Article Contents

Industry Insight: Lumens Vs Kelvin

In the commercial and industrial lighting sector, understanding the distinction between lumens and kelvin is critical to achieving optimal performance, energy efficiency, and workplace safety. Lumens measure the total amount of visible light emitted by a source—directly influencing visibility and illumination levels across warehouses, manufacturing floors, and retail environments. Kelvin, on the other hand, defines the color temperature of light, impacting ambiance, alertness, and even productivity; cooler temperatures (4000K–5000K) are typically favored in industrial settings for their daylight-like clarity. Selecting the right balance of lumens and kelvin ensures not only regulatory compliance but also long-term operational effectiveness. In this context, adherence to international standards such as ETL and CE marks is non-negotiable, serving as benchmarks for electrical safety, performance, and market access in North America and the European Union. Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing commercial and industrial LED lighting solutions. With over two decades of engineering excellence, Beauty STC delivers high-lumen, precision-tuned lighting systems that meet rigorous ETL and CE certifications, combining reliability, efficiency, and innovation for global industrial applications.

Technical Specs & Certifications

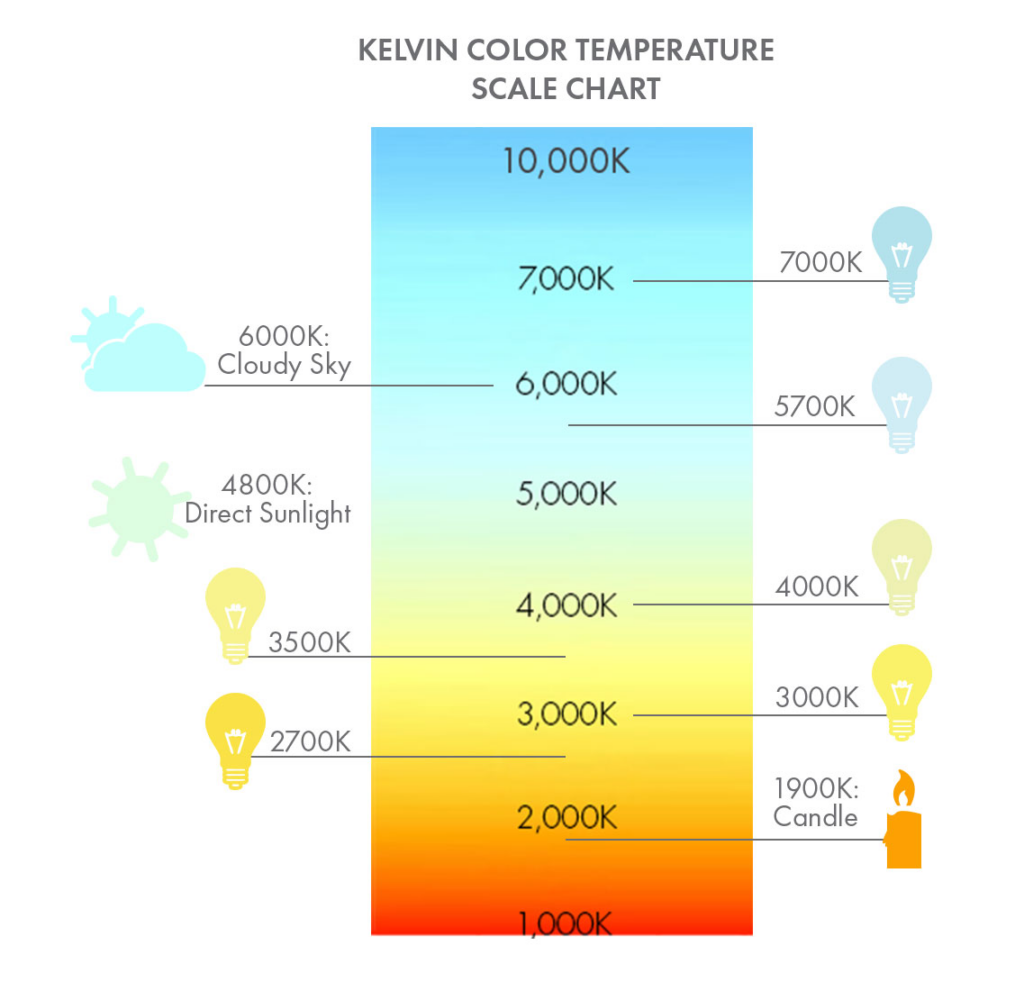

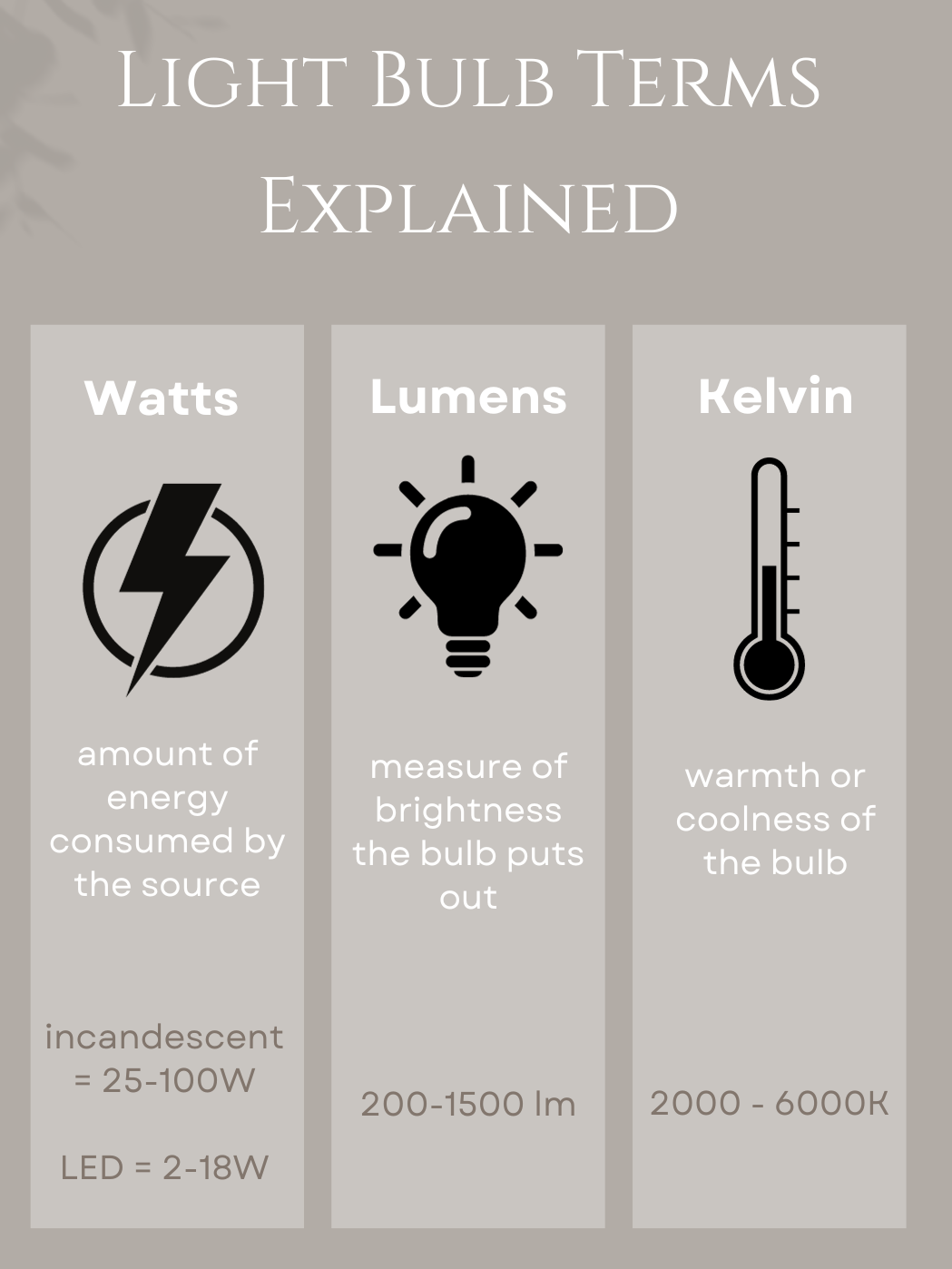

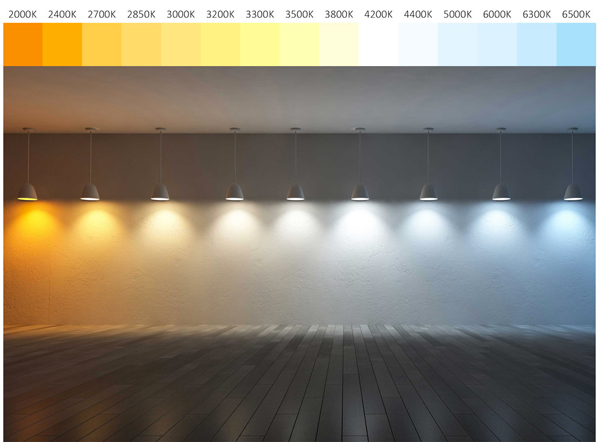

Lumens and Kelvin represent fundamentally distinct photometric properties in LED lighting and should not be conflated as a direct comparison metric. Lumens quantify the total visible light output perceived by the human eye, directly indicating brightness. Kelvin measures correlated color temperature (CCT), describing the visual warmth or coolness of white light, from warm white (2700K-3000K) to neutral (3500K-4500K) and cool daylight (5000K-6500K). The critical relationship relevant