Guide to Led Strip Connector

- Introduction: Navigating the Global Market for led strip connector

- Understanding led strip connector Types and Variations

- Key Industrial Applications of led strip connector

- Strategic Material Selection Guide for led strip connector

- In-depth Look: Manufacturing Processes and Quality Assurance for led strip connector

- Manufacturing Processes for LED Strip Connectors

- Quality Assurance and Control (QA/QC) Frameworks

- Comprehensive Cost and Pricing Analysis for led strip connector Sourcing

- Spotlight on Potential led strip connector Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led strip connector

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip connector Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led strip connector

- Strategic Sourcing Conclusion and Outlook for led strip connector

Introduction: Navigating the Global Market for led strip connector

In the dynamic world of LED lighting solutions, the LED strip connector serves as a critical component that ensures seamless electrical connections, flexibility, and durability across diverse installations. For international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of LED strip connectors is essential to sourcing products that meet stringent quality, compatibility, and cost-efficiency requirements.

This comprehensive guide delves into the core aspects of LED strip connectors, offering actionable insights to empower buyers in making informed procurement decisions. Key topics covered include the various types of connectors—ranging from clip-on and solderless to waterproof designs—along with the materials and manufacturing standards that influence product performance and longevity. Rigorous quality control processes and certifications relevant to different markets are also explored to help mitigate supply chain risks.

Additionally, the guide provides an in-depth analysis of global supplier landscapes, highlighting strategic sourcing tips tailored for buyers in emerging and mature markets alike. Cost considerations and value optimization strategies are emphasized to balance budget constraints with product reliability. To further assist decision-makers, a detailed FAQ section addresses common challenges and technical questions encountered during the sourcing process.

By equipping international buyers with this knowledge, the guide aims to streamline procurement workflows, enhance supply chain resilience, and foster long-term partnerships with reputable LED strip connector manufacturers and suppliers worldwide. Whether for large-scale commercial projects or specialized installations, this resource is designed to support strategic sourcing success in an increasingly competitive and interconnected global market.

Understanding led strip connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2-Pin/4-Pin Clip-On | Tool-free clip connectors for quick installation | Residential & commercial LED strip lighting | Pros: Easy to use, no soldering; Cons: Limited to standard strip sizes and voltages |

| Soldered Connectors | Requires soldering wires directly to strip contacts | Industrial and custom lighting solutions | Pros: Strong, reliable electrical connection; Cons: Labor-intensive, requires skilled labor |

| Magnetic Connectors | Uses magnets for detachable, reusable connections | Temporary setups, event lighting | Pros: Reusable, fast assembly; Cons: Less secure in high-vibration or outdoor environments |

| Waterproof Connectors | Sealed connectors with IP65+ rating for moisture protection | Outdoor and wet-area installations | Pros: Protects against water ingress; Cons: Bulkier and often more expensive |

| Flexible Flat Cable (FFC) Connectors | Thin, flat cable connectors for tight spaces | Automotive and electronics integration | Pros: Compact, flexible; Cons: Requires precise alignment and handling |

2-Pin/4-Pin Clip-On Connectors

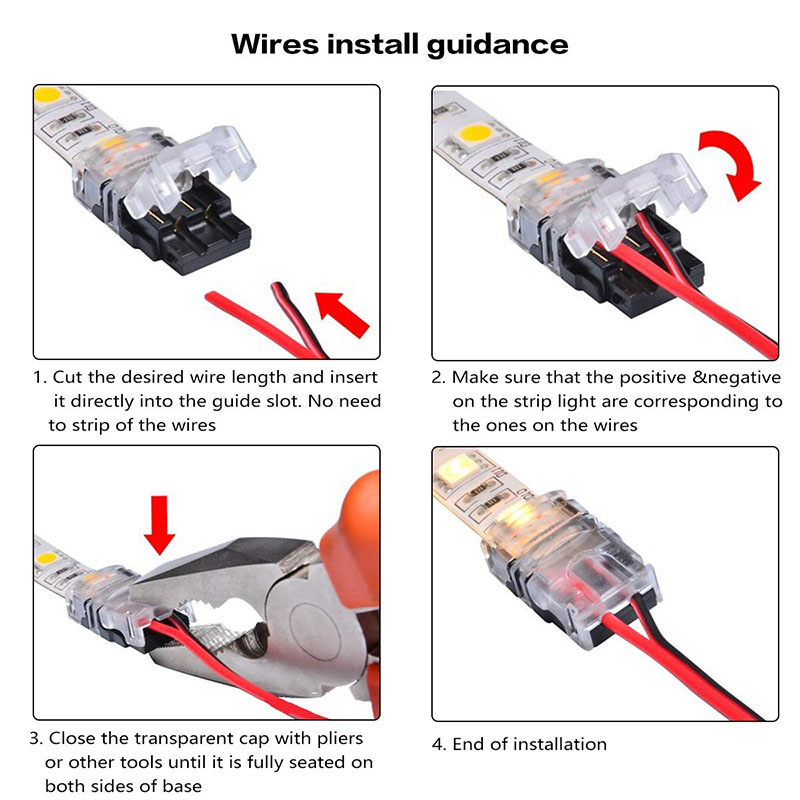

These connectors are designed for rapid, tool-free installation, clipping directly onto LED strip contacts. They are ideal for standard 12V or 24V LED strips used in residential and commercial applications. For B2B buyers, clip-on connectors reduce labor costs and speed up installation but are limited by strip width and type compatibility. Ensuring supplier quality and compatibility with specific LED strip models is critical to avoid connectivity issues.

