Introduction: Navigating the Global Market for led strip mounting clips

In today’s rapidly evolving lighting industry, LED strip mounting clips play a pivotal role in ensuring the stability, durability, and aesthetic appeal of LED installations. For international B2B buyers, especially those operating across Africa, South America, the Middle East, and Europe, understanding the nuances of these seemingly simple yet essential components is key to sourcing products that meet diverse application needs and environmental conditions.

LED strip mounting clips are more than just fastening accessories—they directly influence the longevity and performance of LED strips by providing secure attachment, facilitating optimal light distribution, and protecting against environmental factors such as dust, moisture, and vibration. Their selection impacts installation efficiency, maintenance costs, and overall project success, making them a critical consideration for businesses engaged in commercial, architectural, or industrial lighting projects.

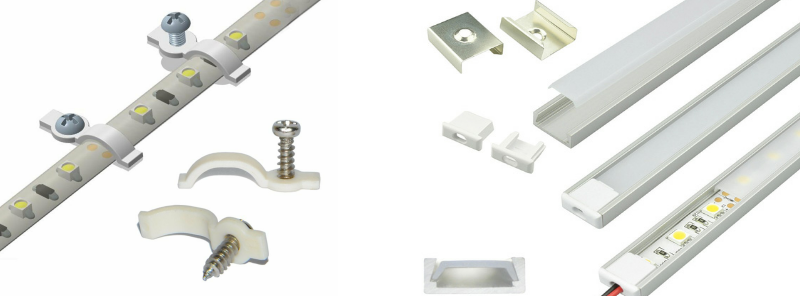

Illustrative Image (Source: Google Search)

This comprehensive guide covers everything B2B buyers need to master the global market for LED strip mounting clips, including:

- Types and designs of clips tailored for various mounting requirements and surfaces

- Material options such as plastic, aluminum, and stainless steel, emphasizing durability and corrosion resistance

- Manufacturing standards and quality control to ensure consistent product performance

- Insights on leading suppliers and sourcing strategies across key international markets

- Cost factors and value analysis to optimize procurement budgets

- Market trends and regional demand dynamics relevant to Africa, South America, the Middle East, and Europe

- A detailed FAQ section addressing common technical and commercial queries

Armed with this knowledge, international buyers can confidently navigate supplier negotiations, assess product suitability, and make informed purchasing decisions that align with their operational goals and regional market challenges. This guide is your strategic partner in unlocking value and reliability in LED strip mounting clip sourcing worldwide.

Understanding led strip mounting clips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| One-side Bracket Fixing Clip | Bracket-shaped clip secured with one screw | General indoor LED strip installations | Pros: Cost-effective, widely available; Cons: Requires drilling |

| Angle Adjustable Clips | Clips with adjustable angles for directional light | Custom lighting projects needing beam control | Pros: Flexible light direction; Cons: Higher cost, complex install |

| Clips with Adhesive Backing | Clips with built-in adhesive for no-drill mounting | Temporary or rental spaces, easy retrofits | Pros: No drilling, quick install; Cons: Adhesive may weaken over time |

| E-Clips | ‘E’-shaped clips ideal for aluminum profile strips | Aluminum channel LED installations | Pros: Secure fit, seamless look; Cons: Limited to profile-compatible strips |

| Plastic Snap Clips | Lightweight, snap-on plastic clips | Lightweight, non-permanent installations | Pros: Easy to install/remove; Cons: Lower durability, less secure |

One-side Bracket Fixing Clips

These clips are the most common and practical for securing LED strips, especially in commercial and residential indoor applications. Their bracket shape holds the strip firmly, and installation requires a single screw, making them cost-effective for bulk procurement. B2B buyers should consider surface type and installation environment since drilling is necessary. Ideal for projects where a permanent, stable mount is required without complex adjustments.

Angle Adjustable Clips

Designed for installations where lighting angles need to be customized, these clips allow the LED strip’s beam to be tilted to optimize illumination. This type suits architectural lighting, retail displays, or exhibitions where dynamic lighting effects are valuable. B2B buyers should note the higher cost and more time-intensive installation but benefit from enhanced lighting control for premium applications.

Clips with Adhesive Backing

These clips combine the mechanical security of clips with the convenience of adhesive mounting, eliminating the need for drilling. They are perfect for temporary setups, rental properties, or quick retrofits where surface damage must be minimized. However, buyers should assess adhesive quality and environmental factors like heat and humidity, which can affect longevity, especially in tropical or dusty climates common in Africa and the Middle East.

E-Clips

E-clips are specialized for use with aluminum LED strip channels, providing a neat, flush mount that maintains strip alignment. They are favored in professional architectural and commercial lighting projects requiring high-quality aesthetics and durability. B2B purchasers should ensure compatibility with aluminum profiles and consider volume discounts when outfitting large-scale projects.