to efficiency is lumens per watt (lm/W), not lumens versus Kelvin. At Beauty STC, our engineering rigor ensures optimal lm/W across CCT ranges through advanced chip-on-board (COB) technology and precision thermal management. Standard commercial-grade LED fixtures achieve 130-160 lm/W at 4000K, with high-efficacy lines exceeding 180 lm/W. Crucially, cooler CCTs (5000K+) typically yield 5-10% higher lm/W than warmer CCTs (2700K-3000K) due to reduced phosphor conversion losses, a factor our thermal design mitigates to maintain consistent high output across all color temperatures.

Color Rendering Index (CRI) exceeding 90 is non-negotiable for applications demanding true color representation, such as beauty salons and retail. Beauty STC fixtures consistently deliver CRI >95, with R9 (saturated red) values >90 and R12 (blue) >85, verified through IES LM-79-19 testing. This surpasses basic CRI>90 requirements by ensuring accurate rendering of skin tones, cosmetics, and textiles. Our proprietary multi-phosphor blends and spectrally optimized LEDs eliminate the common trade-off between high CRI and lm/W, maintaining efficacy while achieving TM-30-15 Rf values >90 and Rg >100 for natural color appearance. This performance is validated under both nominal and sustained operating conditions, not just initial binning.

IP (Ingress Protection) ratings define resistance to dust and moisture ingress, critical for salon safety near sinks, showers, and chemical exposure. Beauty STC fixtures for wet locations (e.g., vanity mirrors, shower zones) carry minimum IP65 certification, with full IP67 compliance for submersible applications like foot spa lighting. Our sealing methodology uses medical-grade silicone gaskets and double-potted driver compartments, exceeding IEC 60529 standards. Importantly, we integrate IK08 impact resistance ratings alongside IP certification to withstand physical contact from tools and equipment in professional environments. All IP-rated products undergo 1,000-hour salt spray testing and thermal cycling validation to prevent seal degradation, ensuring long-term reliability where standard consumer-grade IP claims often fail.

