Article Contents

Industry Insight: Lumen Lux

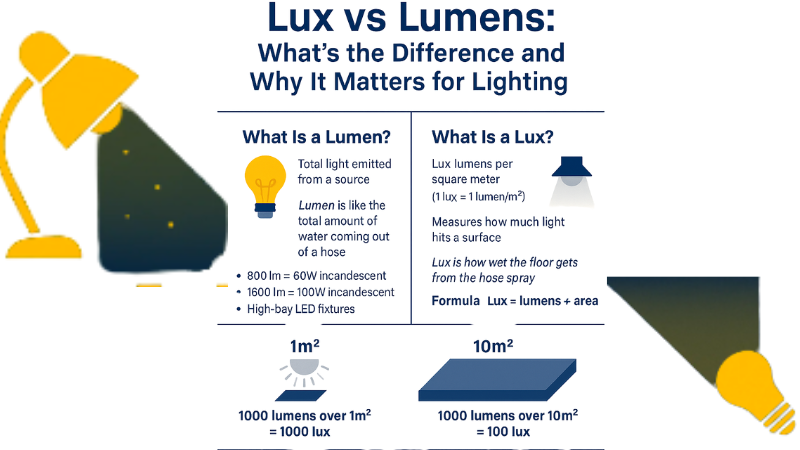

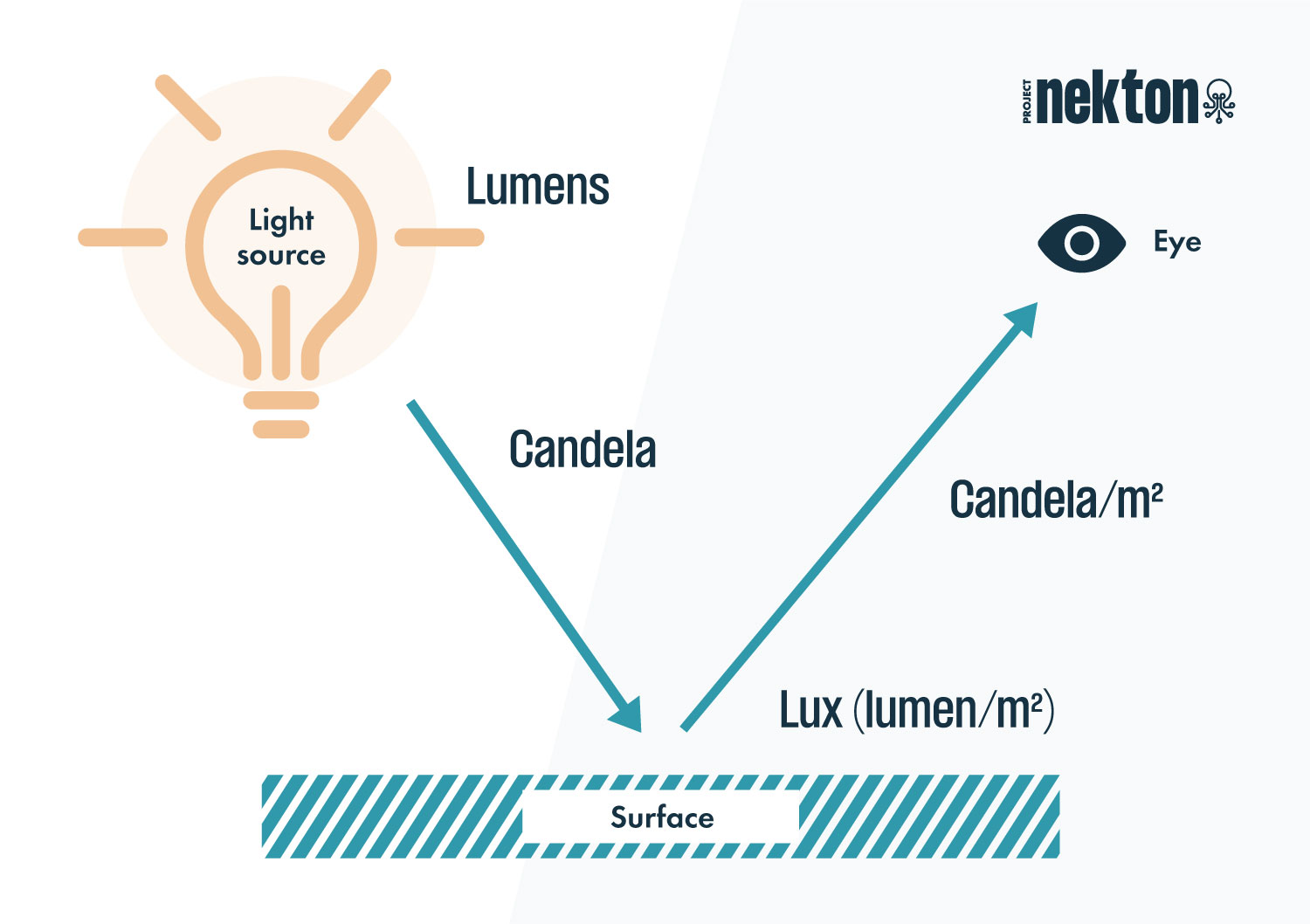

Understanding the precise relationship between lumen output and lux levels is fundamental to effective commercial and industrial lighting design, directly impacting operational efficiency, occupant well-being, and regulatory compliance. Lumens quantify the total visible light emitted by a source, while lux measures the intensity of that light as it falls upon a specific surface area – a critical distinction when illuminating vast warehouse floors, detailed assembly lines, or retail environments where task visibility is paramount. Achieving the optimal lux level for each application isn’t merely about brightness; it’s a strategic balance ensuring safety, enhancing productivity, and minimizing energy consumption across demanding 24/7 operations. