Guide to Led Flexible Led Strip

- Introduction: Navigating the Global Market for led flexible led strip

- Understanding led flexible led strip Types and Variations

- Key Industrial Applications of led flexible led strip

- Strategic Material Selection Guide for led flexible led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for led flexible led strip

- Comprehensive Cost and Pricing Analysis for led flexible led strip Sourcing

- Spotlight on Potential led flexible led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for led flexible led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led flexible led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of led flexible led strip

- Strategic Sourcing Conclusion and Outlook for led flexible led strip

Introduction: Navigating the Global Market for led flexible led strip

The global demand for LED flexible LED strips is accelerating rapidly, driven by their versatility, energy efficiency, and aesthetic appeal across commercial, industrial, and architectural applications. For international B2B buyers—especially in emerging and dynamic markets such as Africa, South America, the Middle East, and Europe—understanding the complexities of sourcing these products is essential to securing quality, reliability, and competitive pricing.

This guide offers a comprehensive roadmap to mastering the global LED flexible strip market. It covers critical topics including the diverse types and materials available, the intricacies of manufacturing processes and quality control standards, and effective strategies for identifying trusted suppliers and manufacturers. Moreover, it addresses cost considerations, market trends, and answers frequently asked questions that often arise during procurement.

By navigating the nuances of this industry—from voltage compatibility and power supply requirements to certifications like CE, RoHS, and UL—buyers can mitigate risks associated with substandard products, such as premature failure or safety hazards. The guide also highlights sourcing channels that international buyers can leverage, including wholesale distributors, direct manufacturers, trade shows, and verified online marketplaces.

For businesses in regions like Kenya or Egypt, where infrastructure and regulatory environments vary, this resource empowers decision-makers to make informed, strategic purchasing choices that align with local market demands and project specifications. Ultimately, this guide equips B2B buyers with actionable insights to optimize their LED flexible strip procurement, ensuring long-term project success and sustainable growth in an increasingly competitive global landscape.

Understanding led flexible led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

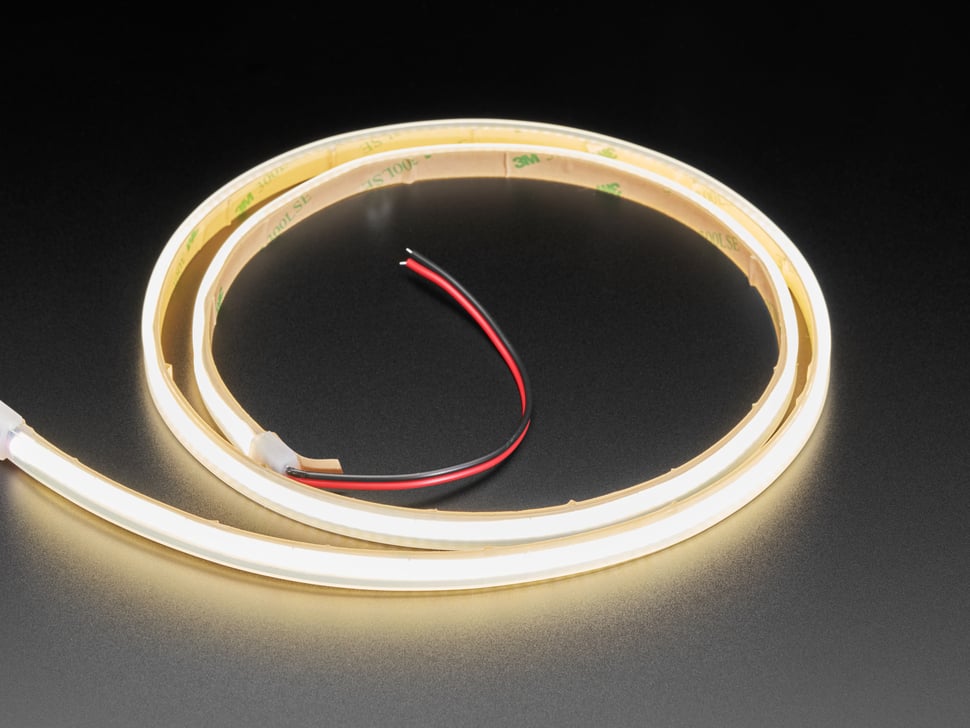

| Single-Color LED Strip | Emits one fixed color, typically white or a specific hue | Retail displays, architectural lighting, signage | Cost-effective, simple installation; limited color options |

| RGB LED Strip | Combines red, green, and blue LEDs allowing color mixing | Hospitality, entertainment, event decoration | Versatile color control; requires compatible controllers |

