Introduction: Navigating the Global Market for solar powered led strip lights

Solar powered LED strip lights represent a transformative advancement in energy-efficient lighting solutions, offering unmatched versatility and sustainability for diverse commercial and industrial applications. As global markets increasingly prioritize renewable energy and cost-effective lighting, these products have become essential components in infrastructure, retail, hospitality, and urban development projects. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe—including dynamic markets like Australia and South Africa—understanding this technology’s nuances is critical for strategic sourcing and competitive advantage.

This guide delivers a thorough exploration of the solar powered LED strip lights market, enabling buyers to make informed procurement decisions with confidence. It covers key product types and materials, highlighting innovations in solar cell integration and LED technology that impact durability and efficiency. Manufacturing processes and quality control standards are examined to ensure reliability and compliance with international certifications. Additionally, detailed insights into supplier landscapes, pricing structures, and cost drivers across different regions empower buyers to optimize their supply chain strategies.

Beyond technical and commercial aspects, the guide addresses common challenges and frequently asked questions, offering practical solutions to hurdles such as installation complexities and maintenance in varied climatic conditions. By equipping B2B buyers with comprehensive knowledge and actionable insights, this resource facilitates strategic partnerships and sustainable investments in solar powered LED strip lights, driving growth in emerging and established markets worldwide.

Understanding solar powered led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

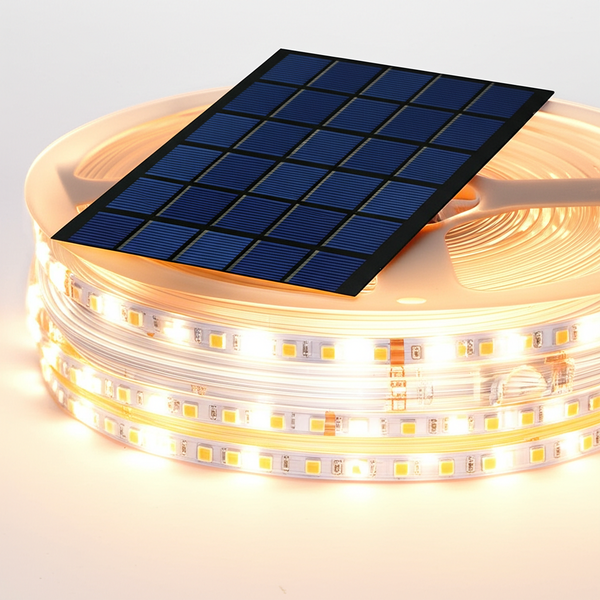

| Flexible Solar LED Strip | Bendable, lightweight strips with integrated solar cells | Outdoor advertising, architectural lighting | + Easy installation, adaptable to irregular surfaces – Limited power output, sensitive to shading |

| Rigid Solar LED Strip | Sturdy, fixed-shape strips with durable solar panels | Industrial zones, perimeter security lighting | + High durability, consistent performance – Less flexible, higher shipping costs |

| Waterproof/IP65+ Solar LED | Waterproof casing and connectors for harsh weather conditions | Agricultural facilities, outdoor retail spaces | + Weather resistant, low maintenance – Slightly higher initial cost |

