Introduction: Navigating the Global Market for ikea led strip

The global demand for high-quality, energy-efficient lighting solutions has surged dramatically, placing IKEA LED strips at the forefront of innovative illumination options. For international B2B buyers—from bustling markets in Africa and South America to dynamic commercial hubs in the Middle East and Europe—understanding the complexities of sourcing IKEA LED strips is essential for sustaining competitive advantage and meeting diverse customer needs. These versatile lighting products not only enhance aesthetic appeal but also offer significant energy savings and long-term reliability, making them a strategic asset for retailers, contractors, and distributors worldwide.

This comprehensive guide is designed to empower B2B buyers with a deep understanding of the IKEA LED strip market, enabling informed and confident sourcing decisions. You will gain insights into the various types and materials used in IKEA LED strips, learn about critical manufacturing and quality control standards, and explore how to identify trustworthy suppliers across regions. Additionally, the guide covers pricing structures, supply chain logistics, and market trends tailored to the unique demands of regions such as Colombia, Australia, the Middle East, and Africa.

By navigating the nuances of product specifications, supplier evaluation, and cost considerations, this resource equips businesses to build resilient supply chains and establish long-term partnerships with reliable manufacturers. Whether you are expanding your product portfolio or upgrading existing offerings, this guide serves as a strategic tool to optimize procurement processes and maximize value in the competitive global LED lighting market.