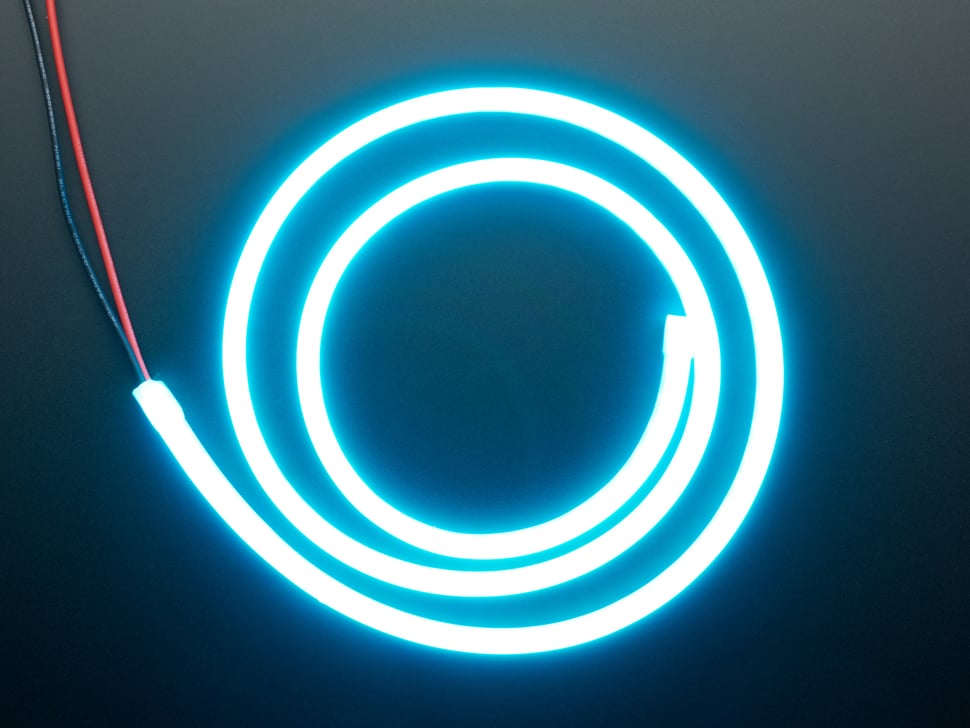

| Waterproof LED Strip | Encased in silicone or epoxy for moisture and dust resistance | Outdoor lighting, industrial environments | Durable in harsh conditions; slightly higher cost and rigidity |

| High-Density LED Strip | Increased LED count per meter for brighter, uniform lighting | Commercial spaces, film sets, photography lighting | Superior brightness; higher power consumption and cost |

| Addressable LED Strip | Individually controllable LEDs for dynamic effects and animations | Advertising, stage design, interactive installations | Highly customizable; complex setup and higher price |

Single-Color LED Strip

This type features LEDs that emit a single, consistent color, often white or warm white, and is the most straightforward LED strip variation. Its simplicity makes it ideal for applications requiring uniform lighting, such as retail shelving or corridor illumination. For B2B buyers in Africa or South America, this type offers cost efficiency and ease of integration, especially in projects with tight budgets or straightforward lighting needs. Key considerations include ensuring voltage compatibility (commonly 12V or 24V) and verifying supplier certifications to guarantee quality.

RGB LED Strip

RGB strips integrate red, green, and blue LEDs to produce millions of color variations via mixing. This flexibility suits dynamic environments like hotels, restaurants, or event venues in the Middle East and Europe. Buyers should assess controller compatibility and the availability of user-friendly control systems. While more expensive than single-color strips, RGB LED strips provide enhanced ambiance and branding opportunities, crucial for businesses aiming to create engaging customer experiences.

Waterproof LED Strip

Designed with protective coatings such as silicone or epoxy, waterproof strips withstand moisture, dust, and outdoor exposure. This makes them essential for outdoor architectural lighting, signage, or industrial settings prevalent in regions with humid or dusty climates like Kenya or Egypt. B2B buyers must evaluate the IP rating (e.g., IP65, IP67) to match environmental demands. Although pricier and less flexible, these strips reduce maintenance costs and enhance durability in challenging conditions.

High-Density LED Strip

Featuring a greater number of LEDs per meter, high-density strips deliver brighter, more uniform illumination. They are preferred in commercial spaces, photography studios, or film sets where lighting quality is paramount. Buyers should consider power requirements and heat dissipation capabilities to avoid performance degradation. This type is suitable for businesses in Europe and South America investing in premium lighting solutions that demand consistent brightness and visual appeal.

Addressable LED Strip

Each LED on an addressable strip can be controlled independently, enabling complex lighting effects, animations, and interactivity. This advanced technology is ideal for advertising, stage design, or interactive exhibits, offering significant differentiation for B2B clients in innovative sectors. However, it requires sophisticated controllers and technical expertise for installation. Buyers must ensure supplier support for customization and after-sales service to maximize the potential of these strips.

Related Video: How to Cut and Connect Led Neon strip Flexible Strip Light | Neon Home Decor | RGB | Rope Light |

Key Industrial Applications of led flexible led strip

| Industry/Sector | Specific Application of led flexible led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Dynamic product display and architectural accent lighting | Enhances customer engagement and boosts sales through attractive visual merchandising | Brightness uniformity, color rendering index (CRI), IP rating for indoor/outdoor use |

| Hospitality & Tourism | Ambient and mood lighting in hotels, restaurants, and cruise ships | Creates inviting atmospheres that improve guest experience and extend stay duration | Dimmability, color temperature options, durability against humidity and heat |

| Automotive & Transport | Interior and exterior vehicle lighting, including dashboards and undercarriage | Improves safety and aesthetic appeal while reducing energy consumption | Flexible form factor, vibration resistance, compliance with automotive standards |

| Manufacturing & Warehousing | Task lighting in assembly lines and storage areas | Increases worker productivity and safety with energy-efficient, focused illumination | High lumen output, long lifespan, easy installation and maintenance |

| Healthcare & Laboratories | Cleanroom and examination lighting | Provides precise, flicker-free lighting critical for medical procedures and research | Non-toxic materials, low heat emission, certifications for medical environments |

Retail & Commercial Applications

In retail environments across Africa, South America, the Middle East, and Europe, flexible LED strips are widely used for dynamic product displays and architectural accents. These strips enable retailers to highlight products with vibrant, customizable lighting that attracts customers and encourages purchases. For international buyers, sourcing LED strips with high color rendering index (CRI) and consistent brightness is essential to ensure true product colors and uniform illumination. Additionally, IP ratings are critical for outdoor or semi-exposed installations, common in commercial plazas or open-air markets.

