Introduction: Navigating the Global Market for adhesive for led light strips

The global demand for LED strip lights continues to surge as industries and commercial spaces across Africa, South America, the Middle East, and Europe adopt energy-efficient, versatile lighting solutions. Central to the successful deployment and longevity of these LED installations is the adhesive used to secure the strips in place. For international B2B buyers, particularly in dynamic markets such as Nigeria and Saudi Arabia, sourcing the right adhesive is not merely about sticking power—it directly impacts installation durability, maintenance costs, and overall customer satisfaction.

This guide offers a comprehensive exploration of adhesives tailored for LED light strips, enabling buyers to make strategic sourcing decisions with confidence. It covers the spectrum of adhesive types—from double-sided tapes to advanced mounting clips—and examines key material properties suited for diverse environmental conditions, including humidity and temperature variations common in target regions.

We delve into critical manufacturing and quality control standards that ensure product reliability and regulatory compliance, providing insights into leading global suppliers and cost considerations. Additionally, the guide addresses common challenges such as adhesion failure and waterproofing compatibility, equipping buyers with practical troubleshooting knowledge.

Whether you are upgrading retail lighting in São Paulo, outfitting commercial projects in Lagos, or designing architectural illumination in Dubai, this guide empowers you with the knowledge to select adhesives that optimize installation efficiency and performance. By understanding the nuances of adhesive technologies and market dynamics, international B2B buyers can streamline procurement processes, reduce risks, and foster long-term partnerships with trusted manufacturers worldwide.

Understanding adhesive for led light strips Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic-Based Adhesive | Strong bonding, moisture resistant, good temperature tolerance | Indoor and outdoor LED strip installations | + Durable, weather-resistant – May leave residue on removal |

| Silicone-Based Adhesive | Flexible, heat resistant, excellent for uneven surfaces | High humidity areas, curved or textured surfaces | + Flexible, long-lasting – Higher cost, slower curing time |

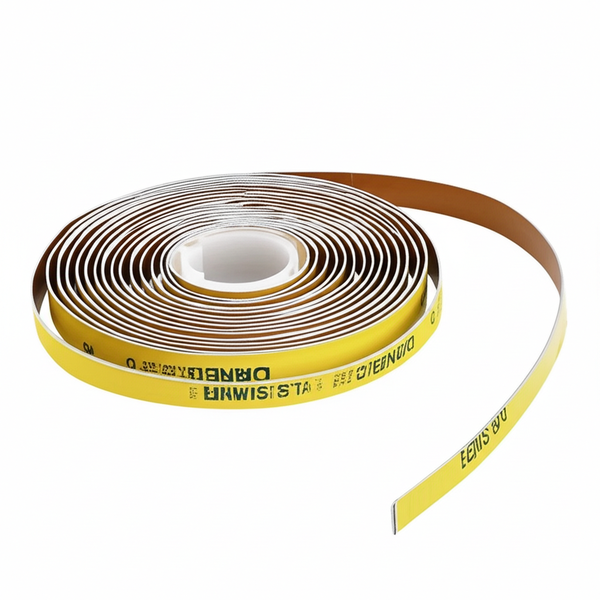

| Double-Sided Foam Tape | Thick, cushioning adhesive, adapts to irregular surfaces | Automotive, industrial, and outdoor LED mounting | + Strong grip, vibration dampening – Bulkier, less aesthetic |

| 3M VHB (Very High Bond) Tape | Industrial-grade, ultra-strong bonding, weatherproof | Heavy-duty, permanent LED strip installations | + Extremely strong, reliable – Difficult to remove, higher price |

| Hot Melt Adhesive | Thermoplastic, fast setting, suitable for quick fixes | Temporary or semi-permanent indoor LED setups | + Fast application, cost-effective – Lower durability, less heat resistant |

Acrylic-Based Adhesive

Acrylic adhesives are widely used for LED strip mounting due to their excellent bonding strength and resistance to moisture and temperature variations. This makes them suitable for both indoor and outdoor applications, including retail displays and architectural lighting. For B2B buyers, acrylic adhesives offer a balance between durability and cost-efficiency, ideal for projects requiring moderate environmental resistance. However, buyers should consider potential residue on surfaces during removal, which could affect future maintenance or repositioning.

Silicone-Based Adhesive

Silicone adhesives excel in environments with high humidity or temperature fluctuations, offering flexibility that accommodates curved or textured surfaces. This type is preferred for installations in bathrooms, kitchens, or outdoor shaded areas common in regions like the Middle East or coastal parts of Africa. B2B buyers prioritizing longevity and adaptability should consider silicone adhesives despite their higher cost and longer curing times, as these factors contribute to reduced maintenance and enhanced reliability.