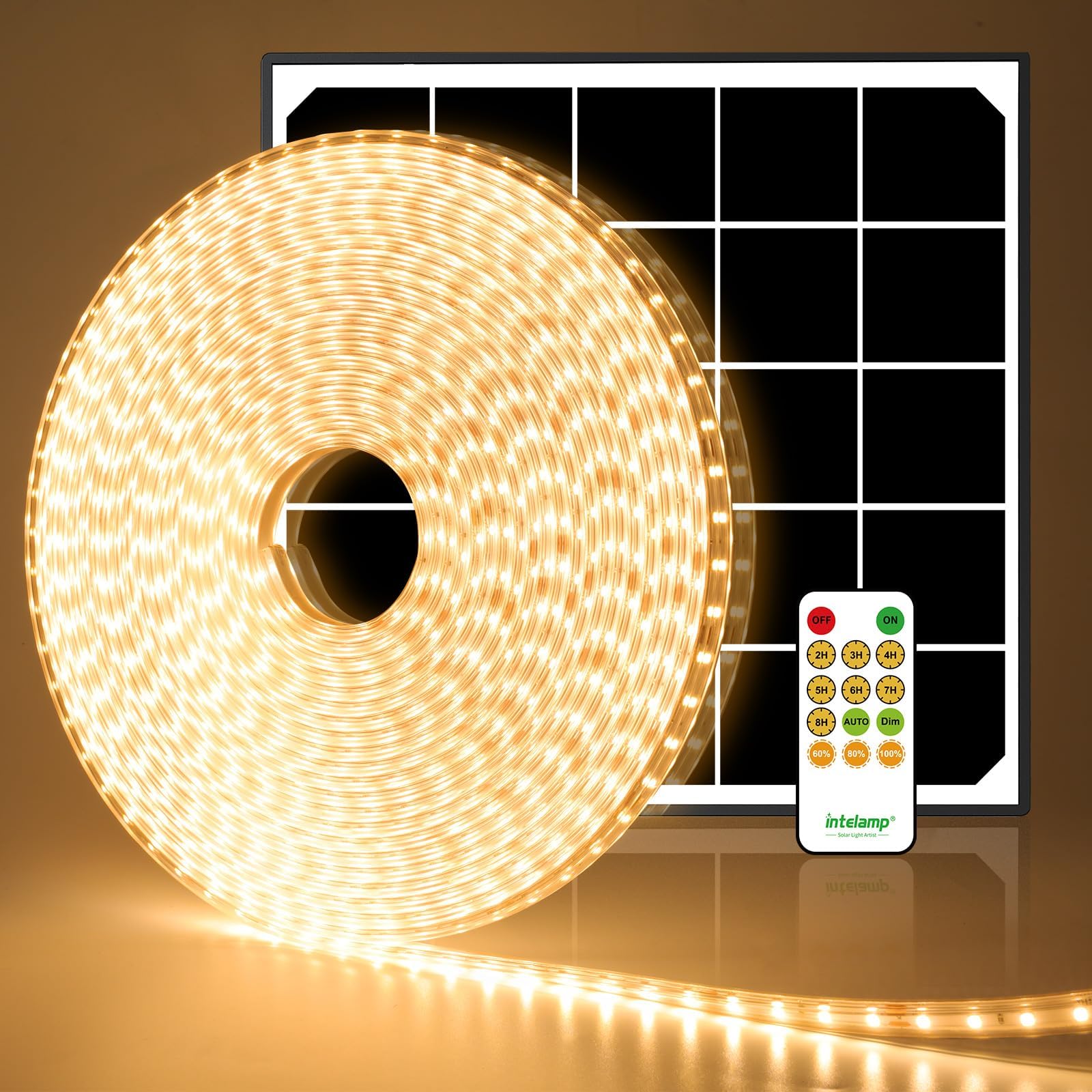

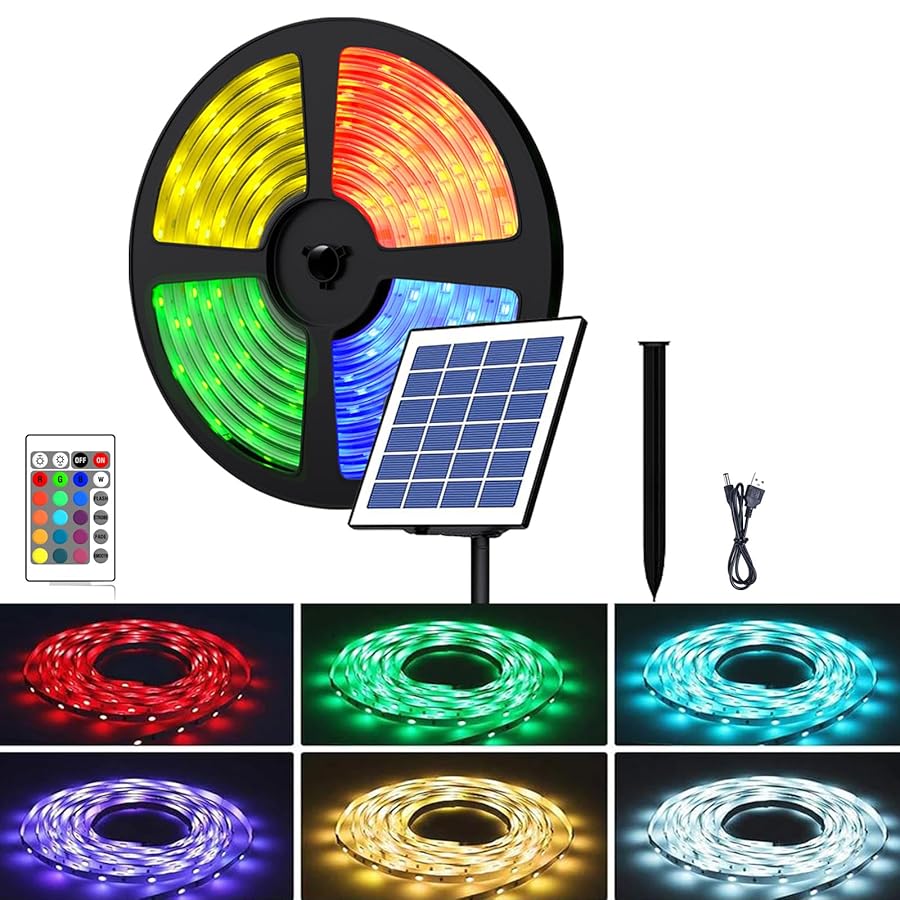

| RGB Solar LED Strip Lights | Multi-color lighting with solar power and remote control options | Hospitality, event venues, retail displays | + Customizable lighting effects, energy efficient – More complex installation, higher price |

| High-Efficiency Mono-Crystalline Solar LED Strips | Use of mono-crystalline solar cells for superior energy conversion | Remote locations, off-grid lighting projects | + Superior energy efficiency, longer lifespan – Higher upfront cost, requires optimal sunlight |

Flexible Solar LED Strip

Flexible solar LED strips are characterized by their bendable, lightweight design, integrating thin solar cells directly onto flexible substrates. These are ideal for applications where the lighting surface is irregular or curved, such as outdoor signage or decorative architectural elements. B2B buyers should evaluate the trade-off between flexibility and power output, as these strips can be more vulnerable to shading and environmental wear. Their ease of installation makes them attractive for rapid deployment in diverse geographic regions, including Africa and South America.

Rigid Solar LED Strip

Rigid solar LED strips feature robust, fixed frames that house durable solar panels and LEDs, offering consistent illumination and long-term reliability. They suit industrial or security lighting where structural stability is paramount. For B2B buyers, the higher shipping weight and less adaptability to installation surfaces must be balanced against the benefit of a longer lifespan and steady performance, making them a preferred choice for European and Middle Eastern infrastructure projects.