Hospitality & Tourism Sector

Hotels, restaurants, and cruise ships leverage flexible LED strips to create tailored ambient and mood lighting that enhances guest comfort and satisfaction. This lighting can be seamlessly integrated into ceilings, walls, and furniture, offering diverse color temperatures and dimmability to match different times of day or themes. Buyers from regions such as Kenya and Egypt should prioritize LED strips with robust moisture resistance and heat tolerance due to variable climate conditions. Reliable after-sales support and warranty coverage are also crucial for maintaining lighting quality in high-usage environments.

Automotive & Transport Industry

Flexible LED strips are increasingly adopted in automotive interiors and exteriors for dashboard illumination, footwell lighting, and undercarriage effects. Their slim, bendable form factor allows integration into complex vehicle designs, improving both aesthetics and visibility while consuming less power than traditional lighting. International B2B buyers must ensure compliance with automotive safety and quality standards, including vibration resistance and temperature range performance, to withstand harsh road conditions prevalent in markets like South America and the Middle East.

Manufacturing & Warehousing Facilities

In industrial settings, LED flexible strips provide bright, focused task lighting along assembly lines and in storage areas, enhancing visibility and reducing workplace accidents. Their energy efficiency translates into lower operational costs, a key concern for businesses in emerging markets. Buyers should look for products with high lumen output and long operational lifespans, combined with easy installation features to minimize downtime. Durability against dust and mechanical impact is also essential in these environments.

Healthcare & Laboratory Use

Cleanrooms, laboratories, and examination rooms require precise, flicker-free lighting that flexible LED strips can deliver effectively. Their low heat emission and use of non-toxic materials make them ideal for sensitive medical environments. Buyers from Europe and the Middle East should verify certifications relevant to medical standards, ensuring the lighting system supports critical tasks such as diagnostics and research. Additionally, long-term reliability and minimal maintenance requirements are important for healthcare facilities aiming to reduce operational disruptions.

Strategic Material Selection Guide for led flexible led strip

When selecting materials for LED flexible LED strips, B2B buyers must consider factors such as durability, environmental resistance, manufacturing complexity, and compliance with international standards. These considerations are critical for markets in Africa, South America, the Middle East, and Europe, where climatic conditions, regulatory frameworks, and application requirements vary significantly.

Polyimide (PI) Flexible Substrate

Key Properties:

Polyimide is a high-performance polymer known for its excellent thermal stability (up to 260°C), mechanical flexibility, and chemical resistance. It withstands high temperatures and resists corrosion from moisture and chemicals, making it ideal for demanding environments.

Pros & Cons:

PI substrates provide excellent durability and flexibility, allowing for intricate designs and tight bending radii. However, they tend to be more expensive than other flexible materials and require precise manufacturing processes to maintain quality. The higher cost can impact project budgets but is justified by longevity and performance.

Impact on Application:

Polyimide-based LED strips are well-suited for industrial, automotive, and outdoor lighting applications where exposure to heat and chemicals is common. Their resistance to UV and moisture makes them reliable in harsh climates such as the Middle East and parts of Africa.

Considerations for International Buyers:

Buyers in regions like Kenya and Egypt should ensure suppliers comply with ASTM D-3350 or DIN standards for thermal and mechanical properties. Additionally, verifying RoHS and REACH compliance is essential to meet European Union import regulations, which often influence trading partners globally.

Polyester (PET) Flexible Substrate

Key Properties:

PET is a cost-effective polymer with good flexibility and moderate temperature resistance (up to 150°C). It offers decent chemical resistance but is less robust than polyimide under extreme conditions.

Pros & Cons:

PET substrates are cheaper and easier to manufacture, making them attractive for large-scale projects with budget constraints. However, their lower heat tolerance limits use in high-temperature environments, and they may degrade faster under prolonged UV exposure.

Impact on Application:

PET is ideal for indoor decorative lighting, retail displays, and architectural accent lighting where environmental stress is minimal. It suits temperate climates found in much of Europe and parts of South America but may require protective coatings for outdoor use in harsher regions.

Considerations for International Buyers:

Buyers should confirm compliance with ISO 9001 quality management and check for certifications like UL or CE to ensure safety and performance. In markets such as South America, where import tariffs and standards vary, sourcing from suppliers with clear documentation can simplify customs clearance.

Silicone Encapsulation

Key Properties:

Silicone is widely used as an encapsulant for flexible LED strips due to its excellent thermal stability (-60°C to 230°C), UV resistance, and waterproofing capabilities. It provides robust protection against dust, moisture, and mechanical damage.

