Introduction: Navigating the Global Market for small led strip lights

Small LED strip lights have emerged as a transformative solution in the global lighting landscape, offering unmatched versatility, energy efficiency, and design flexibility. For international B2B buyers—especially those in dynamic markets like Nigeria, Saudi Arabia, Brazil, and across Europe—these compact lighting solutions unlock new possibilities in commercial, residential, and industrial applications. Their adaptability to various environments and customizable features make them indispensable for businesses aiming to enhance ambiance, improve energy savings, and deliver innovative lighting experiences.

This comprehensive guide delves into every critical aspect of small LED strip lights to empower buyers with actionable insights. You will explore the diverse types of LED strips available, understand the impact of material quality including LED chips and PCBs, and gain clarity on manufacturing and quality control processes that underpin product reliability. Additionally, the guide covers strategic sourcing tips, supplier evaluation criteria, cost optimization strategies, and an overview of emerging trends shaping the market globally.

With a focus on the unique challenges and opportunities faced by buyers in Africa, South America, the Middle East, and Europe, this resource equips you to make well-informed purchasing decisions. Whether you are procuring for large-scale commercial projects or retail distribution, understanding these fundamentals will help you secure high-quality products, negotiate competitive pricing, and ensure timely delivery. Embrace this guide as your strategic partner in navigating the complex global supply chain for small LED strip lights, driving value and success in your business ventures.

Understanding small led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color LED Strips | Emit a single, consistent color; available in warm, cool, or daylight whites | Retail lighting, office accent lighting, industrial task lighting | Pros: Cost-effective, simple installation; Cons: Limited design flexibility |

| RGB LED Strips | Contain red, green, blue LEDs allowing color mixing and dynamic effects | Hospitality, entertainment venues, advertising displays | Pros: Versatile color options, customizable ambiance; Cons: Higher cost, requires controllers |

| Waterproof LED Strips | Encased in silicone or epoxy coating for moisture resistance | Outdoor signage, landscaping, marine applications | Pros: Durable in harsh environments; Cons: Slightly bulkier, higher price point |

| Flexible PCB LED Strips | Built on bendable substrates enabling installation on curved surfaces | Automotive interiors, architectural details, wearable tech | Pros: Highly adaptable installation; Cons: May have lower heat dissipation than rigid types |

| High Lumen Density Strips | Higher LED count per meter for brighter illumination | Industrial facilities, commercial lighting, large-scale projects | Pros: Superior brightness, energy-efficient; Cons: Increased heat generation, requires quality heat management |

Single-Color LED Strips

Single-color LED strips are the most straightforward and widely used type, offering consistent illumination in one color tone such as warm white or cool white. Their simplicity makes them ideal for large-scale installations where uniform lighting is necessary, such as retail shelves or office environments. For B2B buyers, these strips provide cost efficiency and ease of installation but may lack the flexibility needed for dynamic or decorative lighting projects.

RGB LED Strips

RGB LED strips integrate red, green, and blue diodes to produce millions of color combinations, enabling dynamic lighting effects controlled via remote or smart systems. These strips are popular in hospitality, entertainment, and advertising sectors where ambiance and visual impact are crucial. Buyers should consider the additional costs of controllers and power supplies but benefit from offering versatile, modern lighting solutions to end clients.

Waterproof LED Strips

Designed with protective coatings, waterproof LED strips withstand exposure to moisture, dust, and outdoor elements, making them suitable for landscaping, signage, and marine environments. When sourcing for regions with humid or rainy climates, such as parts of Africa or the Middle East, these strips ensure durability and longevity. Buyers must factor in the slightly higher price and installation complexity due to protective layers.

Flexible PCB LED Strips

These LED strips feature flexible printed circuit boards that can conform to curved or irregular surfaces, enabling creative lighting applications in automotive, architectural, and wearable technology markets. For B2B customers, flexible strips offer adaptability but require careful heat management and quality assurance to prevent premature failure. Their unique form factor opens niche market opportunities but may demand specialized installation skills.

High Lumen Density Strips

High lumen density LED strips pack more LEDs per meter, delivering intense brightness suitable for industrial, commercial, and large-scale projects requiring powerful illumination. These strips are energy-efficient yet generate more heat, necessitating effective thermal management solutions. Buyers focusing on performance-driven applications should prioritize suppliers offering robust quality control and certifications to ensure reliability in demanding environments.