Soldered Connectors

Soldered connectors involve manually attaching wires to the LED strip’s copper pads, providing a robust and permanent electrical connection. This type is preferred in industrial or custom lighting applications requiring high reliability and flexibility in strip length and configuration. B2B buyers should consider the additional labor and skill costs but benefit from superior durability and customizability, which is vital for complex projects.

Magnetic Connectors

Magnetic connectors offer a reusable and detachable solution, perfect for temporary installations like exhibitions, events, or displays that require frequent setup and teardown. Although they provide convenience and speed, magnetic connectors may not withstand harsh environments or vibrations well. Buyers should weigh the trade-off between ease of use and connection security depending on the application.

Waterproof Connectors

These connectors feature sealed designs that meet IP65 or higher standards, ensuring protection against moisture and dust. They are essential for outdoor lighting, wet environments, or industrial settings where exposure to elements is a concern. While waterproof connectors typically cost more and are bulkier, they significantly reduce failure rates and maintenance needs, making them a worthwhile investment for long-term, reliable installations.

Flexible Flat Cable (FFC) Connectors

FFC connectors use thin, flat cables to connect LED strips in confined or complex spaces, such as automotive lighting or embedded electronics. Their compactness and flexibility are advantageous for intricate designs, but precise handling is required during installation to avoid misalignment or damage. B2B buyers should prioritize supplier expertise in providing FFC connectors with consistent quality and appropriate specifications for their projects.

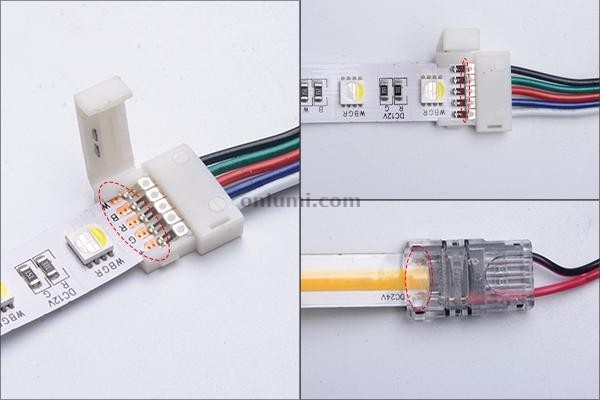

Related Video: How to Use LED Strip Light Connectors

Key Industrial Applications of led strip connector

| Industry/Sector | Specific Application of led strip connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Flexible lighting installations in display cases and store interiors | Enables quick, seamless connection of LED strips, reducing installation time and maintenance costs | Connector compatibility with various LED strip types, ease of installation, durability in high-traffic areas |

| Hospitality & Events | Modular decorative lighting for hotels, restaurants, and event venues | Facilitates scalable and customizable lighting setups, enhancing ambiance and customer experience | Waterproofing and corrosion resistance, flexibility for frequent reconfiguration, supplier reliability |

| Automotive & Transportation | Interior and exterior accent lighting in vehicles and public transport | Provides secure electrical connections in compact spaces, ensuring safety and consistent illumination | Vibration resistance, temperature tolerance, compliance with automotive standards |

| Architecture & Construction | Integration of LED strips in building facades and smart lighting systems | Supports complex lighting designs with reliable connectors that simplify installation and future upgrades | Connector IP rating for outdoor use, compatibility with control systems, long-term durability |

| Industrial Manufacturing | Machine and workspace lighting requiring modular and maintainable LED setups | Improves ease of maintenance and replacement, minimizing downtime and enhancing worker safety | Robustness against industrial environments, ease of access, and electrical safety certifications |

Retail & Commercial Lighting Applications

In retail and commercial environments, LED strip connectors are essential for creating flexible, visually appealing lighting displays. These connectors allow businesses to quickly join LED strips in complex layouts without soldering, reducing installation time and enabling easier maintenance. For international buyers in regions like Europe and South America, connectors must be compatible with a wide range of LED strip types and designed to withstand frequent handling. High durability connectors also help retailers maintain consistent lighting quality in high-traffic areas, enhancing product visibility and customer experience.

Illustrative Image (Source: Google Search)

Hospitality & Events Lighting Solutions

The hospitality sector benefits greatly from LED strip connectors due to the need for adaptable and visually striking lighting arrangements. Hotels, restaurants, and event venues often require modular lighting that can be reconfigured for different themes or occasions. Connectors with waterproof and corrosion-resistant features are crucial for areas exposed to humidity or outdoor elements, especially in Middle Eastern and African markets where environmental conditions can be harsh. Reliable connectors reduce downtime and allow for rapid setup changes, improving operational efficiency and guest satisfaction.

