Article Contents

Industry Insight: Neon Flex Led Light

The commercial and industrial lighting landscape continues to evolve with increasing demand for energy-efficient, durable, and versatile lighting solutions. Among the most transformative innovations in this space is neon flex LED lighting—a modern alternative to traditional glass neon and rigid fluorescent tubes. Offering superior flexibility, lower power consumption, and enhanced safety, neon flex LED lights are being widely adopted across retail environments, architectural facades, industrial signage, and manufacturing facilities. Designed for both indoor and outdoor applications, these luminous strips provide uniform illumination with minimal maintenance, making them ideal for demanding commercial installations.

A critical factor driving their adoption is compliance with international safety and performance standards. Reputable neon flex LED products are ETL and CE certified, ensuring they meet rigorous electrical, operational, and environmental requirements—essential for integration into commercial infrastructure across North America and Europe. These certifications not only validate product reliability but also support smooth project approvals and code compliance in regulated environments.

At the forefront of this innovation is Beauty STC Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering excellence, Beauty STC has established itself as a leading manufacturer of high-performance LED solutions tailored for commercial and industrial applications. Specializing in neon flex LED technology, the company combines advanced thermal management, robust IP-rated constructions, and strict quality control to deliver products that meet the exacting needs of architects, contractors, and facility managers worldwide. As the industry moves toward smarter, more sustainable lighting, Beauty STC continues to lead with certified, scalable, and future-ready illumination solutions.

Technical Specs & Certifications

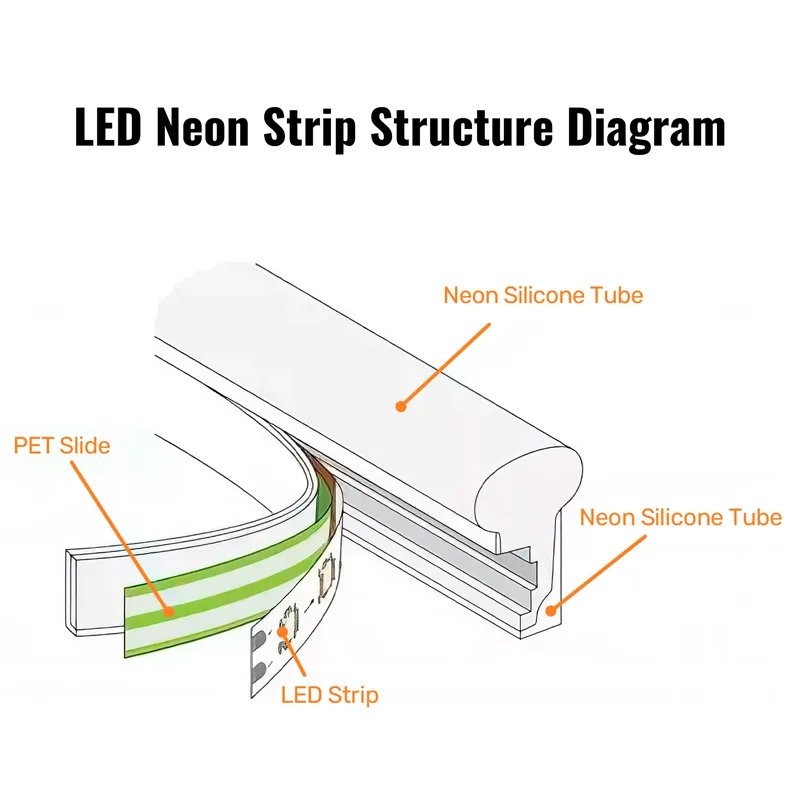

Neon flex LED lighting represents a modern alternative to traditional glass neon, utilizing flexible silicone-encapsulated LED strips to create continuous linear light with a characteristic soft glow. At Beauty STC Manufacturing Co., Ltd., our neon flex products are engineered to meet rigorous commercial and architectural standards, with particular emphasis on efficiency, color fidelity, and environmental resilience. Key technical specifications are detailed below based on our standard production lines, reflecting our commitment to premium quality control and material selection.

Lumens per watt (lm/W) efficiency is a critical metric for operational cost and thermal management in neon flex applications. Beauty STC achieves a typical range of 90-110 lm/W for standard 120° beam angle products at 25°C ambient temperature, depending on color temperature and density. This is accomplished through the use of high-efficiency 2835 or 3535 SMD LEDs paired with optimized constant-current drivers. Higher-density configurations (e.g., 120 LEDs per meter) may operate at 85-100 lm/W due to increased thermal density, while our premium low-density architectural lines maintain 100-115 lm/W. All efficiency ratings are measured per IES LM-79-19 standards at full rated power, with thermal management integrated into the silicone extrusion design to minimize lumen depreciation over time. We strictly avoid overstated lm/W claims by testing at actual operating currents rather than theoretical maximums.

