Introduction: Navigating the Global Market for led strip wiring

The wiring of LED strips forms the backbone of any successful lighting solution, directly impacting performance, safety, and longevity. For international B2B buyers operating across Africa, South America, the Middle East, and Europe—including fast-growing markets such as Mexico and Brazil—mastering the complexities of LED strip wiring is essential to sourcing products that meet stringent quality and regulatory standards. Whether for commercial installations, industrial applications, or innovative architectural projects, the right wiring approach ensures optimal energy efficiency, ease of installation, and reliable operation under diverse environmental conditions.

This comprehensive guide delivers an authoritative resource tailored to the needs of global buyers seeking to navigate the multifaceted LED strip wiring market. It explores a wide array of wiring types and configurations, detailing material selections that balance durability with cost-effectiveness. The guide also delves into manufacturing processes and quality control measures that guarantee product consistency and compliance with international standards. Additionally, it provides strategic insights on evaluating suppliers, analyzing cost structures, and understanding regional market dynamics that influence availability and pricing.

Key features of the guide include:

- In-depth coverage of wiring types and technical specifications relevant to various industrial and commercial applications

- Material and component selection criteria to optimize performance and lifespan

- Quality assurance protocols ensuring safety and durability

- Profiles of reputable global suppliers and manufacturers with proven track records

- Cost analysis frameworks to support budgeting and negotiations

- Market trend evaluations highlighting opportunities and risks in target regions

- Frequently asked questions addressing common buyer concerns and challenges

Armed with this knowledge, B2B buyers can confidently streamline procurement processes, mitigate risks, and secure LED strip wiring solutions that align with their operational goals and regional market requirements.

Understanding led strip wiring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Ended Wiring | Power supplied from one end only; simple two-wire connection | Retail lighting, decorative installations | + Cost-effective and easy to install – Limited length due to voltage drop |

| Double-Ended Wiring | Power supplied from both ends; reduces voltage drop | Large-scale architectural lighting, long runs | + Uniform brightness over long distances – Higher installation complexity and cost |

| Parallel Wiring | Multiple strips wired in parallel to a common power source | Industrial displays, commercial lighting systems | + Maintains consistent voltage across strips – Requires robust power supply and wiring |

| Series Wiring | LED strips wired end-to-end in series | Custom length lighting, low-power applications | + Simplifies wiring for short runs – Voltage drop limits length and brightness consistency |

| Addressable LED Wiring | Individual LED control with multi-wire data and power lines | Dynamic signage, smart lighting systems | + Enables advanced lighting effects – Higher cost and technical complexity |

Single-Ended Wiring

This is the most basic wiring type where power enters the LED strip from one end only. It is suitable for short runs up to 5 meters, commonly used in retail displays and decorative lighting. B2B buyers should consider that longer runs may suffer from voltage drop causing dimming towards the far end. This wiring is cost-effective and straightforward but limits scalability for large projects.

Double-Ended Wiring

Double-ended wiring supplies power at both ends of the LED strip, effectively minimizing voltage drop and ensuring consistent brightness across longer lengths. This type is ideal for architectural and commercial projects requiring runs exceeding 5 meters. Buyers must factor in higher installation complexity and costs due to additional wiring and connectors, but the improved performance often justifies the investment.

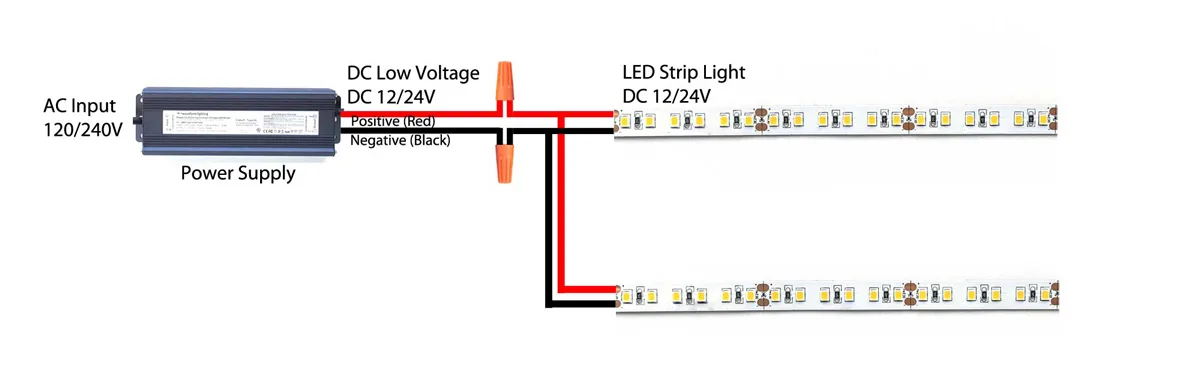

Parallel Wiring

Parallel wiring connects multiple LED strips to a single power source, maintaining voltage stability across all strips. This approach is common in industrial and large commercial lighting where multiple strips operate simultaneously. B2B buyers should ensure the power supply and wiring gauge are adequately rated to handle the total current load, which can increase upfront infrastructure costs.