Double-Sided Foam Tape

This adhesive variation features a thick, cushioning foam layer that conforms to uneven or rough surfaces, providing vibration dampening properties. It is especially suitable for automotive LED applications, industrial settings, and outdoor installations where surface irregularities are common. For international buyers in industrial sectors or vehicle customization, foam tape offers a robust solution. The trade-off includes a bulkier appearance and potentially less sleek finishes, which may be a consideration for aesthetic-driven projects.

3M VHB Tape

3M’s Very High Bond tape is an industrial-grade adhesive known for its exceptional strength and weatherproof qualities. It is ideal for permanent, heavy-duty LED strip installations requiring maximum reliability, such as large-scale commercial lighting or exterior architectural accents. B2B buyers investing in long-term infrastructure projects will find VHB tape valuable despite its premium pricing and difficulty in removal, ensuring minimal risk of failure under harsh conditions.

Hot Melt Adhesive

Hot melt adhesives provide a thermoplastic bonding solution that sets quickly, making them suitable for temporary or semi-permanent indoor LED strip installations. This type is favored for rapid assembly lines or projects with frequent updates, such as event lighting or retail promotions. For buyers focused on cost-effectiveness and speed, hot melt adhesives offer a practical option, though they generally exhibit lower durability and heat resistance compared to other adhesives, limiting their use in demanding environments.

Related Video: What are Diffusion Models?

Key Industrial Applications of adhesive for led light strips

| Industry/Sector | Specific Application of adhesive for led light strips | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in stores and shopping malls | Enhances product visibility and customer experience, driving sales | Adhesive must be strong, residue-free, and compatible with varied surfaces |

| Hospitality & Leisure | Ambient and decorative lighting in hotels, restaurants, and lounges | Creates inviting atmospheres, improving guest satisfaction | Requires adhesives resistant to humidity and temperature fluctuations |

| Automotive & Transportation | Interior LED strip lighting for vehicles and public transport | Improves safety and aesthetics, enabling customization | Adhesive must withstand vibrations, temperature extremes, and UV exposure |

| Architectural & Construction | Cove and under-cabinet lighting in residential and commercial buildings | Adds modern design elements and energy efficiency | Adhesive should be durable, non-damaging to surfaces, and easy to install |

| Electronics & Manufacturing | Machine and equipment status indicators using LED strips | Facilitates operational monitoring and maintenance | Adhesive needs to be heat-resistant and compatible with industrial materials |

In the Retail & Commercial sector, adhesives for LED light strips are primarily used to secure lighting that highlights products and signage. This application demands adhesives with strong bonding power that do not leave residues or damage delicate surfaces like glass or painted walls. For international buyers in regions such as Nigeria or Saudi Arabia, sourcing adhesives that perform well under varied climate conditions and are compliant with local safety standards is crucial to ensure longevity and ease of maintenance in high-traffic environments.

Illustrative Image (Source: Google Search)

Within Hospitality & Leisure, LED strip adhesives enable the installation of ambient lighting that enhances the guest experience in hotels and restaurants. Adhesives selected must resist humidity, temperature changes, and occasional cleaning chemicals. Buyers from humid regions in South America or the Middle East should prioritize waterproof and heat-resistant adhesive formulations to maintain reliable performance and aesthetic appeal in dynamic hospitality settings.

The Automotive & Transportation industry utilizes LED strip adhesives to mount interior lighting in vehicles and public transport systems. Adhesives here must endure vibrations, temperature fluctuations, and exposure to UV rays without degrading. For B2B buyers in Africa and Europe, sourcing adhesives certified for automotive standards and capable of withstanding harsh operational conditions is essential for ensuring safety and durability in vehicle interiors.

In Architectural & Construction projects, adhesives are used to fix LED strips in coves, under cabinets, and along staircases to provide energy-efficient and visually appealing lighting solutions. The adhesive must be strong yet removable without damaging surfaces such as wood, drywall, or metal. European and Middle Eastern buyers should focus on adhesives that comply with building codes and environmental regulations, while also offering ease of installation for contractors and end-users.

Finally, in the Electronics & Manufacturing sector, adhesives secure LED strips used as status indicators on machinery and control panels. These applications require adhesives with excellent heat resistance and compatibility with industrial-grade materials like metals and plastics. Buyers from industrial hubs in South America and Europe should prioritize sourcing adhesives that maintain adhesion under high temperatures and exposure to oils or solvents to ensure operational reliability and safety.

Related Video: How to Cut and Connect LED Light Strips.

Strategic Material Selection Guide for adhesive for led light strips

When selecting adhesives for LED light strips, understanding the material composition is critical to ensure durability, performance, and compatibility with diverse installation environments. This analysis covers four common adhesive materials used in LED strip lighting applications, focusing on their technical properties, practical pros and cons, and strategic considerations for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe.