Related Video: THE SECRET OF GREAT LED STRIP LIGHT INSTALLS – COB

Key Industrial Applications of small led strip lights

| Industry/Sector | Specific Application of small led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in stores and showrooms | Enhances product visibility and store ambiance, driving sales | Choose high CRI, customizable color temperature, and durable adhesive for varied surfaces |

| Hospitality & Events | Mood and decorative lighting in hotels, restaurants, and event venues | Creates immersive environments, improves guest experience | Opt for waterproof, dimmable, and RGB options with reliable warranty and compliance certifications |

| Automotive & Transportation | Interior ambient lighting and dashboard illumination | Improves passenger comfort and vehicle aesthetics | Require flexible, heat-resistant strips with consistent brightness and long lifespan |

| Manufacturing & Warehousing | Task lighting in assembly lines and inspection stations | Increases worker productivity and safety with focused illumination | Prioritize high lumen output, robust build quality, and energy efficiency certifications |

| Architectural & Urban Planning | Façade and pathway lighting for commercial and public spaces | Enhances safety, security, and visual appeal at night | Select weatherproof, UV-resistant strips with easy installation and maintenance features |

Retail & Commercial Lighting Applications

Small LED strip lights are extensively used in retail environments to highlight products and create an inviting atmosphere. Their slim profile and flexibility allow installation in display cases, shelves, and signage, enhancing product appeal and customer engagement. For B2B buyers in regions such as Nigeria or Europe, sourcing LED strips with high color rendering index (CRI) ensures true color representation, crucial for fashion or food retail. Durable adhesive backing is essential to withstand diverse surface materials and climates, while customization options enable alignment with brand aesthetics.

Hospitality & Events Lighting

Hotels, restaurants, and event venues leverage small LED strip lights to craft dynamic lighting schemes that elevate guest experiences. These strips can be programmed for color changes or dimming to suit different moods or event themes. Buyers from the Middle East and South America should prioritize waterproof and dimmable LED strips that comply with international safety standards, ensuring reliability in humid or outdoor settings. Access to RGB models with smart controls allows venues to stay competitive by offering cutting-edge ambiance solutions.

Automotive & Transportation Sector

In the automotive industry, small LED strip lights are integrated into vehicle interiors for ambient lighting and dashboard illumination, enhancing aesthetics and driver comfort. Their compact size and flexibility make them ideal for tight spaces within car cabins or commercial vehicles. International buyers, especially from Europe and Africa, should focus on sourcing heat-resistant and vibration-proof LED strips that meet automotive quality standards to ensure durability and consistent performance under varying operational conditions.

Manufacturing & Warehousing Lighting

LED strip lights serve as efficient task lighting in manufacturing plants and warehouses, providing focused illumination on assembly lines and inspection stations. This improves worker precision and safety while reducing energy costs. Buyers from industrial hubs in Saudi Arabia or South America must select LED strips with high lumen output and robust construction to withstand harsh industrial environments. Energy efficiency certifications and long lifespan ratings are critical for reducing operational expenses and maintenance downtime.

Architectural & Urban Planning Applications

Small LED strip lights are increasingly used in architectural projects for façade lighting, pathway illumination, and public space enhancement. These applications demand weatherproof and UV-resistant strips capable of enduring outdoor exposure. Buyers in regions with extreme climates, such as parts of Africa and the Middle East, should ensure products have strong IP ratings and easy installation features to minimize maintenance. Such lighting solutions not only improve safety but also contribute to the aesthetic value and branding of commercial and municipal projects.