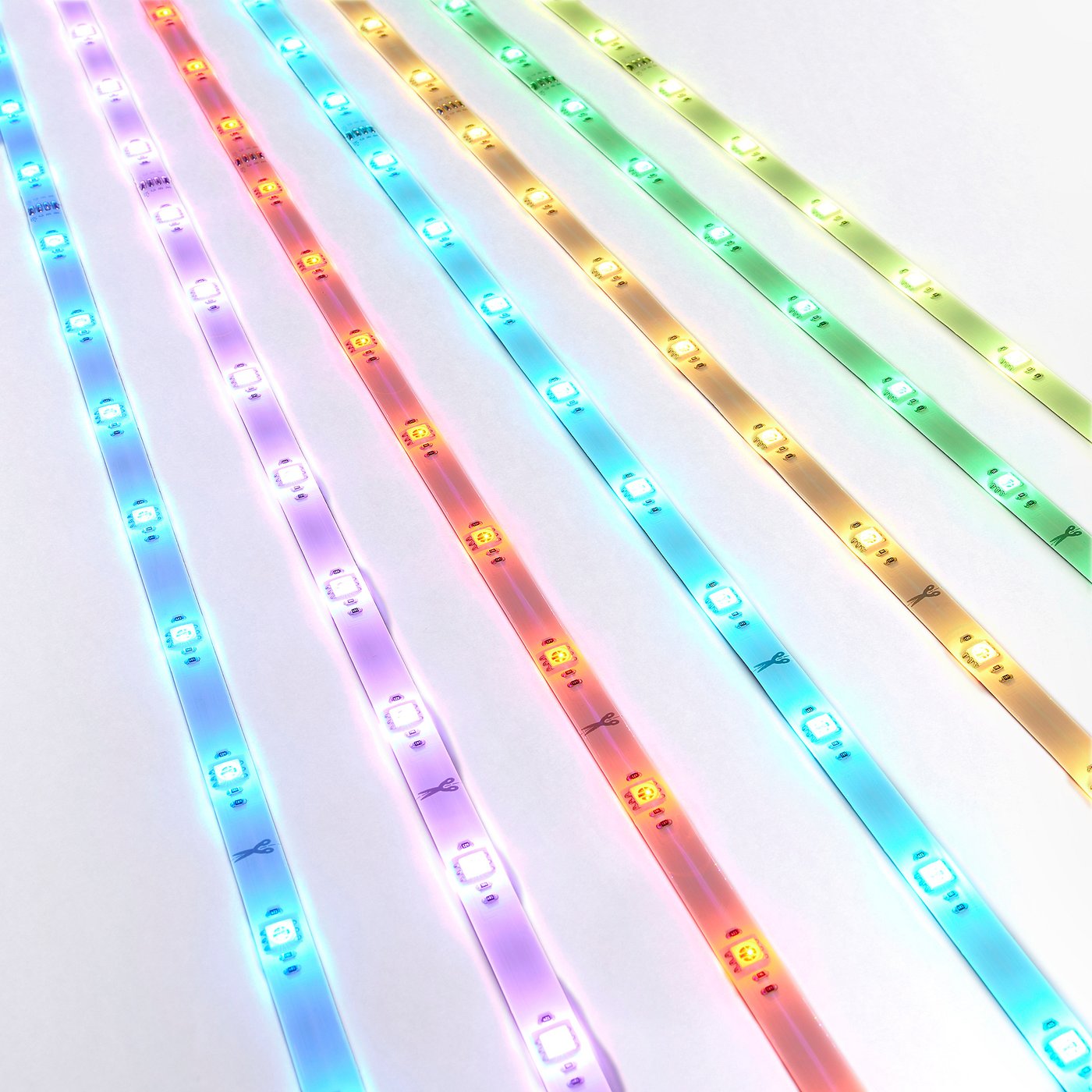

Understanding ikea led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IKEA LEDBERG Strip | Compact, flexible, plug-and-play design; single-color white | Retail lighting, office ambiance, hospitality | Pros: Easy installation, consistent white light; Cons: Limited color options, moderate brightness |

| IKEA OMLOPP Strip | RGB color-changing LED strip with remote control | Decorative lighting, event venues, home staging | Pros: Versatile color options, remote control; Cons: Higher cost, requires compatible power source |

| IKEA LÅNGLÅNGA Strip | High brightness, warm white LED strip, dimmable | Task lighting, workspaces, commercial interiors | Pros: High lumen output, dimmable; Cons: Less flexible length options, premium pricing |

| IKEA TROSS Strip | Waterproof LED strip for outdoor or moisture-prone areas | Outdoor signage, landscape lighting, kitchens | Pros: Water-resistant, durable; Cons: Requires careful installation, higher upfront cost |

| IKEA FIXA Strip | Budget-friendly, standard white LED strip with adhesive backing | Basic indoor lighting, temporary setups | Pros: Cost-effective, easy to mount; Cons: Lower lifespan, limited features |

IKEA LEDBERG Strip

This type is characterized by its slim, flexible design and straightforward plug-and-play setup, emitting consistent single-color white light. It is ideal for retail spaces, offices, and hospitality environments where ease of installation and uniform lighting are priorities. B2B buyers should consider its limited color spectrum and moderate brightness levels when specifying for projects that require dynamic lighting or high illumination.

IKEA OMLOPP Strip

OMLOPP stands out with its RGB capabilities and remote control functionality, making it suitable for decorative and mood lighting in event venues, showrooms, or home staging. For B2B purchasers, the versatility in color customization adds value but comes with higher costs and the need for compatible power infrastructure. This type is best for businesses prioritizing ambiance and aesthetic flexibility.

IKEA LÅNGLÅNGA Strip

Designed for high brightness and warm white output, LÅNGLÅNGA strips are dimmable and geared toward task lighting in commercial workspaces or detailed-oriented environments. Buyers in sectors like offices or workshops will appreciate the high lumen output and dimming options, though they should plan for premium pricing and assess length flexibility against project needs.

IKEA TROSS Strip

TROSS LED strips are waterproof and robust, tailored for outdoor applications or areas with moisture exposure such as kitchens and landscaping. B2B buyers targeting outdoor signage or exterior architectural lighting will value the durability but must consider installation complexities and higher initial investment. Ensuring compatibility with local electrical standards is essential.

IKEA FIXA Strip

FIXA offers a budget-conscious option with standard white light and adhesive backing for easy mounting. It suits basic indoor lighting needs or temporary setups where cost efficiency is critical. Buyers should weigh the trade-offs in lifespan and feature set, making this type appropriate for short-term projects or low-demand environments.

Related Video: Ikea LED Light Strip Review

Key Industrial Applications of ikea led strip

| Industry/Sector | Specific Application of ikea led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and ambient lighting in store displays and shelving | Enhances product visibility and customer experience, driving sales | Consistent color temperature, flexible length options, and durability for high-traffic environments |

| Hospitality & Hotels | Mood lighting in guest rooms, corridors, and common areas | Creates inviting atmospheres, improving guest satisfaction and brand reputation | Energy efficiency, easy installation, and compliance with regional safety standards (e.g., CE, UL) |

| Residential Construction | Integrated under-cabinet and cove lighting in kitchens and living spaces | Adds modern aesthetic appeal and functional illumination for homeowners | Long lifespan, dimmability, and compatibility with smart home systems for premium market segments |

| Automotive & Transportation | Interior ambient lighting in buses, trains, and yachts | Enhances passenger comfort and brand differentiation | Vibration resistance, waterproof ratings, and adherence to transport safety certifications |

| Furniture Manufacturing | Built-in lighting solutions in modular furniture and cabinetry | Increases product value and differentiation in competitive markets | Customizable lengths, adhesive quality, and compatibility with power sources for export markets |

Retail & Commercial Lighting

In retail environments, ikea led strips are widely used to highlight products on shelves, showcase window displays, and create dynamic lighting accents. This targeted illumination helps attract customers’ attention and improves product appeal, directly influencing purchasing decisions. For international buyers, particularly in emerging markets like Africa and South America, sourcing ikea led strips with consistent color temperature and robust adhesive backing is critical to withstand varying store conditions and ensure ease of installation across diverse retail formats.