Series Wiring

In series wiring, LED strips are connected end-to-end, allowing a continuous circuit. This method is typically reserved for short, low-power applications. It simplifies wiring but is prone to voltage drop and inconsistent brightness over longer distances. Buyers focusing on cost-efficiency for small-scale projects may find this suitable but should avoid it for extensive installations.

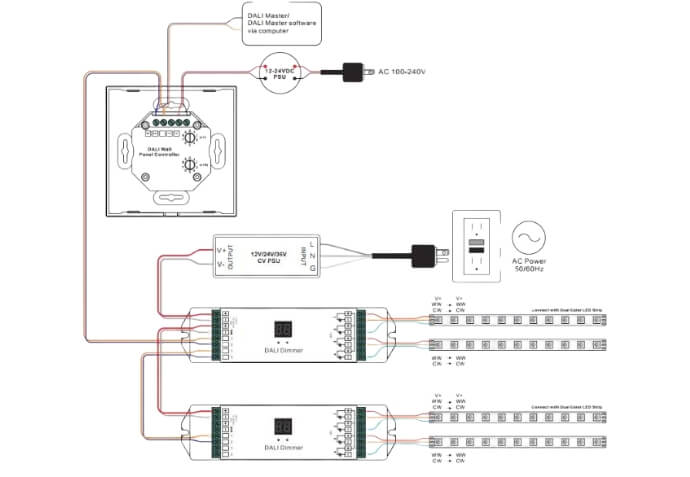

Addressable LED Wiring

This advanced wiring type supports individually controllable LEDs via multi-wire data and power lines, enabling dynamic color changes and effects. It is widely used in smart lighting, digital signage, and entertainment industries. B2B buyers must consider the higher costs, need for compatible controllers, and technical expertise required for installation and maintenance. However, it offers unmatched flexibility and differentiation for premium applications.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led strip wiring

| Industry/Sector | Specific Application of led strip wiring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior and exterior vehicle lighting integration | Enhances vehicle aesthetics and safety, supports brand differentiation | Compliance with automotive standards, durability under vibration and temperature extremes, flexible wiring for complex geometries |

| Retail & Commercial Spaces | Ambient and accent lighting in stores and showrooms | Improves customer experience, highlights products, reduces energy costs | Consistent color rendering, easy installation and maintenance, compatibility with smart control systems |

| Hospitality & Entertainment | Mood and decorative lighting in hotels, restaurants, and event venues | Creates immersive environments, drives customer satisfaction and repeat business | Waterproof and dustproof ratings, customizable wiring lengths, compatibility with dimmers and controllers |

| Industrial & Warehouse Facilities | Task and safety lighting in workspaces and storage areas | Increases operational efficiency, enhances worker safety, reduces downtime | High durability wiring, resistance to dust and moisture, long service life, ease of replacement |

| Residential & Smart Homes | Integrated lighting for kitchens, living rooms, and outdoor spaces | Adds value through modern aesthetics, energy savings, and smart home integration | Low-voltage wiring standards, compatibility with home automation systems, ease of retrofit installation |

Automotive Manufacturing

In automotive production, led strip wiring is essential for integrating both interior ambient lighting and exterior accent lights. These wiring systems must endure extreme temperature fluctuations, vibrations, and exposure to moisture. For B2B buyers in regions like South America and Europe, sourcing wiring that meets stringent automotive quality and safety standards is critical to ensuring reliability and compliance. Flexible wiring solutions enable manufacturers to fit lighting into complex vehicle designs, enhancing both aesthetic appeal and functional visibility.

Retail & Commercial Spaces

Led strip wiring is widely used to power ambient and accent lighting in retail environments, such as stores and showrooms, where lighting plays a pivotal role in product presentation and customer engagement. Buyers from Africa and the Middle East should prioritize wiring that supports consistent color rendering and easy integration with smart lighting controls to create dynamic atmospheres. Additionally, wiring durability and ease of maintenance reduce operational disruptions and long-term costs.

Hospitality & Entertainment

Hotels, restaurants, and event venues utilize led strip wiring to deliver mood and decorative lighting that enhances guest experience. In these sectors, waterproof and dustproof wiring solutions are vital, especially in areas exposed to spills or outdoor conditions common in Middle Eastern and African markets. Customizable wiring lengths and compatibility with dimming and color control systems allow businesses to tailor lighting effects for different events, boosting customer satisfaction and repeat visits.

Industrial & Warehouse Facilities

Led strip wiring in industrial settings focuses on task illumination and safety lighting, which are crucial for operational efficiency and accident prevention. Buyers in Europe and South America should seek wiring products designed for harsh environments—resistant to dust, moisture, and physical wear. Long service life and straightforward replacement processes minimize downtime, a key factor in high-throughput facilities where lighting reliability directly impacts productivity.