Acrylic-Based Adhesives

Key Properties: Acrylic adhesives offer excellent temperature resistance (typically -40°C to 120°C), strong bonding to a variety of substrates including metals and plastics, and good UV and corrosion resistance. They maintain adhesion under moderate humidity and are generally pressure-sensitive.

Pros & Cons: Acrylic adhesives provide durable bonds with good aging properties, making them suitable for long-term indoor and outdoor LED strip installations. However, they tend to be more expensive than basic adhesives and may require precise surface preparation. Manufacturing complexity is moderate due to curing requirements.

Impact on Application: Acrylic adhesives are ideal for mounting LED strips on metal frames, glass, and painted surfaces commonly found in architectural lighting. Their UV resistance makes them suitable for outdoor or high-exposure environments, such as commercial signage in the Middle East or coastal regions of Africa.

International B2B Considerations: Buyers in regions like Nigeria and Saudi Arabia should verify compliance with ASTM D1000 or DIN 16941 standards for acrylic adhesives, ensuring reliability under local climate stresses such as heat and dust. European markets often require REACH compliance and RoHS certification, which acrylic adhesives typically meet.

Silicone-Based Adhesives

Key Properties: Silicone adhesives excel in flexibility and extreme temperature tolerance (-60°C to 250°C). They offer excellent resistance to moisture, chemicals, and UV radiation, making them highly durable in harsh environments.

Pros & Cons: Silicone adhesives are highly durable and maintain elasticity, preventing bond failure due to thermal expansion or vibration. However, they generally have lower initial tack and adhesion strength compared to acrylics, and their cost is relatively high. Application may require specialized equipment or primers.

Impact on Application: These adhesives are preferred for waterproof or outdoor LED strips, especially in humid or chemically aggressive environments such as industrial zones or coastal areas in South America and the Middle East. Their flexibility also suits installations on curved or uneven surfaces.

International B2B Considerations: For buyers in Saudi Arabia or coastal African countries, silicone adhesives offer superior performance in extreme heat and humidity. Compliance with JIS K 6850 (Japanese Industrial Standard for silicone adhesives) or ASTM C920 (for sealants) is advisable. Availability and cost may vary, so sourcing from regional distributors with proven quality is recommended.

Polyurethane-Based Adhesives

Key Properties: Polyurethane adhesives provide strong, flexible bonds with excellent abrasion and impact resistance. They perform well across a broad temperature range (-40°C to 90°C) and resist moisture and many solvents.

Pros & Cons: These adhesives are cost-effective and suitable for high-stress applications where mechanical durability is critical. However, they can yellow over time and are less UV resistant than acrylics or silicones. Manufacturing processes may require moisture control during curing.

Impact on Application: Polyurethane adhesives are suitable for indoor LED strip installations subject to mechanical stress or vibration, such as automotive lighting or retail fixtures in South America and Europe. Their moderate UV resistance limits outdoor use unless protected.

International B2B Considerations: Buyers should ensure that polyurethane adhesives meet ASTM D3498 or DIN EN 1465 standards for bonding performance. In regions with variable climates like Europe or South America, polyurethane adhesives offer a balance of cost and durability for indoor applications.

Hot Melt Adhesives (Thermoplastics)

Key Properties: Hot melt adhesives solidify quickly upon cooling and provide immediate bonding. They have moderate temperature resistance (up to 80°C) and good adhesion to plastics and metals but limited chemical and UV resistance.

Pros & Cons: Hot melts are easy to apply with automated equipment, enabling fast production cycles and lower labor costs. However, their lower heat resistance and potential for bond degradation under prolonged UV exposure limit their use in demanding environments.

Impact on Application: These adhesives are often used in mass production of LED strip assemblies where speed and cost efficiency are priorities, such as consumer electronics or indoor decorative lighting in Europe and South America.

International B2B Considerations: For buyers in Nigeria or the Middle East, hot melt adhesives may be less suitable for outdoor or high-temperature applications. Compliance with ASTM D5167 or DIN 16941 ensures basic quality, but buyers should weigh the trade-offs between cost and environmental resilience.

| Material | Typical Use Case for adhesive for led light strips | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic-Based | Outdoor and indoor architectural lighting, metal and glass mounts | Excellent UV and corrosion resistance | Higher cost, requires surface prep | High |

| Silicone-Based | Waterproof, outdoor, and industrial LED strips on curved surfaces | Extreme temperature tolerance and flexibility | Lower initial tack, higher cost | High |

| Polyurethane-Based | Indoor applications with mechanical stress, automotive, retail | Strong, flexible bonds with abrasion resistance | Less UV resistant, potential yellowing | Medium |

| Hot Melt Adhesives | High-volume indoor LED strip assembly, consumer electronics | Fast curing, cost-effective for mass production | Limited heat and UV resistance | Low |

This guide equips international B2B buyers with critical insights into adhesive material selection tailored to their regional conditions and application needs, enabling informed procurement decisions that optimize LED strip installation performance and longevity.