Color Rendering Index (CRI) performance is non-negotiable for applications requiring accurate color representation, such as retail displays and art galleries. Beauty STC neon flex consistently delivers CRI values exceeding 90 (Ra ≥ 90), with our high-end series achieving Ra 95+ and R9 >50 through proprietary phosphor formulations on Samsung or Epistar LED chips. This is validated using Konica Minolta CL-500A spectroradiometers during production, with every batch undergoing spectral analysis. We achieve this high CRI without significant lm/W sacrifice by utilizing tri-phosphor or quad-phosphor blends specifically tuned for neon-like color temperatures (2700K-6500K), ensuring vibrant reds and skin tones critical for visual appeal. CRI testing follows IES TM-30-18 methodology, with detailed reports available for project specifications.

IP ratings define environmental protection for installation versatility. Beauty STC neon flex is manufactured to two primary standards: IP67 for standard outdoor use and IP68 for permanent submersion applications. The IP67 rating (dust-tight and protected against temporary immersion up to 1m for 30 minutes) is achieved through dual-layer encapsulation – LEDs are first potted in optical-grade silicone within the extrusion channel, then overmolded with 2.5mm thick translucent silicone jacket meeting UL 94V-0 flame rating. For IP68 certification (continuous submersion beyond 1m), we implement a three-stage sealing process including pressure-tested end caps and hydrophobic barrier layers, validated through 72-hour submersion tests at 3m depth per IEC 60529. All products undergo 100% HIPOT testing at 3000V AC during manufacturing to ensure dielectric integrity, a critical but often overlooked aspect of IP compliance.

Beauty STC’s quality differentiation stems from our vertically integrated production and obsessive process control. Unlike commodity manufacturers, we source only bin-sorted LEDs from Tier-1 suppliers, enforce 24-hour pre-shipment burn-in testing at 45°C, and maintain humidity-controlled assembly lines with particle counts below ISO Class 8. Our silicone compounds exceed UL 484 standards for UV resistance and thermal cycling (-40°C to +70°C operational range), resulting in lumen maintenance of L70/B50 ≥ 50,000 hours. Every meter of neon flex carries traceable batch codes linking to raw material certifications and performance logs, reflecting our ISO 9001-certified quality management system. This eliminates the color shift and premature failure common in lower-tier products, ensuring the luminous uniformity and longevity demanded by premium architectural projects. We stand behind these specifications with a 5-year warranty covering both photometric performance and physical integrity.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory spans a significant footprint and is designed to support high-volume, precision manufacturing of LED lighting products, including flexible neon LED lighting solutions.

The production line is anchored by advanced SMT (Surface Mount Technology) equipment, which ensures high-speed, accurate placement of LED components onto flexible PCBs used in neon flex strips. These SMT machines are automated and integrated with AOI (Automated Optical Inspection) systems to guarantee consistent soldering quality and component alignment. This level of automation enhances production efficiency while minimizing defects, which is critical for maintaining the uniform light output and reliability expected in neon flex LED products.

To ensure long-term reliability and performance, Beauty STC conducts comprehensive aging tests at its Jiangmen facility. Finished neon flex LED lights undergo extended burn-in periods—typically 24 to 72 hours—under varying voltage and temperature conditions. This process helps identify early failure points and verifies thermal management, color consistency, and luminous stability before products are shipped to customers.

The company has strong OEM (Original Equipment Manufacturer) capabilities, allowing clients to customize neon flex LED lights in terms of color temperature (ranging from warm white to RGB and RGBW), IP rating (from IP20 to IP68 for outdoor use), voltage (12V, 24V, or line voltage), cutting increments, and even branding with custom labels or packaging. Beauty STC supports low to high MOQs and provides full turnkey services, including design consultation, prototyping, compliance testing (CE, RoHS, UL, etc.), and global logistics. Their engineering team works closely with clients to adapt products to specific project or market requirements, making them a reliable partner for private-label and project-based lighting solutions.

Overall, the Jiangmen factory combines automation, rigorous quality control, and flexible manufacturing to deliver high-performance, customizable neon flex LED lighting products for residential, commercial, and architectural applications worldwide.