Residential & Smart Homes

In residential markets, led strip wiring supports integrated lighting solutions for kitchens, living areas, and outdoor spaces, increasingly linked to smart home systems. For B2B buyers in Mexico and Europe, sourcing low-voltage wiring compatible with automation platforms is essential to meet consumer demand for convenience and energy efficiency. Wiring that facilitates retrofit installations without major renovations offers additional value in mature housing markets.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for led strip wiring

When selecting materials for LED strip wiring, international B2B buyers must carefully consider the performance characteristics, cost implications, and regional compliance standards that influence product suitability across diverse markets such as Africa, South America, the Middle East, and Europe. The choice of wiring material directly impacts durability, safety, and installation efficiency, all critical factors for large-scale procurement and integration in various industrial and commercial applications.

Copper Conductors

Copper is the most widely used conductor material for LED strip wiring due to its excellent electrical conductivity and thermal performance. It typically features a high temperature rating (up to 105°C) and strong resistance to corrosion when properly insulated. Copper wiring offers superior flexibility and low electrical resistance, which minimizes voltage drop—an essential consideration for long LED strip runs.

Pros:

– High electrical and thermal conductivity ensures efficient power delivery.

– Good mechanical strength and flexibility facilitate easier installation and handling.

– Widely accepted and compliant with international standards such as ASTM B170, DIN EN 60228, and IEC 60228.

Cons:

– Copper is relatively more expensive than aluminum alternatives.

– Susceptible to theft in some regions due to its scrap value, which can affect supply chain security.

– Requires quality insulation to prevent oxidation in humid or corrosive environments.

Application Impact:

Copper wiring is ideal for indoor and outdoor LED strip installations where reliability and performance are paramount. Its compatibility with standard connectors and accessories makes it a preferred choice for markets in Europe and the Middle East, where regulatory standards are stringent.

Considerations for International Buyers:

Buyers in Africa and South America should verify the copper purity and insulation quality to ensure durability in harsh climates. Compliance with local electrical codes and certifications (e.g., IEC, UL) is critical. Bulk purchasing agreements can mitigate higher upfront costs.

Aluminum Conductors

Aluminum wiring is gaining traction as a lightweight, cost-effective alternative to copper, especially for large-scale LED strip installations requiring longer cable runs. Aluminum has lower electrical conductivity than copper (approximately 61% of copper’s conductivity), which necessitates larger cross-sectional areas to achieve similar performance.

Pros:

– Lower material cost and lighter weight reduce transportation and handling expenses.

– Good corrosion resistance when properly coated or anodized.

– Suitable for applications where weight savings are critical.

Cons:

– Larger gauge wires are needed to compensate for lower conductivity, potentially increasing installation complexity.

– More prone to mechanical fatigue and breakage if not handled carefully.

– Less flexible compared to copper, complicating installation in tight spaces.

Application Impact:

Aluminum wiring is suitable for budget-conscious projects with less demanding flexibility requirements, such as fixed outdoor LED strip lighting in commercial or industrial zones. It is less common in automotive or high-performance applications due to conductivity limitations.

Considerations for International Buyers:

In regions like Mexico and Brazil, aluminum wiring can offer cost advantages but requires strict adherence to ASTM B211 and ISO standards to ensure quality. Buyers should confirm supplier certifications and test reports to avoid substandard products that could compromise safety and longevity.

Tinned Copper Wiring

Tinned copper wiring involves copper conductors coated with a thin layer of tin, enhancing corrosion resistance and solderability. This material is particularly beneficial in environments with high humidity, salt spray, or chemical exposure.

Pros:

– Excellent corrosion resistance extends wiring lifespan in marine and coastal environments.

– Improved solderability simplifies manufacturing and repair processes.

– Maintains copper’s high conductivity and flexibility.

Cons:

– Slightly higher cost than bare copper due to additional processing.

– Tin coating can wear off if subjected to excessive mechanical abrasion.

– Requires careful handling to avoid damaging the tin layer during installation.

Application Impact:

Tinned copper wiring is ideal for LED strip installations in harsh environments such as coastal regions in the Middle East and Africa or industrial zones with chemical exposure. It supports reliable long-term performance where bare copper might degrade.

Considerations for International Buyers:

Buyers should ensure compliance with standards like IEC 60228 and JIS C 3606 for tinned copper wire. Verifying the tin coating thickness and quality is essential to avoid premature corrosion. This material is favored in Europe and coastal South American markets for premium outdoor LED lighting solutions.

PVC-Insulated Wiring

While not a conductor material, the insulation type is critical in LED strip wiring. Polyvinyl chloride (PVC) insulation is the most common due to its cost-effectiveness, flame retardancy, and chemical resistance. It typically supports temperature ratings up to 70°C to 105°C depending on formulation.

Pros:

– Economical and widely available, facilitating competitive pricing.