Beauty STC’s quality commitment manifests in the rigorous integration of these specifications. Every fixture undergoes 50,000-hour LM-80 accelerated lifetime testing with lumen maintenance (L90/B10) guaranteed at 50,000 hours under real-world thermal loads. Our in-house photometric laboratory cross-verifies lm/W, CCT, and CRI data against third-party reports, eliminating supplier variances. The result is consistent high-performance lighting where efficacy, color fidelity, and environmental resilience are engineered holistically—not as isolated features—ensuring salon professionals achieve perfect illumination without compromising energy efficiency or durability. This systems-level approach, backed by ISO 9001-certified manufacturing and UL/cUL/CE certifications, defines Beauty STC’s leadership in professional LED solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, is a fully integrated LED lighting production plant designed to support high-volume, precision manufacturing with strict quality control. The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for the accurate placement of LED components and other surface-mounted devices onto printed circuit boards. These SMT machines operate with high speed and precision, ensuring consistent soldering quality and component alignment, which are critical for the performance and reliability of LED lighting products.

The Jiangmen factory implements comprehensive aging test procedures as part of its quality assurance process. After assembly, finished lighting products undergo extended operational testing—typically 4 to 12 hours or more—under controlled thermal and electrical conditions. This aging process helps identify early-life failures, verifies thermal management performance, and ensures long-term stability of lumen output and color consistency before products are shipped to customers.