Hospitality & Hotels

Hotels and hospitality venues leverage ikea led strips to craft immersive lighting experiences in guest rooms, hallways, and lounges. Adjustable lighting moods can enhance ambiance and comfort, which is vital for customer satisfaction and repeat business. Buyers from Europe and the Middle East should prioritize energy-efficient models that comply with local safety regulations and offer simple retrofitting options, facilitating smooth integration in both new builds and renovation projects.

Illustrative Image (Source: Google Search)

Residential Construction

In residential projects, ikea led strips are favored for under-cabinet lighting in kitchens and accent lighting in living spaces, delivering both functional and decorative benefits. These strips help homeowners achieve modern aesthetics while improving lighting quality for daily tasks. For B2B buyers in regions like Australia and Europe, sourcing dimmable strips compatible with smart home ecosystems is increasingly important to meet evolving consumer expectations and support premium housing developments.

Automotive & Transportation

Ikea led strips find application in the interior ambient lighting of buses, trains, and luxury yachts, elevating passenger experience and reinforcing brand identity. These lighting solutions must endure vibration and moisture, requiring waterproof and ruggedized designs. Buyers from the Middle East and Europe should ensure compliance with transport safety standards and select strips with flexible installation options tailored to vehicle interiors.

Furniture Manufacturing

Furniture producers integrate ikea led strips into modular units and cabinetry to add value and innovation to their offerings. Built-in lighting creates a modern appeal and functional differentiation in competitive markets. For export-oriented manufacturers in South America and Africa, sourcing strips with customizable lengths, strong adhesive properties, and compatibility with various power sources is essential to meet diverse client requirements and facilitate seamless assembly.

Related Video: LEDBERG – Ikea’s Multicolour LED lighting strip – Unboxing and Setup

Strategic Material Selection Guide for ikea led strip

When selecting materials for IKEA LED strips, international B2B buyers must consider multiple factors including durability, environmental compatibility, manufacturing complexity, and compliance with regional standards. The choice of material directly influences product lifespan, installation flexibility, and overall performance, which are critical for markets spanning Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used as the base material for LED strip casings due to its flexibility, moderate temperature resistance (typically up to 60-80°C), and good electrical insulation. It offers decent resistance to moisture and chemicals but can degrade under prolonged UV exposure.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for mass production. However, it has limited heat resistance and may become brittle in very cold climates. The material’s environmental impact is a concern in some regions due to its chlorine content and difficulty in recycling.

Impact on Application: Ideal for indoor lighting applications where exposure to extreme temperatures or harsh chemicals is minimal. Its flexibility allows easy installation on curved surfaces, a common requirement in residential and commercial settings.

Considerations for International Buyers: Buyers in regions with high UV exposure, like parts of Africa and the Middle East, should verify that the PVC used has UV stabilizers to prevent premature aging. Compliance with standards such as ASTM D1784 (PVC classification) and RoHS for chemical safety is essential. European buyers often prefer PVC formulations that meet stringent REACH regulations.

Silicone Rubber

Key Properties: Silicone rubber offers excellent thermal stability (up to 200°C), outstanding flexibility, and superior resistance to UV radiation, ozone, and moisture. It also provides good electrical insulation and is non-toxic.

Pros & Cons: Silicone’s durability and weather resistance make it suitable for both indoor and outdoor use. The main downside is its higher cost and more complex manufacturing process compared to PVC. Additionally, silicone’s adhesive compatibility can vary, requiring careful selection of mounting materials.

Impact on Application: Perfect for outdoor LED strips or installations in humid and high-temperature environments, such as tropical climates in South America or the Middle East. Its resilience ensures longer service life and reduced maintenance.

Considerations for International Buyers: For buyers targeting markets with extreme weather conditions, silicone rubber is often preferred despite the higher price. Compliance with international standards like UL 94 for flammability and IEC 60529 (IP rating for water resistance) is critical. Buyers should also confirm the material’s certification for food-grade or medical-grade applications if relevant.

Polycarbonate (PC)

Key Properties: Polycarbonate is a rigid, transparent thermoplastic with high impact resistance and excellent heat tolerance (up to 115°C). It also offers good UV resistance and dimensional stability.

Pros & Cons: PC provides superior protection for LED strips against mechanical damage and environmental factors. However, it is less flexible than PVC or silicone, making it less suitable for installations requiring bending. The cost is moderate to high, and manufacturing requires precise molding techniques.