Plastic Snap Clips

These lightweight, snap-on clips offer a non-permanent mounting solution ideal for lightweight LED strips in temporary installations or exhibitions. Their ease of installation and removal makes them attractive for businesses requiring flexibility. However, their lower durability and reduced holding strength mean they are less suitable for outdoor or heavy-duty applications. Buyers should weigh cost savings against potential replacement frequency.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led strip mounting clips

| Industry/Sector | Specific Application of led strip mounting clips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Secure LED strip lighting for accent and display illumination | Enhances product visibility and customer experience, durable hold | Clips must support quick installation, aesthetic integration, and durability in humid or dusty environments common in emerging markets |

| Automotive Manufacturing | Mounting LED strips for interior cabin and dashboard lighting | Reliable fixture stability under vibration and temperature changes | Require clips resistant to heat and vibration; compliance with automotive standards important for global suppliers |

| Hospitality & Leisure | Installation of LED strips in hotels, restaurants, and lounges | Creates ambiance with flexible lighting, easy maintenance | Clips need corrosion resistance and adaptability to curved or irregular surfaces, suitable for tropical climates |

| Industrial & Warehouse | LED strip mounting for task lighting and safety indicators | Improves operational safety and energy efficiency | Must withstand dust, moisture, and mechanical impact; strong fixation to uneven industrial surfaces |

| Architectural & Outdoor | Securing LED strips in façades, signage, and landscape lighting | Durable outdoor mounting that withstands weather and UV exposure | Clips must be UV-resistant, corrosion-proof, and capable of withstanding temperature fluctuations for long-term use |

In Retail & Commercial Spaces, LED strip mounting clips play a pivotal role in securing lighting that highlights merchandise and architectural features. These clips ensure that LED strips stay firmly attached to walls, shelves, or display units, preventing sagging or detachment that could disrupt the visual appeal. For international buyers, particularly from regions like Africa and South America where humidity and dust levels can be high, sourcing clips made from corrosion-resistant materials is essential. Additionally, clips that enable quick installation reduce labor costs and downtime, which is critical for large-scale retail projects.

Within the Automotive Manufacturing sector, mounting clips are indispensable for fixing LED strips inside vehicle interiors, such as dashboard backlighting and ambient cabin illumination. The clips must maintain a secure hold despite constant vibrations and temperature variations experienced during vehicle operation. For buyers in Europe and the Middle East, compliance with automotive industry standards is a key sourcing criterion, ensuring clips do not degrade or loosen over time, which could compromise safety and aesthetics.

The Hospitality & Leisure industry relies heavily on LED strips to craft inviting atmospheres in hotels, restaurants, and bars. Mounting clips allow flexible and discreet installation on curved surfaces, ceilings, and architectural details. For markets like the UAE and Indonesia, where tropical climates accelerate corrosion, clips made from stainless steel or high-grade plastics provide longevity. Buyers must prioritize clips that combine durability with ease of maintenance, as hospitality venues require frequent cleaning without damaging the lighting fixtures.

In Industrial & Warehouse environments, LED strip mounting clips secure task lighting and safety indicators on machinery, shelving, and workstations. The clips must resist dust, moisture, and mechanical impacts common in these settings, ensuring continuous illumination for safety and productivity. For B2B buyers in regions with challenging industrial conditions, selecting clips with robust fixing mechanisms and materials that withstand harsh environments is critical to minimize maintenance costs and downtime.

Finally, the Architectural & Outdoor sector demands LED strip mounting clips that can endure exposure to sunlight, rain, and temperature fluctuations. These clips are used in façades, outdoor signage, and landscape lighting installations. Buyers from Europe and the Middle East should focus on UV-resistant and corrosion-proof clips that maintain structural integrity over time. The ability to handle thermal expansion and contraction without deforming ensures the LED strips remain perfectly aligned, preserving the design intent and reducing replacement frequency.

Related Video: The Best Method for Mounting a Power-strip (or anything)

Strategic Material Selection Guide for led strip mounting clips

Plastic (Polypropylene, PVC, ABS)

Plastic clips are widely used for LED strip mounting due to their lightweight nature and cost-effectiveness. Key properties include good electrical insulation, moderate temperature resistance (typically up to 80-100°C), and decent corrosion resistance against moisture and many chemicals. Plastics like ABS and PVC offer good impact resistance and flexibility, which help absorb minor mechanical stresses without cracking.

Pros: Plastic clips are inexpensive, easy to manufacture in complex shapes via injection molding, and non-conductive, reducing electrical hazards. They are suitable for indoor applications or environments with moderate humidity.