– Good resistance to oils, acids, and abrasion.

– Meets many international fire safety standards (UL 94 V-0, IEC 60332).

Cons:

– Limited temperature tolerance compared to silicone or Teflon insulation.

– Can become brittle over time in extreme cold or UV exposure without additives.

– Less flexible than silicone-insulated wiring, which may affect installation in tight or curved spaces.

Application Impact:

PVC-insulated wiring is appropriate for most indoor LED strip applications and some protected outdoor uses. It is less suited for high-temperature or highly flexible installations such as automotive or specialized industrial lighting.

Considerations for International Buyers:

Buyers in hot climates like the Middle East or tropical regions in Africa should consider UV-stabilized PVC or alternative insulation to prevent degradation. Compliance with ASTM D1784 and IEC 60502 standards is advisable. PVC wiring remains a staple in Europe and South America for general-purpose LED strip wiring due to its balance of cost and performance.

Summary Table

| Material | Typical Use Case for led strip wiring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Indoor/outdoor LED strips requiring high conductivity | Excellent electrical/thermal conductivity | Higher cost and potential theft risk | High |

| Aluminum | Large-scale, budget-sensitive outdoor LED installations | Lightweight and cost-effective | Lower conductivity requires larger wire gauge | Low |

| Tinned Copper | Harsh, corrosive environments (coastal, industrial) | Superior corrosion resistance and solderability | Higher cost and tin layer abrasion risk | Medium |

| PVC-Insulated Wiring | General indoor LED strip wiring | Cost-effective with good chemical and fire resistance | Limited temperature tolerance and flexibility | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip wiring

Manufacturing Processes for LED Strip Wiring

The manufacturing of LED strip wiring involves a series of precise, controlled stages designed to ensure both functional performance and durability. For international B2B buyers, particularly those sourcing for diverse markets such as Africa, South America, the Middle East, and Europe, understanding these stages and their critical control points is essential for selecting reliable suppliers.

1. Material Preparation

The process begins with selecting high-quality raw materials, including copper wire, insulating materials (typically PVC or silicone), and connectors. Copper wires are often tin-plated to enhance corrosion resistance and solderability. Insulation materials are chosen based on flexibility, temperature resistance, and environmental durability, critical for varying climate conditions experienced in regions like Brazil or the Middle East.

Illustrative Image (Source: Google Search)

2. Wire Forming and Cutting

Wires are cut to precise lengths according to product specifications. Automated wire forming machines shape the wires to required configurations, such as straight leads or pre-bent connectors, enhancing ease of installation on LED strips. This stage also includes stripping the wire ends to prepare for soldering or crimping.

3. Assembly and Connection

The core assembly involves attaching wires to LED strip connectors or directly to the LED strip’s copper pads. This is typically done through soldering or crimping:

– Soldering: Precision soldering (often automated) ensures strong electrical connections and mechanical stability.

– Crimping: For modular or detachable connections, crimping is used to attach terminals securely.

The assembly is often performed on automated lines with robotic arms for consistency, especially for large-volume orders catering to markets like Europe or South America.

4. Finishing and Protective Coating

After assembly, wires and connections receive protective treatments. This may include:

– Heat-shrink tubing or silicone coating for insulation and strain relief.

– Application of sealants or potting compounds to protect against moisture and dust, critical for outdoor or industrial applications in regions with harsh weather.

This finishing step enhances longevity and safety, meeting the expectations of B2B buyers requiring robust products for demanding environments.

Quality Assurance Frameworks and Checkpoints

Quality assurance (QA) is a cornerstone of LED strip wiring manufacturing, ensuring product reliability and compliance with international standards. For B2B buyers, a supplier’s QA process directly impacts the risk profile and operational costs of procurement.

Relevant International and Industry Standards

- ISO 9001: This globally recognized quality management system standard ensures consistent manufacturing quality and continuous improvement. Buyers should prioritize suppliers certified under ISO 9001.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, crucial for environmentally conscious markets.

- UL Certification: Particularly important for buyers targeting North American markets but also recognized globally as a mark of electrical safety.

- Additional Regional Standards: Buyers from Africa, South America, and the Middle East should verify compliance with relevant local standards, such as INMETRO in Brazil or SASO in Saudi Arabia.

Key Quality Control (QC) Checkpoints

Quality control in LED strip wiring manufacturing typically follows a structured three-tier approach:

-

Incoming Quality Control (IQC)

– Verification of raw materials (wire gauge, insulation quality, copper purity).

– Checking supplier certificates and batch traceability.

– Random sampling and physical inspection to detect defects before production. -

In-Process Quality Control (IPQC)

– Monitoring assembly processes such as soldering temperature, connection integrity, and insulation placement.

– Visual inspections and automated optical inspections (AOI) to detect assembly flaws.

– Functional tests during assembly, including continuity and resistance measurements.