Impact on Application: Best suited for LED strips used in architectural lighting or commercial fixtures where durability and clarity are paramount. Its rigidity supports protective covers and diffusers, enhancing light quality and lifespan.

Considerations for International Buyers: Buyers in Europe and Australia often demand polycarbonate materials that comply with EN 62262 (IK impact protection) and UL 94 standards. In regions with high dust or sand exposure, such as parts of Africa and the Middle East, PC’s impact resistance is a significant advantage.

Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the elasticity of rubber with the processing ease of plastics. It has good flexibility, moderate temperature resistance (up to 125°C), and excellent chemical resistance.

Pros & Cons: TPE is recyclable and offers better environmental credentials than PVC. It is softer than polycarbonate but more durable than silicone in some formulations. The main limitation is variability in quality depending on the specific compound used, which can affect consistency.

Impact on Application: Suitable for flexible LED strips requiring repeated bending or twisting, such as in automotive or wearable lighting applications. Its chemical resistance makes it compatible with various adhesives and mounting surfaces.

Considerations for International Buyers: Buyers from South America and Africa should ensure that TPE materials meet local environmental and safety regulations, such as INMETRO in Brazil or SABS in South Africa. European buyers prioritize compliance with REACH and RoHS directives. The material’s recyclability aligns well with growing sustainability demands in global markets.

| Material | Typical Use Case for IKEA LED Strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor residential and commercial lighting | Cost-effective and flexible | Limited heat and UV resistance | Low |

| Silicone Rubber | Outdoor, high-temperature, and humid environments | Excellent durability and UV resistance | Higher cost and complex manufacturing | High |

| Polycarbonate (PC) | Protective covers for architectural and commercial lighting | High impact resistance and clarity | Rigid and less flexible | Medium |

| Thermoplastic Elastomer (TPE) | Flexible applications needing chemical resistance | Good flexibility and recyclability | Variable quality and consistency | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for ikea led strip

Overview of Manufacturing Processes for IKEA LED Strip

The production of IKEA LED strips involves a sophisticated, multi-stage manufacturing process that ensures durability, energy efficiency, and aesthetic consistency. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding these stages provides critical insight into product reliability and supplier capabilities.

1. Material Preparation

The process begins with sourcing high-grade raw materials, including flexible printed circuit boards (PCBs), LED chips, resistors, capacitors, and adhesives. The PCB substrate is typically a flexible polyimide or polyester film, selected for its heat resistance and flexibility. Materials undergo rigorous incoming quality control (IQC) checks to verify specifications such as thickness, electrical conductivity, and adhesive strength.

Illustrative Image (Source: Google Search)

2. Circuit Formation and Component Placement

The next stage involves forming the circuit pattern on the PCB through photolithography or screen printing of conductive copper layers. Advanced pick-and-place machines then position LED chips and electronic components with micron-level precision. Automated soldering, often via reflow ovens, ensures strong electrical connections while minimizing thermal stress on components.

3. Assembly and Encapsulation

Following component placement, the LED strips are assembled with protective layers—commonly silicone or epoxy coatings for waterproof models. This encapsulation enhances durability against moisture, dust, and mechanical damage. Additionally, connectors and mounting accessories are integrated. Adhesive backing is applied with uniform pressure to maintain consistent peel strength.

4. Finishing and Packaging

Final finishing includes cutting strips to standardized lengths, adding labels with batch and certification information, and packaging in moisture-proof, anti-static materials. Packaging standards are critical for international shipping, especially to regions with variable climate conditions such as high humidity in South America or dust-prone Middle Eastern markets.

Quality Assurance Framework for IKEA LED Strips

Quality assurance (QA) in IKEA LED strip production is robust, aligning with international standards and customer-specific requirements. B2B buyers must evaluate these QA measures to ensure compliance, reduce risk, and maintain product consistency across shipments.

Relevant International and Industry Standards

- ISO 9001: Core quality management system standard ensuring consistent process control and continuous improvement.

- CE Marking: Mandatory for European markets, ensuring compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, crucial for markets with stringent environmental regulations such as the EU and Australia.

- UL Certification: Commonly requested for North American and Middle Eastern markets, focusing on electrical safety.

- IP Ratings: Essential for waterproof LED strips, indicating ingress protection levels against solids and liquids.

Critical Quality Control Checkpoints

Effective QA integrates multiple inspection phases throughout manufacturing:

- Incoming Quality Control (IQC): Inspection of raw materials and components for conformance to specifications.

- In-Process Quality Control (IPQC): Monitoring during assembly, including solder joint integrity, LED placement accuracy, and adhesion strength.