Cons: Their temperature tolerance is limited, making them less ideal for high-heat environments. UV exposure can degrade some plastics over time, leading to brittleness, which is a concern in outdoor installations. Additionally, plastics generally have lower mechanical strength compared to metals.

Application Impact: Plastic clips are best suited for residential and commercial indoor lighting installations where temperatures are controlled. In humid or mildly corrosive environments, plastics perform well but may require UV stabilization for outdoor use.

B2B Considerations: For buyers in Africa, South America, and the Middle East, where high temperatures and intense sunlight are common, selecting UV-resistant or flame-retardant plastic grades is critical. Compliance with international standards such as ASTM D638 (tensile properties of plastics) or UL 94 (flammability) is often required. European buyers may demand RoHS compliance and REACH chemical safety adherence. Cost sensitivity in emerging markets often favors plastic clips, but durability trade-offs must be managed.

Stainless Steel

Stainless steel clips are prized for their exceptional strength, corrosion resistance, and temperature tolerance, often withstanding up to 500°C depending on the alloy. Common grades like 304 and 316 stainless steel resist oxidation, salt spray, and harsh chemicals, making them ideal for outdoor and industrial environments.

Pros: High durability, excellent corrosion resistance, and strong mechanical retention. Stainless steel clips maintain integrity under extreme weather, UV exposure, and chemical contact. They offer a premium, long-lasting solution for demanding installations.

Cons: Stainless steel is heavier and more expensive than plastics or aluminum. Manufacturing complexity is higher due to machining or stamping processes. It may require surface finishing to avoid sharp edges or improve aesthetics.

Application Impact: Stainless steel is preferred for outdoor, marine, or industrial LED strip installations exposed to corrosive environments, such as coastal regions or chemical plants. It ensures long-term stability and reduces maintenance costs.

B2B Considerations: Buyers in coastal regions of Africa and the Middle East (e.g., UAE) benefit from stainless steel’s corrosion resistance. Compliance with ASTM A240 or EN 10088 standards is common. European buyers often require certifications for food-grade or sanitary applications if relevant. The higher upfront cost is justified by longevity and reduced replacement frequency.

Aluminum

Aluminum clips offer a balanced option with good strength-to-weight ratio, corrosion resistance, and thermal conductivity. Typically made from alloys such as 6061 or 5052, aluminum clips can withstand temperatures up to 150-200°C and resist corrosion naturally due to the oxide layer.

Pros: Lightweight, corrosion-resistant, and excellent at dissipating heat from LED strips, aluminum clips help prolong LED lifespan. They are relatively easy to manufacture via extrusion or stamping and can be anodized for enhanced durability and aesthetics.

Cons: Aluminum is softer than stainless steel and can deform under high mechanical stress. It is more expensive than plastic but less costly than stainless steel. Electrical conductivity may require insulation considerations to prevent short circuits.

Application Impact: Aluminum clips are ideal for medium-duty applications, including indoor and outdoor commercial lighting. Their heat dissipation properties make them suitable for high-power LED strips that generate more heat.

B2B Considerations: International buyers should verify compliance with ASTM B209 or EN 573 standards for aluminum alloys. In regions with high humidity or salt exposure, anodized or coated aluminum is preferred. European markets often emphasize sustainability and recyclability, favoring aluminum. Cost is moderate, appealing to buyers balancing performance and budget.

Zinc Alloy (Die-Cast)

Zinc alloy clips, produced via die-casting, provide good mechanical strength and moderate corrosion resistance. They typically withstand temperatures up to 200°C and offer a smooth, finished surface that can be plated or painted for enhanced protection.

Pros: Zinc alloy clips are strong, dimensionally stable, and allow for intricate designs with tight tolerances. They provide a premium feel and are more durable than plastics while being less expensive than stainless steel.

Cons: Corrosion resistance is lower than stainless steel or aluminum unless properly coated. Zinc alloys are heavier than plastic and can be brittle under impact. Manufacturing requires specialized die-casting equipment, increasing initial tooling costs.

Application Impact: Zinc alloy clips suit medium to heavy-duty indoor applications and some outdoor uses where moderate corrosion protection is sufficient. They are often chosen for aesthetic appeal and mechanical reliability.

B2B Considerations: Buyers in Europe and the Middle East should ensure compliance with relevant DIN or ISO standards for zinc alloys. Protective coatings like powder coating or nickel plating are recommended for humid or coastal environments common in Africa and South America. Cost is medium to high, justified by durability and design flexibility.

