Guide to Ac Led Strip Light

- Introduction: Navigating the Global Market for AC LED strip light

- Understanding AC LED strip light Types and Variations

- Key Industrial Applications of AC LED strip light

- Strategic Material Selection Guide for AC LED strip light

- In-depth Look: Manufacturing Processes and Quality Assurance for AC LED strip light

- Manufacturing Processes for AC LED Strip Lights

- Quality Assurance (QA) and Control (QC) Framework

- Verifying Supplier Quality Control: Practical Steps for B2B Buyers

- Summary: Actionable Insights for International B2B Buyers

- Comprehensive Cost and Pricing Analysis for AC LED strip light Sourcing

- Spotlight on Potential AC LED strip light Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for AC LED strip light

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the AC LED strip light Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of AC LED strip light

- Strategic Sourcing Conclusion and Outlook for AC LED strip light

Introduction: Navigating the Global Market for AC LED strip light

The global demand for AC LED strip lights is surging as businesses across Africa, South America, the Middle East, and Europe increasingly seek energy-efficient, versatile lighting solutions. These flexible lighting systems are transforming commercial, industrial, and architectural projects by offering superior illumination, ease of installation, and long-term cost savings. For international B2B buyers—whether distributors, contractors, or resellers—understanding the complexities of sourcing AC LED strip lights is paramount to securing quality products that meet diverse market needs.

This comprehensive guide dives deep into the critical aspects of the AC LED strip light market, equipping buyers with the knowledge to make informed decisions. It covers a wide array of topics, including the various types of AC LED strip lights, materials and components used, and essential manufacturing and quality control standards. Buyers will gain insights into selecting trustworthy suppliers, navigating pricing structures, and optimizing supply chains to ensure reliability and cost efficiency.

Special attention is given to the unique challenges and opportunities faced by buyers in emerging and established markets such as Nigeria, the UAE, Brazil, and European hubs. From managing lead times and logistics to evaluating product certifications and customization options, this guide empowers you to build resilient partnerships and scale your business confidently.

By mastering these critical factors, international B2B buyers can confidently source AC LED strip lights that combine performance, durability, and value—ensuring competitive advantage in a rapidly evolving global marketplace.

Understanding AC LED strip light Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color AC LED Strip | Operates directly on AC power with a fixed color output | Retail displays, signage, architectural lighting | Pros: Simplified wiring, cost-effective; Cons: Limited color options |

| RGB AC LED Strip | Integrated RGB LEDs with AC-compatible drivers for color mixing | Hospitality, event venues, advertising | Pros: Versatile color control; Cons: Higher cost, requires controllers |

| Waterproof AC LED Strip | Encapsulated with silicone or epoxy for outdoor/wet environments | Outdoor signage, landscape lighting, industrial | Pros: Durable, weather-resistant; Cons: Slightly higher price, less flexible |

| High-Density AC LED Strip | More LEDs per meter for brighter, uniform illumination | High-end retail, galleries, film sets | Pros: Superior brightness; Cons: Increased power consumption and cost |

| Dimmable AC LED Strip | Compatible with AC dimmer switches for adjustable brightness | Office lighting, residential projects, hotels | Pros: Energy saving, ambiance control; Cons: Requires compatible dimmers |

Single-Color AC LED Strip

Single-color AC LED strips are designed to operate directly on alternating current without the need for external DC drivers, simplifying installation and reducing costs. They typically emit a fixed color, most commonly white or warm white, making them ideal for straightforward lighting needs such as retail shelving or architectural accents. B2B buyers should consider their application’s color requirements and ensure the product’s voltage compatibility with local power standards, especially in markets like Nigeria or UAE where voltage may vary.

RGB AC LED Strip

These strips incorporate red, green, and blue LEDs with integrated AC-compatible drivers that enable color mixing directly from AC power sources. They are favored in applications demanding dynamic lighting effects, such as hospitality venues and event spaces. For B2B buyers, evaluating the quality of the color controller, the ease of integration with existing systems, and the supplier’s ability to provide reliable after-sales support is critical, particularly when planning large-scale installations in diverse regions.

Waterproof AC LED Strip

Encased in durable, weather-resistant materials like silicone, waterproof AC LED strips are suited for outdoor and industrial environments subject to moisture or dust. They are widely used for outdoor signage, landscape lighting, and industrial facility illumination. Buyers should verify the IP rating (commonly IP65 or higher), confirm material certifications for UV and temperature resistance, and assess logistics capabilities for safe shipping to regions with harsh climates such as parts of Africa and the Middle East.

High-Density AC LED Strip

Featuring a higher concentration of LEDs per meter, high-density AC strips deliver intense, uniform brightness ideal for premium applications like high-end retail displays and art galleries. These strips tend to consume more power and come at a premium price, so buyers must balance brightness needs against energy efficiency goals. Partnering with manufacturers who can guarantee consistent LED quality and offer scalable production is essential for sustaining supply in competitive European and South American markets.