- Final Quality Control (FQC)

– Comprehensive electrical testing of finished wiring assemblies, including insulation resistance, dielectric withstand voltage, and current-carrying capacity.

– Mechanical testing for tensile strength and flexibility to simulate real-world installation stresses.

– Environmental stress tests like thermal cycling and humidity exposure, especially for products intended for harsh climates.

Common Testing Methods in LED Strip Wiring QA

For B2B buyers, understanding testing methodologies helps evaluate supplier reliability and product suitability:

- Continuity Testing: Ensures electrical path integrity, detecting breaks or shorts.

- Insulation Resistance Testing: Measures the effectiveness of the insulating materials to prevent leakage currents.

- Dielectric Withstand Testing: Applies high voltage to verify the insulation’s ability to resist breakdown.

- Mechanical Flexibility and Tensile Testing: Assesses wire durability under bending and pulling forces.

- Environmental Simulation: Includes salt spray tests for corrosion resistance and temperature/humidity cycling to mimic operational conditions.

How B2B Buyers Can Verify Supplier Quality Assurance

Due diligence is vital for international buyers to mitigate risks associated with product defects and supply chain disruptions. Recommended verification strategies include:

- Factory Audits: On-site or third-party audits assess manufacturing capabilities, process controls, and compliance with quality standards. For buyers in regions with developing inspection infrastructure, partnering with global inspection agencies is advisable.

- Review of QC Documentation: Requesting detailed inspection reports, test certificates, and compliance documents (e.g., ISO 9001 certificates, CE declarations) helps verify supplier claims.

- Third-Party Inspections: Independent inspections before shipment provide an unbiased assessment of product quality, crucial when direct factory visits are impractical.

- Sample Testing: Procuring product samples for in-house or third-party laboratory testing ensures materials and performance meet expectations.

- Long-Term Supplier Relationships: Establishing ongoing communication and feedback loops with suppliers supports continuous quality improvement and responsiveness to market-specific needs.

QC and Certification Nuances for International Buyers

International B2B buyers must navigate regional variations in quality expectations and certification requirements:

- Africa: Many African markets rely on international certifications like CE and ISO but may also require compliance with local electrical safety standards. Importers should confirm the acceptance of certifications and consider local testing where necessary.

- South America (e.g., Brazil): Compliance with INMETRO certification is often mandatory. Buyers should verify that suppliers can provide INMETRO-approved products or work with certified local partners.

- Middle East: Regional certifications such as SASO (Saudi Standards, Metrology and Quality Organization) are critical. Buyers should ensure suppliers understand these requirements and can supply compliant documentation.

- Europe: The CE mark and RoHS compliance are non-negotiable. Additionally, EU buyers may require adherence to REACH regulations and expect rigorous quality documentation and traceability.

For all regions, buyers should be aware that counterfeit certifications and substandard products are risks in the LED supply chain. Partnering with reputable suppliers who demonstrate transparent QA processes and provide verifiable documentation is essential.

Conclusion

For international B2B buyers sourcing LED strip wiring, a thorough understanding of manufacturing processes and quality assurance practices empowers smarter procurement decisions. By focusing on material quality, controlled assembly techniques, rigorous QC checkpoints, and compliance with internationally recognized standards, buyers can secure products that meet performance expectations and regulatory demands across diverse global markets. Leveraging audits, documentation review, and third-party testing further mitigates risks, ensuring supply chain reliability and end-customer satisfaction in Africa, South America, the Middle East, and Europe.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for led strip wiring Sourcing

When sourcing LED strip wiring for international B2B procurement, understanding the detailed cost structure and pricing dynamics is essential to secure competitive offers without compromising quality or compliance. Buyers from regions such as Africa, South America, the Middle East, and Europe must navigate various factors influencing pricing to optimize their total cost of ownership.

Key Cost Components in LED Strip Wiring

-

Materials

The primary cost driver is the raw materials, including copper conductors, insulating polymers (e.g., PVC or silicone), and connectors. Material quality directly impacts durability and electrical performance, with higher-grade materials demanding premium pricing. -

Labor

Skilled labor for precise wire assembly, cutting, soldering, and insulation adds to costs. Labor rates vary significantly by manufacturing location, influencing the final product price. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation can lower overhead, benefiting pricing. -

Tooling and Equipment

Custom tooling for specific wiring configurations or connectors may require upfront investment, which is amortized over production runs and reflected in unit pricing. -

Quality Control (QC)

Rigorous testing for conductivity, insulation resistance, and safety certifications (e.g., CE, RoHS) adds operational costs but ensures product reliability and regulatory compliance. -

Logistics and Freight

Shipping costs depend on order volume, weight, transport mode (air, sea, or land), and destination. For buyers in Africa, South America, and the Middle East, logistical challenges and customs clearance fees can significantly affect landed costs. -

Supplier Margin

Suppliers include a margin to cover risk, profit, and market positioning. Margins vary by supplier reputation, exclusivity of product, and competitive landscape.