Waterproof/IP65+ Solar LED Strips

Designed with waterproof casings and sealed connectors, these strips endure harsh weather conditions, including dust and heavy rain. This makes them highly suitable for outdoor agricultural facilities or open-air retail environments common in regions with variable climates like South Africa and the Middle East. Buyers should consider the slightly higher upfront cost offset by reduced maintenance and replacement expenses, ensuring long-term operational savings.

RGB Solar LED Strip Lights

These LED strips combine solar power with multi-color RGB lighting capabilities and often include remote control or automation features. They are ideal for hospitality and event venues, adding aesthetic versatility while reducing energy costs. B2B purchasers must account for the more complex installation and higher price point, but the ability to customize lighting ambiance can offer significant marketing and customer experience advantages.

High-Efficiency Mono-Crystalline Solar LED Strips

Utilizing mono-crystalline solar cells, these strips provide superior energy conversion efficiency and longer operational life, making them optimal for remote or off-grid lighting solutions. They are particularly valuable in regions with abundant sunlight but limited electrical infrastructure, such as parts of Africa and South America. While the initial investment is higher, the improved energy yield and durability can lead to lower total cost of ownership, an important consideration for large-scale B2B projects.

Related Video: Transform Your Outdoor Space: Solar Powered Strip Lights by Luhlee

Key Industrial Applications of solar powered led strip lights

| Industry/Sector | Specific Application of solar powered led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Greenhouse and outdoor crop lighting | Extends growing hours, reduces energy costs, and supports sustainable farming | Weather resistance, energy autonomy, and ease of installation |

| Mining and Exploration | Perimeter and pathway illumination in remote sites | Enhances safety, reduces dependency on grid power, and lowers operational costs | Robustness, long battery life, and compliance with safety standards |

| Hospitality and Tourism | Outdoor ambiance lighting for resorts, eco-lodges, and event venues | Creates attractive environments while minimizing energy consumption and carbon footprint | Aesthetic flexibility, durability in harsh climates, and solar efficiency |

| Urban Infrastructure | Street, pathway, and public space lighting in off-grid or solar-friendly zones | Improves public safety and visibility with reduced infrastructure costs | Compliance with local regulations, brightness levels, and maintenance ease |

| Transportation | Solar-powered lighting for bus stops, parking lots, and transit shelters | Provides reliable lighting in remote or underserved areas, enhancing user experience | Durability, solar panel efficiency, and vandal resistance |

Agriculture

In regions across Africa, South America, and parts of Europe where grid electricity may be unreliable or costly, solar powered LED strip lights serve as an ideal solution for greenhouse and outdoor crop lighting. They enable farmers to extend daylight hours, improving photosynthesis and crop yields without increasing energy expenses. Buyers should prioritize weatherproof designs and solar autonomy to withstand variable climates and ensure continuous operation during cloudy periods.

Mining and Exploration

Remote mining operations in the Middle East and Australia benefit significantly from solar powered LED strip lights for perimeter and pathway illumination. These lights enhance worker safety by providing consistent, reliable lighting without the need for extensive electrical infrastructure. For B2B buyers, sourcing units with durable casings, extended battery capacity, and compliance with industrial safety standards is critical to withstand harsh environments and meet regulatory requirements.

Hospitality and Tourism

Eco-conscious resorts and event venues in coastal South Africa and Mediterranean Europe leverage solar powered LED strip lights to create visually appealing outdoor spaces while reducing their carbon footprint. These lights offer flexible color and brightness options to enhance ambiance, with the added benefit of low operating costs. International buyers should focus on products with high solar conversion efficiency and resistance to saltwater corrosion and UV exposure.

Urban Infrastructure

Municipalities in emerging markets and developed regions alike are adopting solar powered LED strip lights for street and public space illumination, especially in off-grid or solar-friendly zones. This reduces reliance on costly electrical grids and supports sustainability goals. Buyers must ensure that lighting solutions comply with local regulations, provide adequate luminosity for safety, and offer easy maintenance to optimize long-term operational efficiency.

Transportation

Solar powered LED strip lights are increasingly used for lighting bus stops, parking areas, and transit shelters in remote or underserved locations across Europe and South America. They improve security and user comfort without the need for expensive electrical wiring. Key sourcing factors include the durability of solar panels, protection against vandalism, and adaptability to varying weather conditions to ensure consistent performance.

Related Video: DIY Solar Shed Lighting! Affordable LED Setup

Strategic Material Selection Guide for solar powered led strip lights

When selecting materials for solar powered LED strip lights, international B2B buyers must consider factors such as environmental durability, thermal management, corrosion resistance, and compliance with regional standards. These factors directly impact product longevity, performance, and suitability for diverse climatic conditions found across Africa, South America, the Middle East, and Europe (including Australia and South Africa).

1. Flexible Polyimide (PI) Substrate

Key Properties:

Polyimide substrates offer excellent thermal stability (up to 400°C), outstanding electrical insulation, and good mechanical flexibility. They resist UV degradation and have moderate chemical resistance, making them suitable for outdoor solar applications.

Pros & Cons:

– Pros: High-temperature tolerance enables efficient heat dissipation from LEDs, enhancing lifespan. Flexibility allows for versatile installation on curved or irregular surfaces. Lightweight and thin, reducing overall product bulk.

– Cons: Higher material cost compared to standard PCBs. Manufacturing complexity can increase due to handling delicate films. Less impact-resistant than rigid substrates.

Impact on Application:

Ideal for solar LED strips requiring flexible deployment, such as architectural lighting or portable solar solutions. Its UV resistance suits high-sunlight regions like the Middle East and Africa.