- Final Quality Control (FQC): Comprehensive testing of finished products, including electrical performance and visual inspection.

Common Testing Methods for LED Strip Quality

B2B buyers should expect their suppliers to conduct the following tests:

- Electrical Testing: Verifies voltage, current, and power consumption to ensure energy efficiency and safety.

- Luminous Intensity and Color Consistency: Uses photometers and spectrometers to confirm uniform brightness and color temperature across batches.

- Thermal Performance: Thermal imaging and heat dissipation tests prevent overheating and prolong lifespan.

- Adhesive Peel Strength Test: Confirms the robustness of the mounting adhesive, critical for installation reliability.

- Waterproof Testing: IP rating verification through water spray or immersion testing for applicable models.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers in diverse international markets, due diligence in supplier QA verification is essential:

- Factory Audits: Conduct or commission on-site inspections to assess manufacturing processes, equipment, and quality controls.

- Review of Quality Documentation: Request ISO certificates, test reports, and compliance declarations.

- Third-Party Inspections: Engage independent quality inspection agencies to perform random batch testing and shipment verification.

- Sample Testing: Obtain product samples and conduct in-house or third-party laboratory tests, focusing on critical parameters relevant to the buyer’s market conditions.

Quality Assurance Nuances for International Markets

- Africa and South America: Environmental factors such as high humidity and temperature fluctuations necessitate rigorous waterproofing and thermal testing. Buyers should verify that suppliers’ QA processes include climate simulation testing.

- Middle East: Electrical safety certifications like UL and compliance with strict fire retardancy standards are often required due to regional regulations.

- Europe and Australia: Emphasis on environmental compliance (RoHS) and CE certification is critical. Buyers should ensure traceability in documentation for regulatory audits.

- Logistics Impact: In all regions, packaging quality and shock/vibration testing during transit are important to prevent damage in long-distance shipments.

Key Takeaways for B2B Buyers

- Prioritize suppliers with transparent, documented manufacturing processes and multiple QA checkpoints.

- Insist on certifications relevant to your target market to facilitate customs clearance and regulatory compliance.

- Use a combination of factory audits, sample testing, and third-party inspections to safeguard product quality.

- Consider environmental and regulatory conditions specific to your region when evaluating QC reports.

- Establish long-term partnerships with manufacturers demonstrating consistent quality and proactive communication.

By thoroughly understanding IKEA LED strip manufacturing and quality assurance practices, B2B buyers can optimize procurement decisions, mitigate risks, and ensure product excellence tailored to diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for ikea led strip Sourcing

When sourcing IKEA LED strips for international B2B purposes, understanding the detailed cost structure and pricing influencers is critical to optimizing procurement and ensuring competitive margins. This analysis unpacks key cost components, pricing drivers, and strategic buyer considerations tailored to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in IKEA LED Strip Pricing

-

Raw Materials: The primary material costs include LED chips, flexible printed circuit boards (PCBs), adhesives, and protective coatings. Variations in LED quality (e.g., brightness, color rendering index) and waterproofing significantly impact costs.

-

Labor and Manufacturing Overhead: Labor costs depend on the manufacturing location and automation level. Overhead includes factory utilities, equipment depreciation, and management expenses. Factories with advanced automation may offer better cost-efficiency.

-

Tooling and Setup: Initial tooling for custom designs or packaging incurs upfront costs, often amortized over production volumes. For standardized IKEA LED strips, tooling costs tend to be lower but still affect small-batch pricing.

-

Quality Control (QC): Rigorous QC processes to ensure compliance with safety and performance standards (e.g., CE, RoHS, UL) add to cost. Suppliers investing in thorough testing reduce risk of returns and warranty claims.

-

Logistics and Shipping: Freight costs vary widely based on shipment mode (air, sea), distance, and import duties. For buyers in Africa and South America, longer transit times and customs can increase landed costs substantially.

-

Supplier Margin: Manufacturers and distributors apply margins reflecting brand positioning, market demand, and after-sales support. Established suppliers with proven reliability may price higher but offer greater value.

Price Influencers to Monitor

-

Order Volume and Minimum Order Quantities (MOQ): Larger orders typically unlock volume discounts. However, MOQ requirements vary; negotiating flexible MOQs can reduce inventory risk, especially for emerging market buyers.

-

Product Specifications and Customization: Custom colors, lengths, dimming capabilities, or special certifications will elevate price. Off-the-shelf IKEA LED strips are generally more cost-effective but may limit differentiation.

-

Material Quality and Certifications: Higher-grade LEDs and certified components command premium prices but enhance longevity and safety, critical for commercial installations.