Summary Table

| Material | Typical Use Case for led strip mounting clips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Indoor residential and commercial lighting | Low cost, lightweight, easy to manufacture | Limited temperature and UV resistance | Low |

| Stainless Steel | Outdoor, marine, industrial, harsh environments | Superior corrosion resistance and durability | Higher cost and weight, complex manufacturing | High |

| Aluminum | Medium-duty indoor/outdoor, high-heat LED strip installations | Good heat dissipation, corrosion resistance, lightweight | Softer material, electrical conductivity concerns | Medium |

| Zinc Alloy | Medium to heavy-duty indoor, aesthetic-focused applications | Strong, precise manufacturing, premium finish | Moderate corrosion resistance, brittle under impact | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip mounting clips

Manufacturing Processes for LED Strip Mounting Clips

The production of LED strip mounting clips involves a series of carefully controlled stages to ensure durability, precision, and compatibility with LED strip systems. Understanding these manufacturing stages enables international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—to assess supplier capabilities and product quality effectively.

1. Material Preparation

The process begins with selecting raw materials, typically metals such as stainless steel, aluminum, or sometimes high-grade plastics for clips. Metals are favored for their strength and corrosion resistance, critical for both indoor and outdoor applications. Material preparation includes:

- Cutting and sizing raw metal sheets or plastic pellets.

- Surface cleaning to remove oils, dust, and oxidation, ensuring better forming and finishing results.

- Alloying or coating at this stage may occur if corrosion resistance or enhanced mechanical properties are required.

2. Forming and Shaping

This stage shapes the raw materials into the clip’s functional form. Common techniques include:

- Stamping and punching: High-precision dies shape metal sheets into clip components with holes or slots for screws.

- Injection molding: For plastic clips, molten plastic is injected into molds to produce complex shapes consistently.

- Bending and forming: Press brakes or roll forming machines bend metal into the required angles or curves for clip functionality.

- Die casting: Sometimes used for metal clips requiring intricate designs or thicker sections.

3. Assembly

For clips with multiple parts (e.g., clips with adjustable angles or combined metal and plastic components), assembly is a crucial step:

- Mechanical fastening: Screws, rivets, or snap-fits join components.

- Welding or soldering: For metal parts requiring permanent joints.

- Adhesive application: In some cases, especially when clips have adhesive backing or require sealing.

4. Surface Finishing

Finishing enhances corrosion resistance, aesthetics, and compatibility with LED strips:

- Electroplating or anodizing: Common for metal clips to prevent rust and improve appearance.

- Powder coating or painting: Provides durable, uniform finishes suited to various environments.

- Polishing or deburring: Removes sharp edges and ensures smooth surfaces for safe handling and installation.

- Adhesive application: For clips with pre-applied adhesive backing, specialized tapes like 3M VHB are applied here.

Quality Assurance and Control (QA/QC) for LED Strip Mounting Clips

Robust QA/QC systems are vital for maintaining consistent product quality, ensuring compliance with international standards, and meeting the diverse requirements of global markets. B2B buyers should evaluate manufacturers based on their adherence to these standards and practices.

Key International and Industry Standards

- ISO 9001: The foundational quality management system standard, ensuring consistent manufacturing and continual improvement.

- CE Marking: Mandatory for products entering the European Economic Area, demonstrating compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment, crucial for environmentally conscious markets.

- REACH Regulation: Governs chemical safety in the EU, relevant for materials used in clips.

- UL Certification: Indicates compliance with safety standards, particularly relevant for electrical component accessories.

- Local Standards: For regions such as the Middle East (e.g., SASO in Saudi Arabia) or South America (e.g., INMETRO in Brazil), compliance with local regulations is essential.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Verifies raw materials and components upon receipt. B2B buyers should confirm that suppliers perform material composition analysis, dimensional checks, and surface inspections.

- In-Process Quality Control (IPQC): Conducted during forming, assembly, and finishing stages. Includes monitoring of tooling accuracy, assembly alignment, and coating uniformity to catch defects early.

- Final Quality Control (FQC): Comprehensive inspection of finished clips, focusing on mechanical strength, dimensional tolerances, surface finish, and packaging integrity.

Common Testing Methods

- Dimensional Measurement: Using calipers, micrometers, and coordinate measuring machines (CMM) to ensure adherence to design specifications.

- Mechanical Testing: Tensile strength, bend tests, and fatigue tests validate clip durability and flexibility.

- Corrosion Resistance Testing: Salt spray tests or humidity chambers simulate environmental exposure, crucial for buyers in humid or coastal regions.

- Adhesion Tests: For clips with adhesive backing, peel strength and tack tests confirm bonding reliability.

- Visual Inspection: Checks for surface defects, coating uniformity, and proper assembly.

How B2B Buyers Can Verify Supplier Quality Control

For buyers from diverse regions, verifying supplier QC is essential to mitigate risks associated with product failure or non-compliance.

- Factory Audits: Conduct or commission on-site audits focusing on process controls, equipment calibration, worker training, and documentation practices.