Regional Considerations:

Buyers should verify compliance with ASTM D3350 (polymer film standards) and IEC 61000 (electromagnetic compatibility). The material’s thermal properties align well with the hot climates in South America and Africa, reducing heat-related failures.

2. Aluminum PCB (Metal Core PCB)

Key Properties:

Aluminum PCBs provide excellent thermal conductivity (up to 2.0 W/mK) and mechanical strength. They exhibit strong corrosion resistance when anodized and can withstand moderate environmental stresses.

Pros & Cons:

– Pros: Superior heat dissipation enhances LED efficiency and longevity, critical for solar-powered lighting exposed to direct sunlight. Durable and rigid, suitable for fixed installations. Cost-effective for medium to large-scale production.

– Cons: Less flexible, limiting use on curved surfaces. Heavier than polymer substrates, potentially increasing shipping costs.

Impact on Application:

Widely used in outdoor solar LED strips where heat management is crucial, such as street lighting or solar garden lights. Aluminum’s robustness suits harsh environments like coastal areas in Europe and South America.

Regional Considerations:

Compliance with DIN EN 485-2 (aluminum sheet standards) and ISO 9227 (corrosion testing) is important. Buyers in humid or saline environments (e.g., coastal South Africa) should specify anodized or coated aluminum to prevent corrosion.

3. Silicone Encapsulation

Key Properties:

Silicone materials used for encapsulating LED strips offer excellent UV resistance, flexibility, and waterproofing (IP67 or higher). They maintain elasticity over a wide temperature range (-60°C to 200°C).

Pros & Cons:

– Pros: Provides superior protection against moisture, dust, and mechanical shocks. Enhances durability in extreme weather conditions, including high UV exposure and temperature fluctuations.

– Cons: Higher material and processing costs. Silicone can be more challenging to apply uniformly, increasing manufacturing complexity.

Impact on Application:

Essential for solar LED strips used in outdoor or industrial environments, especially in regions with heavy rainfall or high humidity like parts of Europe and South America. Also beneficial for desert climates in the Middle East where UV degradation is a concern.

Regional Considerations:

Buyers should ensure compliance with IP rating standards (IEC 60529) and consider local environmental regulations regarding silicone disposal. The material’s flexibility and protection make it attractive for versatile installations in Africa’s diverse climates.

4. Polycarbonate (PC) Housing

Key Properties:

Polycarbonate is a strong, impact-resistant thermoplastic with excellent optical clarity and UV resistance. It can withstand temperatures up to 135°C and offers good chemical resistance.

Pros & Cons:

– Pros: Durable and lightweight, providing mechanical protection for LED strips and solar cells. Transparent grades allow optimal light transmission. Cost-effective and easy to mold into various shapes.

– Cons: Can yellow over time under prolonged UV exposure if not treated. Moderate thermal resistance compared to metals.

Impact on Application:

Commonly used for protective covers or housings in solar LED strip light assemblies. Suitable for urban and commercial lighting applications across Europe and Australia where aesthetic and durability are priorities.

Regional Considerations:

Compliance with ASTM D635 (flammability) and EN 62262 (impact resistance) is critical. UV-stabilized grades are preferred in high-sunlight regions such as the Middle East and Africa to prevent discoloration and material degradation.

Summary Table

| Material | Typical Use Case for solar powered led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Polyimide | Flexible, curved installations; portable solar lighting | High thermal stability and UV resistance | Higher cost and manufacturing complexity | High |

| Aluminum PCB | Fixed outdoor installations requiring heat dissipation | Excellent heat dissipation and durability | Rigid and heavier, limited flexibility | Medium |

| Silicone Encapsulation | Outdoor/industrial use needing waterproofing and UV protection | Superior environmental protection and flexibility | Higher material and processing costs | High |

| Polycarbonate Housing | Protective covers and housings for solar LED strips | Strong, impact-resistant, and optically clear | Potential yellowing under prolonged UV exposure | Medium |

This material selection guide equips international B2B buyers with critical insights to optimize solar powered LED strip light sourcing decisions tailored to diverse regional climates and standards. Prioritizing materials that balance durability, cost, and compliance will ensure product reliability and customer satisfaction across global markets.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for solar powered led strip lights

Overview of Manufacturing Processes for Solar Powered LED Strip Lights

The production of solar powered LED strip lights involves a series of precise, integrated stages designed to ensure product functionality, durability, and energy efficiency. For international B2B buyers, understanding these stages helps in evaluating supplier capabilities and ensuring product quality that meets regional and global requirements.

1. Material Preparation

Material preparation is foundational, involving the sourcing and inspection of raw materials such as LED chips, flexible PCB substrates, solar panels, rechargeable batteries, and protective coatings. High-quality materials are essential for longevity and consistent performance under varying environmental conditions typical across Africa, South America, the Middle East, and Europe.

- LED Chips and PCB: LED chips are typically sourced from reputable manufacturers with strict luminous efficacy and color consistency standards. Flexible PCBs are cut and cleaned to ensure optimal conductivity and flexibility.

- Solar Panels: Solar cells, often monocrystalline or polycrystalline silicon, undergo initial testing for power output and durability.

- Battery Cells: Lithium-ion or lithium-polymer batteries are selected based on capacity, charge cycles, and safety certifications.

2. Forming and Fabrication

This stage involves shaping and assembling the core components into functional units.

- PCB Assembly: Surface Mount Technology (SMT) places LED chips and electronic components onto the flexible PCB. This is performed via automated pick-and-place machines for precision.