-

Supplier Reliability and Experience: Established manufacturers with robust supply chains can offer stable pricing and mitigate risks of delays or quality issues, justifying potential cost premiums.

-

Incoterms and Payment Terms: Terms like FOB, CIF, or DDP significantly influence total cost. Buyers should carefully assess who bears freight, insurance, and customs clearance responsibilities to avoid unexpected expenses.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, lead times, warranty conditions, and after-sales service to improve overall value.

-

Evaluate Total Cost of Ownership (TCO): Factor in installation, maintenance, energy consumption, and replacement frequency. Higher upfront costs may be offset by lower lifecycle expenses.

-

Leverage Local Partnerships: Collaborate with regional distributors or logistics providers to reduce transit times and customs complexities, especially relevant for African and South American markets.

-

Request Detailed Cost Breakdowns: Transparency helps identify cost-saving opportunities such as alternative materials or streamlined packaging.

-

Consider Currency Fluctuations and Tariffs: Hedging strategies or multi-currency contracts can protect against volatility impacting landed costs.

-

Validate Certifications and Compliance: Ensure products meet local regulatory requirements to avoid costly delays or fines.

-

Pilot Small Orders: Test supplier quality and logistics performance before scaling volumes to minimize risks.

Indicative Pricing Disclaimer

Pricing for IKEA LED strips varies by supplier, order size, and regional factors. Typical wholesale unit costs may range from $5 to $15 per meter, excluding shipping and taxes. Buyers should use this as a general benchmark and perform detailed quotations tailored to their specific requirements.

By dissecting cost drivers and price influencers, international B2B buyers can make informed sourcing decisions that balance cost-efficiency with quality and reliability. This approach is especially vital for markets in Africa, South America, the Middle East, and Europe, where logistical and regulatory nuances significantly impact the final procurement cost structure.

Spotlight on Potential ikea led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ikea led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ikea led strip

Critical Technical Properties of IKEA LED Strip

Understanding the technical specifications of IKEA LED strips is crucial for B2B buyers who aim to source reliable, high-quality lighting products that meet diverse market demands across Africa, South America, the Middle East, and Europe.

-

Material Grade and PCB Quality

IKEA LED strips typically use high-grade flexible printed circuit boards (PCBs) with copper thickness ranging from 35 to 70 microns. Higher copper thickness improves electrical conductivity and heat dissipation, which enhances durability and performance. For buyers, this means longer product life and fewer returns, especially important in hot climates or industrial environments. -

Color Temperature (Kelvin Scale)

Color temperature defines the light’s warmth or coolness, measured in Kelvin (K). IKEA LED strips commonly range from warm white (2700K) to daylight white (6500K). Different markets have preferences: warm whites are popular in residential and hospitality sectors, while daylight whites suit commercial and retail environments. Specifying the right color temperature ensures market suitability and customer satisfaction. -

Luminous Flux (Brightness)

Measured in lumens per meter (lm/m), this indicates the brightness level of the LED strip. IKEA strips often deliver between 300 to 1000 lm/m, balancing energy efficiency with sufficient illumination. Brightness affects application scope—higher lumens for workspace lighting, moderate for decorative use. For B2B buyers, matching lumens to end-use avoids over- or under-specification, optimizing cost and energy consumption. -

Power Consumption and Voltage

IKEA LED strips usually operate at 12V or 24V DC with power ratings from 4.8W/m to 14.4W/m. Lower voltage strips reduce safety risks and simplify installation, while wattage impacts energy costs and heat output. Buyers must align these specs with local electrical standards and installation capabilities to ensure compliance and operational efficiency. -

Ingress Protection (IP Rating)

The IP rating classifies the strip’s resistance to dust and water. Common IKEA LED strips feature IP20 (indoor use) or IP65/IP67 for water resistance. For international buyers, knowing the IP rating is essential to meet environmental and regulatory requirements, especially for outdoor or humid regions. -

Cutting and Connection Tolerance

These strips are designed with designated cut points every 5-10 cm to allow customization. Understanding cutting tolerance and connector compatibility helps buyers ensure ease of installation and reduces waste in large-scale projects.