In-depth Look: Manufacturing Processes and Quality Assurance for adhesive for led light strips

Overview of Manufacturing Processes for Adhesive Used in LED Light Strips

The production of adhesives specifically designed for LED light strips involves a series of carefully controlled stages to ensure the final product meets stringent performance and durability requirements. These adhesives must provide strong bonding, flexibility, heat resistance, and longevity under various environmental conditions.

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials, which typically include polymers (such as acrylics or silicones), tackifiers, plasticizers, and curing agents. The quality of these base materials directly influences adhesive performance, so suppliers often source high-purity chemicals that meet industry standards. For heat-sensitive LED applications, materials are chosen for thermal stability and non-corrosiveness.

2. Forming and Mixing

The raw materials undergo precise mixing and compounding using high-shear mixers or twin-screw extruders to achieve a uniform adhesive matrix. Additives like UV stabilizers and anti-oxidants may be incorporated to enhance durability. For pressure-sensitive adhesives (PSAs), the mixture is often processed into a viscous liquid or semi-solid state suitable for coating.

3. Coating and Assembly

The adhesive is then applied onto carrier substrates or release liners through coating techniques such as slot-die, gravure, or roll coating. Uniform thickness and consistent coverage are critical to ensure reliable bonding of LED strips to various surfaces. This stage may also include lamination with protective films or backing materials that improve handling and application.

4. Curing and Finishing

Depending on the adhesive type, curing is achieved via thermal, UV, or moisture processes to solidify the adhesive layer and activate bonding properties. Post-curing, the adhesive rolls are slit into specified widths compatible with LED strip dimensions. Finishing processes include quality inspections, packaging in moisture-proof materials, and labeling according to customer or regulatory requirements.

Key Quality Assurance Measures in Adhesive Production

For B2B buyers, understanding the rigorous quality control (QC) frameworks manufacturers employ is essential to ensure product reliability and compliance with international standards.

International and Industry-Specific Standards

- ISO 9001: This global standard for quality management systems is foundational. Adhesive manufacturers certified under ISO 9001 demonstrate consistent process control and continuous improvement, critical for dependable product quality.

- CE Marking: For adhesives sold in European markets, CE certification ensures compliance with EU safety, health, and environmental protection legislation.

- RoHS and REACH Compliance: These regulations restrict hazardous substances, important for buyers prioritizing environmental safety and regulatory adherence.

- Industry-Specific Certifications: Depending on the application, adhesives may also require certifications such as UL (Underwriters Laboratories) for electrical safety or API (American Petroleum Institute) standards if used in industrial LED applications.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are rigorously tested upon receipt. This includes verifying chemical composition, viscosity, and contamination levels.

- In-Process Quality Control (IPQC): Throughout mixing, coating, and curing, continuous monitoring ensures parameters like temperature, coating thickness, and curing time meet specifications. Automated sensors and manual inspections are common.

- Final Quality Control (FQC): Finished adhesive products undergo comprehensive testing before shipment. This includes adhesion strength tests, peel tests, aging simulations, and visual inspections for defects such as bubbles or uneven coating.

Common Testing Methods

- Peel Adhesion Test: Measures the force required to peel the adhesive from a substrate, ensuring it meets bonding strength requirements for LED strips.

- Tack and Shear Tests: Evaluate the initial stickiness and resistance to shear forces, important for applications exposed to vibrations or movement.

- Environmental Aging Tests: Simulate exposure to heat, humidity, and UV light to predict long-term performance.

- Thermal Stability Analysis: Assesses adhesive performance at elevated temperatures typical in LED applications.

- Chemical Resistance Tests: Ensures adhesives withstand exposure to cleaning agents or environmental contaminants.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers from Africa, South America, the Middle East, and Europe, establishing trust in supplier QC is paramount due to geographic and regulatory differences.

1. Factory Audits and Site Visits

Conducting or commissioning on-site audits allows buyers to verify manufacturing processes, equipment calibration, and employee training. Audits should assess compliance with ISO 9001 and other relevant certifications, production traceability, and hygiene standards.

2. Review of Quality Documentation

Request detailed QC documentation including raw material certificates of analysis (CoA), batch production records, and test reports. These documents provide transparency on adherence to specifications and traceability for each adhesive batch.

3. Third-Party Inspections and Testing

Engaging independent inspection agencies to perform pre-shipment inspections or sample testing in accredited laboratories can provide unbiased validation of product quality. This is especially important for buyers in regions with less stringent local regulatory enforcement.