Related Video: Building DIY LED lights

Strategic Material Selection Guide for small led strip lights

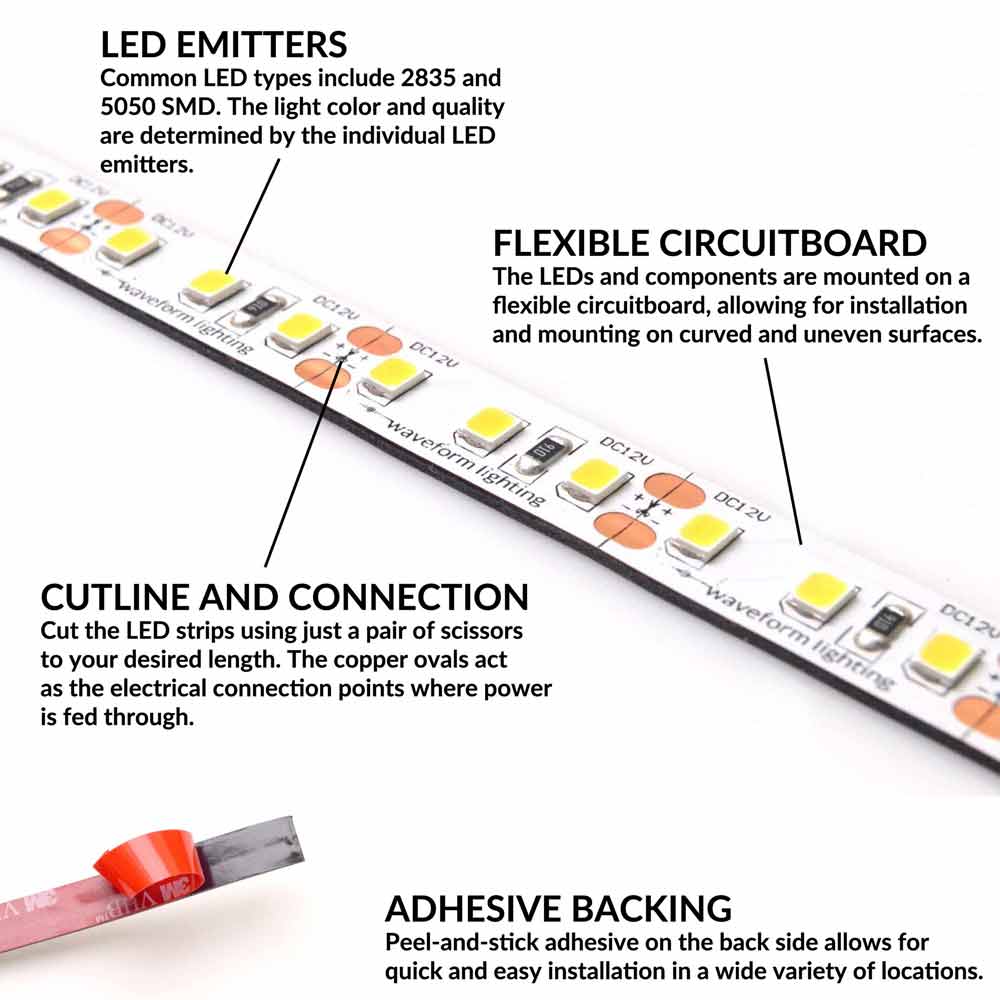

Printed Circuit Board (PCB) Material: Flexible vs. Rigid

Key Properties:

PCBs serve as the base for mounting LED chips and conducting electricity. Flexible PCBs are typically made from polyimide or polyester films, offering excellent bendability and moderate temperature resistance (up to ~150°C). Rigid PCBs use FR4 material, known for high mechanical strength and better heat dissipation but lack flexibility. Both types must exhibit corrosion resistance to withstand environmental exposure.

Pros & Cons:

Flexible PCBs enable installation in curved or confined spaces, ideal for intricate designs, but they have lower heat dissipation compared to rigid boards, potentially affecting lifespan under high loads. Rigid PCBs provide superior thermal management and durability but are less adaptable to non-flat surfaces. Manufacturing flexible PCBs can be more complex and costly due to material and handling requirements.

Impact on Application:

For small LED strip lights used in architectural accents or automotive interiors, flexible PCBs allow seamless integration into curved surfaces. Rigid PCBs suit applications requiring robust heat management, such as task lighting or industrial environments. In humid or dusty conditions common in parts of Africa and the Middle East, PCBs with protective coatings improve longevity.

International B2B Considerations:

Buyers in regions like Nigeria and Saudi Arabia should ensure PCBs comply with international standards such as IPC-2221 for PCB design and ASTM D257 for electrical properties. Suppliers offering RoHS and UL certifications provide assurance of quality and safety, critical for regulatory acceptance in Europe and Middle Eastern markets.

LED Chips: High-Quality vs. Standard Grade

Key Properties:

LED chips determine brightness, color accuracy, and energy efficiency. High-quality chips typically feature superior semiconductor materials (e.g., gallium nitride) with luminous efficacy exceeding 100 lumens per watt and longer operational lifespans (>50,000 hours). Standard chips may have lower brightness and shorter lifespans.

Pros & Cons:

Premium LED chips deliver consistent light output, better color rendering, and reduced power consumption, justifying higher upfront costs. Standard chips reduce initial investment but risk early degradation, color shifts, and higher energy use over time. Manufacturing with top-tier chips demands stricter quality control and sourcing from reputable suppliers.

Impact on Application:

For commercial and hospitality sectors in Europe and South America, where lighting quality impacts customer experience, high-grade chips are essential. In cost-sensitive projects common in emerging African markets, standard chips may be acceptable if durability and color consistency are less critical. High-quality chips also support smart lighting technologies favored in advanced markets.

International B2B Considerations:

Buyers should verify chip origin and certifications like CE, UL, or IEC standards to ensure compliance with local import regulations. Regional climate factors, such as high ambient temperatures in the Middle East, necessitate chips rated for thermal stability to avoid premature failure.

Adhesive Backing: Acrylic vs. Silicone-Based

Key Properties:

Adhesive backing secures LED strips during installation. Acrylic adhesives offer strong initial tack and good long-term adhesion on smooth surfaces, with temperature resistance typically up to 80°C. Silicone-based adhesives excel in high-temperature environments (up to 200°C) and maintain adhesion on uneven or oily surfaces.

Pros & Cons:

Acrylic adhesives are cost-effective and suitable for indoor applications but may fail in humid or hot outdoor conditions. Silicone adhesives provide superior durability and environmental resistance but come at a higher cost and can be more challenging to apply cleanly.

Impact on Application:

For outdoor or industrial use in regions with extreme heat or dust (e.g., Saudi Arabia, northern Africa), silicone adhesives ensure strips remain firmly attached. Indoor decorative lighting in European or South American markets often benefits from acrylic adhesives due to ease of installation and lower cost.