- Solar Panel Integration: Solar cells are laminated and framed to withstand outdoor exposure. Integration with the LED strip involves soldering or connector assembly to the power management circuit.

- Battery Integration: Batteries are securely housed with protective circuitry to manage charging and discharging, ensuring safety and efficiency.

3. Assembly

In assembly, the prepared components are combined into the final product.

- Encapsulation: LED strips and solar panels are coated with waterproof and UV-resistant materials, such as silicone or epoxy resins, to enhance durability in harsh climates.

- Wiring and Connectors: Electrical wiring is carefully routed and insulated. Connectors are tested for secure fitting and compatibility with different installation environments.

- Control Units: Installation of microcontrollers or sensors (e.g., light sensors, motion detectors) that regulate lighting based on ambient conditions.

4. Finishing and Packaging

Final touches include cosmetic finishing and packaging tailored for international shipping.

- Quality Labeling: Each unit is marked with batch numbers, certification marks, and usage instructions in multiple languages.

- Packaging: Designed to minimize damage during transport, packaging often includes anti-static materials and shock absorbers.

- Documentation: Inclusion of warranty cards, test reports, and compliance certificates supports transparency and buyer confidence.

Quality Assurance and Control (QA/QC) Protocols

Quality assurance in solar powered LED strip light manufacturing is critical to guarantee product reliability, safety, and compliance with international standards. Robust QC practices help B2B buyers mitigate risks related to product failure and non-compliance in diverse markets.

Relevant International and Industry Standards

- ISO 9001: This international standard for quality management systems ensures suppliers have structured processes for consistent product quality and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, CE marking confirms conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, important for environmental and health safety, especially in European and South American markets.

- IEC Standards: International Electrotechnical Commission standards cover electrical safety, performance, and environmental testing of LED and solar products.

- UL and API Certifications: Particularly relevant for buyers in Australia, South Africa, and the Middle East, these certifications validate electrical safety and product reliability.

- IP Ratings (Ingress Protection): Commonly IP65 or higher for outdoor LED strips, indicating resistance to dust and water—crucial for varying climates.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components before entering the production line. This includes LED chip luminosity tests, solar panel voltage checks, and battery safety inspections.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, such as solder joint inspections, electrical circuit testing, and waterproofing integrity checks.

- Final Quality Control (FQC): Comprehensive product testing before shipment, including:

- Electrical safety tests (insulation resistance, leakage current)

- Functional testing (brightness uniformity, solar charging efficiency)

- Environmental simulation (thermal cycling, UV exposure)

- Mechanical durability (flexibility, vibration resistance)

Common Testing Methods and Tools

- Photometric Testing: Measures LED brightness, color temperature, and uniformity to ensure lighting performance meets specifications.

- Electrical Testing: Multimeters and specialized testers verify voltage, current, and power consumption align with design parameters.

- Environmental Stress Testing: Simulates exposure to heat, moisture, and UV radiation to assess product durability.

- Battery Cycle Testing: Evaluates charge/discharge cycles to estimate battery life and performance under typical usage.

- Waterproof Testing: Pressure and immersion tests confirm IP ratings, critical for outdoor applications.

How B2B Buyers Can Verify Supplier Quality Control

For buyers, especially those importing into Africa, South America, the Middle East, and Europe, verifying supplier QC is essential to avoid costly product failures and regulatory issues.

- Factory Audits: Conduct or commission on-site factory audits to review manufacturing processes, worker training, and quality control systems in place.

- Review QC Documentation: Request detailed inspection reports, certificates of conformity, and test data for each production batch.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing of products before shipment.

- Sample Testing: Obtain product samples for in-house or local lab testing to verify performance claims.

- Supplier Certifications: Confirm that suppliers hold relevant international and regional certifications, such as ISO 9001, CE, or UL.

QC and Certification Nuances for International Markets

- Africa: Emphasis on durable, weather-resistant designs with robust IP ratings due to diverse climates. Certifications like CE and IEC are increasingly recognized, but local standards may also apply.

- South America: Buyers often require RoHS compliance and CE marking due to environmental regulations. Importers should verify battery safety certifications due to strict customs controls.

- Middle East: High-temperature endurance and dust resistance are critical. UL certification and IEC standards are highly valued for safety and reliability.

- Europe (including Australia and South Africa): Stringent adherence to CE, RoHS, and ISO standards is mandatory. Energy efficiency labeling and environmental impact assessments are often required by law.

Actionable Insights for Buyers

- Prioritize suppliers with integrated quality management systems certified to ISO 9001.

- Insist on transparent QC checkpoints with documented evidence at IQC, IPQC, and FQC stages.

- Require compliance with international safety and environmental standards relevant to your market.

- Utilize third-party inspections and factory audits to mitigate risks before placing large orders.

- Understand local certification requirements and ensure suppliers can provide appropriate documentation to facilitate smooth import and distribution.

By thoroughly evaluating manufacturing processes and quality assurance protocols, international B2B buyers can secure reliable, high-performance solar powered LED strip lights that meet diverse market demands and regulatory frameworks.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for solar powered led strip lights Sourcing

Breakdown of Cost Components for Solar Powered LED Strip Lights

When sourcing solar powered LED strip lights, understanding the detailed cost components helps international buyers negotiate better and optimize procurement strategies:

-

Materials: The primary expense includes high-quality LED chips, flexible PCB substrates, solar panels, rechargeable batteries, and protective coatings. Material costs vary significantly based on the grade of solar cells (monocrystalline vs polycrystalline), LED efficacy, and battery chemistry (Li-ion vs LiFePO4).