Common Trade Terminology in IKEA LED Strip Procurement

Navigating international procurement requires familiarity with key trade terms. Here are essential terms for B2B buyers engaging with IKEA LED strip suppliers:

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce LED strips that may be rebranded or customized for another company. B2B buyers seeking private labeling or product differentiation should inquire about OEM capabilities to tailor products for their markets. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell per order. IKEA LED strips often have MOQs that vary by model or customization level. Understanding MOQ helps buyers plan inventory, manage cash flow, and negotiate better terms for bulk or repeat orders. -

RFQ (Request for Quotation)

RFQ is a formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specific product requirements. Crafting detailed RFQs with technical specs ensures accurate quotes and streamlines supplier evaluation. -

Incoterms (International Commercial Terms)

These are standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Knowing Incoterms helps buyers understand cost implications and risk allocation during shipment. -

Lead Time

Lead time is the duration between order placement and product delivery. For IKEA LED strips, lead time can vary with customization and order volume. Accurate lead time expectations are vital for project scheduling and supply chain reliability. -

Certification and Compliance

Certifications such as CE (Europe), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) indicate product safety and regulatory compliance. Buyers should verify these certifications to ensure legal market entry and reduce liability risks.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and build resilient supply chains for IKEA LED strips tailored to their regional markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ikea led strip Sector

Market Overview & Key Trends

The global market for LED strip lighting, including IKEA’s LED strip offerings, is shaped by rapid technological advancement, increasing demand for energy efficiency, and evolving consumer preferences. For international B2B buyers—especially from regions such as Africa, South America, the Middle East, and Europe—the LED strip sector represents a dynamic blend of innovation and opportunity.

Key market drivers include the growing adoption of smart lighting solutions, expanding construction and renovation activities, and the rising emphasis on ambient and accent lighting in commercial and residential projects. Countries like Colombia and Australia are witnessing increased demand in urban infrastructure and hospitality sectors, fueling the need for versatile, easy-to-install LED strips like those offered by IKEA.

Emerging sourcing trends emphasize flexibility and reliability in supply chains. B2B buyers are prioritizing manufacturers and suppliers who offer consistent product quality, scalable production capabilities, and transparent communication. Given the volatility in global logistics, especially with fluctuating freight costs and intermittent material shortages, buyers increasingly seek long-term partnerships rather than one-off transactions to ensure supply stability.

Technological advancements have introduced features such as tunable white LEDs, integrated smart controls compatible with IoT ecosystems, and improved waterproofing standards. These innovations align well with IKEA’s design philosophy of blending functionality with aesthetics, making their LED strips attractive to buyers targeting modern, eco-conscious markets.

For buyers across diverse regions, understanding local regulations, import duties, and certification requirements (such as CE for Europe or RoHS for the Middle East) is essential. This knowledge ensures compliance and smoother market entry. Additionally, regional preferences—for example, warmer color temperatures favored in African markets versus cooler tones in European commercial spaces—can influence purchasing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers in the LED strip lighting sector, particularly when sourcing from global brands like IKEA. The environmental impact of lighting products spans manufacturing processes, raw material sourcing, energy consumption during use, and end-of-life disposal.

Ethical sourcing begins with selecting suppliers who adhere to stringent environmental standards and labor practices. For LED strips, this includes ensuring conflict-free minerals, reducing hazardous substances, and embracing circular economy principles such as recyclability and modular design. IKEA’s commitment to sustainability is reflected in its efforts to use materials like recycled plastics and lead-free soldering in its LED strips, which reduces ecological footprint and enhances product safety.

Green certifications play a pivotal role in B2B procurement decisions. Certifications such as Energy Star, UL Environment, and TCO Certified demonstrate compliance with energy efficiency and environmental responsibility standards. Buyers should verify these credentials to ensure their supply chain aligns with corporate social responsibility goals and increasingly strict government regulations in regions like Europe and the Middle East.

Incorporating LED strips with low power consumption and long lifespans supports sustainability objectives by minimizing energy costs and reducing waste. Furthermore, buyers can leverage IKEA’s transparency on product lifecycle impacts and recycling programs to bolster their own sustainability reporting and customer assurance.

Evolution of the IKEA LED Strip Sector

IKEA’s journey in the LED strip lighting market reflects broader industry trends toward affordable, energy-efficient, and design-centric lighting solutions. Initially focused on basic LED bulbs, IKEA expanded into strips as consumer demand for customizable and mood-enhancing lighting grew. Their product development emphasizes user-friendly installation, modularity, and integration with smart home systems.

Over the past decade, IKEA has shifted towards more sustainable production methods and materials, positioning its LED strip products as accessible yet environmentally responsible options for both residential and commercial buyers. This evolution aligns with global shifts in lighting technology—from incandescent and fluorescent to LED—and highlights IKEA’s role in democratizing smart, sustainable lighting worldwide.

For B2B buyers, IKEA’s established brand reputation combined with continuous innovation offers a reliable source for LED strips that meet modern performance, aesthetic, and sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of ikea led strip

-

How can I effectively vet suppliers of IKEA LED strips for international B2B purchases?