Pricing Influencers for LED Strip Wiring

-

Order Volume and Minimum Order Quantities (MOQ)

Larger orders typically yield lower per-unit prices due to economies of scale. Buyers should negotiate MOQs that balance inventory costs with price benefits. -

Specifications and Customization

Custom wire lengths, unique connector types, or enhanced insulation ratings increase complexity and cost. Standardized products usually offer better pricing. -

Material Grades and Certifications

Wiring meeting international standards (UL, CE) commands higher prices but reduces risk in regulated markets, a critical consideration for European and Middle Eastern buyers. -

Supplier Factors

Established suppliers with consistent quality and traceability may price higher but provide reliability and after-sales support, crucial for long-term contracts. -

Incoterms and Payment Terms

Terms such as FOB, CIF, or DDP influence the cost allocation between buyer and supplier. Understanding these terms helps buyers anticipate additional costs like insurance and import duties.

Strategic Tips for International Buyers

-

Negotiate Beyond Price

Consider value-added services like extended warranties, technical support, and flexible payment terms. These can enhance overall procurement value beyond the unit price. -

Assess Total Cost of Ownership (TCO)

Factor in installation ease, product lifespan, and failure rates. Cheaper wiring may increase replacement and maintenance expenses, especially in harsh environments typical in some African and South American regions. -

Leverage Regional Supplier Networks

Sourcing closer to your market (e.g., European buyers sourcing within the EU or Middle Eastern buyers from nearby hubs) can reduce logistics costs and lead times. -

Understand Pricing Nuances

Be aware of seasonal demand fluctuations, currency exchange impacts, and geopolitical risks that can affect pricing and supply stability. -

Audit Samples and Certifications

Always request samples and verify certifications before finalizing bulk orders to avoid costly compliance issues.

Important Disclaimer

Prices for LED strip wiring vary widely based on product specifications, order size, market conditions, and supplier negotiation. The information provided here is indicative and should be supplemented with direct supplier quotes and market research tailored to your specific sourcing context.

By comprehensively analyzing these cost and pricing elements, international B2B buyers can strategically position themselves to secure reliable, cost-effective LED strip wiring solutions that meet both technical requirements and budgetary constraints.

Spotlight on Potential led strip wiring Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip wiring’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip wiring

Key Technical Properties of LED Strip Wiring

Understanding the essential technical properties of LED strip wiring is crucial for international B2B buyers to ensure product reliability, compatibility, and performance across diverse applications and markets.

-

Conductor Material and Grade

Most LED strip wiring uses copper conductors due to copper’s excellent electrical conductivity and flexibility. High-grade oxygen-free copper (OFC) enhances conductivity and reduces signal loss, which is vital for maintaining consistent brightness and color accuracy over long runs. For buyers in regions with high humidity or industrial environments, verifying conductor grade ensures longevity and resistance to corrosion. -

Wire Gauge (AWG or mm²)

Wire gauge indicates the thickness of the wiring and directly affects current-carrying capacity and voltage drop. For LED strips, common gauges range from 18 AWG to 24 AWG. Selecting the correct gauge is critical to avoid overheating and ensure efficient power delivery, especially for longer installations common in commercial or industrial projects. -

Insulation Material and Rating

The insulation protects wires from environmental factors and electrical hazards. Common materials include PVC, silicone, and Teflon, each with different temperature and flexibility ratings. Silicone insulation, for example, offers superior heat resistance and flexibility, suitable for applications in hot climates or where wiring must bend around tight corners. Buyers should confirm insulation complies with regional safety standards (e.g., CE, RoHS). -

Voltage and Current Tolerance

LED strip wiring must support the voltage and current requirements of the LED strips, typically 12V or 24V DC systems. Overrating voltage and current capacity by 20-30% provides operational safety margins, reducing risk of failures in power surges or extended operation, which is especially important for large-scale projects or fleet installations. -

Temperature Range

Wiring should be rated for the ambient temperature conditions expected in the installation environment. For example, wiring that tolerates -20°C to +80°C is suitable for most indoor and outdoor applications. Buyers in regions with extreme climates (e.g., Middle East heat or South American cold zones) must verify temperature ratings to prevent insulation degradation and conductor fatigue. -

Flexibility and Bend Radius

Flexibility is a practical consideration for LED strip wiring routed through confined spaces or curved surfaces. Wire that supports a small minimum bend radius without damage facilitates easier installation and reduces mechanical stress, which enhances system durability and lowers maintenance costs.

Common Trade Terminology in LED Strip Wiring Procurement

For B2B buyers navigating international LED strip wiring markets, familiarity with key trade terms ensures clear communication and smoother transactions.