-

Labor: Manufacturing labor costs depend on the country of origin and complexity of assembly. Labor-intensive processes such as precise soldering, waterproof sealing, and quality inspections add to overall costs.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and production management expenses. Efficient factories with automation can reduce overhead and improve pricing.

-

Tooling and Equipment: Initial tooling for custom LED strip designs, injection molds for casing, and solar panel integration setups represent upfront investments amortized over production volume.

-

Quality Control (QC): Rigorous QC processes—such as photometric testing, waterproofing checks, and battery performance validation—ensure product reliability but increase cost.

-

Logistics and Shipping: For B2B buyers in Africa, South America, the Middle East, and Europe, shipping costs vary by port accessibility, freight mode (sea vs air), and customs clearance. Solar LED strips are relatively lightweight but may require careful packaging to avoid damage.

-

Supplier Margin: Profit margins differ based on supplier type—OEM manufacturers often offer lower margins than branded distributors, affecting pricing.

Key Pricing Influencers in the International Market

Several factors shape the final pricing of solar powered LED strip lights for international B2B buyers:

-

Order Volume and Minimum Order Quantities (MOQ): Larger volumes typically yield better unit pricing due to economies of scale. MOQ requirements can influence total purchase cost and inventory strategy.

-

Product Specifications and Customization: Customized lengths, brightness levels, color temperatures, or integrated smart controls increase costs. Standardized models are generally more cost-effective.

-

Material Quality and Certifications: Products with internationally recognized certifications (CE, RoHS, IP65/IP67 waterproof ratings) command premium prices but reduce risks related to compliance and durability.

-

Supplier Reliability and Location: Established suppliers with proven track records may price higher but offer greater reliability and support. Proximity to shipping hubs or free trade zones can reduce logistics costs.

-

Incoterms and Payment Terms: Terms such as FOB, CIF, or DDP affect who bears shipping and customs costs. Buyers should factor in these terms to evaluate total landed costs accurately.

Actionable Buyer Tips for Cost-Efficient Sourcing

To maximize value and minimize risks when purchasing solar powered LED strip lights internationally, consider the following:

-

Negotiate Beyond Unit Price: Focus on total cost of ownership including shipping, customs, warranty support, and after-sales service. Request breakdowns of cost components to identify negotiation levers.

-

Leverage Volume Discounts Wisely: Consolidate orders across regions or partners to meet MOQs and unlock better pricing, but balance this against storage and cash flow constraints.

-

Prioritize Quality Certifications: For markets like Europe and Australia, compliance is critical. Investing upfront in certified products reduces costly returns or regulatory issues.

-

Assess Supplier Logistics Capabilities: For buyers in Africa or South America, suppliers offering DDP terms or local warehousing can significantly reduce lead times and hidden costs.

-

Consider Long-Term Partnerships: Establish relationships with manufacturers who offer customization flexibility and technical support, enabling continuous product improvement and cost optimization.

-

Evaluate Warranty and Lifecycle Costs: Solar powered LED strips with higher upfront costs but longer lifespans and battery durability deliver better ROI over time.

Disclaimer on Pricing

Prices for solar powered LED strip lights vary widely based on specification, volume, supplier, and market conditions. The insights provided are indicative and should be validated through direct supplier quotations and market research. Buyers are encouraged to conduct due diligence and request detailed quotations to obtain accurate pricing tailored to their specific requirements.

By carefully analyzing cost components and pricing influencers, international B2B buyers can strategically source solar powered LED strip lights that align with their budget, quality expectations, and operational needs across diverse global markets.

Spotlight on Potential solar powered led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar powered led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solar powered led strip lights

Key Technical Properties of Solar Powered LED Strip Lights

Understanding the critical technical specifications of solar powered LED strip lights is essential for B2B buyers to ensure product suitability, longevity, and cost-effectiveness in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Solar Panel Efficiency (%)

This measures the ability of the solar panel integrated with the LED strip to convert sunlight into electrical energy. Higher efficiency panels generate more power under the same sunlight conditions, vital for regions with varying solar irradiance. For buyers, selecting products with proven panel efficiency guarantees consistent lighting performance and reduces reliance on supplemental power sources. -

LED Chip Quality and Type

The LED chips determine brightness, color rendering, and energy consumption. Common types include SMD (Surface Mounted Device) LEDs like 3528, 5050, or 2835, each with differing luminous efficacy and power draw. Premium-grade chips provide longer lifespan and better light quality, crucial for commercial and industrial applications demanding durability and visual appeal. -

Battery Capacity and Chemistry

Solar LED strips rely on rechargeable batteries (usually lithium-ion or lithium iron phosphate) to store energy. Battery capacity (measured in mAh or Wh) affects runtime during low sunlight periods. Buyers should prioritize batteries with stable discharge rates, high cycle life, and temperature resilience to suit harsh climates found in many emerging markets. -

Ingress Protection (IP) Rating

The IP rating indicates the product’s resistance to dust and water. Typical ratings for outdoor solar LED strips range from IP65 to IP68. A higher IP rating ensures reliability in humid, dusty, or rainy environments, which is a critical factor for installations in tropical or desert regions. -

Material Grade and Flexibility

The substrate material (often flexible PCB with protective silicone or epoxy coating) affects durability and ease of installation. High-quality, UV-resistant materials prevent degradation from prolonged sun exposure. Flexibility enables fitting into diverse architectural designs, an advantage for urban and rural infrastructure projects. -

Voltage and Power Tolerance

Operating voltage (commonly 12V or 24V DC) and power tolerance determine compatibility with solar panels and controllers. Consistent voltage ensures stable LED performance, while tolerance to voltage fluctuations protects against damage from inconsistent solar input, a frequent challenge in developing regions.