Pros & Cons:

Silicone encapsulation enhances strip longevity and enables outdoor and wet-area applications. It is more expensive than epoxy but offers superior flexibility and environmental resistance. The manufacturing process is more complex, potentially increasing lead times.

Impact on Application:

Silicone-encapsulated LED strips are preferred for outdoor lighting, signage, and marine environments, making them highly relevant for buyers in coastal regions of Africa and the Middle East. Their waterproof nature supports IP65 to IP68 ratings, critical for durability.

Considerations for International Buyers:

Ensure suppliers provide IP rating certifications and compliance with IEC 60529 standards. For buyers in Europe, adherence to RoHS and WEEE directives is mandatory. In African and Middle Eastern markets, verifying product performance under local climatic conditions is crucial.

Copper Clad Laminate (CCL)

Key Properties:

Copper clad laminates form the conductive base of flexible LED strips, offering excellent electrical conductivity and thermal dissipation. The copper layer is typically 35µm thick, balancing cost and performance.

Pros & Cons:

CCL ensures efficient current flow and heat management, which prolongs LED lifespan. However, copper is prone to oxidation if not properly coated, which can affect reliability. Manufacturing requires precision to avoid delamination or short circuits.

Impact on Application:

High-quality CCL is essential for high-power LED strips used in commercial and industrial lighting. Its thermal properties are beneficial in hot climates such as those in the Middle East and parts of Africa, where heat dissipation is critical.

Considerations for International Buyers:

Buyers should check for compliance with IPC standards (e.g., IPC-4101 for laminates) and ensure the supplier uses protective coatings to prevent corrosion. In South America and Europe, environmental regulations may affect material sourcing and disposal, necessitating responsible supplier practices.

| Material | Typical Use Case for led flexible led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) | Industrial, automotive, outdoor lighting | High thermal stability and chemical resistance | Higher cost and complex manufacturing | High |

| Polyester (PET) | Indoor decorative, retail, architectural accent lighting | Cost-effective and easy to manufacture | Limited heat and UV resistance | Low |

| Silicone Encapsulation | Outdoor, marine, wet-area lighting | Excellent waterproofing and UV resistance | More expensive and complex production | Medium |

| Copper Clad Laminate (CCL) | Conductive base for high-power LED strips | Superior electrical conductivity and heat dissipation | Susceptible to oxidation without proper coating | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for led flexible led strip

Understanding the manufacturing processes and rigorous quality assurance practices behind flexible LED strips is critical for international B2B buyers aiming to secure reliable, high-performance products. This section breaks down the key production stages, quality control frameworks, and verification methods that buyers—especially those from Africa, South America, the Middle East, and Europe—should consider when sourcing LED flexible strips.

Manufacturing Process of Flexible LED Strips

The production of flexible LED strips involves several precise stages, each requiring specialized materials and techniques to ensure product durability, flexibility, and consistent illumination.

1. Material Preparation

- Substrate Selection: Flexible LED strips commonly use polyimide (PI) or flexible printed circuit boards (FPC) as substrates. These materials provide the necessary bendability and thermal resistance.

- LED Chip Procurement: High-quality LEDs (SMD types like 3528, 5050) are sourced, often from trusted suppliers with verified certifications.

- Electronic Components: Resistors, capacitors, and IC chips for control functions are prepared, emphasizing compatibility and electrical stability.

2. Circuit Forming and Patterning

- Copper Cladding and Etching: Copper foil is laminated onto the flexible substrate and chemically etched to create precise circuit paths.

- Solder Mask Application: A protective layer is applied to prevent oxidation and shorts while leaving exposed pads for soldering.

- Surface Treatment: The substrate surface undergoes cleaning and sometimes coating to enhance solderability and adhesion.

3. Assembly

- SMD LED Placement: Automated pick-and-place machines accurately position LEDs and other components on the substrate.

- Reflow Soldering: The assembly passes through a reflow oven where solder paste melts and solidifies, securing components.

- Protective Coating: Depending on product type, silicone or epoxy coatings are applied for waterproofing and mechanical protection, often via dipping or spraying.

4. Finishing and Packaging

- Cutting and Sectioning: Strips are cut into standard lengths with precision, ensuring clean edges for connectivity.

- Connector Attachment: Connectors or terminals are added to facilitate easy installation.

- Labeling and Packaging: Final products are labeled with product specs and certifications, then packaged to prevent damage during transit.

Quality Assurance Frameworks and Standards

Robust quality control is non-negotiable for flexible LED strips, especially when serving diverse international markets with varying regulatory requirements.

International and Industry Standards

- ISO 9001: This global quality management system standard ensures consistent process control and continuous improvement. Suppliers with ISO 9001 certification demonstrate reliable production governance.

- CE Marking: Mandatory for products entering the European Economic Area, CE certification verifies compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electronic products, crucial for environmental and user safety.

- UL Certification: Especially relevant for North America but increasingly recognized globally, UL ensures electrical safety.

- IP Ratings: For flexible LED strips, ingress protection ratings (e.g., IP65, IP67) indicate resistance to dust and water, critical for outdoor or harsh environment applications.

