cap + WAGO 221 inside stainless box; feed every 10 m from switched-primary driver (ETL Class 2, <60 V) |

| Mall fascia | Side-bend 16×16 mm, 24 V, RGBW, DMX512 | Use 30 × 30 mm powder-coated channel; expansion gap every 3 m for –20 °C to 50 °C delta; T-joint power tee every 5 m to keep V-drop <5 % |

| Bar back-lit onyx | 24 V, 240 LED/m, 180° dome optic | Mount on 5 mm stand-offs; thermally conductive tape to stone sub-panel; dim via 0-10 V or DALI as per CE-EMC 55015 |

2. Office & Circulation – Human-Centric, Glare-Free

| Zone | Spec | Contractor Tip |

|---|---|---|

| Reception cove | 24 V, 8 W/m, 4000 K, CRI >90, UGR <19 | Pair with 45 ° aluminum profile and opal diffuser; driver in ceiling void, accessible per NEC 410.136 (ETL) |

| Stair nosing | Side-bend 10 × 10 mm, IP65, 2.5 kV surge | Embed in fire-rated aluminum nosing; use 24 V isolated supply, RCD 30 mA; route 1.5 mm² FR-PVC cable inside conduit |

3. Façade & Landscape – Weather-Proof, Code-Compliant

| Zone | Spec | Code/Install |

|---|---|---|

| Parapet outline | 24 V, 12 W/m, 5700 K, UV-stable silicone, –40 °C to +55 °C | ETL wet-location listed; mount on 2 mm 304-stainless bracket, 200 mm centers; loop 150 mm service slack every 2 m |

| Ground path marker | IP68, 24 V, 6 W/m, 240 LED/m, IK08 | Buried in 30 mm gravel + polycarbonate lens; feeder hub with gel-filled splice; T-joint every 5 m, RCD 30 mA Type B |

4. OEM/Custom Runs – Architect-Driven Lengths

Beauty STC Lighting supports 24 h continuous neon flex (up to 15 m @ 24 V) with factory-injected current-balancing boards. Provide drawing (DWG/DXF) and we laser-etch cut points ±0.5 mm, terminate with ETL-listed pottant, and ship ready-to-install reels with barcode MAC address for DMX addressing.

Contractor Checklist – Before Power-Up

- Verify driver V-out tolerance: ±5 %; load ≤80 % of rated wattage (ETL 210.20).

- Megger 500 V DC; insulation >100 MΩ phase-to-earth.

- Record Tc point (hottest spot) after 30 min; must be <80 °C per EN 60598-2-21.

- Submit installation PDF + serial numbers to [email protected] for 5-year factory warranty activation.

Engineered & manufactured in Jiangmen since 1998 – ETL & TUV-CE files available on request.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Trusted Neon Flex Solutions for Global Projects

Global Compliance & Certification Standards

Our Neon Flex LED Strip products are certified to ETL standards for North American markets and TÜV CE for European Union compliance. These certifications validate safety, performance, and electrical safety requirements for commercial and industrial applications, meeting IEC 60598 and UL 1598 specifications. All products undergo rigorous environmental and electrical testing to ensure reliability in extreme conditions.

Technical Specifications for Professional Applications

| Parameter | Specification |

|---|---|

| IP Rating | IP65 (standard), IP67 (optional for submersible applications) |

| Voltage Options | 12V DC, 24V DC |

| CRI | >90 (standard), up to 95 (premium high-fidelity color rendering) |

| Color Temperature | 2700K–6500K (adjustable across warm to cool white spectrums) |

| Max Continuous Length | Up to 15m per run (with proper power injection) |

| Beam Angle | 120° (diffused uniform lighting, pixel-free appearance) |

| Customization | OEM/ODM services available (DMX512 programmable, side-bend capability, custom lengths, color profiles) |

25+ Years of Industrial Manufacturing Excellence

Since 1998, Beauty STC has operated from our 41st Caihong Road facility in Jiangmen’s High-tech Industrial Zone, Guangdong. Our vertically integrated production process ensures end-to-end quality control—from raw material sourcing to final assembly. All products undergo 100% burn-in testing and comply with ISO 9001 quality management protocols, ensuring consistent performance in high-volume commercial deployments.

Integrated Global Supply Chain

With exports to 50+ countries across Europe, North America, Southeast Asia, Australia, Russia, Japan, and Korea, we manage international logistics, customs documentation, and regional compliance requirements seamlessly. Our supply chain is optimized for just-in-time delivery to project sites worldwide, with dedicated support for bulk orders (100+ units) and large-scale infrastructure projects.

Project-Specific Engineering Support

Our technical team provides dedicated support for architectural and commercial projects, including:

Custom color and profile design for unique aesthetic requirements

Electrical compatibility assessments for existing infrastructure

Installation guidelines for wet/dry locations and harsh environments

Compliance documentation for regional certifications (ETL, TÜV CE, etc.)

Contact our engineering team for project-specific technical support and custom solutions.

Manager: [email protected]

Phone: +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).