- Review of QC Documentation: Request detailed inspection reports, material certificates, and test data. Ensure traceability of batches and compliance certificates.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment. This is especially valuable for first-time or large-volume orders.

- Sample Testing: Obtain pre-production and production samples for in-house or third-party lab testing to validate performance claims.

- Supplier Certifications: Verify current ISO 9001 certificates and any relevant product-specific certifications.

QC and Certification Nuances for International B2B Buyers

Africa & South America

- Emphasis on durability and corrosion resistance due to tropical climates and outdoor installations.

- Preference for suppliers with RoHS and REACH compliance as environmental regulations tighten.

- Local import regulations may require product certification and testing upon entry; working with suppliers who provide comprehensive documentation expedites customs clearance.

Middle East (e.g., UAE)

- Demand for high-quality finishes and robustness due to harsh desert environments.

- CE marking and compliance with GCC Standardization Organization (GSO) requirements are often mandatory.

- Buyers should confirm suppliers’ familiarity with SASO regulations and regional electrical safety standards.

Europe

- Strict adherence to CE, RoHS, REACH, and WEEE directives.

- Preference for suppliers implementing environmentally sustainable manufacturing practices.

- Buyers may require detailed Life Cycle Assessments (LCA) and carbon footprint data as part of procurement.

Southeast Asia (e.g., Indonesia)

- Growing demand for cost-effective yet reliable products.

- Compliance with SNI (Indonesian National Standard) and other local regulations may be required.

- Buyers should verify suppliers’ capacity for customized solutions to meet diverse installation environments.

Summary for B2B Buyers

- Insist on transparent manufacturing process documentation covering material selection, forming techniques, assembly methods, and finishing treatments.

- Prioritize suppliers with robust QC systems aligned with ISO 9001 and relevant regional certifications.

- Use a combination of audits, third-party inspections, and sample testing to verify supplier claims.

- Factor in local environmental and regulatory conditions when evaluating product specifications and certifications.

- Seek suppliers who demonstrate flexibility in meeting specific regional needs, including customized clip designs and finishes for varying climates and installation scenarios.

This comprehensive understanding of manufacturing and quality assurance empowers international B2B buyers to make informed sourcing decisions, ensuring durable, compliant, and high-performance LED strip mounting clips for their markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip mounting clips Sourcing

When sourcing LED strip mounting clips for international B2B projects, understanding the detailed cost structure and pricing dynamics is critical to optimizing procurement and ensuring long-term value. These clips, essential for securely installing LED strips, involve multiple cost components and pricing influencers that vary significantly by supplier, region, and product specifications.

Key Cost Components in LED Strip Mounting Clips

-

Materials: The primary raw materials include plastics (such as ABS or polycarbonate) or metals (aluminum, stainless steel). Material choice directly affects durability, corrosion resistance, and cost. Metal clips typically cost more than plastic but offer greater longevity, especially for outdoor or industrial applications.

-

Labor: Labor costs depend on the manufacturing country and complexity of the clip design. Injection molding for plastic clips requires skilled labor for mold setup and quality control, while metal clips may involve stamping or CNC machining.

-

Manufacturing Overhead: This includes factory utilities, maintenance, and indirect labor. High automation levels can reduce overhead but may increase tooling expenses.

-

Tooling: Injection molds or metal stamping dies represent a significant upfront investment. Custom clip designs increase tooling costs, which are amortized over production volume.

-

Quality Control (QC): Ensuring clips meet mechanical strength, dimensional accuracy, and compliance standards (e.g., RoHS, REACH) involves inspection and testing, adding to the cost.

-

Logistics: Freight charges, customs duties, and warehousing impact the landed cost. Clips are generally lightweight but bulky, influencing shipping mode and cost.

-

Supplier Margin: Profit margins vary based on supplier scale, market positioning, and negotiation leverage.

Pricing Influencers to Consider

-

Order Volume / Minimum Order Quantity (MOQ): Larger orders significantly reduce unit cost through economies of scale. Buyers from Africa, South America, the Middle East, and Europe should consolidate demand to leverage volume discounts and optimize freight costs.

-

Specifications and Customization: Custom sizes, finishes (e.g., powder coating), or added features (like adhesive backing) increase price. Standard clips are more affordable and readily available.

-

Material Quality and Certifications: Clips with certifications (UL, CE) or made from flame-retardant materials command premium pricing but assure safety and compliance in regulated markets.

-

Supplier Location and Reliability: Sourcing from established manufacturers in Asia often offers cost advantages but requires thorough vetting. Local or regional suppliers may provide faster delivery and easier communication but at higher prices.

-

Incoterms and Payment Terms: FOB, CIF, or DDP terms affect the responsibility and cost burden. Buyers should negotiate terms that minimize hidden costs and clarify liability.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, consider installation ease, durability, replacement frequency, and after-sales support. Higher-quality clips may reduce long-term maintenance costs.