4. Sampling and Pilot Testing

Before large-scale procurement, buyers should insist on sample deliveries for in-house testing under local environmental conditions and application requirements. This step helps verify adhesive performance on intended LED strip materials and substrates.

Navigating Quality Assurance Nuances for International Markets

Buyers from diverse regions face unique challenges and considerations in QC for adhesives used in LED lighting:

-

Africa & Middle East (e.g., Nigeria, Saudi Arabia): High temperatures and humidity necessitate adhesives with superior thermal and moisture resistance. Buyers should prioritize suppliers with proven environmental aging test results. Additionally, import regulations may require CE marking and compliance with local standards.

-

South America: Variable climate conditions and infrastructure constraints highlight the need for adhesives with robust adhesion on diverse surfaces. Documentation supporting RoHS and REACH compliance is increasingly demanded by multinational projects.

-

Europe: Stringent environmental and safety regulations require suppliers to maintain comprehensive certifications (ISO, CE, UL). European buyers often expect advanced traceability systems and full transparency in QC processes.

Summary and Actionable Insights for B2B Buyers

- Demand full visibility into the manufacturing stages, from raw material sourcing to final packaging, to ensure adhesive quality aligns with LED strip application needs.

- Verify supplier certifications such as ISO 9001, CE, RoHS, and industry-specific standards relevant to your market.

- Implement a robust supplier evaluation strategy combining factory audits, quality documentation review, and independent third-party testing.

- Conduct application-specific testing of adhesive samples under local environmental conditions to confirm suitability.

- Consider regional regulatory nuances and ensure supplier compliance to avoid customs delays and product rejections.

- Leverage mounting alternatives and complementary products (e.g., mounting clips, aluminum channels) where adhesive performance might be challenged by environmental or surface factors.

By thoroughly understanding the manufacturing and quality assurance processes behind adhesives for LED light strips, international B2B buyers can make informed procurement decisions that reduce risk, ensure compliance, and support long-term project success.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for adhesive for led light strips Sourcing

Understanding the cost and pricing dynamics of adhesives for LED light strips is essential for international B2B buyers aiming to optimize procurement while ensuring product reliability and performance. This analysis breaks down key cost components, pricing influencers, and practical buyer strategies tailored to markets such as Africa, South America, the Middle East, and Europe.

Key Cost Components in Adhesive Production

-

Raw Materials

The primary materials include specialized polymers, tackifiers, and additives designed for strong bonding, flexibility, and resistance to heat and moisture. High-quality materials, especially those certified for safety and environmental compliance (e.g., RoHS, REACH), command a premium but reduce long-term risks. -

Labor Costs

Labor expenses vary significantly by country and impact the overall unit cost. Regions with skilled labor for adhesive formulation and quality control can offer competitive pricing without compromising quality.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead

This includes energy, plant maintenance, and indirect labor. Adhesive production requires precise temperature and mixing controls, which add to overhead. -

Tooling and Equipment

Costs for molds, mixing tanks, and dispensing machinery contribute upfront capital expenditures amortized over production runs. Custom adhesive formulations may require specialized tooling. -

Quality Control (QC) and Testing

Rigorous QC ensures consistent adhesion strength, curing time, and durability, vital for LED strip applications where failure can cause costly rework. QC costs include lab testing and batch inspections. -

Logistics and Distribution

Shipping adhesives involves considerations for hazardous material handling and packaging to prevent contamination or degradation. Logistics costs can be significant for international buyers due to customs, freight, and storage. -

Supplier Margin

Margins vary by supplier scale and market positioning. Premium brands with certifications and proven performance charge higher margins, justified by lower failure rates and better support.

Influencers on Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically reduce per-unit cost due to economies of scale. Buyers in emerging markets should negotiate MOQs aligned with demand to avoid overstocking and tying up capital. -

Customization and Specifications

Adhesives tailored for specific LED strip substrates, waterproofing needs, or temperature ranges incur higher costs. Standard formulations are more affordable but may not suit all applications. -

Material Quality and Certifications

Adhesives with certifications for fire retardancy, UV resistance, or eco-friendliness attract higher prices but reduce regulatory and warranty risks. -

Supplier Location and Capabilities

Proximity to manufacturing hubs (e.g., China, Europe) influences freight costs and lead times. Suppliers with integrated R&D and quality assurance offer better value despite potentially higher prices. -

Incoterms and Delivery Terms

Pricing varies depending on terms like FOB, CIF, or DDP, which dictate responsibility for shipping, insurance, and customs clearance. Buyers must factor these into landed cost calculations.