International B2B Considerations:

Buyers should confirm adhesive compatibility with target surfaces and environmental conditions. Compliance with standards like DIN EN 1939 for adhesive strength and ASTM D3330 for peel adhesion can guide quality assessment. Packaging that protects adhesive integrity during shipping is crucial for long-distance imports.

Protective Coating: Silicone Encapsulation vs. Epoxy Resin

Key Properties:

Protective coatings shield LED strips from moisture, dust, and mechanical damage. Silicone encapsulation provides flexibility, excellent UV resistance, and IP65 to IP67 waterproof ratings. Epoxy resin coatings offer rigid protection with high chemical resistance but less flexibility and potential yellowing over time.

Pros & Cons:

Silicone coatings are ideal for outdoor and harsh environments due to their elasticity and weather resistance, although they increase production costs. Epoxy coatings are more affordable and suitable for indoor applications but may crack under mechanical stress or degrade under prolonged UV exposure.

Impact on Application:

In tropical or desert climates found in South America and the Middle East, silicone-encapsulated strips deliver reliable performance. European indoor architectural projects may opt for epoxy coatings to balance cost and protection. The choice affects maintenance cycles and warranty claims.

International B2B Considerations:

Buyers must ensure coatings meet IP standards (e.g., IP65 for water resistance) and comply with RoHS and REACH regulations in Europe. Certifications like UL 746C for polymeric materials can indicate coating reliability, important for import approvals and customer confidence.

| Material | Typical Use Case for small led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PCB (Flexible & Rigid) | Flexible PCBs for curved installations; Rigid PCBs for task lighting | Flexible PCBs enable complex shapes; Rigid PCBs provide superior heat dissipation | Flexible PCBs have lower heat tolerance; Rigid PCBs lack flexibility | Medium |

| LED Chips (High vs Standard) | High-quality chips for commercial/residential; standard for budget projects | High efficiency and longevity with premium chips | Higher cost and sourcing complexity for premium chips | High |

| Adhesive Backing (Acrylic vs Silicone) | Acrylic for indoor smooth surfaces; Silicone for harsh outdoor/industrial | Acrylic is cost-effective and easy to apply; Silicone withstands heat and harsh conditions | Acrylic fails in extreme environments; Silicone is costlier and harder to apply | Low to Medium |

| Protective Coating (Silicone vs Epoxy) | Silicone for outdoor/harsh environments; Epoxy for indoor use | Silicone offers flexibility and UV resistance; Epoxy is affordable and chemically resistant | Silicone increases cost; Epoxy can yellow and crack | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for small led strip lights

The manufacturing of small LED strip lights is a sophisticated process that blends precision engineering, advanced materials, and stringent quality control to deliver reliable, high-performance lighting solutions. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding these processes and quality assurance measures is critical to selecting trustworthy suppliers and ensuring product consistency.

Key Stages in Manufacturing Small LED Strip Lights

-

Material Preparation and Sourcing

The foundation of quality LED strip lights lies in sourcing premium raw materials. This includes high-quality LED chips (often from renowned manufacturers like Cree, Samsung, or Nichia), copper-clad flexible or rigid PCBs, and durable adhesives suited for various environments (e.g., waterproof or heat-resistant). Suppliers who maintain strict incoming quality control (IQC) on these components reduce the risk of defects and underperformance. -

PCB Fabrication and Preparation

The printed circuit board (PCB) serves as the platform for LED mounting and electrical connectivity. For small LED strips, flexible PCBs are common, allowing installation in curved or irregular spaces. Fabrication involves etching copper traces, applying solder mask, and ensuring excellent thermal conductivity to dissipate heat effectively, which extends LED lifespan and maintains brightness. -

LED Chip Mounting and Soldering

Precision placement of LED chips onto the PCB is typically automated via pick-and-place machines. High-quality soldering techniques—such as reflow soldering—are employed to secure chips and resistors. This step requires exact temperature control to avoid damaging components. Manufacturers often apply protective coatings or encapsulants to enhance durability and moisture resistance. -

Cutting, Testing, and Assembly

After assembly, the long LED strips are cut into specified lengths according to customer requirements. Connector attachments and optional features like dimming controllers or waterproof silicone coatings are added. Each strip undergoes initial electrical testing to verify circuit integrity and correct illumination. -

Finishing and Packaging

Final stages include applying adhesive backing, protective films, and packaging designed to prevent damage during transport. Packaging may be customized with branding, batch numbers, and handling instructions. Proper packaging is especially important for long-distance shipping to markets in Africa, the Middle East, or South America, where environmental conditions can be challenging.

Quality Assurance and Control (QC) Protocols

Robust QC processes at every manufacturing stage ensure small LED strip lights meet performance and safety standards, reducing returns and warranty claims.

International and Industry Standards Relevant to LED Strip Lights

- ISO 9001: A fundamental quality management system standard ensuring consistent manufacturing processes and continuous improvement. Suppliers certified to ISO 9001 demonstrate commitment to quality and traceability.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electronics, critical for environmental and consumer safety.