Quality Control Checkpoints

Quality assurance in LED strip manufacturing typically follows a multi-layered inspection approach:

- Incoming Quality Control (IQC): Raw materials and components undergo testing upon receipt to verify specifications such as LED lumen output, substrate flexibility, and solder paste quality.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly includes solder joint inspections, component placement accuracy, and reflow profile adherence.

- Final Quality Control (FQC): Finished strips are tested for electrical functionality, uniformity of illumination, waterproofing integrity, and physical defects.

Common Testing Methods

- Electrical Testing: Checks voltage, current, and resistance to ensure circuit integrity and LED functionality.

- Optical Testing: Measures brightness, color temperature, and color rendering index (CRI) for lighting quality consistency.

- Environmental Stress Tests: Includes thermal cycling, moisture resistance, and UV exposure simulations to predict product lifespan under real-world conditions.

- Mechanical Flexibility Tests: Assesses the strip’s ability to withstand bending, twisting, and installation stresses without performance degradation.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, verifying supplier quality assurance is essential to mitigate risks of substandard products that could lead to project delays, increased costs, or reputational damage.

Supplier Audits and Factory Inspections

- Onsite Audits: Buyers or third-party inspection agencies can conduct factory visits to evaluate manufacturing processes, equipment, and quality control systems firsthand.

- Process Capability Reviews: Assessing supplier adherence to process standards like ISO 9001 and capability to meet volume and quality requirements.

- Sample Testing: Requesting product samples for independent lab testing to verify claims on certifications and performance.

Documentation and Certification Review

- Quality Control Reports: Suppliers should provide detailed IQC, IPQC, and FQC reports demonstrating systematic inspections.

- Certification Verification: Confirm authenticity of CE, RoHS, UL, and other certificates through official registries or third-party validation platforms.

- Test Data Transparency: Access to raw data from electrical, optical, and environmental testing builds buyer confidence.

Third-Party Inspection Services

Engaging independent inspection firms offers unbiased assessment of product quality, packaging, and compliance with contractual specifications before shipment. This is particularly valuable for buyers in regions like Kenya, Egypt, or South America where direct factory visits may be challenging.

Illustrative Image (Source: Google Search)

Nuances in Quality Assurance for International B2B Buyers

Regional Standards and Market Expectations

- Africa and Middle East: Buyers should prioritize suppliers with certifications recognized by local authorities and consider environmental robustness (e.g., high IP ratings) due to climate conditions.

- South America: Emphasis on RoHS compliance and energy efficiency standards is growing, aligning with global sustainability trends.

- Europe: Stringent CE and RoHS compliance is mandatory, alongside increasingly demanding energy efficiency and eco-design requirements.

- Documentation Language and Support: Suppliers able to provide documentation and after-sales support in multiple languages and aligned with regional regulations reduce friction in import and certification processes.

Logistics and After-Sales Considerations

- Warranty Terms: Confirm warranty coverage that accounts for international shipping and local conditions.

- Spare Parts Availability: Ensure suppliers can provide replacement components or strips to facilitate maintenance.

- Technical Support: Access to remote or local technical assistance is crucial for installation and troubleshooting.

By comprehensively understanding the manufacturing stages and quality assurance protocols, B2B buyers across Africa, South America, the Middle East, and Europe can make informed sourcing decisions. Prioritizing suppliers with transparent processes, internationally recognized certifications, and proven quality management systems will significantly reduce risks and enhance the success of LED flexible strip lighting projects.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led flexible led strip Sourcing

Understanding the detailed cost structure and pricing dynamics of sourcing LED flexible LED strips is crucial for international B2B buyers seeking optimal value and reliability. This analysis breaks down the key cost components, price influencers, and actionable buyer tips, with a focus on markets such as Africa, South America, the Middle East, and Europe.

Key Cost Components in LED Flexible Strip Pricing

-

Materials

The primary cost driver is the raw materials, including LED chips (SMD types like 3528, 5050, or 2835), flexible PCB substrates, adhesives, and protective coatings (silicone or epoxy). Higher-grade LEDs and substrates increase both quality and price but also enhance longevity and brightness. -

Labor and Manufacturing Overhead

Labor costs vary significantly by manufacturing region. Chinese factories, which dominate global production, tend to offer lower labor costs, whereas suppliers in Europe or the Middle East may have higher overheads. Overhead includes utilities, factory maintenance, and indirect labor, impacting the final unit cost. -

Tooling and Equipment

Initial tooling and setup costs for production lines—such as PCB assembly machines and LED placement robots—are amortized across production volumes. Custom designs or new product lines incur higher tooling expenses, reflected in pricing. -

Quality Control (QC) and Testing

Rigorous QC, including lumen output testing, waterproofing verification (IP ratings), and electrical safety checks, adds to costs but is essential for ensuring product reliability and compliance with international standards. -

Logistics and Shipping

Freight charges, customs duties, and import taxes significantly affect landed costs, especially for buyers in Africa and South America where shipping infrastructure can add delays and surcharges. Bulk shipments by sea reduce per-unit logistics costs, while air freight increases them.

Illustrative Image (Source: Google Search)

- Supplier Margin

Supplier markup covers profit and business sustainability. Margins vary depending on supplier scale, brand positioning, and market demand.