Dimmable AC LED Strip

Dimmable variants are designed to work seamlessly with AC dimmer switches, allowing users to adjust brightness levels for energy savings and ambiance control. They are commonly applied in office spaces, hotels, and residential developments where flexible lighting is valued. For B2B procurement, compatibility with local dimming standards and the availability of technical support for installation are key considerations, ensuring smooth integration and customer satisfaction across diverse international markets.

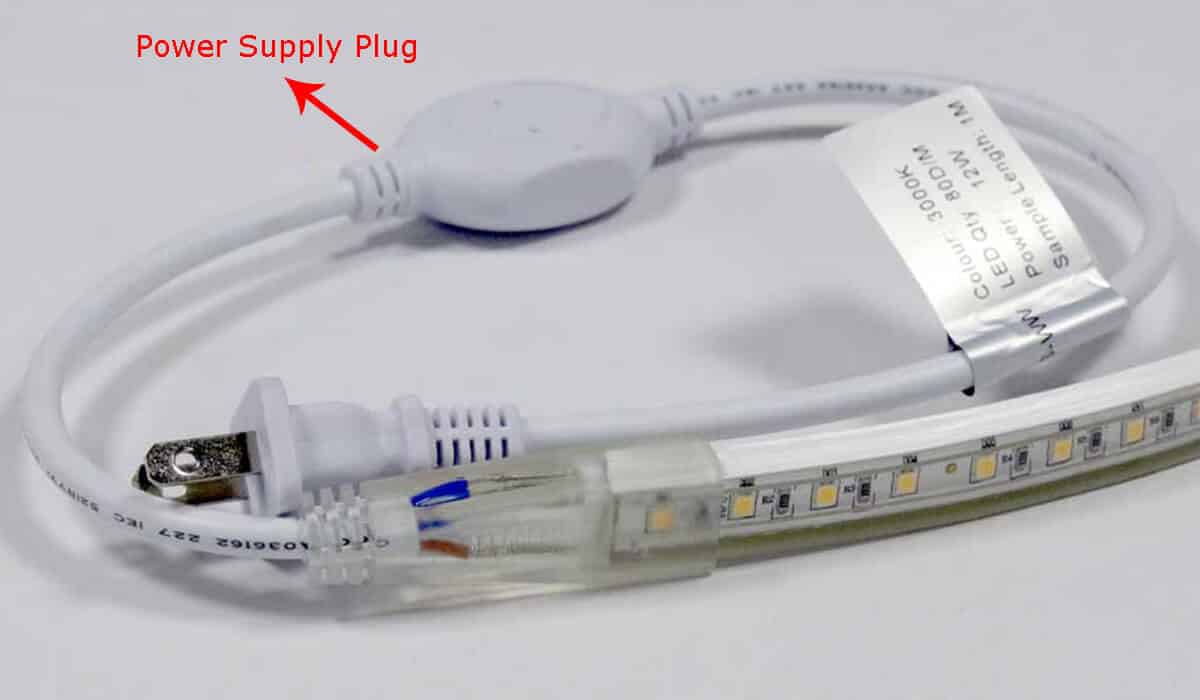

Related Video: AC LED Strip Light – Cutting and Connecting

Key Industrial Applications of AC LED strip light

| Industry/Sector | Specific Application of AC LED strip light | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in storefronts | Enhances product visibility and customer engagement | Consistent color rendering, energy efficiency, ease of installation |

| Hospitality & Tourism | Decorative lighting in hotels and resorts | Creates inviting atmospheres, reduces energy costs | Waterproof ratings, dimming capabilities, color temperature options |

| Transportation | Interior lighting in buses, trains, and airports | Durable, low-maintenance lighting improves passenger comfort | Vibration resistance, compliance with transport safety standards |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Improves worker productivity and safety with uniform illumination | High brightness, long lifespan, robust build quality |

| Real Estate & Construction | Architectural lighting for façades and walkways | Enhances aesthetic appeal and security of buildings | Weather resistance, UV protection, customization options |

Retail & Commercial Applications

In retail environments across Africa, South America, the the Middle East, and Europe, AC LED strip lights are widely used for ambient and accent lighting to highlight products and create an appealing shopping atmosphere. These lights offer consistent brightness and color rendering, which are critical for visual merchandising. For B2B buyers, sourcing LED strips with energy efficiency and easy installation features ensures reduced operational costs and quick deployment in diverse retail settings, including markets in Nigeria and the UAE where power fluctuations can occur.

Hospitality & Tourism Industry

Hotels, resorts, and restaurants rely on AC LED strip lights to craft inviting and dynamic spaces that enhance guest experiences. The ability to dim lights and select from various color temperatures allows for tailored ambiance during different times of day or events. Buyers from regions like the Middle East and Europe should prioritize waterproof and corrosion-resistant strips for outdoor or poolside use. Additionally, energy-efficient lighting solutions contribute to sustainability goals and lower utility expenses in hospitality operations.

Transportation Sector

AC LED strip lighting is increasingly adopted in buses, trains, and airport terminals to improve passenger comfort and safety. The strips provide uniform, low-glare illumination suitable for long operational hours and harsh environments. For B2B buyers in emerging markets such as Nigeria and South America, sourcing products that meet international transport safety certifications and offer vibration resistance is essential to ensure durability and compliance with local regulations.