- UL Certification: Particularly important for buyers targeting the US or Middle East markets, UL ensures product safety through rigorous testing.

- IP Ratings: Define the ingress protection level against dust and water, vital for outdoor or industrial applications.

- Other Certifications: Depending on the market, certifications like FCC (for electromagnetic compatibility) or BIS (Bureau of Indian Standards) may be relevant.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components upon receipt, verifying specifications such as LED chip brightness, PCB quality, and adhesive strength.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, LED placement accuracy, and functional electrical testing.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips, including:

- Electrical Testing: Checking voltage, current, and power consumption.

- Light Performance: Measuring luminous intensity, color temperature, and uniformity.

- Durability Tests: Thermal cycling, moisture resistance, and adhesion tests.

- Visual Inspection: Detecting defects such as discoloration, soldering faults, or physical damage.

Common Testing Methods

- Lumen Measurement: Using photometers or integrating spheres to ensure brightness matches specifications.

- Color Rendering Index (CRI) and Correlated Color Temperature (CCT) Testing: Ensures color accuracy and consistency.

- Thermal Imaging: Detects hotspots or uneven heat dissipation that could affect lifespan.

- Electrical Safety Tests: Including insulation resistance and dielectric strength to prevent short circuits.

- Environmental Stress Testing: Simulates real-world conditions like humidity, vibration, or UV exposure.

Verifying Supplier Quality Control: Actionable Steps for B2B Buyers

-

Request Comprehensive QC Documentation

Ask suppliers for detailed quality control reports, including IQC and FQC test results, batch traceability, and certificates of conformity. Reliable manufacturers maintain transparent records that can be audited. -

Conduct Factory Audits and Inspections

Where feasible, arrange on-site audits or employ third-party inspection agencies to verify manufacturing capabilities, QC processes, and working conditions. For buyers in Nigeria, Saudi Arabia, or Brazil, partnering with local inspection firms can facilitate this. -

Obtain Product Samples for Testing

Before bulk purchasing, request samples for independent lab testing in your region to validate performance under local conditions. -

Third-Party Certification Verification

Confirm certifications like CE, RoHS, and UL are authentic and current. Many certification bodies offer online validation tools. -

Evaluate Supplier Responsiveness and After-Sales Support

Quality assurance extends beyond production. Suppliers with robust customer service and clear warranty policies minimize risks related to defective products.

QC and Certification Nuances for International Buyers

-

Regional Compliance Requirements:

Buyers from Europe must prioritize CE and RoHS compliance, while Middle Eastern buyers often require UL or SASO certifications. African and South American markets may have less stringent but evolving standards, so working with suppliers familiar with local regulations is beneficial. -

Climate Considerations:

High humidity in parts of Africa and South America necessitates LED strips with strong adhesive and moisture-resistant coatings. Verify that QC testing includes humidity and corrosion resistance to ensure product longevity. -

Logistics and Packaging:

Given the longer shipping routes and varying infrastructure in these regions, robust packaging and shock-proof designs are critical quality aspects to confirm during supplier evaluation. -

Customs and Import Regulations:

Understanding local import restrictions and certification recognition can avoid shipment delays and extra costs. Engage suppliers who provide compliant documentation and support.

By grasping the detailed manufacturing processes and stringent quality controls behind small LED strip lights, international B2B buyers can make informed sourcing decisions. Prioritizing suppliers with transparent QC protocols, relevant certifications, and tailored solutions for regional market needs ensures procurement of reliable, high-quality LED strip lights that meet both performance expectations and regulatory demands.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for small led strip lights Sourcing

Breakdown of Cost Components in Small LED Strip Lights Sourcing

When evaluating the pricing of small LED strip lights for bulk procurement, understanding the underlying cost components is essential to make informed purchasing decisions:

-

Materials: The primary cost driver includes LED chips, printed circuit boards (PCBs), adhesive backing, and protective coatings. Premium LED chips and high-quality PCBs improve light efficiency and durability but increase unit costs. Adhesive quality affects installation reliability, especially in humid or outdoor environments.

-

Labor: Skilled assembly, including precise soldering of LED chips to PCBs, impacts costs. Labor expenses vary significantly depending on the manufacturing location and automation level.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Advanced quality control systems and testing equipment add to overhead but ensure product reliability.

-

Tooling and Setup: Customizing LED strip lengths, colors, or packaging requires specialized tooling and setup costs. These are amortized over production volumes but can increase unit costs for smaller orders or unique specifications.

-

Quality Control (QC): Rigorous testing for brightness, color accuracy, waterproofing, and certification compliance (CE, RoHS, UL) adds cost but reduces risks of defects and returns.

-

Logistics: Shipping, customs duties, and inland transportation form a significant part of the landed cost. Freight costs can vary widely depending on shipment size, origin, and destination, particularly for buyers in Africa, South America, the Middle East, and Europe.