-

Request Samples and Test Locally: Especially important for buyers in emerging markets (Africa, South America) to ensure compatibility with local installation practices and environmental conditions.

-

Leverage Group Purchasing: Collaborate with regional partners to pool orders, reducing MOQ constraints and shipping costs.

-

Clarify Specifications Early: Precise technical details reduce risk of costly redesigns or rejects.

-

Factor in Import Duties and Taxes: Understand local customs regulations to avoid unexpected expenses that can erode margins.

-

Choose Reliable Logistics Partners: Timely delivery is crucial for project schedules; delays can inflate costs and damage client relationships.

-

Stay Informed on Currency Fluctuations: Volatile exchange rates in markets like the UAE or Indonesia can affect final costs; consider forward contracts or multi-currency payment options.

Indicative Pricing Overview

Prices for standard plastic LED strip mounting clips typically range from $0.05 to $0.20 per unit at moderate volumes (thousands of pieces), while metal clips can cost between $0.15 and $0.50 per unit depending on complexity. Customizations, certifications, and packaging add incremental costs. Freight and import duties vary widely by destination and shipment size.

Note: All pricing and cost components are indicative and subject to change based on supplier negotiations, market conditions, and geopolitical factors. Buyers should conduct detailed due diligence and request formal quotations tailored to their specific project requirements and logistics scenarios.

Spotlight on Potential led strip mounting clips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip mounting clips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip mounting clips

Critical Technical Properties of LED Strip Mounting Clips

Understanding the essential technical specifications of LED strip mounting clips is crucial for international B2B buyers aiming to source the right products for durable, efficient installations. These properties directly impact installation quality, longevity, and compatibility with LED strips across diverse environments.

-

Material Grade

Clips are typically manufactured from high-grade plastics (e.g., polycarbonate, ABS) or stainless steel (304 or 316 grades). Plastic clips offer lightweight and corrosion resistance, suitable for indoor or mild environments, while stainless steel clips provide superior strength and resistance to harsh outdoor or industrial conditions. Choosing the correct material grade ensures durability and compliance with regional safety standards, especially in humid or corrosive climates found in Africa, the Middle East, and South America. -

Dimensional Tolerance

Precise dimensional tolerance (often ±0.1 mm) ensures clips fit LED strips snugly without causing damage or slack. Tight tolerances are critical for maintaining strip alignment, which affects light uniformity and aesthetic outcomes. For large-scale projects, consistent tolerances reduce installation errors and rework costs, making tolerance an important quality metric for bulk buyers. -

Load Capacity & Fixing Strength

This refers to the clip’s ability to securely hold the LED strip under static and dynamic forces, including vibration or wind pressure in outdoor applications. Load capacity depends on clip design and fastening method (screw, nail, or adhesive backing). Buyers targeting outdoor or industrial installations must verify load ratings to avoid premature failures. -

UV and Temperature Resistance

Especially vital for outdoor or high-temperature environments, clips should have UV stabilization additives if plastic, or be made from UV-resistant stainless steel. Operating temperature ranges (e.g., -40°C to +80°C) indicate suitability for climates such as the Middle East or tropical regions. This property prolongs clip life and prevents brittleness or deformation under heat exposure. -

Surface Finish and Coating

Surface treatments like powder coating or anodizing on metal clips enhance corrosion resistance and aesthetic appeal. For plastic clips, smooth finishes reduce dust accumulation and facilitate easier cleaning. In markets where aesthetics are critical (luxury retail, hospitality sectors in Europe or UAE), surface finish quality can influence procurement decisions. -

Mounting Method Compatibility

Clips vary by installation type—some designed exclusively for screw mounting, others with adhesive backing or snap-fit designs. Ensuring compatibility with local mounting hardware and installation preferences minimizes adaptation costs and installation time.

Common Trade Terminology for LED Strip Mounting Clips

Navigating international trade requires familiarity with key industry terms to facilitate smooth procurement, negotiation, and logistics. Below are essential terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce mounting clips that other companies rebrand and sell under their own label. Buyers seeking customization or private labeling often engage OEMs to reduce costs and tailor product features to specific market needs. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest order size a supplier is willing to accept. Understanding MOQ helps buyers balance inventory costs with project scale. For emerging markets or smaller businesses in Africa or South America, negotiating MOQs can be critical to avoid overstocking. -

RFQ (Request for Quotation)

RFQ is a formal inquiry sent to suppliers requesting detailed pricing, lead times, and terms for specific clip models and quantities. A well-prepared RFQ speeds up supplier response and ensures clear comparison among competing offers. -

Incoterms (International Commercial Terms)

Incoterms specify the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding these is essential for budgeting total landed costs and managing cross-border logistics. -

Lead Time

This is the duration between order confirmation and delivery. Lead times vary depending on production complexity and shipping routes. Buyers in regions with longer shipping times, such as remote areas of Africa or South America, must factor lead time into project schedules to avoid delays. -

Batch Consistency

Refers to uniformity in product quality and specifications across multiple production runs. Consistency is vital for large-scale projects requiring multiple shipments over time, ensuring that clips from different batches fit and perform identically.