Manufacturing & Warehousing

In industrial settings, AC LED strip lights serve as task and safety lighting along production lines and storage areas. Their uniform illumination reduces shadows and eye strain, boosting worker productivity and minimizing accidents. Buyers in sectors across Africa and Europe should focus on high-brightness, long-life LED strips with robust construction to withstand dust, moisture, and mechanical stress typical in manufacturing environments.

Real Estate & Construction

Architectural lighting using AC LED strip lights enhances building façades, walkways, and outdoor landscapes, combining functionality with aesthetic appeal. These applications often require weatherproof and UV-resistant strips to endure outdoor exposure. For international buyers, particularly in regions with harsh climates like the Middle East, selecting customizable lighting solutions that integrate with smart control systems can add significant value to real estate projects by improving security and visual impact.

Strategic Material Selection Guide for AC LED strip light

When selecting materials for AC LED strip lights, international B2B buyers must consider factors such as durability, thermal management, corrosion resistance, and compliance with regional standards. The choice of materials directly influences product reliability, lifespan, and suitability for diverse environmental conditions common in markets like Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

1. Flexible Printed Circuit Board (FPC) Substrate – Polyimide (PI)

Key Properties:

Polyimide substrates offer excellent thermal stability, withstanding temperatures up to 260°C. They provide good mechanical flexibility and chemical resistance, making them ideal for bending and shaping LED strips without damage.

Pros & Cons:

– Pros: High heat resistance ensures stable LED performance and longevity. Good dielectric properties reduce electrical failures. Resistant to many chemicals and UV exposure.

– Cons: Higher cost compared to polyester-based substrates. Manufacturing complexity is greater due to material handling requirements.

Impact on Application:

Polyimide-based FPCs are suited for high-temperature environments and outdoor applications, including architectural lighting in hot climates such as the UAE or Nigeria. Their flexibility allows for custom installations in curved surfaces or confined spaces.

Considerations for International Buyers:

Buyers should verify compliance with international standards like UL 796 (Printed-Wiring Boards) and IPC-2221 (Generic Standard on Printed Board Design). In Europe, adherence to RoHS and REACH regulations is critical. For African and Middle Eastern markets, durability against UV and dust is essential, favoring polyimide substrates.

2. Flexible Printed Circuit Board (FPC) Substrate – Polyester (PET)

Key Properties:

Polyester substrates typically handle temperatures up to 150°C, offering moderate flexibility and good dimensional stability. They are less expensive and easier to process than polyimide.

Pros & Cons:

– Pros: Cost-effective and widely available. Suitable for indoor applications with controlled temperature. Easier to manufacture, reducing lead times.

– Cons: Lower thermal resistance limits use in high-heat environments. Less chemical and UV resistance, which can reduce lifespan outdoors.

Impact on Application:

PET substrates are ideal for indoor AC LED strip light installations such as retail displays or office lighting in temperate climates like parts of Europe or South America. They are less suited for outdoor or harsh environments.

Considerations for International Buyers:

Buyers from regions with high ambient temperatures should avoid PET for outdoor use due to potential thermal degradation. Compliance with ASTM D150 (Dielectric Strength) and local fire safety standards is advised. PET substrates may be preferred in cost-sensitive markets prioritizing indoor applications.

3. Silicone Encapsulation Material

Key Properties:

Silicone encapsulants provide excellent thermal stability (up to 200°C), high flexibility, and outstanding UV and moisture resistance. They protect LED components from environmental damage.

Pros & Cons:

– Pros: Superior weatherproofing and resistance to corrosion and dust. Maintains flexibility across temperature extremes. Enhances LED lifespan in outdoor or industrial settings.

– Cons: Higher material and processing costs. Requires specialized manufacturing processes. May increase overall product thickness.

Impact on Application:

Silicone encapsulation is preferred for AC LED strip lights intended for outdoor use or harsh environments, such as coastal regions in Africa or the Middle East where humidity and salt exposure are concerns.

Considerations for International Buyers:

Ensure the silicone used complies with IEC 60529 for ingress protection ratings (IP65, IP67, or higher). Buyers should also verify certifications like UL 94 V-0 for flame retardancy. The higher upfront cost is offset by reduced maintenance and replacement frequency in challenging climates.

4. Aluminum Backing/Heat Sink

Key Properties:

Aluminum backing serves as a heat sink, dissipating heat generated by LEDs to maintain performance and prevent premature failure. It offers good corrosion resistance, especially when anodized.

Pros & Cons:

– Pros: Enhances thermal management, improving LED lifespan and brightness stability. Lightweight and easy to integrate into strip designs. Corrosion-resistant anodized finishes extend durability.

– Cons: Adds to material and shipping weight. Cost varies based on grade and finish. Requires precise manufacturing to ensure good thermal contact.

Impact on Application:

Aluminum-backed AC LED strips are essential for installations with continuous or high-power use, such as commercial lighting in Europe or industrial facilities in South America. They are also favored in regions with higher ambient temperatures.