-

Supplier Margin: Suppliers add a markup to cover profit, marketing, and business risks. Margins vary based on supplier reputation, exclusivity of technology, and negotiation leverage.

Key Pricing Influencers for International Buyers

Several factors directly impact the quoted prices for small LED strip lights and should be carefully considered during supplier evaluation:

-

Order Volume & Minimum Order Quantity (MOQ): Larger volumes typically unlock lower per-unit pricing. MOQ requirements can vary from a few hundred to thousands of meters, affecting buyers with smaller project scopes.

-

Product Specifications & Customization: Customized lengths, color temperatures, waterproof ratings, or packaging increase costs due to additional tooling and quality checks.

-

Material Quality & Certifications: Certified products compliant with international standards (CE, RoHS, UL) command premium pricing but ensure safety and longevity, crucial for commercial applications.

-

Supplier Reliability & Location: Established suppliers with proven quality records may price higher but reduce risks of shipment delays or defective products. Suppliers closer to the buyer or those offering consolidated shipments can lower logistics costs.

-

Incoterms: Terms such as FOB, CIF, or DDP affect who bears shipping and customs risk and costs. Buyers should clarify these terms upfront to avoid unexpected expenses.

Strategic Buyer Tips for Cost-Efficiency and Negotiation

International B2B buyers—especially those from Nigeria, Saudi Arabia, Brazil, or European countries—can leverage the following tactics to optimize sourcing costs and total cost of ownership (TCO):

-

Conduct Total Cost Analysis: Look beyond unit price. Include shipping, customs duties, installation, warranty support, and potential replacement costs to assess true value.

-

Request Samples for Quality Verification: Before committing to large orders, obtain samples to test performance and compatibility with local conditions (temperature, humidity).

-

Negotiate MOQ and Payment Terms: Some suppliers may reduce MOQ or offer flexible payment schedules to secure long-term partnerships. This is particularly beneficial for emerging markets with budget constraints.

-

Consolidate Orders: Combining multiple product variants or suppliers into a single shipment can significantly reduce freight costs and customs complexity.

-

Leverage Local Expertise: Collaborate with local agents or sourcing specialists familiar with supplier landscapes, import regulations, and tariff optimizations.

-

Prioritize Certified Products: While cheaper uncertified strips may be tempting, certified products lower compliance risks and potential liabilities, especially in regulated markets.

-

Clarify Incoterms and Delivery Responsibilities: Ensure clarity on who covers shipping, insurance, and customs clearance to avoid hidden charges.

Indicative Pricing Disclaimer

Prices for small LED strip lights vary widely based on specifications, order size, supplier, and market conditions. As a rough benchmark, wholesale prices may range from $0.50 to $2.50 per meter depending on quality and features. Buyers should treat these figures as indicative and conduct direct supplier inquiries for precise quotations.

By thoroughly analyzing these cost components and pricing influencers, international B2B buyers can strategically source small LED strip lights that balance quality, price, and reliability—maximizing value for projects across diverse markets in Africa, South America, the Middle East, and Europe.

Spotlight on Potential small led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘small led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for small led strip lights

Critical Technical Properties of Small LED Strip Lights

1. LED Chip Quality

The LED chips are the core light-emitting components on the strip. High-quality chips ensure better luminous efficacy (more light output per watt), longer lifespan, and consistent color rendering. For B2B buyers, investing in premium chips means reduced maintenance costs and higher customer satisfaction due to durable, bright lighting solutions.

2. PCB Material and Type

The printed circuit board (PCB) supports the LED chips and manages heat dissipation. Flexible PCBs offer adaptability for curved or tight spaces, while rigid PCBs provide structural stability for flat installations. The material grade affects thermal management — poor heat dissipation leads to shorter LED life. Buyers must match PCB type and quality to their installation environment and longevity expectations.

3. Brightness (Lumen Output)

Measured in lumens per meter, brightness determines how much light the strip emits. Selecting strips with appropriate lumen levels is crucial to meet the functional lighting requirements of the project, whether for accent lighting or task illumination. Overly bright or dim strips can impact energy efficiency and user experience.

4. Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) ranges from warm white (around 2700K) to cool white (6500K) and affects the ambiance of a space. CRI indicates how accurately colors appear under the light source, with values above 80 preferred for most commercial applications. Understanding these specs helps buyers ensure the lighting matches the intended aesthetic and functional needs.

5. IP Rating (Ingress Protection)

IP ratings classify the strip’s resistance to dust and water. For example, IP20 suits indoor dry environments, while IP65 or higher is necessary for outdoor or humid conditions. This rating is critical for buyers targeting markets with diverse climates, such as parts of Africa or the Middle East, to ensure product durability and safety compliance.

6. Voltage and Power Consumption

Most small LED strips operate at 12V or 24V DC. Power consumption (watts per meter) affects energy costs and power supply requirements. Buyers should confirm voltage compatibility with existing infrastructure and balance power efficiency with brightness needs.