In terms of OEM capabilities, Beauty STC offers full customization of LED lighting solutions, including precise control over photometric specifications such as lumens (light output) and Kelvin (color temperature). Clients can specify desired lumen packages across various color temperatures—ranging from warm white (2700K–3000K) to neutral (4000K) and cool white (5000K–6500K)—and the factory can tailor optical design, driver configuration, and thermal management to meet those targets. This level of customization is supported by in-house engineering, optical simulation, and photometric testing using integrating spheres and spectroradiometers, ensuring accurate and repeatable results for every OEM project.

Application Scenarios

Understanding the distinct roles of lumens (light output quantity) and Kelvin (color temperature) is critical for effective lighting design in commercial spaces. Lumens determine how bright a space feels and must align with task requirements and safety standards, while Kelvin influences ambiance, visual comfort, and even human behavior through its warm-to-cool spectrum. Misapplying either can compromise functionality or user experience. Below is a breakdown by venue type with specific guidance, followed by universal installation considerations.

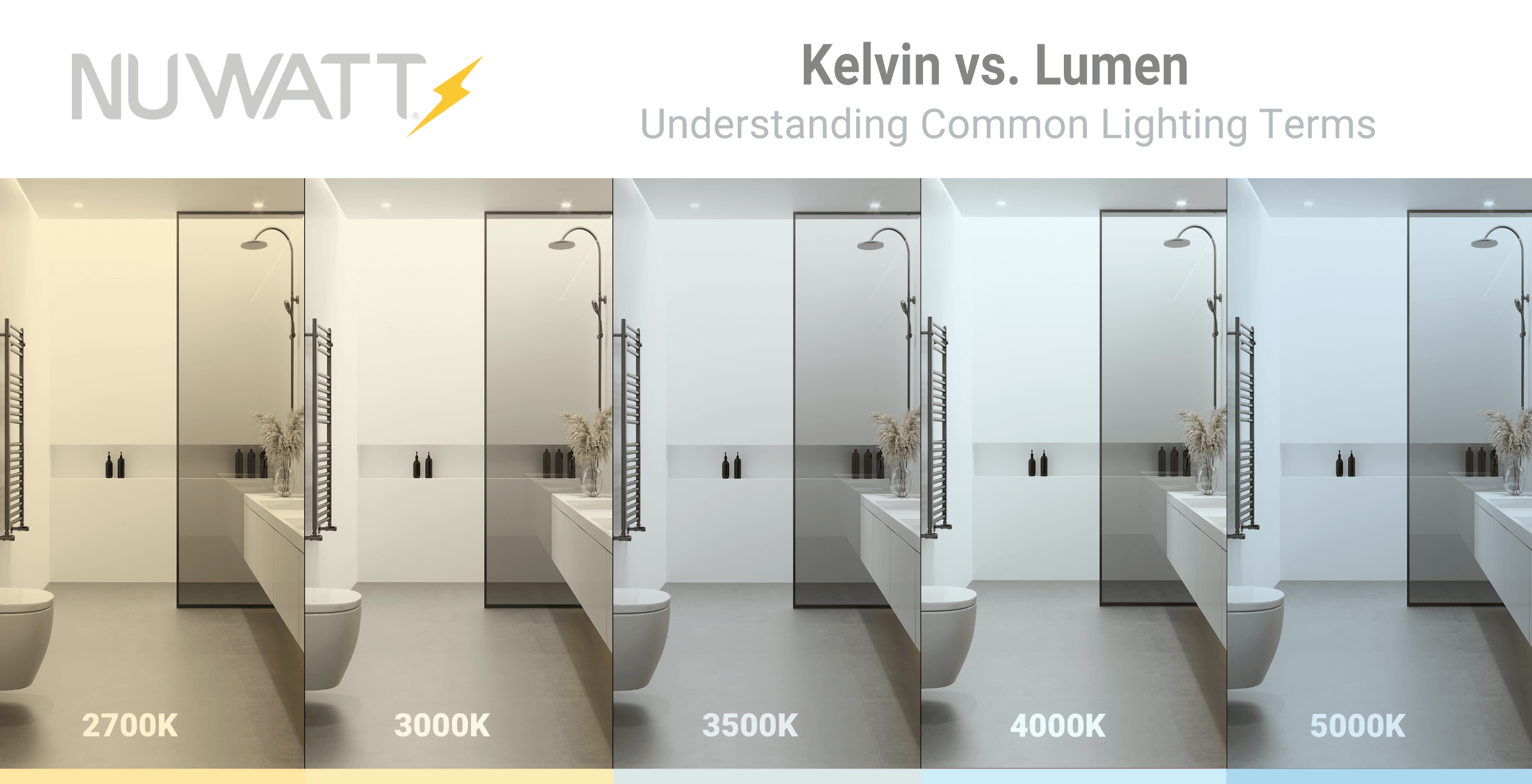

Hotels demand layered lighting strategies where Kelvin sets the emotional tone and lumens support practical needs. Guest rooms require warm Kelvin temperatures (2700K–3000K) to foster relaxation, but lumen levels should be carefully zoned: lower near beds (500–800 lumens for bedside lamps) and higher in workspaces (1500–2000 lumens for desks). Lobbies benefit from slightly cooler Kelvin (3000K–3500K) to convey modernity without sterility, with lumen density ensuring safe navigation (200–300 lux on floor surfaces). Restaurant areas vary sharply—fine dining uses very warm Kelvin (2200K–2700K) with dimmed lumens for intimacy, while buffet zones need neutral Kelvin (3500K) and high lumens (500 lux) for food visibility. Crucially, guest room bathrooms require both high lumens (for grooming tasks) and consistent Kelvin (3000K) to avoid color distortion in mirrors.

Malls prioritize visual merchandising and crowd flow, making Kelvin selection vital for product presentation and spatial perception. Retail storefronts often use 3500K–4000K Kelvin to enhance color accuracy (especially for textiles), paired with high lumen outputs (750–1000 lux) on displays. Corridors and common areas should maintain uniform Kelvin (3000K–3500K) to prevent disorientation, with lumen levels sufficient for safety (200 lux minimum) but avoiding glare. Food courts lean toward warmer Kelvin (3000K) for comfort, though lumen requirements spike during cleaning (500 lux). Emergency egress paths mandate strict lumen compliance (10 lux min per IBC codes) regardless of Kelvin, often using dedicated 4000K fixtures for alertness. Avoid mixing Kelvin temperatures within sightlines—such as cool retail displays against warm corridor lighting—as this creates visual discord that distracts shoppers.