Strategic Tips for International B2B Buyers

-

Negotiate Volume Discounts and Flexible MOQs

Engage suppliers early to discuss scalable MOQs and incremental pricing tiers. This flexibility is critical for markets with fluctuating demand like Nigeria or Saudi Arabia. -

Assess Total Cost of Ownership (TCO)

Beyond unit price, consider installation efficiency, adhesive longevity, and failure rates. High-quality adhesives may reduce labor and replacement costs, improving overall ROI. -

Request Samples and Certification Documentation

Validate adhesive performance under local environmental conditions, such as high humidity in the Middle East or temperature swings in Europe. -

Optimize Logistics and Customs Planning

Work with freight forwarders familiar with hazardous goods regulations and local import duties to minimize delays and additional costs. -

Leverage Local Partnerships

Collaborate with regional distributors or agents to benefit from local market knowledge, faster response times, and potentially better pricing. -

Monitor Market Trends and Currency Fluctuations

Exchange rate volatility can impact landed cost. Consider forward contracts or multi-supplier strategies to mitigate risks.

Indicative Pricing Disclaimer

Prices for adhesives suitable for LED light strips vary widely depending on formulation, volume, and delivery terms. As a rough benchmark, industrial-grade adhesives may range from $1 to $5 per meter of LED strip coverage in bulk orders. Buyers should request detailed quotations and perform cost comparisons tailored to their specific project requirements and regional market conditions.

This comprehensive cost and pricing framework equips B2B buyers with the insights needed to navigate supplier negotiations, optimize procurement costs, and ensure reliable adhesive performance for LED strip installations across diverse international markets.

Spotlight on Potential adhesive for led light strips Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘adhesive for led light strips’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for adhesive for led light strips

Critical Technical Properties of Adhesive for LED Light Strips

When sourcing adhesives for LED light strips, understanding key technical specifications is essential to ensure product performance, durability, and compatibility with various installation environments.

-

Adhesive Material Grade

This refers to the chemical composition and quality level of the adhesive, commonly silicone-based, acrylic, or rubber-based. High-grade adhesives offer superior bonding strength and resistance to temperature fluctuations, UV exposure, and humidity. For B2B buyers in regions with harsh climates such as the Middle East or tropical Africa, opting for a material grade that withstands environmental stress ensures longevity and reduces maintenance costs. -

Bonding Strength (Shear and Peel Strength)

Bonding strength measures the adhesive’s ability to hold the LED strip firmly on different surfaces, often quantified in Newtons per square centimeter (N/cm²). Shear strength relates to resistance against sliding forces, while peel strength defines resistance against peeling off. Strong bonding is critical for installations on uneven or textured surfaces common in industrial or commercial settings in South America and Europe. -

Temperature Tolerance Range

Adhesives must perform reliably within specified temperature ranges, typically from -20°C to +80°C or higher. This property is crucial for buyers in regions with extreme temperature variations, such as Saudi Arabia’s hot climate or colder European winters. Temperature tolerance prevents adhesive failure, ensuring consistent illumination and safety. -

Water and Humidity Resistance

The ability to resist moisture ingress is vital for LED strips used in bathrooms, kitchens, outdoor signage, or humid environments. Waterproof adhesives or those rated with IP65 or above provide protection against water and condensation, which is a common requirement in coastal areas of Africa and South America. -

Curing Time and Application Conditions

This defines how quickly the adhesive sets and how it should be applied (e.g., room temperature curing, UV curing). For large-scale installations or projects with tight deadlines, adhesives with fast curing times improve efficiency and reduce labor costs. Understanding application conditions helps buyers plan installation logistics and ensure quality control. -

Surface Compatibility and Residue-Free Removal

Adhesives vary in their compatibility with substrates like aluminum, plastic, glass, or painted surfaces. Some adhesives allow residue-free removal, which is important for temporary installations or leased properties. Buyers targeting commercial real estate or retail sectors in Europe and the Middle East should prioritize adhesives that combine strong adhesion with clean removal options.

Common Trade Terminology for Adhesive Procurement in LED Strip Projects

Navigating the procurement process for adhesives involves familiarity with several industry-standard terms that facilitate clear communication between buyers and suppliers.