Key Trade Terminology for Small LED Strip Lights

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are purchased by another company and retailed under the purchasing company’s brand. For B2B buyers, OEM partnerships enable customized LED strips that align with brand identity and specific technical requirements.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ helps buyers plan inventory and cash flow, especially important for businesses in emerging markets with budget constraints or limited storage.

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers asking for price, lead time, and terms for specified products. It is a critical step for buyers to obtain competitive pricing and clarify product specifications before committing to large orders.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps buyers from different regions (e.g., Nigeria, Saudi Arabia) negotiate logistics effectively and avoid unexpected costs.

Dimmable

This term describes LED strips that can adjust brightness levels via compatible controllers. Dimmable options provide flexibility for dynamic lighting environments and energy savings, appealing to clients who want advanced lighting control.

RGB (Red Green Blue) LED Strips

RGB strips feature LEDs capable of producing multiple colors through color mixing. These are popular for decorative and dynamic lighting applications. B2B buyers should evaluate RGB strips for compatibility with controllers and software if smart lighting solutions are desired.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed purchasing decisions, optimize project outcomes, and negotiate effectively with suppliers in a competitive global market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the small led strip lights Sector

Market Overview & Key Trends

The global market for small LED strip lights is expanding rapidly, driven by rising demand for energy-efficient and versatile lighting solutions across residential, commercial, and industrial sectors. International B2B buyers, especially from Africa (e.g., Nigeria), South America, the Middle East (e.g., Saudi Arabia), and Europe, are increasingly prioritizing LED strip lights for their cost-effectiveness, adaptability, and technological advancements. These regions are witnessing growing infrastructure development, urbanization, and modernization efforts that fuel lighting upgrades, thereby boosting demand for compact, flexible LED strips.

Key market dynamics include a shift toward smart LED strip lights integrated with IoT and app-controlled features, enabling customizable lighting environments and energy management. Buyers are also gravitating toward RGB and tunable white LED strips for enhanced aesthetic and functional applications, from retail displays to hospitality venues. The sourcing landscape is evolving with a trend toward direct procurement from manufacturers in Asia, particularly China, to leverage competitive pricing, customization options, and faster delivery times. However, buyers are advised to vet suppliers thoroughly to ensure product quality, warranty, and compliance with regional standards.

Another emerging trend is the adoption of modular and plug-and-play LED strip systems, simplifying installation and maintenance for large-scale projects. For B2B buyers in developing markets, such innovations reduce labor costs and installation time, making LED strips more accessible. Additionally, bulk purchasing and wholesale partnerships enable businesses to secure better pricing and consistent supply, essential for scaling projects in retail, commercial, and industrial sectors.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers of small LED strip lights, driven by increasing regulatory pressures and corporate social responsibility commitments. LED technology inherently offers energy savings by consuming significantly less power than traditional lighting, reducing carbon footprints across operations. However, the environmental impact extends beyond usage to include material sourcing, manufacturing processes, and end-of-life disposal.

Ethical sourcing is paramount, particularly in the LED chip and PCB supply chain. Buyers should seek suppliers who demonstrate transparency and adhere to international environmental and labor standards, such as RoHS (Restriction of Hazardous Substances), CE marking, and REACH compliance. These certifications ensure that products are free from harmful substances like lead and mercury, which can pose environmental and health risks. Furthermore, suppliers investing in eco-friendly materials—such as halogen-free PCBs and recyclable packaging—contribute to greener supply chains.

For B2B buyers in Africa, South America, the Middle East, and Europe, partnering with manufacturers committed to sustainability can enhance brand reputation and align with government incentives for green technologies. Emphasizing long lifespan and durability in LED strips also reduces waste by minimizing frequent replacements. Lastly, buyers should consider the supplier’s capacity for take-back or recycling programs, which are becoming increasingly important in circular economy frameworks.

Brief Evolution of Small LED Strip Lights

Small LED strip lights have evolved from simple, low-intensity lighting tapes to sophisticated, multifunctional lighting systems. Initially developed in the early 2000s as decorative accent lighting, advances in semiconductor technology and PCB manufacturing have enabled higher brightness, improved color rendering, and greater flexibility. Over the past decade, integration with smart controls and miniaturization have expanded their applications to include task lighting, automotive, architectural, and entertainment uses.

This evolution reflects broader trends in lighting technology, where energy efficiency, customization, and ease of installation are prioritized. For B2B buyers, understanding this trajectory underscores the importance of sourcing from suppliers who stay abreast of technological innovations and can provide tailored solutions for diverse market needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of small led strip lights

-

How can I effectively vet suppliers of small LED strip lights for international B2B purchases?

Start by verifying the supplier’s business credentials, such as business licenses and certifications like ISO, CE, or RoHS, which indicate compliance with quality and safety standards. Check for established online presence and customer reviews, especially from buyers in your region (Africa, South America, Middle East, Europe). Request product samples to assess quality firsthand. Also, inquire about the supplier’s production capacity, warranty policies, and after-sales support. Partnering with suppliers who have experience exporting to your target markets ensures smoother logistics and better understanding of local regulations. -

What customization options are typically available for small LED strip lights when buying wholesale?