Offices balance productivity and well-being through precise lumen-Kelvin pairing. General workspaces thrive at 3500K–4000K Kelvin to sustain alertness, with lumen levels calibrated to task intensity (300–500 lux for open offices, 750 lux for drafting tables). Meeting rooms need flexibility: cooler Kelvin (4000K) during presentations for screen clarity, warmer (3000K) for brainstorming, supported by dimmable lumens. Reception areas use warmer Kelvin (3000K) for approachability but require higher lumens (400 lux) than workstations for document handling. Critical errors include excessive lumens causing screen glare or overly cool Kelvin (>4500K) inducing fatigue. Always measure horizontal illuminance at desk height during commissioning—many offices default to 500 lux when 300 lux suffices, wasting energy.

Installation requires physics-aware execution beyond basic wiring. Position fixtures to avoid direct glare in task zones, particularly in offices where pendant lights should hang 30–36 inches above desks. In hotels, embed wall sconces at 60-inch heights to eliminate harsh shadows on faces. Malls demand precise beam angle calculations—narrow spots (15°) for jewelry displays at high lumens, wide floods (60°) for escalator landings. Always verify Kelvin consistency across batches; a 200K variance (e.g., 2800K vs 3000K) becomes visible in large open spaces. Install dimmers rated for LED loads in hospitality settings to maintain Kelvin stability during dimming—cheap trailing-edge dimmers shift warm LEDs greenish. Finally, prioritize service access: in mall atriums, use track systems with tool-free lens removal, and in offices, avoid placing fixtures above suspended ceiling tiles that block maintenance. Commissioning should include lux meter validation at multiple points, not just center-room measurements, to catch uneven distribution.

Why Choose Beauty STC Lighting

Understanding the difference between lumens and kelvin is essential for choosing the right lighting solution for any space. Lumens measure brightness, while kelvin defines the color temperature of light—impacting ambiance and functionality. At Beauty (STC) Manufacturing Co., Ltd., we specialize in delivering high-performance LED lighting solutions tailored to your project’s unique needs. Whether you’re designing for commercial, industrial, or architectural environments, our engineering expertise ensures optimal lumen output and kelvin selection for superior lighting quality.

Partner with Beauty STC to leverage our technical knowledge, innovative products, and reliable manufacturing standards. For expert guidance on lumens vs. kelvin and customized lighting solutions, contact us today at [email protected]. Let us help you illuminate success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.