Automotive & Transportation Lighting

LED strip connectors in automotive and transportation industries must meet stringent requirements for vibration resistance and temperature tolerance. These connectors enable secure electrical connections in confined spaces such as vehicle interiors, dashboards, and public transport lighting systems. For buyers in emerging markets like Indonesia and South America, sourcing connectors compliant with automotive safety standards ensures reliability and longevity. Proper connectors reduce maintenance costs and prevent electrical failures that could affect vehicle safety and passenger comfort.

Illustrative Image (Source: Google Search)

Architecture & Construction Applications

In architecture and construction, LED strip connectors facilitate the integration of lighting into building facades and smart lighting systems. These connectors must support complex wiring schemes and be rated for outdoor use, especially in European and Middle Eastern climates with variable weather conditions. High IP-rated connectors enable architects and contractors to install long-lasting, weatherproof lighting solutions that are easy to upgrade or expand. For B2B buyers, ensuring compatibility with control systems and selecting connectors with proven durability is critical for project success.

Industrial Manufacturing Lighting

Industrial manufacturing environments demand robust LED strip connectors that can withstand exposure to dust, chemicals, and mechanical stress. These connectors simplify maintenance by allowing quick disconnection and replacement of LED strips, minimizing production downtime. For industrial buyers in Africa and South America, sourcing connectors with strong electrical safety certifications and rugged construction is key to ensuring worker safety and operational continuity. Easy-to-access connectors also improve efficiency in large-scale manufacturing facilities where lighting needs frequent adjustments.

Related Video: LED light Strip connector For Beginners

Strategic Material Selection Guide for led strip connector

Common Materials for LED Strip Connectors: An In-Depth B2B Analysis

Selecting the right material for LED strip connectors is critical for ensuring product reliability, ease of installation, and longevity in diverse environments. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must consider factors like environmental conditions, compliance with regional standards, and cost-effectiveness when choosing materials.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its excellent impact resistance, high temperature tolerance (typically up to 120°C), and good electrical insulation properties. It is lightweight and offers moderate resistance to UV radiation and chemicals.

Pros & Cons:

– Pros: Durable, transparent or translucent options for visual inspection, cost-effective for mass production, and easy to mold into complex shapes.

– Cons: Moderate UV resistance means it can degrade under prolonged sun exposure without additives; less resistant to certain solvents and chemicals compared to specialized plastics.

Impact on Application:

Polycarbonate connectors are ideal for indoor LED strip installations where mechanical protection and electrical insulation are priorities. They perform well in dry or mildly humid environments but require UV stabilizers for outdoor use.

Considerations for International Buyers:

Buyers from regions with high UV exposure (e.g., Middle East, parts of Africa) should verify UV resistance specifications. Compliance with international standards such as IEC 60695 for flammability and UL 94 for plastic materials is common. European buyers often require RoHS compliance, which polycarbonate typically meets. Cost-effectiveness and availability make PC connectors attractive for large-scale projects in emerging markets like South America.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile plastic with good electrical insulation, moderate temperature resistance (up to 70-80°C), and excellent chemical resistance. It is also flame retardant and widely used in electrical applications.

Pros & Cons:

– Pros: Low cost, good resistance to moisture and many chemicals, flexible options available for easier installation.

– Cons: Lower temperature tolerance than polycarbonate, can become brittle over time in harsh UV or cold environments, and environmental concerns regarding plasticizers and additives.

Impact on Application:

PVC connectors suit indoor applications with moderate environmental stress. Their flexibility aids in installations requiring bending or twisting. However, for outdoor or high-temperature environments, PVC may degrade faster, limiting lifespan.

Considerations for International Buyers:

In regions with stringent environmental regulations (e.g., Europe), buyers should seek PVC formulations free from harmful phthalates and compliant with REACH and RoHS directives. For Africa and South America, cost advantages and local availability often outweigh these concerns. Buyers in hot climates (Middle East, Indonesia) should consider temperature limitations carefully.

3. Nickel-Plated Brass

Key Properties:

Nickel-plated brass is a metal alloy connector material offering excellent electrical conductivity, corrosion resistance, and mechanical strength. The nickel plating enhances surface hardness and protects against oxidation.

Pros & Cons:

– Pros: Superior electrical performance, durable in harsh environments, excellent corrosion resistance, and high mechanical strength.

– Cons: Higher cost compared to plastics, heavier, and more complex manufacturing processes. Susceptible to galvanic corrosion if paired improperly with other metals.

Impact on Application:

Ideal for connectors in high-performance LED strip lighting requiring reliable electrical contact and durability, especially in humid or corrosive environments. Suitable for both indoor and outdoor use, including industrial applications.

Considerations for International Buyers:

Buyers in coastal or high-humidity regions (e.g., parts of South America, Indonesia) benefit from the corrosion resistance of nickel-plated brass. Compliance with standards such as ASTM B16 (for brass) and ISO 4520 (nickel plating) is critical. European buyers often require RoHS compliance and may prefer nickel-plated brass for premium products. The higher cost is justified by longevity and reliability in demanding applications.