Wholesale suppliers often offer customization in length, LED chip type, color temperature, brightness levels, adhesive backing, and packaging. For markets like Saudi Arabia or Nigeria, you might request specific certifications or packaging languages. Custom RGB or dimmable options are common for dynamic lighting projects. Ensure you communicate your exact specifications early in the negotiation to confirm feasibility and lead times. Custom branding on packaging or private labeling is also widely available, which helps maintain consistent brand identity for resale or project use. -

What are typical minimum order quantities (MOQs) and lead times for wholesale small LED strip lights?

MOQs vary widely by supplier and product type but typically range from 100 to 500 units per model or roll length. Lead times usually span 2 to 6 weeks, depending on customization, order size, and production schedules. For buyers in regions like South America or the Middle East, factor in additional transit time for shipping and customs clearance. Confirm MOQs and lead times upfront to align with your project timelines. Negotiating consolidated shipments can reduce costs and improve delivery efficiency. -

Which payment terms are standard for international B2B buyers of LED strip lights?

Common payment terms include a 30% deposit upfront with the balance paid before shipment or upon delivery. Letters of credit (LC) are frequently used for higher-value orders to mitigate risk. Some suppliers may accept PayPal or escrow services for smaller orders. For buyers in emerging markets, establishing a trusted relationship over time can lead to more flexible terms. Always verify payment methods to ensure security and confirm the supplier’s banking details independently to avoid fraud. -

How important are quality assurance processes and certifications when sourcing small LED strip lights internationally?

Quality assurance is critical to avoid costly returns and ensure product reliability, especially in demanding environments across Africa, Europe, or the Middle East. Look for suppliers with documented quality control steps, including incoming material inspection, in-line testing, and final product checks. Certifications such as CE, RoHS, UL, or IEC confirm compliance with international safety and environmental standards. Request test reports or certification copies before purchase. These assurances reduce risks and increase buyer confidence in the product’s longevity and performance. -

What logistics considerations should I keep in mind when importing small LED strip lights?

Shipping LED strip lights typically involves ocean freight for cost efficiency, though air freight is faster for urgent orders. Consider the supplier’s location relative to your port of entry and the availability of consolidated shipping options. Verify packaging quality to protect fragile components during transit. Understand import duties, taxes, and customs clearance procedures specific to your country. Partnering with freight forwarders experienced in electronics can streamline delivery. Also, plan for possible delays during peak seasons or due to regulatory inspections. -

How can I handle disputes or quality issues with international suppliers effectively?

Establish clear contract terms detailing product specifications, quality standards, delivery schedules, and dispute resolution methods. Maintain communication records and document product issues with photos or videos. Use third-party inspection services before shipment to minimize surprises. If problems arise, negotiate amicably first, offering the supplier a chance to rectify defects. Escalate disputes through trade platforms or chambers of commerce if needed. For large orders, consider legal counsel familiar with international trade law and your supplier’s jurisdiction. -

Are there specific challenges or opportunities for B2B buyers of small LED strip lights in Africa, South America, the Middle East, and Europe?

Each region has unique factors: Africa and South America may face longer shipping times and customs complexities, requiring robust supplier relationships and flexible lead times. The Middle East often demands high-quality certifications and tailored lighting solutions for commercial and architectural projects. European buyers prioritize energy efficiency and compliance with stringent environmental regulations, making certified products essential. Leveraging regional trade agreements and sourcing from suppliers with local warehouses can reduce costs and speed delivery. Understanding these nuances helps optimize procurement strategies across diverse markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for small led strip lights

Strategic sourcing of small LED strip lights unlocks significant advantages for international B2B buyers. By prioritizing quality materials, such as premium LED chips and durable PCBs, businesses ensure long-lasting performance and energy efficiency, critical for customer satisfaction and operational cost savings. Leveraging wholesale purchasing not only reduces unit costs but also offers access to customization options and the latest lighting technologies, enabling tailored solutions for diverse markets across Africa, South America, the Middle East, and Europe.

Successful procurement hinges on partnering with reliable suppliers who demonstrate stringent quality control, warranty support, and transparent logistics. For buyers in emerging and established markets alike, understanding specific application needs—whether waterproofing for outdoor use or dynamic RGB capabilities—drives smarter purchasing decisions and project scalability.

Illustrative Image (Source: Google Search)

Looking ahead, the LED strip lighting industry continues to innovate rapidly, with smart integration and sustainability shaping future demand. B2B buyers are encouraged to engage proactively with suppliers to harness these advancements and stay competitive. Embrace strategic sourcing as a catalyst for growth, ensuring your lighting solutions remain cutting-edge, cost-effective, and aligned with evolving global standards. Now is the time to deepen supplier relationships and invest in high-quality small LED strip lights that illuminate new business opportunities worldwide.