By prioritizing these technical properties and mastering key trade terminology, B2B buyers can make informed decisions, optimize procurement strategies, and ensure successful, cost-effective LED strip installations tailored to their regional market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip mounting clips Sector

Market Overview & Key Trends

The global market for LED strip mounting clips is experiencing steady growth driven by the expanding LED lighting industry and increasing demand for flexible, efficient lighting solutions. B2B buyers from Africa, South America, the Middle East, and Europe—regions characterized by rapid urbanization and infrastructural development—are key contributors to this growth. In particular, emerging economies like the UAE and Indonesia are investing heavily in smart city projects and sustainable building designs, which elevate demand for reliable LED mounting accessories that ensure optimal installation and durability.

Key market dynamics include the rising preference for clip mounting over adhesive solutions due to enhanced security and longevity, especially in outdoor and industrial applications. Clips made from durable materials such as aluminum and high-grade plastics are favored for their resistance to harsh environmental conditions like dust, humidity, and UV exposure. This trend aligns with the increasing use of angle-adjustable and E-clip variants that offer flexibility for varied lighting angles and seamless integration into aluminum profiles.

From a sourcing perspective, international buyers are focusing on suppliers who can offer customization options, just-in-time delivery, and compliance with international quality standards such as RoHS and CE certification. The demand for modular, easy-to-install clip systems is rising as businesses seek to reduce installation time and costs while maintaining high-quality outcomes. Additionally, digital procurement platforms and global trade fairs are becoming vital channels for discovering innovative clip designs and negotiating bulk orders efficiently.

Sustainability & Ethical Sourcing in B2B

Sustainability is rapidly becoming a critical factor in procurement decisions for LED strip mounting clips. The environmental impact of materials and manufacturing processes is under scrutiny, with B2B buyers increasingly prioritizing suppliers who demonstrate commitment to reducing carbon footprints and waste. Clips manufactured from recyclable materials such as anodized aluminum or bio-based plastics are gaining traction, as they align with circular economy principles and reduce landfill contributions.

Ethical sourcing is equally important. Buyers from regions with stringent regulatory frameworks, like Europe, are demanding transparent supply chains that ensure fair labor practices and responsible mining of raw materials. Certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) serve as benchmarks for evaluating supplier sustainability credentials.

Furthermore, suppliers offering green-certified products that comply with directives like the EU’s Ecodesign and Energy Labelling framework provide added value to buyers aiming to meet corporate social responsibility goals. By selecting suppliers with robust sustainability policies, B2B buyers can enhance their brand reputation, reduce regulatory risks, and contribute to global sustainability efforts.

Evolution of LED Strip Mounting Clips

The evolution of LED strip mounting clips parallels the broader development of LED lighting technology. Initially, adhesive tapes were the dominant method for mounting LED strips due to their simplicity and low cost. However, as LED applications expanded into more demanding environments, the need for more secure and durable mounting solutions became evident.

This led to the introduction of clip mounting systems, which provide mechanical fastening through screws or nails, offering superior stability and longevity. Over time, manufacturers innovated with specialized clips such as angle-adjustable variants and E-clips designed for integration with aluminum profiles, enabling precise light positioning and enhanced aesthetics.

Today’s mounting clips combine functionality with design flexibility, catering to diverse installation contexts from residential to industrial. Their development reflects a shift toward modular, high-performance lighting systems that prioritize ease of installation, durability, and adaptability to evolving market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led strip mounting clips

-

How can I effectively vet suppliers of LED strip mounting clips for international B2B purchases?

Vet suppliers by verifying their business licenses, certifications (e.g., ISO 9001), and product compliance with international standards such as CE or RoHS. Request detailed product datasheets and samples to assess quality firsthand. Check references and client reviews, especially from buyers in your region (Africa, Middle East, South America, Europe). Additionally, conduct video calls or virtual factory tours to ensure manufacturing capabilities and quality control processes meet your expectations. Partnering with suppliers who have experience exporting to your region can minimize customs and compliance risks. -

Is customization available for LED strip mounting clips, and how should I approach this with suppliers?