Start by verifying the supplier’s business credentials, including their registration and certifications such as ISO, CE, RoHS, or UL, which ensure product safety and quality compliance. Check their industry reputation through trade show participation, customer reviews, and third-party audits. Request detailed product catalogs and samples to validate quality. For buyers in Africa, South America, the Middle East, and Europe, also confirm the supplier’s experience with international shipping and customs regulations to avoid delays and compliance issues. -

Is it possible to customize IKEA LED strips for specific project requirements?

Yes, many suppliers offer customization options such as length, color temperature, brightness, waterproofing, and connectors to suit different applications. When negotiating, clarify your exact technical needs and request a prototype or sample for approval. Ensure the manufacturer has R&D capabilities and is willing to support modifications without compromising quality. For international buyers, discuss lead times and potential MOQ adjustments for customized orders to align with your project timeline and budget. -

What are typical Minimum Order Quantities (MOQs) and lead times for IKEA LED strips in B2B transactions?

MOQs vary by supplier but often range from 100 to 500 units depending on customization and product type. Lead times typically span 2 to 6 weeks, influenced by order complexity and shipping mode. For buyers in regions like Africa and South America, factor in additional time for customs clearance. Negotiate MOQs early, especially if you are testing new products or markets, and consider building a trial order relationship to minimize risk while establishing a supply chain. -

Which payment terms are advisable when sourcing IKEA LED strips internationally?

Common payment terms include letters of credit (L/C), telegraphic transfers (T/T), and escrow services, with partial upfront payments (30-50%) and balance after delivery. Letters of credit offer more security for large transactions, especially across continents. Ensure clear agreements on payment milestones and penalties for delays. For buyers in emerging markets, working with suppliers experienced in cross-border payments and currency fluctuations helps mitigate financial risks. -

What quality assurance measures should I expect from reputable IKEA LED strip manufacturers?

Reliable manufacturers conduct rigorous quality checks, including brightness consistency, heat dissipation testing, adhesive strength verification, and waterproof certifications if applicable. Look for suppliers with documented QA processes and compliance with international standards (e.g., IEC, CE). Request third-party lab test reports and factory inspection records. Regular audits and batch testing during production are crucial to ensure consistent product performance, especially for large-scale international orders. -

How do certifications impact the import and resale of IKEA LED strips in diverse international markets?

Certifications like CE (Europe), RoHS (environmental safety), UL (US safety), and IEC standards facilitate smoother customs clearance and market acceptance. For buyers in Africa, South America, and the Middle East, verifying compliance with local import regulations and electrical safety standards is essential to avoid product seizures or penalties. Always request up-to-date certificates and ensure the supplier can provide documentation for both manufacturing origin and product quality. -

What logistics considerations are critical when importing IKEA LED strips internationally?

Choose suppliers with experience in handling international shipments and established partnerships with freight forwarders. Decide between air freight (faster but costlier) and sea freight (more economical but slower) based on urgency and budget. Clarify Incoterms (e.g., FOB, CIF) to understand your responsibilities. Also, consider packaging that protects LED strips from moisture and mechanical damage during transit. For remote regions, factor in inland transport and customs brokerage services to avoid delays.

- How should I handle disputes or quality issues with IKEA LED strip suppliers after shipment?

Establish clear contractual terms covering warranties, return policies, and dispute resolution mechanisms before ordering. Maintain detailed records of purchase orders, communications, and product inspections. If defects arise, promptly notify the supplier with photographic evidence and request remediation such as replacements or refunds. Utilize third-party arbitration or trade platforms’ dispute resolution if needed. For international buyers, working with suppliers who offer responsive after-sales support and local representatives can greatly ease conflict resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ikea led strip

Strategic sourcing of IKEA LED strips offers international B2B buyers a compelling opportunity to enhance product offerings with reliable, energy-efficient lighting solutions that align with evolving market demands. Key takeaways emphasize the importance of partnering with manufacturers who demonstrate consistent quality, transparent certifications, and proven supply chain resilience. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with strong regional logistics capabilities and flexible customization options to meet diverse application needs and regulatory requirements.

Strategic sourcing advantages include:

- Ensuring supply continuity through long-term partnerships with reputable manufacturers

- Leveraging product innovation to stay competitive in dynamic lighting markets

- Optimizing cost efficiency without compromising on quality or service

- Navigating compliance with international standards such as CE, RoHS, and UL

Looking ahead, the global demand for sustainable and smart lighting solutions will continue to grow, driving the need for agile supply chains and innovation-driven collaborations. International buyers are encouraged to adopt a proactive sourcing strategy—engage early with trusted suppliers, conduct thorough product testing, and build scalable relationships that support growth in diverse markets. By doing so, businesses can secure their position as leaders in energy-efficient lighting solutions and capitalize on emerging opportunities worldwide.