Common Trade Terminology for B2B Buyers

Navigating international trade requires familiarity with key industry terms. These facilitate clear communication and streamline procurement processes.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products or components that are purchased by another company and retailed under that purchasing company’s brand. For buyers, engaging with OEMs can allow customization, branding opportunities, and often better pricing for bulk orders. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. MOQs can vary widely by manufacturer and product type. Understanding MOQ is critical for budget planning and inventory management, especially for buyers in emerging markets seeking to balance cost with storage capacity. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting pricing, terms, and product specifications. An RFQ is an essential step in sourcing to compare competitive offers and negotiate terms that align with business needs. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing these terms helps buyers clarify cost allocation and logistics responsibilities, reducing risks in cross-border transactions. -

Lead Time

The duration from placing an order to receiving the goods. Accurate lead time expectations help buyers plan projects and manage supply chains effectively, especially in regions with longer shipping durations or customs clearance delays. -

Warranty and Certification

Warranty terms guarantee product reliability and after-sales support. Certifications (e.g., CE, RoHS, IEC standards) ensure compliance with safety, environmental, and quality standards relevant to different markets. Buyers should verify these to mitigate risks and meet regulatory requirements.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and build reliable supply chains for solar powered LED strip lighting solutions tailored to their regional needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar powered led strip lights Sector

Market Overview & Key Trends

The global market for solar powered LED strip lights is expanding rapidly, driven by increasing demand for energy-efficient, off-grid lighting solutions in both commercial and industrial sectors. Key growth regions include Africa, South America, the Middle East, and Europe, where infrastructure development and renewable energy adoption are priorities. In Africa and South America, solar LED strips are particularly valued for their ability to provide reliable lighting in remote areas lacking stable electricity grids. Meanwhile, Europe and the Middle East focus heavily on integrating smart, sustainable lighting into urban and commercial projects.

Emerging B2B sourcing trends emphasize modularity, ease of installation, and integration with IoT platforms to enable smart lighting control and energy management. Buyers increasingly seek suppliers offering customizable solutions tailored to regional climate conditions and regulatory standards. For example, in regions with intense sunlight like the Middle East, solar panels with high-efficiency photovoltaic cells are prioritized to maximize energy capture.

Supply chain dynamics reveal a growing preference for direct partnerships with manufacturers who can ensure quality control and timely delivery, mitigating risks associated with global logistics disruptions. African and South American buyers often benefit from regional distributors or manufacturers who understand local market nuances and certification requirements. Additionally, the push for competitive pricing has led to diversified sourcing strategies, including multi-supplier models to reduce dependency on single regions.

Technological advancements such as improved battery storage capacity, flexible LED strips, and enhanced waterproofing have enhanced product durability and performance, expanding applications into outdoor, industrial, and commercial environments. These innovations align with international buyers’ needs for long-lasting, low-maintenance lighting solutions that reduce total cost of ownership.

Sustainability & Ethical Sourcing in B2B

Sustainability is a core consideration for international buyers of solar powered LED strip lights. These products inherently contribute to reduced carbon emissions by harnessing renewable solar energy and offering energy-efficient LED illumination. However, the sustainability profile extends beyond operation to encompass manufacturing practices, materials sourcing, and end-of-life disposal.

Ethical supply chains are critical in ensuring that raw materials—such as rare earth elements used in LEDs and photovoltaic components—are sourced responsibly, avoiding conflict minerals and minimizing environmental degradation. B2B buyers should prioritize suppliers with transparent supply chains and certifications like ISO 14001 (Environmental Management) and adherence to the Responsible Minerals Initiative.

Materials innovation is also advancing sustainability. Buyers increasingly seek LED strips using recyclable, non-toxic materials and solar panels manufactured with reduced chemical waste. Incorporating biodegradable or recyclable packaging further supports green procurement policies.

Certifications such as CE, RoHS, and UL ensure compliance with international safety and environmental standards, while emerging eco-labels focus on lifecycle impacts and energy efficiency. For buyers in Europe and Australia, compliance with regional directives like the EU’s EcoDesign and Waste Electrical and Electronic Equipment (WEEE) regulations is essential.

By integrating sustainability criteria into sourcing decisions, B2B buyers not only align with global environmental goals but also enhance brand reputation, meet growing regulatory requirements, and respond to the increasing demand for green products from end-users.

Evolution and Historical Context

Solar powered LED strip lights have evolved significantly over the past two decades. Initially, LED strips were primarily low-power, decorative lighting solutions dependent on traditional electricity grids. The integration of solar technology emerged as photovoltaic cell efficiency improved and battery storage became more affordable, enabling truly off-grid LED lighting.

This convergence responded to the global shift towards renewable energy and decentralized power generation, especially critical in emerging markets with limited grid access. Over time, product designs transitioned from rigid, limited-use strips to flexible, robust, and weatherproof variants suitable for diverse industrial and commercial applications.

Today’s solar LED strips represent a mature technology combining energy efficiency, smart controls, and sustainable materials—making them a strategic choice for international B2B buyers seeking reliable, eco-friendly lighting solutions tailored to regional market needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of solar powered led strip lights

-

How can I effectively vet suppliers of solar powered LED strip lights for international B2B purchases?