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce wiring components or LED strips under another brand’s specifications. Partnering with OEMs can offer cost advantages and customization but requires thorough quality audits to ensure compliance with buyer standards. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs vary widely and impact inventory management and pricing. Buyers from emerging markets or smaller businesses should negotiate MOQs or explore consolidated purchasing to optimize costs. -

RFQ (Request for Quotation)

A formal process where buyers solicit detailed pricing, lead times, and specifications from suppliers. Providing clear technical requirements in RFQs helps suppliers offer accurate quotes and reduces procurement cycle times. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers from Africa, South America, and the Middle East manage logistics and cost risks effectively. -

Lead Time

The time interval between placing an order and receiving the goods. Lead times affect project scheduling and cash flow. Buyers should confirm lead times upfront, especially when sourcing from distant manufacturers, to avoid delays in installation or production. -

Certification Compliance

Indicates adherence to relevant standards such as CE (Europe), RoHS (Restriction of Hazardous Substances), or UL (Underwriters Laboratories). Certifications assure product safety and market acceptance, which is critical for buyers targeting regulated markets or government contracts.

By focusing on these technical properties and mastering trade terminology, international B2B buyers can make informed decisions, optimize procurement strategies, and secure high-quality LED strip wiring tailored to their regional and operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip wiring Sector

Market Overview & Key Trends

The global led strip wiring market is experiencing robust growth driven by the widespread adoption of LED lighting technology across commercial, industrial, and residential sectors. For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, understanding the evolving landscape is critical for strategic procurement. Key market drivers include increasing demand for energy-efficient lighting solutions, advancements in smart lighting integration, and expanding infrastructure development in emerging economies like Mexico and Brazil.

Current sourcing trends highlight a shift towards modular and customizable wiring solutions that cater to diverse installation environments, including waterproof and flexible wiring options suited for outdoor and industrial applications. Buyers are increasingly prioritizing suppliers who offer end-to-end solutions combining LED strips with compatible wiring harnesses and connectors to ensure seamless integration and reduce installation complexities.

Market dynamics are also influenced by supply chain considerations. Geopolitical factors and raw material availability, particularly copper and specialized polymers used in wiring insulation, affect lead times and pricing. Buyers in Africa and the Middle East benefit from sourcing partnerships with manufacturers in Asia and Europe who have optimized logistics networks to mitigate delays. Additionally, demand for compliance with international safety standards such as UL, CE, and RoHS is rising, compelling suppliers to enhance quality assurance protocols.

Technological innovation is another pivotal trend. The integration of smart wiring capable of supporting IoT-enabled LED strips is gaining traction, enabling remote control, energy monitoring, and adaptive lighting schemes. This is particularly relevant for commercial buyers in Europe and South America who are investing in smart building projects. Consequently, B2B buyers should focus on suppliers demonstrating expertise in advanced wiring solutions compatible with emerging smart lighting technologies to future-proof their investments.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a fundamental consideration in the led strip wiring sector, driven by growing environmental regulations and corporate responsibility commitments worldwide. For international buyers, sourcing wiring components that minimize ecological impact while maintaining performance standards is increasingly important. This includes prioritizing wiring materials that are recyclable or derived from renewable sources, such as halogen-free flame retardants and low-VOC (volatile organic compound) insulation materials.

Ethical sourcing extends beyond environmental factors to encompass supply chain transparency and labor practices. Buyers in regions like Africa and South America are advised to engage with suppliers who provide clear certifications and audits verifying compliance with fair labor standards and conflict-free material sourcing. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) serve as critical benchmarks for evaluating supplier sustainability credentials.

Furthermore, green certifications related to electrical components, including compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensure that wiring products do not contain harmful substances that can compromise health or the environment. B2B buyers should request detailed documentation and third-party testing results to validate these claims.

Incorporating sustainability into procurement decisions not only mitigates reputational risks but also aligns with global trends toward circular economy practices. Buyers can leverage sustainable sourcing to enhance their corporate ESG (Environmental, Social, Governance) profiles, which is increasingly demanded by investors and end clients across Europe and the Middle East.

Evolution and Historical Context

The evolution of led strip wiring parallels the broader development of LED lighting technology, which gained commercial viability in the early 2000s. Initially, wiring solutions were basic and often lacked durability or flexibility, limiting LED strip applications primarily to indoor decorative uses. Over time, advancements in materials science and manufacturing processes enabled the production of wiring that could withstand harsher environments, including outdoor and industrial settings.

This progression has been driven by increasing demand for integrated lighting systems that combine LED strips with compatible wiring harnesses designed for quick installation and reliable long-term performance. The rise of smart lighting further accelerated innovation, necessitating wiring capable of supporting data transmission and power management.

For B2B buyers, understanding this historical context underscores the importance of selecting wiring solutions that not only meet current technical specifications but are adaptable to future upgrades in LED technology and control systems. The market has matured from simple electrical connections to sophisticated systems integral to modern lighting infrastructure worldwide.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip wiring

-

How can I effectively vet suppliers of LED strip wiring to ensure reliability and quality?