4. Stainless Steel (304 or 316 Grade)

Key Properties:

Stainless steel connectors offer exceptional corrosion resistance, high tensile strength, and excellent temperature tolerance (up to 870°C for 304 grade). Grades 304 and 316 differ mainly in corrosion resistance, with 316 being superior in marine environments.

Pros & Cons:

– Pros: Outstanding durability, corrosion resistance, and mechanical strength; suitable for extreme environments.

– Cons: High cost, heavier than plastic or brass, and more difficult to manufacture with tight tolerances.

Impact on Application:

Best suited for outdoor or industrial LED strip connectors exposed to harsh chemicals, saltwater, or extreme temperatures. Stainless steel ensures long-term reliability where failure is not an option, such as in architectural or marine lighting.

Considerations for International Buyers:

European and Middle Eastern buyers often require compliance with EN 10088 (stainless steel standards) and may prefer 316 grade for coastal installations. In Africa and South America, cost can be a limiting factor, but stainless steel connectors are favored for premium or safety-critical projects. The material’s recyclability aligns well with sustainability goals in Europe.

Summary Table

| Material | Typical Use Case for led strip connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor connectors requiring impact resistance and insulation | Durable, cost-effective, easy to mold | Moderate UV resistance, chemical sensitivity | Low |

| Polyvinyl Chloride (PVC) | Indoor, flexible connectors with chemical and moisture resistance | Low cost, flexible, flame retardant | Limited temperature tolerance, UV degradation | Low |

| Nickel-Plated Brass | High-performance connectors needing excellent conductivity and corrosion resistance | Superior electrical contact and durability | Higher cost, heavier, risk of galvanic corrosion | Medium |

| Stainless Steel (304/316) | Outdoor/industrial connectors exposed to harsh environments | Exceptional corrosion resistance and strength | High cost, heavy, complex manufacturing | High |

This guide helps B2B buyers across diverse regions make informed decisions balancing cost, durability, and environmental compatibility when sourcing LED strip connectors. Understanding material trade-offs ensures optimal product performance and supply chain efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for led strip connector

Manufacturing Processes for LED Strip Connectors

The production of LED strip connectors involves a series of well-defined stages to ensure that the final product meets the stringent requirements of electrical connectivity, durability, and compatibility with various LED strip types. Understanding these manufacturing stages provides B2B buyers with insight into supplier capabilities and quality assurance practices.

1. Material Preparation

Material selection and preparation form the foundation of connector quality. Common materials include:

- Conductive Metals: Copper alloys or phosphor bronze are typically used for the internal conductive parts due to their excellent electrical conductivity and corrosion resistance.

- Insulating Components: High-grade plastics such as polycarbonate (PC) or polyamide (PA) are chosen for the connector housing to ensure durability, heat resistance, and electrical insulation.

- Surface Treatments: Metals often undergo plating processes such as tin or nickel plating to enhance conductivity and prevent oxidation.

Suppliers source raw materials from certified vendors, and initial incoming quality control (IQC) checks verify material specifications, chemical composition, and mechanical properties before manufacturing begins.

2. Forming and Machining

The conductive metal parts are shaped through precision stamping or progressive die cutting, which allows high-volume production with tight tolerances. This stage ensures the connector pins and contacts conform exactly to design specifications critical for reliable electrical connections.

In some cases, CNC machining or molding may be used for complex components. The insulating parts are typically produced via injection molding, offering consistent shape, strength, and resistance to environmental factors.

3. Assembly

Assembly integrates the conductive and insulating parts into a functional connector. This can be done manually or with automated assembly lines depending on order volume and complexity.

Key assembly steps include:

- Contact Insertion: Precisely placing and securing the metal contacts into the plastic housing.

- Soldering or Welding: In some designs, contacts may be soldered or ultrasonic welded to ensure mechanical stability.

- Connector Locking: Implementing clips, latches, or snap-fit features to secure the connector onto the LED strip firmly.

Automation in assembly improves consistency and reduces human error, especially important for large-scale orders common in B2B transactions.

4. Finishing and Packaging

After assembly, connectors undergo cleaning to remove residues and are visually inspected for defects such as burrs, misalignment, or incomplete assembly.

Packaging is tailored to protect connectors during transport and storage. For international buyers, packaging may be customized to meet destination-specific requirements, including moisture-proofing and labeling in compliance with import regulations.

Quality Assurance and Control (QA/QC) Frameworks

Ensuring the reliability and safety of LED strip connectors is paramount, especially for B2B buyers sourcing for diverse markets across Africa, South America, the Middle East, and Europe. Quality assurance encompasses compliance with international standards, rigorous testing protocols, and transparent supplier verification processes.

International and Industry Standards

-

ISO 9001: This globally recognized quality management system standard ensures that manufacturers maintain consistent quality processes, continuous improvement, and customer satisfaction. Buyers should verify supplier ISO 9001 certification as a baseline quality indicator.

-

CE Marking: Required for products sold in the European Economic Area (EEA), CE certification confirms conformity with EU safety, health, and environmental requirements. For European buyers, CE compliance is often mandatory.

-

RoHS Compliance: Restriction of Hazardous Substances directives limit the use of harmful materials like lead and mercury in electrical components, crucial for environmental safety and regulatory adherence in Europe and increasingly in other regions.