To vet suppliers, start by verifying their business credentials, such as export licenses and company registration. Request samples to assess product quality and consistency. Check for relevant certifications like CE, RoHS, or IEC standards, which ensure compliance with international safety and environmental norms. Evaluate their manufacturing capacity and quality control processes through virtual audits or third-party inspections. Additionally, gather feedback from existing clients, preferably within your region (Africa, South America, Middle East, Europe), to confirm reliability and after-sales support. -

What customization options are typically available for solar powered LED strip lights, and how can I ensure they meet my market’s needs?

Most manufacturers offer customization in length, color temperature, brightness levels, waterproof ratings (IP65, IP67, etc.), and solar panel size. Some suppliers also provide custom branding and packaging. To ensure market fit, communicate your specific technical requirements and local environmental conditions upfront. For instance, regions with high humidity or dust may require higher IP ratings. Request prototypes or small pilot batches to test before scaling. Collaborate closely with suppliers to align product specifications with local regulations and customer preferences. -

What are common MOQ (Minimum Order Quantity) requirements and lead times for solar powered LED strip lights in international B2B trade?

MOQ can vary widely depending on supplier capacity and customization level, typically ranging from 500 to 5,000 units per order. Lead times generally span 4 to 8 weeks, factoring in production, quality checks, and shipping. For buyers in Africa, South America, or the Middle East, factor in additional time for customs clearance and logistics. Negotiate with suppliers for flexible MOQs or phased deliveries, especially when entering new markets. Establish clear timelines and penalties for delays in contracts to mitigate supply chain risks. -

What payment terms are standard when importing solar powered LED strip lights internationally, and how can I protect my transactions?

Standard payment terms often include a 30%-50% deposit upfront with the balance paid upon shipment or after inspection. Letters of Credit (LC) are widely used to protect both parties, especially in new supplier relationships. For trusted partners, Net 30 or Net 60 terms may be negotiated. Always use secure payment platforms and avoid full prepayments without guarantees. Insist on detailed proforma invoices and contracts specifying payment milestones tied to inspection or delivery to minimize financial risks.

Illustrative Image (Source: Google Search)

-

Which quality assurance certifications and testing standards should I look for when sourcing solar powered LED strip lights?

Look for internationally recognized certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), IEC (International Electrotechnical Commission) standards, and UL (Underwriters Laboratories) if applicable. Testing should cover waterproofing (IP ratings), solar panel efficiency, LED lifespan, and electrical safety. Request test reports from accredited labs and ensure suppliers conduct in-house quality checks at various production stages. These certifications not only ensure compliance but also facilitate smoother customs clearance in diverse international markets. -

What logistical challenges should I anticipate when importing solar powered LED strip lights to regions like Africa, South America, or the Middle East?

Key challenges include extended shipping times due to port congestion, customs delays, and variable import duties. Solar LED strips often contain lithium batteries, which require special handling and documentation. Partner with freight forwarders experienced in handling electronics and hazardous materials. Plan shipments well in advance, considering seasonal weather impacts on solar product demand. Use trackable shipping methods and consolidate shipments to reduce costs. Establish contingency plans for delays and ensure all import documentation complies with local regulations to avoid penalties. -

How can I effectively manage disputes with suppliers regarding quality or delivery issues in international solar LED strip light transactions?

First, maintain clear, documented communication including contracts with detailed product specifications, delivery terms, and quality standards. Implement third-party inspection before shipment to catch defects early. If disputes arise, attempt negotiation and mediation referencing contract terms. Use arbitration clauses to resolve conflicts without costly litigation. Build relationships with suppliers who have a proven track record of responsiveness. Additionally, consider trade insurance to cover financial losses and work with trade organizations or chambers of commerce in your region for support. -

What are the best practices for ensuring sustainable and energy-efficient solar powered LED strip light procurement for international B2B buyers?

Prioritize suppliers who use high-efficiency solar panels and LEDs with long lifespans to minimize energy consumption and waste. Verify that products comply with environmental certifications like RoHS and use recyclable materials. Request lifecycle data and energy performance metrics to assess sustainability. Encourage suppliers to adopt eco-friendly packaging and responsible manufacturing practices. Sustainable procurement not only meets increasing regulatory demands in Europe and Australia but also appeals to environmentally conscious customers across all regions, enhancing your brand reputation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar powered led strip lights

Strategic sourcing of solar powered LED strip lights offers international B2B buyers a compelling opportunity to optimize costs, enhance sustainability, and secure reliable supply chains. Key takeaways for buyers across Africa, South America, the Middle East, and Europe include prioritizing suppliers with proven expertise in integrating high-efficiency solar technology and durable LED components. Leveraging supplier partnerships that emphasize quality certifications and compliance with regional standards ensures product longevity and performance in diverse climates.

Emphasizing strategic sourcing enables businesses to:

- Access innovative solar LED solutions that reduce energy dependency and operational costs

- Navigate complex logistics by partnering with experienced manufacturers and distributors

- Benefit from scalable order volumes and flexible customization tailored to local market demands

- Mitigate risks associated with supply chain disruptions through diversified sourcing strategies

Looking ahead, the global shift toward renewable energy and smart lighting systems will continue to drive demand for solar powered LED strip lights. For B2B buyers, embracing strategic sourcing is essential to capitalize on emerging technologies and expanding markets. By proactively engaging with forward-thinking suppliers and investing in sustainable lighting infrastructure, businesses in Africa, South America, the Middle East, and Europe can not only meet growing energy efficiency goals but also unlock new revenue streams and competitive advantages.

Take action now: prioritize strategic partnerships and informed sourcing decisions to lead in the evolving solar LED lighting landscape.