Influencers of Pricing Variability

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically command substantial price reductions due to economies of scale. MOQs can range from a few hundred meters to thousands, influencing pricing tiers. -

Product Specifications and Customization

Specifications such as LED density (LEDs per meter), color temperature, waterproof rating, and special features (e.g., RGB control, dimmability) affect unit price. Custom lengths or branding add costs. -

Material Quality and Certifications

LED strips with certifications like CE, RoHS, and UL generally cost more but assure compliance with safety and environmental standards crucial for international markets. -

Supplier Reputation and Capabilities

Established suppliers with robust quality management systems and after-sales support often price higher but reduce risks of defects and supply chain disruptions. -

Incoterms and Payment Terms

Pricing depends on agreed Incoterms (e.g., FOB, CIF, DDP). For example, DDP (Delivered Duty Paid) includes all shipping and customs fees, simplifying procurement but at a premium cost.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO)

Focus beyond unit price by factoring in warranty terms, product lifespan, energy consumption, and potential reordering costs. Lower upfront costs can result in higher TCO if quality is compromised. -

Leverage Volume Discounts and Flexible MOQs

Engage suppliers early to negotiate volume pricing or flexible MOQs, especially when consolidating orders across multiple projects or partners. -

Validate Certifications and Request Samples

Always verify certifications relevant to your region (e.g., CE for Europe, SABS for South Africa) and request product samples for testing before bulk purchasing. -

Consider Local Import Regulations and Logistics Partners

Work with experienced freight forwarders familiar with your destination country’s import procedures to minimize delays and unexpected costs. -

Use Transparent Pricing Models

Insist on clear pricing breakdowns including packaging, shipping, and any ancillary fees to avoid hidden costs. -

Build Long-Term Supplier Relationships

Establishing trust with suppliers can unlock better pricing, priority production slots, and tailored solutions, particularly valuable in emerging markets like Kenya and Egypt.

Indicative Pricing Disclaimer

Prices for LED flexible strips vary widely based on the above factors. As a rough guide, basic 12V LED strips can start from around $1–$3 per meter at wholesale volumes, while premium or customized options may range from $5 to $15 or more per meter. Buyers should obtain multiple quotes and perform due diligence tailored to their specific project requirements.

By understanding these cost and pricing elements, international B2B buyers can make informed sourcing decisions that balance quality, cost-efficiency, and operational reliability in the competitive LED flexible strip market.

Spotlight on Potential led flexible led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘led flexible led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led flexible led strip

Understanding the technical properties and trade terminology of LED flexible strips is crucial for international B2B buyers to make informed purchasing decisions, ensure product compatibility, and optimize supply chain efficiency. Below is a concise guide tailored to buyers from Africa, South America, the Middle East, and Europe.

Critical Technical Properties of LED Flexible Strips

-

Material Grade and Flexibility

LED strips are typically mounted on a flexible printed circuit board (FPC). The material grade of the FPC affects durability and bending radius. High-grade materials (such as high-quality polyimide) allow tighter bends without damaging the circuitry, essential for installations in curved or irregular spaces. For B2B buyers, specifying material grade ensures the strip meets durability standards and suits the intended application environment. -

Voltage and Current Rating

Common LED strips operate at 12V or 24V DC. Voltage rating impacts power supply compatibility and installation safety. Current rating, often expressed in milliamps (mA) per LED or per meter, affects brightness and energy consumption. For bulk buyers, matching voltage and current specs with reliable power supplies prevents flickering and premature failure, critical for long-term projects. -

LED Density (LEDs per Meter)

This indicates how many LEDs are mounted per meter of strip, often ranging from 30 to 120 LEDs/m. Higher density means brighter and more uniform light but increases power consumption and cost. Buyers should align LED density with project requirements—whether for ambient lighting, accent lighting, or high-intensity illumination. -

Color Temperature and Color Rendering Index (CRI)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, e.g., 2700K for warm white or 6000K for daylight white. CRI measures color accuracy; a CRI above 80 is generally preferred for true color representation. For B2B buyers, selecting appropriate color temperature and CRI is vital for achieving desired lighting effects in commercial or residential projects. -

IP Rating (Ingress Protection)

The IP rating classifies protection against dust and water. For example, IP20 is suitable for indoor use without moisture exposure, while IP65 or higher indicates waterproofing for outdoor or humid environments. Understanding IP ratings helps buyers specify products that meet environmental conditions in regions like coastal Africa or humid Middle Eastern climates.

- Cutting and Connection Points

Flexible strips can be cut at designated intervals without damaging the circuitry, allowing customization of length. The quality and type of connectors (soldered or plug-in) impact ease of installation and maintenance. B2B buyers should verify cutting precision and connector standards to reduce installation errors and labor costs.

Key Trade Terminology for International LED Strip Buyers

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products that can be rebranded or customized for buyers. Engaging OEM suppliers allows buyers to order LED strips tailored to specific technical or branding requirements, often at lower costs with volume orders. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and budget effectively, especially when entering new markets or testing product lines in regions like South America or Africa. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for price, lead times, and terms for specific products. Mastering RFQ processes enables buyers to compare offers transparently and negotiate favorable terms. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs between buyers and sellers. Familiarity with Incoterms empowers buyers to control logistics costs and risks when importing LED strips internationally. -

Certification (CE, RoHS, UL)

Compliance marks indicating that products meet safety, environmental, and quality standards. Certifications are often mandatory for market access in Europe, the Middle East, and increasingly in African countries. Buyers should insist on certified products to avoid regulatory issues. -

Lead Time

The time between placing an order and receiving the goods. For LED strips, lead times can vary based on customization, supplier capacity, and shipping method. Accurate lead time management is essential for project scheduling and supply chain reliability.