-

UL / ETL Certifications: Particularly relevant for North American markets but often requested globally, these certifications attest to product safety and electrical performance.

-

API and Regional Standards: Some countries in the Middle East, Africa, and South America may have specific electrical safety or import standards. Buyers should inquire about regional certifications or testing reports relevant to their market.

Quality Control Checkpoints

A robust QC system involves multiple inspection stages:

-

Incoming Quality Control (IQC): Verification of raw materials and components for compliance with specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including dimensional checks, assembly accuracy, and solder joint integrity.

-

Final Quality Control (FQC): Comprehensive testing of finished connectors before shipment, including functional testing and appearance inspection.

Common Testing Methods

-

Electrical Conductivity and Resistance Testing: Ensures low contact resistance and reliable electrical performance.

-

Mechanical Durability Testing: Includes insertion and withdrawal force tests to simulate repeated use without failure.

-

Environmental Testing: Exposure to humidity, temperature cycling, and corrosion resistance tests verify connector robustness under varying conditions.

-

Visual and Dimensional Inspection: Automated optical inspection (AOI) systems and precision measuring tools confirm adherence to design tolerances.

Verifying Supplier Quality: Recommendations for B2B Buyers

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality assurance practices is critical to mitigate risks related to substandard products or shipment delays.

-

Request Supplier Certifications and Test Reports: Always ask for copies of ISO 9001 certificates, CE marking documentation, RoHS compliance reports, and any relevant third-party testing certificates.

-

Conduct Factory Audits: On-site or virtual audits enable buyers to assess manufacturing capabilities, QC processes, and workforce competency. Audits also provide opportunities to verify traceability systems and inventory management.

-

Third-Party Inspections: Employ independent inspection agencies to perform pre-shipment inspections (PSI), random sampling, and lab testing. This adds an unbiased layer of quality verification.

-

Sample Testing: Before placing large orders, request samples for in-house testing or validation by local labs to ensure product compatibility with specific LED strips and operational conditions.

-

Supply Chain Transparency: Engage suppliers who maintain transparent communication and digital documentation, including batch traceability, inspection records, and non-conformance reports.

QC and Certification Nuances for International Markets

-

Africa & South America: Regulatory frameworks may vary widely; buyers should verify if imported connectors require local approvals or additional testing. Sourcing from ISO-certified manufacturers with international certifications reduces compliance risks.

-

Middle East: Some countries mandate conformity to Gulf Cooperation Council (GCC) standards or specific electrical safety marks. Buyers should confirm supplier familiarity with these regulations.

-

Europe (e.g., Italy): Compliance with CE and RoHS is non-negotiable. Additionally, buyers may require detailed Technical Files and Declaration of Conformity documentation for customs clearance.

-

Indonesia and Southeast Asia: While local standards may be evolving, buyers often expect international certifications. Understanding import regulations and possible additional testing requirements is advisable.

Summary:

For B2B buyers sourcing LED strip connectors internationally, a deep understanding of the manufacturing process and quality assurance framework is essential. Scrutinizing supplier materials, production techniques, and QC systems, alongside ensuring compliance with relevant international and regional standards, safeguards product quality and operational success. Proactive verification through audits, certifications, and independent inspections empowers buyers to build resilient supply chains and confidently serve diverse markets worldwide.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip connector Sourcing

When sourcing LED strip connectors for international B2B procurement, understanding the underlying cost structure and pricing dynamics is essential to optimize purchasing decisions and enhance supply chain efficiency. This analysis breaks down key cost components, pricing influencers, and strategic buyer considerations tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Strip Connector Pricing

-

Materials

The primary cost driver is the raw materials used, typically including copper for conductive paths, plastics or silicone for insulation, and sometimes metal alloys for contacts. Higher-grade materials that ensure better conductivity, durability, or water resistance will increase base costs but often improve product lifespan and performance. -

Labor and Manufacturing Overhead

Labor costs depend heavily on the manufacturing location. Countries with lower labor costs often offer more competitive pricing, but buyers should balance this against quality control standards. Manufacturing overhead includes factory utilities, equipment depreciation, and indirect labor, which influence the final unit cost. -

Tooling and Setup Costs

Initial tooling for connector molds and assembly lines can be significant, especially for customized designs or low-volume orders. These costs are usually amortized over production volumes, meaning that higher order quantities reduce the per-unit cost. -

Quality Control (QC)

Rigorous QC processes—such as electrical testing, environmental resistance checks, and certification compliance—add to costs but reduce risks of defects and returns. Suppliers with internationally recognized certifications (e.g., CE, RoHS) may charge premiums reflecting their compliance investments. -

Logistics and Shipping

Transportation, customs duties, and handling fees vary by destination and shipping terms. Bulk shipments via sea freight reduce per-unit logistics costs but increase lead times. Air freight is faster but more expensive, which may be justified for urgent orders or high-value shipments. -

Supplier Margin

Suppliers incorporate profit margins based on market positioning, competition, and service levels (e.g., after-sales support, warranty). Negotiating these margins is often possible, especially for repeat or high-volume buyers.