To vet suppliers, prioritize those with verifiable certifications such as ISO 9001 for quality management and RoHS compliance for safety. Request detailed product datasheets and sample testing reports. Evaluate supplier track records by checking client testimonials, case studies, and industry reputation, especially in your region (Africa, South America, Middle East, Europe). Visiting factories or using third-party inspection services can further validate manufacturing capabilities. Transparent communication and responsiveness also indicate professionalism and reliability. -

What customization options are typically available for LED strip wiring in bulk orders?

Many suppliers offer customization including wire length, gauge, insulation type, connector styles, and color coding to match your project requirements. Some provide options for waterproofing levels (IP ratings) and specific certifications to meet regional standards. Custom packaging and branding services are often available for large orders. Clarify these options early in negotiations to align with your application needs and regulatory compliance, particularly for diverse markets like Mexico or Brazil. -

What are common minimum order quantities (MOQs) and lead times for LED strip wiring, and how can I negotiate better terms?

MOQs vary widely but typically range from 500 to 5,000 units depending on complexity and customization. Lead times generally span 3 to 8 weeks, factoring in production and shipping. To negotiate better terms, consolidate orders, establish long-term partnerships, or offer upfront payments. Also, inquire about partial shipments to reduce inventory costs. Suppliers may be more flexible if you demonstrate consistent purchasing potential across multiple regions. -

Which quality assurance processes and certifications should I require to ensure compliance and product durability?

Demand that suppliers follow strict quality assurance protocols including incoming material inspections, in-line testing, and final product audits. Key certifications to verify include CE (Europe), UL (North America), RoHS (hazardous substances), and ISO 9001. For harsh environments common in Africa and the Middle East, confirm IP ratings for water and dust resistance. Request sample batch testing reports and independent lab certifications to mitigate risks associated with substandard wiring. -

What are the best logistics practices for importing LED strip wiring into African, South American, Middle Eastern, and European markets?

Choose suppliers experienced with international shipping and customs procedures specific to your region. Use freight forwarders familiar with local regulations to avoid delays and excessive duties. Opt for consolidated shipments to reduce costs and track orders closely with real-time updates. Plan for potential seasonal disruptions and factor in buffer times. Clear documentation including commercial invoices, packing lists, and certificates of origin expedites customs clearance. -

How should I handle payment terms to balance risk and cash flow when sourcing LED strip wiring internationally?

Common payment terms include 30% upfront deposit with balance upon shipment or letter of credit (LC) for larger orders. Negotiate terms that protect both parties; for example, escrow services or milestone payments linked to production stages. Verify supplier credibility before advance payments. For first-time or smaller buyers, consider safer options like PayPal or trade assurance platforms. Establishing trust over time can enable more favorable terms such as net 30 or net 60 days. -

What strategies can help resolve disputes or quality issues with overseas LED strip wiring suppliers?

Maintain thorough documentation including contracts, specifications, and communication records. Initiate prompt, clear communication upon detecting issues and seek amicable resolution such as replacement, refund, or discount. Use third-party inspection or arbitration services if necessary. Understand your legal rights under international trade agreements and Incoterms. Building long-term relationships and mutual understanding often prevents disputes and facilitates smoother conflict resolution. -

How can I ensure that LED strip wiring products meet regional electrical and safety standards?

Research specific standards applicable to your target market, such as IEC standards in Europe or NOM certification in Mexico. Insist suppliers provide test reports and certification documents verifying compliance. Engage local testing labs for independent verification if needed. Adapt product specifications like voltage ratings and insulation materials to regional requirements to ensure safe installation and operation. Staying informed about evolving regulations helps avoid costly non-compliance penalties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip wiring

Strategic sourcing of LED strip wiring is a critical lever for international B2B buyers aiming to optimize cost, quality, and supply chain resilience. Key takeaways include prioritizing suppliers with robust quality assurance, clear compliance with regional electrical standards, and scalable manufacturing capabilities. Understanding the technical specifications—such as voltage compatibility, waterproof ratings, and connector types—enables buyers to select wiring solutions that align precisely with their application requirements, from architectural lighting in Europe to commercial installations in South America and industrial projects in the Middle East.

For markets across Africa and Latin America, where infrastructure variability and import logistics can pose challenges, establishing strong partnerships with manufacturers and distributors who offer localized support and flexible delivery terms is especially valuable. Moreover, integrating sustainability criteria and innovative materials into sourcing decisions can future-proof investments as global regulations and customer expectations evolve.

Illustrative Image (Source: Google Search)

Looking ahead, international buyers should actively monitor emerging trends such as smart wiring integration and enhanced durability coatings, which promise to unlock new efficiencies and market opportunities. By adopting a strategic, informed approach to LED strip wiring procurement, businesses in Mexico, Brazil, Nigeria, the UAE, and beyond can secure competitive advantages, ensure operational continuity, and accelerate growth in the dynamic lighting sector. Engage proactively with trusted suppliers today to harness these benefits and lead your market tomorrow.