By thoroughly understanding these technical specifications and trade terms, B2B buyers can confidently source LED flexible strips that align with their project needs, regulatory environments, and budget constraints, ensuring successful procurement and long-term operational success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led flexible led strip Sector

Market Overview & Key Trends

The global market for LED flexible LED strips is experiencing robust growth driven by rising demand for energy-efficient, versatile lighting solutions across commercial, industrial, and residential sectors. International B2B buyers, particularly from emerging and developing regions such as Africa (e.g., Kenya, Egypt), South America, the Middle East, and Europe, are increasingly adopting flexible LED strips due to their adaptability, long lifespan, and cost-efficiency.

Key market drivers include:

- Energy Efficiency & Cost Savings: Governments and businesses worldwide are prioritizing energy-saving technologies to reduce operational costs and meet sustainability goals. LED flexible strips consume significantly less power than traditional lighting, making them attractive for large-scale infrastructure and retail projects.

- Technological Advancements: Innovations in LED chip technology, flexible circuit substrates, and smart control integration (e.g., IoT-enabled lighting) are enhancing product performance and customization options. This trend enables tailored solutions for architectural lighting, signage, and dynamic displays.

- Supply Chain Localization: Buyers from Africa and the Middle East are increasingly seeking regional distributors and manufacturers to mitigate supply chain disruptions caused by geopolitical tensions and logistics challenges. European buyers, meanwhile, emphasize compliance with stringent safety and environmental standards.

- Customization & Integration: Demand is growing for flexible LED strips that support various voltages (commonly 12V and 24V), IP ratings for outdoor use, and color temperature ranges to suit diverse project needs. Compatibility with LED power supplies and controllers is a critical purchasing consideration.

- Bulk Purchasing & Wholesale Channels: International buyers prioritize suppliers offering transparent pricing, volume discounts, and reliable after-sales support. Established distributors with verified certifications (CE, RoHS, UL) are preferred to ensure product consistency and safety.

For B2B buyers in these regions, leveraging trade shows, verified online platforms, and direct manufacturer partnerships can optimize sourcing strategies while ensuring access to the latest technologies and competitive pricing.

Sustainability & Ethical Sourcing in B2B LED Flexible LED Strip Procurement

Sustainability considerations have become paramount in the procurement of LED flexible strips, reflecting a broader shift toward responsible business practices in the lighting industry. The environmental impact of LED manufacturing and disposal processes, alongside ethical sourcing of raw materials, significantly influences supplier selection for international B2B buyers.

Key sustainability insights include:

- Environmental Impact Reduction: LED flexible strips inherently consume less energy, contributing to lower carbon footprints. However, the production process involves electronic components and plastics, which necessitate careful management to minimize waste and hazardous substances.

- Green Certifications: Buyers should prioritize products certified with RoHS (Restriction of Hazardous Substances), CE (Conformité Européenne), and WEEE (Waste Electrical and Electronic Equipment) compliance. These certifications ensure reduced toxic material usage and facilitate recycling and safe disposal.

- Ethical Supply Chains: Transparency in the sourcing of components such as LEDs, copper, and flexible substrates is crucial. Buyers from Africa and South America, where regulatory frameworks may be evolving, benefit from suppliers who demonstrate responsible labor practices and conflict-free material sourcing.

- Recyclability & Longevity: Selecting LED strips designed for durability and easy recycling supports circular economy principles. Durable products reduce replacement frequency, lowering overall environmental impact.

- Energy-Efficient Power Supplies: Complementary sourcing of high-efficiency LED drivers and power supplies further enhances sustainability by minimizing energy loss and heat generation during operation.

Incorporating these sustainability criteria into procurement decisions not only aligns with global environmental goals but also meets increasing demands from end clients for green building certifications and corporate social responsibility commitments.

Evolution of LED Flexible LED Strips: A B2B Perspective

The evolution of LED flexible strips over the past two decades has transformed lighting solutions for businesses worldwide. Initially developed as rigid, low-efficiency light sources, LED technology rapidly advanced with improvements in semiconductor materials and manufacturing processes.

Flexible LED strips emerged as a breakthrough, combining thin, bendable substrates with surface-mounted LEDs, enabling versatile applications previously unattainable with traditional lighting. Early iterations focused on basic white lighting, but advancements soon introduced RGB color control, dimmability, and integration with smart controls.

For B2B buyers, this evolution means access to highly customizable, scalable lighting solutions suitable for diverse industries—from retail and hospitality to industrial automation and urban infrastructure. The ability to source flexible LED strips with tailored specifications, certified safety standards, and sustainable credentials now defines competitive advantage in international markets, particularly for buyers in Africa, South America, the Middle East, and Europe aiming to meet dynamic customer and regulatory demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of led flexible led strip

-

How can I effectively vet LED flexible strip suppliers to ensure product quality and reliability?