Primary Pricing Influencers

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes dramatically lower unit prices through economies of scale. MOQ requirements can be a barrier for smaller buyers but offer significant leverage for negotiation and cost reduction. -

Product Specifications and Customization

Customized connectors—such as unique pin configurations, waterproofing, or specialized materials—command higher prices due to additional tooling and testing. Standardized products typically offer the best cost-efficiency. -

Material Quality and Certifications

Certified components ensure compliance with international safety and environmental standards, essential for markets like Europe and the Middle East. Certification costs are often embedded in pricing but provide risk mitigation and market acceptance. -

Supplier Location and Reputation

Suppliers based in established manufacturing hubs may offer competitive pricing and reliable quality. However, emerging markets might provide cost advantages but require careful vetting to avoid quality or delivery risks. -

Incoterms and Payment Terms

The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping and customs costs, impacting total landed cost. Favorable payment terms (e.g., letters of credit, net 30/60) can improve cash flow and reduce financing costs.

Strategic Tips for International B2B Buyers

-

Negotiate Beyond Unit Price

Consider total cost of ownership, including shipping, taxes, and warranty services. Request volume discounts, bundled deals, or extended payment terms to improve overall procurement economics. -

Evaluate Total Cost of Ownership (TCO)

Factor in connector durability, compatibility with LED strips, and maintenance costs. Investing slightly more upfront in higher-quality connectors can reduce downtime and replacement expenses. -

Leverage Local Import Regulations and Trade Agreements

Buyers in Africa, South America, the Middle East, and Europe should explore preferential tariffs or trade agreements that can reduce customs duties, optimizing landed costs. -

Request Samples and Certifications

Always request product samples and verify certifications before committing to large orders. This mitigates risks associated with quality discrepancies and regulatory non-compliance. -

Consolidate Orders to Optimize Logistics

Combining multiple SKUs or orders reduces shipping frequency and cost. Coordinate with suppliers for consolidated shipments, especially when sourcing from Asia or Europe. -

Understand Pricing Fluctuations

Raw material prices, particularly copper and plastics, fluctuate globally. Locking in prices through contracts or sourcing from diversified suppliers can stabilize procurement costs.

Indicative Pricing Disclaimer

Prices for LED strip connectors vary widely depending on specifications, order size, and supplier location. As a general guideline, basic connectors may range from $0.10 to $1.00 per unit at wholesale volumes, while customized or certified connectors can exceed this range. Buyers should use these figures as indicative and conduct detailed supplier quotations to obtain accurate pricing.

By dissecting cost components and pricing drivers, international B2B buyers can make informed sourcing decisions for LED strip connectors that balance cost, quality, and supply chain reliability—critical factors for success in diverse markets such as Africa, South America, the Middle East, and Europe.

Spotlight on Potential led strip connector Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led strip connector’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip connector

Key Technical Properties of LED Strip Connectors

When sourcing LED strip connectors, understanding their technical properties is crucial for ensuring compatibility, reliability, and long-term performance. Here are the most critical specifications international B2B buyers should consider:

-

Material Grade and Conductivity

Connectors typically use copper or copper alloys for the conductive parts, often plated with tin or gold to prevent corrosion. High-grade materials ensure minimal electrical resistance and better durability, directly impacting the LED strip’s efficiency and lifespan. For buyers in humid or outdoor environments (e.g., Middle East or South America), corrosion-resistant plating is especially important. -

Current and Voltage Rating

Each connector is rated for maximum current (amperage) and voltage. Selecting connectors with appropriate ratings prevents overheating and electrical failure. For example, connectors used in high-power LED strips for commercial lighting in Europe or industrial projects in Africa must meet or exceed the operational load to ensure safety and compliance. -

Connector Compatibility and Size Tolerance

LED strip connectors come in various sizes and pin configurations (e.g., 2-pin, 4-pin). Precise dimensional tolerances are critical to ensure a secure fit with the LED strip’s copper pads or solder points. Incorrect sizing leads to poor electrical contact or mechanical failure, resulting in costly returns or installation delays. -

Waterproofing and Environmental Protection

For outdoor or damp locations, connectors with an IP65 rating or higher are preferred. Waterproof connectors protect against moisture ingress, dust, and other contaminants. Buyers targeting outdoor lighting markets (such as in Indonesia or coastal areas in Europe) should prioritize connectors tested for environmental resistance. -

Ease of Installation and Reusability

Tool-free or snap-fit connectors reduce installation time and labor costs, important for large-scale projects. Some connectors are designed for multiple reuse cycles, which can be advantageous for prototyping or modular lighting setups, reducing waste and procurement frequency. -

Temperature Range

Operating temperature specifications indicate how well connectors perform under extreme heat or cold. This is vital for regions with significant temperature fluctuations, such as parts of Africa and the Middle East, to avoid material degradation or loss of contact integrity.