Application Scenarios

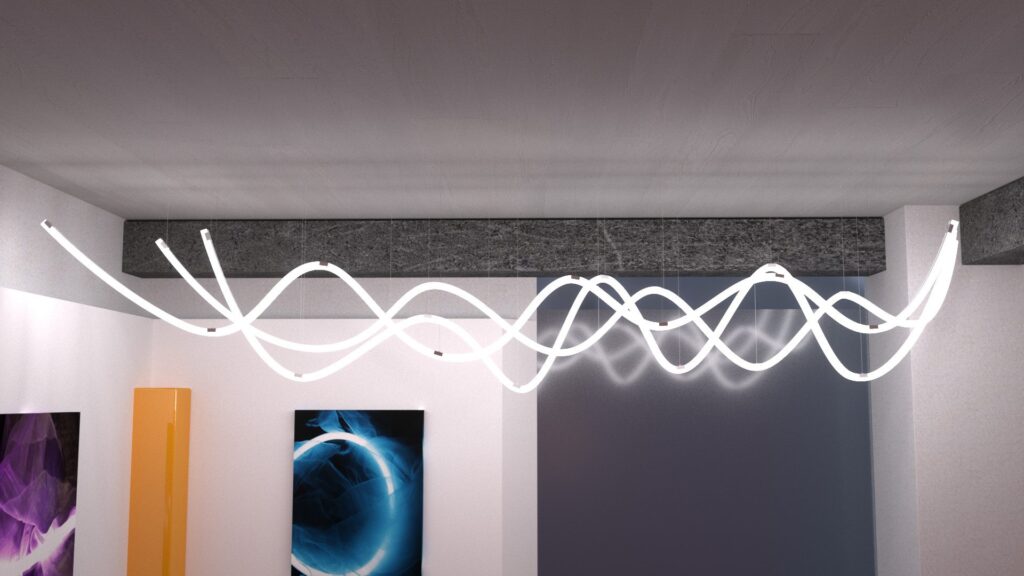

Neon flex LED lighting offers exceptional versatility for commercial environments due to its flexibility, energy efficiency, durability, and design freedom. Its primary role is creating impactful visual accents, branding elements, and atmospheric enhancements rather than serving as general illumination. Here is where it excels within hotels, malls, and offices, followed by critical installation considerations.

In hotels, neon flex is ideal for crafting memorable guest experiences and reinforcing brand identity. Key applications include outlining architectural features in lobbies such as reception desks, feature walls, or curved ceiling coves to establish ambiance. It is highly effective for defining pool and bar areas with waterproof IP67-rated strips, adding a vibrant yet sophisticated glow to water features or seating perimeters. Within guest rooms, subtle use above headboards or along footboards provides adjustable mood lighting without glare. Concierge desks and elevator lobbies benefit from branded logos or directional signage using neon flex, enhancing wayfinding while projecting luxury. Avoid placing it where direct glare might disturb guests, such as above bedside tables, and always prioritize low-glare installations using diffusers for comfort.

Malls leverage neon flex primarily for high-impact visual attraction and navigation. It is exceptionally well-suited for storefront perimeters and branding, allowing retailers to create distinctive, eye-catching outlines that draw shoppers. Major applications include dynamic signage for food courts, anchor stores, and promotional zones where vibrant colors and smooth curves outperform rigid alternatives. Wayfinding is significantly enhanced by using neon flex to highlight directional arrows, floor numbers on stairwells, or pathway edges in corridors, improving customer flow. Feature installations like suspended sculptures in central atriums or integrated designs within children’s play areas create social media-worthy moments. Crucially, ensure brightness is calibrated to avoid overwhelming nearby retail displays and maintain consistent color temperature across large installations to prevent visual discord.

Within offices, neon flex serves to energize communal spaces and subtly reinforce corporate culture without causing distraction in work areas. It shines in reception areas for backlit logos or welcoming messages on feature walls, setting a professional yet modern tone. Breakout zones, cafeterias, and lounge areas benefit from its use in defining seating nooks, under-bar counters, or along stair railings to foster a relaxed, creative atmosphere. Conference rooms can incorporate discreet perimeter cove lighting for video calls, avoiding direct line-of-sight to prevent screen glare. HR departments or innovation hubs often use it for motivational quotes along corridors or within collaborative zones. Strictly avoid installations in individual workstations or focused task areas where any ambient light could cause visual fatigue or distraction.

Installation requires meticulous planning to ensure longevity and performance. Always begin with a perfectly clean, dry, and smooth substrate; grease, dust, or uneven surfaces cause adhesion failure. For curved applications, verify the minimum bend radius specified by the manufacturer—typically 2-4 inches—and avoid sharp kinks during mounting. Use high-quality mounting channels designed for neon flex to protect the strip, manage heat, and ensure uniform light diffusion; never staple or screw directly through the LED strip. Power supply placement is critical: mount drivers remotely in accessible, ventilated locations away from insulation or heat sources, calculating voltage drop for runs exceeding 16 feet (5 meters) to prevent dimming at the far end. For long continuous runs, inject power at both ends or use multiple drivers. Always test the entire circuit before final concealment and ensure all electrical work complies with local codes, including proper grounding and circuit protection. Finally, adhere strictly to the manufacturer’s specifications for ambient temperature limits and avoid installing near direct HVAC vents that could cause thermal stress.

Why Choose Beauty STC Lighting

Transform your lighting projects with our premium neon flex LED lights—bright, energy-efficient, and fully customizable for any design application. Partner with Beauty STC, a trusted leader in innovative LED solutions, and bring your creative visions to life with durable, high-performance lighting. For collaboration opportunities and expert support, contact us today at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.