To vet suppliers, request detailed product specifications, certifications (CE, RoHS, UL), and samples for testing. Verify their factory audits or third-party inspection reports. Check their track record by reviewing client testimonials and case studies, particularly from similar markets like Africa or the Middle East. Confirm their ability to comply with international standards and inquire about warranty and after-sales support. Engaging suppliers who participate in reputable trade shows or have transparent supply chain practices helps reduce risks associated with quality and delivery. -

Is it possible to customize LED flexible strips to meet specific voltage, color, or length requirements for different markets?

Yes, many manufacturers offer customization including voltage options (12V, 24V), color temperatures, RGB capabilities, and specific reel lengths. For international buyers, customization can also include compliance with local safety standards or certifications. When negotiating, clarify MOQ (Minimum Order Quantity) for custom orders and lead times, as these may differ from standard products. Customization enhances product differentiation and better serves local market preferences but requires clear communication on technical and logistical details upfront. -

What are typical minimum order quantities (MOQs) and lead times for wholesale LED flexible strip orders?

MOQs vary widely based on supplier and customization but typically range from 500 to 2,000 meters per order. Lead times average 2 to 6 weeks depending on order complexity, stock availability, and shipping logistics. Buyers in Africa, South America, and the Middle East should factor in additional time for customs clearance and inland transport. Negotiating flexible MOQs or phased deliveries can mitigate inventory risks, especially for new product launches or market tests. -

Which payment terms and methods are most secure and commonly accepted in international B2B LED strip transactions?

Secure payment methods include letters of credit (LC), escrow services, and verified bank transfers (T/T). Many suppliers accept partial upfront payments (30-50%) with balance upon shipment or delivery. For new suppliers, using trade assurance services on platforms like Alibaba can reduce risks. Buyers should negotiate clear payment milestones linked to production and inspection stages. Transparent payment terms combined with documented contracts help protect both parties and build trust for long-term partnerships. -

What quality assurance practices should I expect from reputable LED flexible strip manufacturers?

Reputable manufacturers implement strict quality control processes including incoming material inspections, in-line production checks, and final testing for brightness, color consistency, and waterproof ratings. Certifications such as ISO 9001 indicate robust quality management systems. Request factory audit reports or arrange third-party inspections before shipment. Ensure suppliers provide test reports for electrical safety and lifespan. Reliable QA reduces defects, returns, and warranty claims, critical for maintaining reputation in competitive international markets. -

How do international shipping and logistics impact the procurement of LED flexible strips, and what can buyers do to optimize this?

Shipping LED strips internationally involves navigating customs regulations, tariffs, and potential delays. Bulk orders benefit from sea freight for cost efficiency but require longer lead times, while air freight suits urgent or smaller shipments at higher costs. Buyers should partner with freight forwarders experienced in handling electronics and verify proper packaging to avoid damage. Consolidating shipments, understanding Incoterms, and pre-clearing customs documents can significantly reduce delays and costs, especially in regions with complex import procedures like Africa or South America. -

What certifications should I verify to ensure compliance and safety of LED flexible strips in my target market?

Key certifications include CE (European conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories for North America), and IEC standards. For African and Middle Eastern markets, compliance with regional electrical safety and EMC regulations is crucial. Verify that suppliers provide authentic certification documents, not just copies, and confirm they apply to the specific product batch. Compliance ensures product acceptance by customs and end users, minimizes liability risks, and enhances market credibility. -

How should disputes related to quality or delivery be managed when dealing with international LED flexible strip suppliers?

Establish clear contractual terms covering product specifications, delivery timelines, payment conditions, and dispute resolution mechanisms before order confirmation. Use trade mediation or arbitration clauses to handle conflicts efficiently. Document all communications and inspections meticulously. In cases of quality issues, request root cause analysis and corrective action plans from suppliers. Maintaining a professional relationship and prompt communication often facilitates amicable resolutions. For higher-value transactions, consider trade credit insurance or third-party escrow services to protect financial interests.

Strategic Sourcing Conclusion and Outlook for led flexible led strip

Strategic sourcing of LED flexible strip lighting is a critical success factor for B2B buyers across Africa, South America, the Middle East, and Europe. By prioritizing suppliers who offer certified, high-quality products with proven compatibility and robust after-sales support, buyers can ensure long-term project reliability and energy efficiency. Leveraging established wholesale distributors, verified online marketplaces, and direct manufacturer partnerships enhances supply chain resilience and cost-effectiveness.

Key takeaways for international buyers include:

- Demanding comprehensive certifications such as CE, RoHS, and UL to guarantee safety and compliance.

- Focusing on supplier transparency with clear pricing, warranty terms, and responsive technical support.

- Evaluating product compatibility to avoid costly mismatches in voltage and wattage requirements.

- Exploring trade shows and industry events for networking and discovering cutting-edge innovations.

Looking ahead, the LED flexible strip market continues to evolve rapidly, with increasing emphasis on energy efficiency, smart lighting integration, and customizable solutions. Buyers in emerging and established markets should adopt a proactive sourcing strategy that balances quality, innovation, and cost. Establishing strategic partnerships with trusted suppliers will not only secure supply continuity but also position businesses to capitalize on growing demand for flexible, sustainable lighting solutions.

For forward-thinking international buyers, now is the time to deepen supplier relationships and embrace emerging technologies to drive competitive advantage in the dynamic LED lighting landscape.