Common Trade Terminology for LED Strip Connectors

Navigating international procurement requires familiarity with essential trade and industry terms. Here are key terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strip connectors which other brands may rebrand or customize. Engaging with OEMs can allow buyers to request tailored designs or packaging, essential for businesses seeking private label products or unique specifications. -

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and cash flow, especially for SMEs or distributors in emerging markets where upfront capital might be limited. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specified product requirements. Efficient RFQs ensure buyers receive competitive offers and clear information to compare suppliers, streamlining sourcing decisions. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Familiarity with Incoterms prevents misunderstandings in shipping costs and risk transfer. -

Lead Time

The period from order placement to delivery. For bulk LED strip connector orders, shorter lead times reduce project delays. Buyers should negotiate lead times that align with their project schedules and inventory strategies. -

Batch Consistency

Indicates the uniformity of product quality across manufacturing batches. Consistent batches reduce variability and defects, which is critical for large-scale installations where uniform performance is required.

Understanding these technical properties and trade terms empowers B2B buyers from Africa, South America, the Middle East, and Europe to make informed purchasing decisions, optimize supply chains, and secure reliable, cost-effective LED strip connectors tailored to their market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip connector Sector

Market Overview & Key Trends

The global LED strip connector market is experiencing robust growth, fueled by the accelerating adoption of LED strip lighting across commercial, industrial, and residential sectors. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, this growth presents both opportunities and challenges shaped by evolving technology, sourcing strategies, and market dynamics.

Key Market Drivers:

– Rising Demand for Flexible Lighting Solutions: LED strip connectors enable seamless installation and customization of LED strips in diverse applications, from architectural lighting in Europe’s urban centers to energy-efficient retail displays in South America. The demand for connectors that support various strip types (e.g., RGB, waterproof, high-lumen) is increasing.

– Technological Advancements: Innovations such as tool-free connectors, waterproof designs, and smart connectivity features (integrating with IoT systems) are becoming mainstream. Buyers from technologically progressive markets like Italy and Indonesia prioritize connectors with enhanced compatibility and ease of installation to reduce labor costs and project timelines.

– Supply Chain Localization & Diversification: Geopolitical tensions and logistics disruptions have encouraged buyers, especially in Africa and the Middle East, to diversify suppliers beyond traditional hubs in China. Emerging manufacturers in Southeast Asia and Europe are gaining traction by offering competitive pricing and shorter lead times.

– Customization and Scalability: Bulk buyers seek connectors tailored to specific LED strip dimensions and electrical requirements. Suppliers offering custom lengths, connector configurations, and packaging solutions provide a competitive edge. This is particularly relevant for large-scale infrastructure projects in growing economies where consistency and scalability are critical.

Market Dynamics:

– Competitive Pricing Pressure: Global overcapacity in LED components keeps prices competitive, benefiting buyers but also emphasizing the need to balance cost with quality and reliability.

– Regulatory Compliance: European buyers, notably in Italy, must navigate stringent safety and electromagnetic compatibility standards, influencing connector design and certification requirements.

– Digital Procurement Platforms: Increasing adoption of e-procurement and supply chain visibility tools empowers buyers to track orders, forecast needs, and optimize inventory, reducing risks associated with delays and overstocking.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional in the LED strip connector sector—it is a strategic imperative. B2B buyers across Africa, South America, the Middle East, and Europe are increasingly demanding transparency around the environmental footprint and ethical sourcing practices of their suppliers.

Environmental Impact:

– Manufacturing connectors involves the use of plastics, metals (often copper and tin), and electronic components. Responsible sourcing of raw materials reduces the depletion of finite resources and minimizes pollution. Suppliers adopting recycled or bio-based plastics and lead-free soldering processes help lower carbon footprints and hazardous waste generation.

– Energy-efficient manufacturing and minimized packaging waste contribute to greener supply chains, aligning with global carbon reduction commitments. For example, European companies often require compliance with the EU’s RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives.

Ethical Supply Chains:

– Buyers prioritize suppliers with certifications such as ISO 14001 (Environmental Management), ISO 45001 (Occupational Health & Safety), and SA8000 (Social Accountability) to ensure fair labor practices and safe working conditions.

– Transparency in sourcing metals—particularly avoiding conflict minerals—is essential. International buyers increasingly demand chain-of-custody documentation and third-party audits to mitigate reputational risks.

Green Certifications and Materials:

– Connectors certified under programs like UL’s ECOLOGO or TCO Certified demonstrate adherence to strict environmental and social criteria.

– The use of halogen-free, flame-retardant materials and recyclable components is becoming a baseline expectation.

– Buyers may also look for suppliers participating in extended producer responsibility (EPR) schemes, ensuring end-of-life recycling and reducing electronic waste.

By integrating sustainability into procurement decisions, B2B buyers not only comply with regulatory frameworks but also enhance brand value and meet the growing consumer preference for environmentally responsible products.

Evolution and Historical Context

The LED strip connector sector has evolved significantly alongside advancements in LED lighting technology. Initially, connectors were simple, often requiring soldering and offering limited flexibility. As LED strips gained popularity for their versatility and energy efficiency in the early 2000s, the need for easier installation solutions became apparent.

This led to the development of tool-free connectors, which revolutionized the market by enabling quick, solderless connections, reducing installation time and technical skill requirements. Over the last decade, connectors have diversified to accommodate different strip widths, voltages, and environmental conditions, including waterproof and UV-resistant designs.