Considerations for International Buyers:

Buyers should confirm aluminum grades meet ASTM B221 or equivalent standards. Anodizing quality affects corrosion resistance, critical for humid or coastal regions like Nigeria or the UAE. Aluminum-backed strips may command higher prices but offer superior reliability.

Summary Table

| Material | Typical Use Case for AC LED strip light | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) FPC Substrate | High-temperature, outdoor, flexible installations | Excellent thermal stability and UV resistance | Higher cost and manufacturing complexity | High |

| Polyester (PET) FPC Substrate | Indoor, low to moderate temperature environments | Cost-effective and easy to manufacture | Limited heat and UV resistance | Low |

| Silicone Encapsulation | Outdoor, harsh environments requiring moisture and UV protection | Superior weatherproofing and flexibility | Increased cost and product thickness | High |

| Aluminum Backing/Heat Sink | Commercial/industrial lighting with high power or continuous use | Effective heat dissipation and corrosion resistance | Adds weight and cost; requires precise manufacturing | Medium |

This guide equips international B2B buyers with critical insights to select materials that balance performance, cost, and compliance, ensuring AC LED strip lights meet diverse market demands across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for AC LED strip light

Manufacturing Processes for AC LED Strip Lights

The production of AC LED strip lights involves several meticulously controlled stages to ensure high performance, durability, and safety. Understanding these stages helps B2B buyers evaluate suppliers more effectively and align procurement with quality expectations.

1. Material Preparation

The manufacturing process begins with sourcing and preparing raw materials, including:

- LED chips and modules: High-quality semiconductor chips are selected based on brightness, power consumption, and color temperature.

- Flexible PCB substrates: Typically made from polyimide or fiberglass materials that offer durability and heat resistance.

- Resistors, capacitors, and drivers: These components regulate current and voltage, crucial for AC operation stability.

- Adhesives and encapsulants: Used for waterproofing and protecting LEDs from environmental factors.

- Connectors and packaging materials: Ensuring ease of installation and safe shipment.

Material sourcing is a critical stage where partnering with reputable suppliers ensures component reliability, which directly impacts final product performance.

2. Forming and PCB Assembly

Once materials are prepared, the flexible printed circuit board (FPCB) is fabricated:

- PCB patterning and etching: Copper layers are etched to form circuits tailored for AC voltage compatibility.

- Solder paste application: Precise solder paste deposition prepares the board for component placement.

- Surface Mount Technology (SMT): Automated machines place LED chips, resistors, and drivers onto the PCB with high accuracy.

- Reflow soldering: This process solidifies connections by melting solder paste under controlled heat.

Advanced SMT lines ensure consistent placement and solder quality, essential for long-term reliability under AC current conditions.

3. Assembly and Integration

Following PCB assembly, the strip lights undergo further integration:

- Encapsulation: LEDs are coated or covered with silicone or epoxy to protect against moisture, dust, and mechanical damage.

- Cutting and segmenting: Strips are cut into specified lengths with designated solder points for easy customization.

- Attachment of connectors: End connectors, plugs, or wires are affixed for plug-and-play installation.

- Adhesive backing application: High-quality 3M or equivalent tapes are applied to the strip back for secure mounting.

This stage focuses on enhancing durability and installation convenience, vital for diverse applications across different markets.

4. Finishing and Packaging

Final steps prepare the product for shipment:

- Visual inspection: Checking for any visible defects like solder bridges, misaligned LEDs, or surface blemishes.

- Protective packaging: Strips are rolled or folded carefully, then sealed in anti-static bags or waterproof packaging.

- Labeling: Compliance information, batch numbers, and product specifications are printed for traceability.

Proper finishing and packaging reduce damage risks during transportation, crucial for international buyers who rely on intact delivery.

Quality Assurance (QA) and Control (QC) Framework

Quality assurance in AC LED strip light manufacturing is a multi-layered process governed by international standards and industry-specific certifications. For B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding these frameworks is key to selecting reliable suppliers and ensuring product compliance.

Relevant International and Industry Standards

- ISO 9001: This global standard ensures manufacturers maintain consistent quality management systems, focusing on process control, continuous improvement, and customer satisfaction.

- CE Marking: Mandatory for products sold in the European Economic Area, it signifies compliance with health, safety, and environmental requirements.

- RoHS (Restriction of Hazardous Substances): Ensures products are free from toxic materials like lead and mercury.

- UL Certification: Particularly relevant for the U.S. and some Middle Eastern markets, it verifies product safety and electrical compliance.

- API and IEC standards: Relevant for electrical performance and safety in various regions.

Buyers should prioritize suppliers with these certifications to mitigate risks associated with non-compliance, customs delays, or safety hazards.

Key Quality Control Checkpoints

Quality control is implemented at multiple production stages:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt to verify specifications and detect defects early.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB assembly, soldering, and encapsulation to catch deviations immediately.

- Final Quality Control (FQC): Comprehensive testing of finished strips before packaging, including electrical and visual inspections.

This layered QC approach ensures problems are identified and corrected promptly, reducing defective output and enhancing product reliability.

Common Testing Methods

Manufacturers employ various tests to validate AC LED strip light quality:

- Electrical Testing: Verification of voltage, current, and power consumption to ensure compliance with AC operation requirements.