-

OEM (Original Equipment Manufacturer)

This term refers to suppliers or manufacturers who produce adhesives that can be branded and sold by other companies. International buyers often engage OEMs to customize adhesives according to their specific requirements, ensuring product differentiation and cost control. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of adhesive units a supplier is willing to sell. Understanding MOQ is vital for buyers from emerging markets such as Nigeria or smaller enterprises in South America, as it impacts inventory management, upfront investment, and cash flow. -

RFQ (Request for Quotation)

An RFQ is a formal document sent by buyers to suppliers asking for price quotes based on specified adhesive properties and order quantities. Clear and detailed RFQs help expedite supplier responses and improve the accuracy of bids, which is crucial for competitive sourcing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities and risks between buyers and sellers during shipping. Common terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). B2B buyers must understand Incoterms to negotiate favorable delivery terms, especially when importing adhesives from global manufacturers to ports in Africa, the Middle East, or Europe. -

Lead Time

Lead time is the period from order placement to delivery. For project planners and supply chain managers, knowing the lead time helps coordinate installation schedules and avoid costly delays, particularly when adhesives need to meet seasonal demand fluctuations. -

Technical Data Sheet (TDS)

A TDS provides detailed information on the adhesive’s chemical properties, application methods, safety precautions, and performance metrics. Requesting and reviewing TDS documents ensures buyers select adhesives that meet both technical and regulatory standards relevant to their markets.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and secure high-quality adhesives that enhance the performance and durability of LED light strip installations across diverse environments.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the adhesive for led light strips Sector

Market Overview & Key Trends

The global market for adhesives used in LED light strip applications is experiencing robust growth, driven by expanding demand in commercial, residential, and industrial lighting sectors. International B2B buyers, especially from emerging markets like Nigeria and Saudi Arabia, are increasingly investing in LED lighting solutions for energy efficiency and modern aesthetics. This trend fuels demand for high-performance adhesives that ensure reliable mounting on diverse surfaces, including metals, plastics, and wood.

Key market drivers include the rapid urbanization and infrastructure development in Africa and the Middle East, alongside increasing adoption of smart home technologies in Europe and South America. These regions seek adhesives that provide strong bonding with heat resistance and moisture durability, critical for LED strips used in both indoor and outdoor environments. Additionally, manufacturers are innovating with specialized adhesives tailored for flexible, waterproof, and UV-resistant LED strips, addressing the unique challenges posed by different climates and installation conditions.

From a sourcing perspective, international buyers are prioritizing suppliers who offer certifications for quality and compliance with regional standards (e.g., REACH in Europe, GCC regulations in the Middle East). Digital sourcing platforms and virtual trade fairs have become essential channels for cross-border procurement, enabling buyers to evaluate product samples and negotiate terms efficiently. Furthermore, modular adhesive solutions such as mounting clips and aluminum channels are gaining traction as complementary products, offering enhanced installation flexibility and durability.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical factor shaping procurement decisions in the adhesive sector for LED light strips. Adhesives traditionally contain volatile organic compounds (VOCs) and synthetic chemicals that pose environmental and health risks. Progressive suppliers are responding by developing low-VOC, solvent-free, and bio-based adhesive formulations that reduce carbon footprint and improve indoor air quality.

For B2B buyers, especially in environmentally conscious markets such as Europe, sourcing adhesives with recognized eco-certifications (e.g., GREENGUARD, UL ECOLOGO) is increasingly important. These certifications validate the environmental performance and safety of products, facilitating compliance with green building standards like LEED and BREEAM. Ethical sourcing also encompasses transparent supply chains, ensuring raw materials are responsibly procured without exploitation or environmental degradation.

Buyers from regions like South America and Africa can benefit from partnering with suppliers who demonstrate commitment to circular economy principles, including adhesive recyclability and minimal packaging waste. This not only aligns with global sustainability goals but also enhances brand reputation and meets the growing demand from end-users for greener lighting solutions.

Evolution and Historical Context

The adhesive technology for LED light strips has evolved significantly alongside the rise of LED lighting itself. Initially, LED strips relied on basic pressure-sensitive adhesive backings that offered limited durability and adhesion strength. As LED applications diversified—extending from simple accent lighting to architectural and automotive uses—there was a clear need for adhesives that could withstand environmental stresses such as heat, humidity, and vibration.

Over the past decade, advancements have focused on high-performance acrylic adhesives, silicone-based adhesives, and hybrid formulations that combine flexibility with robust bonding. The integration of mounting accessories like aluminum channels and clips further transformed installation practices, allowing for more secure and professional finishes.

This evolution reflects the broader trend of the LED lighting industry moving towards more sophisticated, durable, and user-friendly products, enabling B2B buyers across continents to deploy LED solutions in increasingly complex and demanding environments.

Related Video: Understanding the Global Trade Item Number (GTIN)

Frequently Asked Questions (FAQs) for B2B Buyers of adhesive for led light strips

-

How can I effectively vet suppliers of adhesive for LED light strips in international markets like Nigeria or Saudi Arabia?

Vet suppliers by verifying their certifications (ISO, RoHS, REACH) and requesting product samples to assess adhesive strength and durability. Check their export history and client references, especially within your region, to confirm reliability and compliance with local regulations. Visiting trade fairs or conducting virtual audits can provide deeper insights into their manufacturing processes. Establish clear communication channels to evaluate responsiveness and technical support capabilities before committing. -

Is it possible to customize adhesive formulations or packaging when sourcing from overseas suppliers?