Most reputable manufacturers offer customization services including clip size, material (plastic, metal), shape, and surface finish to match your specific LED strip requirements. Clearly communicate your technical specifications, application environment, and volume needs upfront. Request prototypes or 3D models before bulk production to avoid costly errors. Understand the supplier’s minimum order quantities (MOQs) for custom orders and inquire about additional costs or lead times associated with customization, which can be longer than standard product deliveries. -

What are typical MOQs and lead times for bulk orders of LED strip mounting clips when sourcing internationally?

MOQs vary widely depending on the supplier and customization level but typically range from 1,000 to 10,000 pieces for standard clips. Lead times for production usually span 3-6 weeks, with additional time for shipping (2-4 weeks depending on logistics). For custom clips, expect longer lead times due to tooling and prototype approval phases. Negotiate MOQs and lead times early in discussions, considering your inventory turnover and demand forecasts, especially when shipping to regions like Africa or South America where logistics may add complexity. -

Which payment terms are common and safest when importing LED strip mounting clips from overseas suppliers?

Common payment terms include a 30% deposit upfront and 70% balance before shipment or upon receipt of the bill of lading. Letters of credit (LC) provide higher security for both parties but may incur bank fees. For trusted suppliers, net 30 or net 60 days terms can be negotiated. Use escrow services or trade platforms that offer payment protection. Always confirm payment terms in the contract and ensure compliance with your country’s foreign exchange regulations to avoid delays or disputes. -

What quality assurance measures and certifications should I require from LED strip mounting clip suppliers?

Require suppliers to provide quality assurance documentation including ISO 9001 certification, material safety data sheets (MSDS), and test reports for mechanical strength and durability. Clips intended for outdoor or industrial use should comply with IP ratings or corrosion resistance standards. Ask for batch inspection reports and evidence of in-process quality control. For import into regions with strict regulations (e.g., EU CE marking), ensure the supplier’s products meet all relevant safety and environmental standards to facilitate smooth customs clearance. -

How can I optimize logistics and shipping for bulk LED strip mounting clips to Africa, South America, or the Middle East?

Work with suppliers experienced in international shipping and familiar with your target region’s customs requirements. Choose the right shipping mode—sea freight for cost-efficiency on large volumes, air freight for urgent deliveries. Consolidate shipments when possible to reduce costs. Ensure accurate HS codes and commercial invoices to prevent customs delays. Partner with reliable freight forwarders and consider incoterms like FOB or CIF that clearly define responsibilities and costs. Plan shipments around seasonal weather and regional holidays to avoid supply chain disruptions. -

What strategies can I use to resolve disputes or quality issues with overseas LED strip mounting clip suppliers?

Establish clear contractual terms detailing quality standards, inspection procedures, and remedies for non-conformance. Use third-party inspection agencies to verify product quality before shipment. In case of disputes, communicate promptly and professionally, providing photographic evidence and detailed reports. Leverage arbitration clauses in contracts or engage trade mediation services if needed. Maintain a good relationship with suppliers by addressing issues collaboratively, which often leads to faster resolutions and long-term partnerships. -

Are there specific considerations for sourcing LED strip mounting clips for different regional markets such as the UAE, Indonesia, or Brazil?

Yes, regional considerations include compliance with local electrical and safety standards (e.g., IEC standards in UAE, INMETRO certification in Brazil), climate-related material requirements (e.g., UV resistance in tropical Indonesia), and import tariffs or trade agreements. Understand local market preferences for clip types and installation methods. Additionally, factor in language barriers and cultural business practices during negotiations. Working with suppliers who have regional experience or local agents can streamline compliance and improve supply chain reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip mounting clips

Securing the right LED strip mounting clips is a critical step for ensuring durable, efficient, and visually appealing LED installations. For international B2B buyers in Africa, South America, the Middle East, and Europe, prioritizing strategic sourcing means balancing quality, cost-efficiency, and supplier reliability. Clips must align with project-specific needs—whether for permanent outdoor setups requiring robust metal clips or flexible indoor installations favoring adhesive-backed options.

Key sourcing considerations include evaluating clip material, compatibility with LED strip profiles, ease of installation, and environmental resilience. Leveraging suppliers who offer customizable solutions and maintain consistent quality standards will mitigate risks related to product failure and installation delays. Additionally, understanding regional market dynamics and logistics capabilities can unlock competitive advantages in pricing and delivery.

Illustrative Image (Source: Google Search)

Looking ahead, the demand for innovative mounting solutions that integrate seamlessly with smart lighting and energy-efficient systems will grow. Buyers are encouraged to engage with manufacturers who invest in R&D and sustainable production practices, positioning their supply chains for future-proof LED applications.

Take proactive steps now: deepen supplier partnerships, explore emerging clip technologies, and tailor procurement strategies to your region’s unique infrastructure and market trends. This approach will secure your competitive edge in the rapidly evolving LED lighting industry.