- Lumen and Color Consistency Testing: Measuring brightness and color temperature uniformity across the strip.

- Thermal Performance Testing: Assessing heat dissipation to prevent premature LED failure.

- Waterproof Testing (IP Rating): Especially important for outdoor or humid environments, confirming ingress protection levels.

- Adhesive Strength Testing: Ensuring mounting tapes maintain strong bonds under different environmental conditions.

- Durability and Life Cycle Testing: Simulating long-term usage to assess product lifespan and failure rates.

Requesting detailed test reports or witnessing testing procedures can provide buyers with confidence in product quality.

Verifying Supplier Quality Control: Practical Steps for B2B Buyers

For international B2B buyers, especially from regions like Nigeria, UAE, Brazil, or South Africa, verifying a supplier’s QC practices is essential to safeguard investments and maintain supply chain integrity.

1. Factory Audits and Site Visits

- On-site audits: Visiting manufacturing facilities allows buyers to observe production processes, equipment, and workforce expertise firsthand.

- Third-party audits: Engaging independent inspection agencies (e.g., SGS, Bureau Veritas) to conduct unbiased factory evaluations and product inspections.

- Virtual audits: When travel is constrained, video walkthroughs and live demonstrations can substitute physical visits.

2. Reviewing Documentation and Certifications

- Request ISO, CE, RoHS, and UL certificates: Confirm authenticity and validity directly with issuing bodies if needed.

- Examine QC procedure manuals: Understanding their quality control workflow provides transparency.

- Analyze test reports: Look for consistency in batch testing and adherence to agreed specifications.

3. Sample Testing and Pilot Orders

- Order samples: Test them under real-world conditions relevant to your market.

- Conduct independent lab tests: Send samples to accredited labs for verification of electrical safety, luminous efficacy, and environmental compliance.

- Start with trial orders: Assess supplier responsiveness, delivery timeliness, and product consistency before scaling up.

4. Understanding Regional QC and Regulatory Nuances

- Africa and Middle East: Emphasize electrical safety certifications and robustness against environmental factors like heat and humidity. Compliance with local standards (e.g., SASO in Saudi Arabia) can be critical.

- South America: Look for certifications accepted by Mercosur countries and consider import regulations that may require additional documentation.

- Europe: CE and RoHS compliance are mandatory. Buyers should also consider WEEE (Waste Electrical and Electronic Equipment) regulations for end-of-life product management.

Working with suppliers knowledgeable about these regional requirements minimizes customs clearance issues and regulatory risks.

Summary: Actionable Insights for International B2B Buyers

- Prioritize manufacturers with robust, transparent manufacturing processes that include advanced SMT assembly, rigorous encapsulation, and precise finishing.

- Verify supplier quality through multiple QC checkpoints—from IQC to FQC—and insist on documented testing results aligned with international standards.

- Leverage third-party audits and independent lab testing to supplement supplier-provided information, especially for initial orders or new partnerships.

- Understand and demand compliance with region-specific certifications and regulations relevant to your target markets, such as CE for Europe or SASO for the Middle East.

- Establish long-term relationships with manufacturers who demonstrate consistent quality control, timely communication, and capacity to scale production as your business grows.

By applying these insights, B2B buyers from Africa, South America, the Middle East, and Europe can confidently source AC LED strip lights that meet quality expectations, regulatory requirements, and market demands—laying the foundation for successful, sustainable business partnerships.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for AC LED strip light Sourcing

Understanding the cost and pricing dynamics of AC LED strip lights is essential for international B2B buyers aiming to optimize procurement strategies and maximize value. This analysis breaks down the key cost components, pricing influencers, and offers actionable tips tailored to buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in AC LED Strip Light Sourcing

-

Materials

The primary cost driver includes LED chips, flexible PCB substrates, drivers, connectors, adhesives, and protective coatings. High-quality components, such as premium LED chips or waterproofing materials, increase costs but enhance longevity and performance. Material sourcing from reputable suppliers can reduce defects and returns. -

Labor

Labor costs vary significantly depending on the manufacturing location. Countries with advanced automation may offer competitive pricing despite higher wages, while manual assembly in lower-cost regions can reduce direct labor expenses but may affect consistency.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, maintenance, and administrative expenses. Efficient factories with streamlined processes tend to keep overheads lower, which benefits buyers through better pricing. -

Tooling and Setup Costs

Initial tooling for custom designs, molds, or specialized assembly lines can be significant. These are often amortized over production volume, so low Minimum Order Quantities (MOQs) may result in higher per-unit costs. -

Quality Control (QC)

Rigorous QC processes—such as in-line testing, burn-in tests, and certification compliance—add to costs but ensure product reliability, reducing downstream warranty claims and enhancing brand reputation. -

Logistics and Shipping

Freight costs depend on shipment size, mode (air vs. sea), and destination port. Buyers in regions like Nigeria, UAE, or Brazil should factor in customs duties, import taxes, and inland transportation expenses, which can significantly impact landed cost. -

Supplier Margin

Supplier profit margins vary with market competition, volume commitments, and relationship strength. Long-term partnerships often enable margin negotiation, leading to improved pricing.