Yes, many manufacturers offer customization options for adhesive properties such as curing time, temperature resistance, and tackiness to suit specific LED strip applications. Packaging can also be tailored, including private labeling and bulk formats, which is beneficial for branding and logistics. Always negotiate customization terms upfront, including minimum order quantities (MOQs) and lead times, to ensure feasibility and cost-effectiveness for your market. -

What are typical MOQs and lead times when ordering adhesive for LED strips from international suppliers?

MOQs vary widely depending on the supplier and adhesive type but generally range from a few hundred to several thousand units. Lead times typically span 3 to 8 weeks, factoring in production, quality checks, and shipping. For buyers in Africa, South America, or the Middle East, additional time should be considered for customs clearance. Early planning and clear communication with suppliers can help synchronize production schedules with your project timelines. -

Which payment terms are standard for international B2B transactions of LED strip adhesives, and how can buyers mitigate payment risks?

Common payment terms include 30% upfront deposit with balance paid before shipment or upon receipt of shipping documents. Letters of Credit (LC) and escrow services provide additional security for both parties. Buyers should perform due diligence on suppliers’ financial stability and use trade assurance platforms where possible. Negotiating payment terms aligned with shipment milestones can also minimize risk and improve cash flow management.

-

What quality assurance measures and certifications should B2B buyers require for adhesives used in LED strip installations?

Insist on adhesives that comply with international standards such as ISO 9001 for quality management and environmental certifications like RoHS to ensure non-toxicity. UL or CE marks indicate safety compliance, crucial for markets in Europe and the Middle East. Request batch-specific test reports covering adhesion strength, aging resistance, and waterproof capabilities. Third-party lab testing and factory audits further validate product consistency and reliability. -

How should international buyers handle logistics and shipping challenges for adhesive products?

Select suppliers experienced in exporting chemical adhesives with proper classification under hazardous materials regulations. Consolidate shipments to optimize freight costs and choose reliable freight forwarders familiar with your destination’s import rules. Factor in customs duties, import taxes, and potential delays due to inspections. Utilizing Incoterms like FOB or CIF clearly defines responsibilities and helps avoid misunderstandings during transit. -

What strategies can buyers employ to resolve disputes related to adhesive quality or shipment delays?

Establish clear contract terms specifying product specifications, delivery schedules, and penalty clauses for non-compliance. Maintain detailed records of communications and inspections. Engage in early negotiation and mediation to resolve issues amicably. If unresolved, leverage international arbitration bodies or trade dispute resolution mechanisms relevant to the supplier’s jurisdiction. Building strong supplier relationships and setting realistic expectations upfront reduces conflict risks. -

Are there specific considerations for sourcing adhesives suitable for harsh climates found in regions like Africa or the Middle East?

Yes, adhesives must withstand extreme temperatures, high humidity, and UV exposure common in these regions. Buyers should request formulations with enhanced heat resistance, waterproof properties, and UV stabilization. Certifications or testing results demonstrating performance under such conditions are essential. Collaborate with suppliers to identify or develop adhesives tailored to local environmental challenges to ensure longevity and reduce maintenance costs in end applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for adhesive for led light strips

Strategic sourcing of adhesives for LED light strips presents a unique opportunity for international B2B buyers to enhance product quality, installation reliability, and customer satisfaction. Key takeaways emphasize the importance of selecting adhesives that balance strong bonding with surface compatibility, environmental resistance, and ease of application. Buyers should prioritize suppliers offering advanced adhesive technologies such as high-performance double-sided tapes and specialized waterproof adhesives, which cater to diverse installation conditions found across Africa, South America, the Middle East, and Europe.

Effective sourcing strategies include:

- Thorough supplier vetting to ensure product consistency and certification compliance.

- Evaluating adhesive performance under local climate challenges, including humidity and temperature fluctuations.

- Leveraging modular solutions like mounting clips and channels to complement adhesive use and improve installation outcomes.

- Negotiating flexible supply agreements that support scalable demand and regional distribution.

Looking ahead, the adhesive market for LED strip lighting is poised for innovation driven by sustainability and smart installation needs. Buyers in emerging and established markets alike should engage proactively with manufacturers to access cutting-edge products and tailor solutions that align with evolving project complexities. By embedding strategic sourcing principles into procurement processes, businesses can secure competitive advantages, reduce installation failures, and accelerate growth in the dynamic LED lighting sector.

Take action now: build partnerships with trusted adhesive suppliers, invest in product trials, and explore integrated mounting systems to future-proof your LED lighting solutions.