For B2B buyers, understanding this evolution is crucial. It highlights the importance of selecting connectors that not only meet current project specifications but also align with emerging trends such as smart lighting integration and sustainability standards. This historical progression underscores the sector’s shift from a purely functional component to a strategic enabler of efficient, scalable, and responsible lighting solutions worldwide.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip connector

-

How can I effectively vet suppliers of LED strip connectors for international B2B trade?

Vet suppliers by assessing their business licenses, certifications (such as ISO 9001 or CE), and years of experience in LED components. Request product samples to verify quality and compatibility with your LED strips. Check references or client testimonials, especially from buyers in your region (Africa, South America, Middle East, Europe). Use third-party inspection services to audit manufacturing facilities if possible. Reliable communication, transparent pricing, and clear warranty terms are also key indicators of trustworthy suppliers. -

Are customization options available for LED strip connectors, and how should I approach them?

Yes, many manufacturers offer customization such as connector size, pin configuration, waterproof rating, and packaging. To ensure your requirements are met, provide detailed technical specifications and intended use cases upfront. Custom orders may require MOQ adjustments and longer lead times, so negotiate these terms early. Tailored connectors can improve installation efficiency and product compatibility, which is crucial for projects targeting diverse markets with specific standards or environmental conditions. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for LED strip connector suppliers?

MOQs vary widely but typically range from 500 to 5,000 units depending on customization and supplier scale. Lead times can span from 2 to 8 weeks, influenced by order complexity and production schedules. Payment terms usually include a 30-50% deposit upfront with the balance paid before shipment or upon delivery. For new international buyers, suppliers may require full prepayment or use secure payment methods like letters of credit or escrow services to mitigate risks. -

Which quality assurance certifications should I look for when sourcing LED strip connectors internationally?

Look for certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and ISO 9001 quality management. These certifications indicate compliance with international safety and environmental standards, reducing risks of product failure or import issues. Additionally, certifications related to IP ratings (e.g., IP65, IP67) confirm waterproof or dustproof capabilities, essential for outdoor or industrial applications. -

How can I optimize logistics and shipping when importing LED strip connectors from overseas suppliers?

Coordinate closely with your supplier to consolidate shipments and choose the most cost-effective transport modes (sea freight for large volumes, air freight for urgent orders). Verify packaging quality to avoid damage during transit. Use freight forwarders experienced in your destination region to navigate customs and import regulations smoothly. Consider incoterms like FOB or CIF to clarify responsibilities and costs. Accurate documentation and early customs clearance preparation reduce delays and extra fees. -

What strategies can help resolve disputes or quality issues with LED strip connector suppliers?

Maintain clear communication channels and document all agreements, specifications, and quality expectations. If defects arise, request photographic evidence and propose a third-party inspection. Negotiate amicable solutions such as partial refunds, replacements, or rework. Use contracts with defined dispute resolution clauses, including mediation or arbitration. Building long-term supplier relationships based on trust and transparency often minimizes conflicts and accelerates resolution. -

How important is supplier location for B2B buyers in Africa, South America, the Middle East, and Europe?

Supplier location impacts shipping costs, lead times, and customs complexity. Buyers in Africa and South America may benefit from suppliers with regional warehouses or distribution centers to reduce delays and import duties. European buyers often prefer EU-based suppliers for faster delivery and compliance with local standards. For the Middle East, proximity to key ports and experience with regional regulations can streamline procurement. Evaluate suppliers’ logistics capabilities alongside product quality for optimal sourcing. -

What payment methods are safest for international transactions when purchasing LED strip connectors?

Secure payment methods include letters of credit (LC), escrow services, and PayPal for smaller orders. LCs provide buyer protection by ensuring payment is only released upon meeting agreed terms. Escrow services hold funds until the buyer confirms satisfactory receipt. Wire transfers (T/T) are common but riskier without verified suppliers. Negotiate payment terms balancing trust and risk, and always confirm supplier legitimacy to protect your investment.

Strategic Sourcing Conclusion and Outlook for led strip connector

Efficient sourcing of LED strip connectors is a pivotal factor in securing a competitive edge in the global LED lighting market. For international B2B buyers—especially those in Africa, South America, the Middle East, and Europe—prioritizing quality, supplier reliability, and cost-effectiveness is essential. Strategic partnerships with reputable manufacturers who offer customizable solutions and robust supply chain support can significantly enhance product performance and reduce operational risks.

Key considerations include diversifying supplier bases to mitigate disruptions, leveraging technology-enabled inventory and logistics management, and focusing on connectors that meet regional standards and application-specific requirements. Buyers should also evaluate warranty terms and after-sales service to safeguard long-term investment value. By integrating these elements into their procurement strategy, businesses can optimize costs while ensuring seamless project execution.

Looking ahead, the rising demand for smart and flexible LED lighting solutions will drive innovation in connector designs and sourcing models. Buyers who proactively engage with forward-thinking suppliers and embrace digital tools for supply chain transparency will be best positioned to capitalize on emerging opportunities. We encourage international buyers to adopt a strategic, informed approach to sourcing LED strip connectors—building resilient supply chains that support scalable growth and sustainable success in the evolving lighting landscape.