Influencers Impacting AC LED Strip Light Pricing

-

Order Volume and MOQs

Larger volumes typically unlock economies of scale, reducing per-unit prices. Buyers should evaluate their forecasted demand and negotiate MOQs that balance cost efficiency with inventory risks. -

Product Specifications and Customization

Customized features—such as color temperature tuning, dimming compatibility, or waterproof ratings—increase complexity and cost. Standard product lines are generally more affordable and faster to deliver. -

Material Quality and Certifications

Compliance with certifications like CE, RoHS, UL, or ISO adds value and cost. Buyers targeting regulated markets in Europe or the Middle East must prioritize certified products despite premium pricing. -

Supplier Reputation and Location

Established manufacturers with proven track records can command higher prices but offer reliability and consistent quality. Sourcing from regions with favorable trade agreements or free zones (e.g., UAE) may reduce tariffs and expedite delivery. -

Incoterms and Payment Terms

Terms such as FOB, CIF, or DDP affect cost visibility and risk allocation. Buyers should clarify responsibilities for shipping, insurance, and customs clearance to avoid hidden costs.

Practical Buyer Tips for Cost Efficiency and Negotiation

-

Negotiate Beyond Price

Focus on total value, including lead times, payment terms, after-sales support, and warranty. A slightly higher price may be justified by superior service and reduced risk. -

Calculate Total Cost of Ownership (TCO)

Consider product lifespan, energy efficiency, installation complexity, and potential maintenance costs. Higher upfront cost strips with better durability can lower long-term expenses. -

Leverage Volume Aggregation

Buyers in emerging markets can collaborate with regional partners to consolidate orders, achieving better pricing and reducing shipping overhead. -

Request Samples and Test Thoroughly

Especially critical for new suppliers or customized products. Testing ensures product meets performance expectations, preventing costly returns. -

Understand Regional Import Regulations

Compliance with local standards and import documentation avoids delays and penalties. Engage with customs brokers familiar with the target market. -

Use Supply Chain Technology Tools

Real-time tracking and inventory management software help optimize reorder points and reduce storage costs.

Indicative Pricing Disclaimer

Pricing for AC LED strip lights varies widely based on specifications, order size, and supplier factors. As a general reference, wholesale prices can range from approximately $1.50 to $5.00 per meter for standard products, excluding shipping and duties. Buyers should obtain multiple quotes and consider all cost factors before finalizing procurement decisions.

By thoroughly analyzing these cost components and price influencers, international B2B buyers can negotiate more effectively, reduce total acquisition costs, and build resilient supply chains tailored to their regional market needs.

Spotlight on Potential AC LED strip light Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘AC LED strip light’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for AC LED strip light

Critical Technical Properties of AC LED Strip Lights

Understanding the key technical specifications of AC LED strip lights is essential for B2B buyers aiming to source reliable, high-performance products suitable for diverse markets such as Africa, South America, the Middle East, and Europe. These specifications impact product durability, efficiency, and compatibility with local electrical standards.

-

Voltage Compatibility (AC Voltage Rating)

AC LED strip lights are designed to operate directly on alternating current (AC), commonly at 110V or 220-240V depending on the region. Confirming voltage compatibility ensures safe operation and compliance with local power infrastructure, avoiding costly modifications or failures. -

Material Grade and PCB Quality

The substrate material, typically a flexible printed circuit board (PCB), affects heat dissipation and durability. High-grade PCBs (e.g., FR4 or aluminum-based) offer better thermal management, extending the lifespan of the LEDs and reducing maintenance costs, which is crucial for large-scale installations. -

Luminous Flux and Color Temperature

Luminous flux (measured in lumens per meter) determines the brightness output, while color temperature (Kelvin scale) affects light tone—from warm white to cool white. Buyers must select strips that meet specific lighting requirements, whether for commercial, industrial, or decorative applications. -

IP Rating (Ingress Protection)

The IP rating defines the strip’s resistance to dust and moisture. For outdoor or humid environments common in many African and Middle Eastern markets, a minimum of IP65 is recommended. This ensures reliability and reduces the risk of product failure due to environmental exposure. -

Cuttable Length and Tolerance

AC LED strips are typically segmented to allow cutting at designated points without damaging the circuit. Understanding the minimum cuttable unit and manufacturing tolerance (±5% length or voltage) helps buyers plan installations efficiently and minimize waste. -

Dimming and Control Compatibility

Compatibility with dimmers or smart controllers (e.g., TRIAC dimmers, RF controllers) adds versatility. Buyers should verify if the strips support dimming to meet advanced lighting needs, which can be a competitive advantage in modern building projects.

Key Industry and Trade Terminology for AC LED Strip Lights

Navigating the LED strip light market requires familiarity with common trade terms. These terms facilitate clearer communication with suppliers and help avoid misunderstandings during procurement.

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers who produce products that are rebranded and sold by other companies. For B2B buyers seeking customized branding or unique specifications, partnering with an OEM ensures tailored solutions and scalability. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity a supplier is willing to sell per order. Understanding MOQs is critical for budgeting and inventory planning, especially for businesses entering new markets or testing products in different regions. -

RFQ (Request for Quotation)

An RFQ is a formal inquiry sent to suppliers asking for pricing and terms based on specified product requirements. Crafting precise RFQs helps buyers obtain competitive quotes and clarifies expectations on quality, lead time, and logistics. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for shipping, insurance, and customs clearance. Familiarity with terms like FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) enables buyers to negotiate favorable delivery conditions and control costs. -

IP Rating (Ingress Protection)

Although a technical property, IP rating is also a trade term used to specify product suitability for various environments. Clear communication of required IP ratings ensures suppliers provide products fit for local climate conditions. -

Lead Time

Lead time is the period between placing an order and receiving the goods. Buyers should consider lead times carefully to align procurement with project schedules and avoid stockouts, especially when sourcing from overseas manufacturers.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and establish strong, transparent relationships with AC LED strip light suppliers across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the AC LED strip light Sector

Market Overview & Key Trends

The global AC LED strip light market is experiencing robust growth driven by increasing demand for energy-efficient, versatile lighting solutions across commercial, residential, and industrial sectors. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the appeal lies in AC LED strip lights’ simplified installation process—owing to their ability to connect directly to AC power without requiring external drivers—coupled with long operational lifespans and reduced maintenance costs.

Key market drivers include government policies favoring energy conservation, rising urbanization, and expanding infrastructure projects, particularly in emerging economies like Nigeria and Brazil. In the UAE and other Gulf countries, rapid real estate development and smart city initiatives fuel demand for advanced lighting solutions. European buyers, meanwhile, prioritize compliance with stringent energy efficiency and safety standards, pushing suppliers to innovate continuously.

Emerging sourcing trends highlight a shift towards direct manufacturer partnerships to secure competitive pricing and reliable supply chains. Buyers increasingly seek suppliers capable of offering customization—such as specific color temperatures, IP ratings for waterproofing, and flexible form factors—to meet diverse project requirements. Digital platforms and supply chain management technologies are enhancing transparency and agility, enabling buyers to monitor inventory, forecast demand, and optimize logistics.

Market dynamics emphasize the importance of supplier reliability and product quality, especially in regions where infrastructure challenges can complicate logistics. Diversification of suppliers and multi-sourcing strategies mitigate risks associated with global disruptions. Additionally, the integration of smart controls (e.g., dimming, IoT compatibility) in AC LED strips is gaining traction, adding value for B2B clients aiming to future-proof their lighting installations.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly pivotal in B2B procurement decisions for AC LED strip lights. The environmental impact of lighting products encompasses raw material extraction, manufacturing energy consumption, and end-of-life disposal. Buyers from Europe and progressive markets in the Middle East and Africa are demanding suppliers demonstrate adherence to eco-friendly practices and ethical sourcing standards.

Ethical supply chains ensure that raw materials such as rare earth elements and electronic components are sourced responsibly, avoiding conflict minerals and supporting fair labor conditions. This is crucial for buyers committed to corporate social responsibility (CSR) and compliance with international regulations like the EU’s Conflict Minerals Regulation.

Green certifications such as RoHS (Restriction of Hazardous Substances), CE, UL, and increasingly Energy Star and TUV certifications, serve as benchmarks for environmentally safe and energy-efficient products. B2B buyers should prioritize suppliers who invest in sustainable manufacturing processes, including waste reduction, energy-efficient production lines, and recyclable packaging.

Material innovation is also shaping sustainability trends. The use of lead-free solder, halogen-free PCBs, and low-power consumption LEDs contributes to lowering the carbon footprint of AC LED strip lights. Furthermore, the modular design of strips facilitates easier repair and recycling, extending product life cycles and reducing electronic waste.

By integrating sustainability into procurement strategies, international buyers not only align with global environmental goals but also enhance their brand reputation and meet growing customer expectations for responsible business practices.

Brief Evolution and Historical Context

The evolution of AC LED strip lights is rooted in the broader advancement of LED technology over the past two decades. Initially, LED strips were predominantly DC-powered, requiring external drivers and limiting their application flexibility. The development of AC LED strip lights marked a significant milestone by integrating driver circuitry directly into the strip, simplifying installation and reducing costs.

This innovation gained momentum in the 2010s as LED efficiency improved and manufacturing techniques matured. The ability to run directly on AC mains power made these strips especially attractive for large-scale commercial and architectural lighting projects, where installation speed and reduced maintenance are critical.

For B2B buyers, understanding this evolution underscores the value proposition of AC LED strip lights—not only as a cost-effective lighting solution but also as a product category that continuously adapts to market needs with improved reliability, customization options, and enhanced energy efficiency. This historical context helps buyers appreciate the technological maturity behind current offerings and informs long-term sourcing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of AC LED strip light

-

How can I effectively vet AC LED strip light suppliers for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications such as ISO, CE, RoHS, and UL, which indicate compliance with international quality and safety standards. Request references or case studies from other international buyers, especially those in your region (Africa, South America, Middle East, Europe). Assess their production capacity, years in business, and participation in trade fairs. Always request product samples to test performance and durability. Finally, evaluate their communication responsiveness and after-sales support to ensure a reliable long-term partnership. -

What customization options are typically available for AC LED strip lights, and how do I request them?

Manufacturers usually offer customization in length, LED density, color temperature, waterproof rating, adhesive backing, and connectors. Some suppliers also provide custom PCB designs and packaging tailored to your brand. When requesting customization, clearly specify your technical requirements, intended application, and compliance needs. Early engagement with the supplier’s R&D or technical team is crucial to confirm feasibility, pricing, and lead times. Custom orders may require minimum order quantities (MOQs), so clarify these upfront to align with your procurement plans.

-

What are common minimum order quantities (MOQs) and lead times for AC LED strip lights in international trade?

MOQs vary by supplier but typically range from 100 to 500 meters per SKU for standard products. Custom orders may have higher MOQs due to tooling and setup costs. Lead times generally span 2 to 6 weeks, depending on order size, customization complexity, and current factory workload. For buyers in regions like UAE or Nigeria, factor in additional shipping and customs clearance time. Negotiate MOQs and lead times upfront to optimize inventory planning and avoid stockouts or excessive holding costs. -

Which payment terms are standard for international B2B transactions of AC LED strip lights, and how can I mitigate payment risks?

Common payment terms include 30% upfront deposit with the balance paid before shipment or upon delivery. Letters of credit (LC) and escrow services offer higher security for both parties. To mitigate risks, conduct due diligence on suppliers and use secure payment platforms. Negotiate clear contract terms regarding payment schedules, penalties for delays, and quality disputes. For first-time transactions, consider smaller trial orders with milestone payments to build trust before scaling up. -

What quality assurance (QA) measures and certifications should I expect from reputable AC LED strip light manufacturers?

Reputable manufacturers implement stringent QA processes including raw material inspection, in-line production checks, and final product testing for brightness, color consistency, waterproofing, and electrical safety. Certifications such as ISO 9001, CE, RoHS, UL, and FCC are critical as they demonstrate compliance with international standards. Request test reports and certification documents before purchase. Additionally, inquire if the supplier offers third-party inspection services or factory audits to ensure ongoing quality adherence. -

How should I plan logistics and shipping for bulk AC LED strip light orders to Africa, South America, the Middle East, or Europe?

Coordinate with your supplier to select optimal shipping methods—air freight for urgent orders or sea freight for cost efficiency. Confirm packaging standards to prevent damage during transit, especially for sensitive electronic components. Understand import regulations, customs duties, and taxes specific to your country. Working with experienced freight forwarders familiar with your region’s logistics can streamline clearance and reduce delays. Also, consider incoterms like FOB or CIF to clarify responsibilities and risks during shipment. -

What steps can I take to resolve disputes or quality issues with AC LED strip light suppliers internationally?

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution mechanisms before ordering. If issues arise, document defects with photos and test results, and communicate promptly with the supplier. Request replacement, repair, or refund based on contract terms. Mediation or arbitration clauses can help resolve conflicts without costly litigation. Building long-term relationships with suppliers who prioritize transparency and customer service reduces the likelihood of disputes.

Illustrative Image (Source: Google Search)

- How can I ensure consistent supply and avoid stockouts when sourcing AC LED strip lights internationally?

Develop strong partnerships with multiple reliable suppliers to diversify risk and ensure backup options. Use supply chain management tools to monitor inventory levels and forecast demand accurately. Negotiate flexible MOQs and reorder schedules aligned with your sales cycles. Consider establishing local warehousing or distribution hubs in key markets like UAE or Nigeria to shorten delivery times. Regularly review supplier performance and market conditions to proactively adjust procurement strategies and maintain uninterrupted supply.

Strategic Sourcing Conclusion and Outlook for AC LED strip light

Efficient and strategic sourcing of AC LED strip lights is pivotal for international B2B buyers seeking to enhance product quality, optimize costs, and secure reliable supply chains. Key takeaways emphasize the importance of partnering with experienced manufacturers who demonstrate consistent quality, robust production capacity, and strong certifications. Prioritizing suppliers with proven track records and transparent communication ensures timely deliveries and scalable solutions, critical for diverse markets such as Africa, South America, the Middle East, and Europe.

Strategic sourcing demands:

– Diversification of suppliers to mitigate risks and avoid disruptions.

– Thorough product testing to confirm durability and performance under local conditions.

– Leveraging technology for supply chain visibility and demand forecasting.

– Building long-term partnerships that provide flexibility, customization, and after-sales support.

Looking ahead, the AC LED strip light market is poised for continued growth fueled by increasing demand for energy-efficient, customizable lighting solutions. Buyers in emerging and mature markets alike should capitalize on strategic sourcing to gain competitive advantage, reduce lead times, and meet evolving customer expectations. For businesses in regions like the UAE, Nigeria, Brazil, and beyond, proactively engaging with trusted manufacturers and optimizing supply chain operations will be essential to thriving in this dynamic industry landscape.

Take action now: Invest in due diligence, foster collaborative supplier relationships, and embrace innovation to future-proof your AC LED strip light sourcing strategy.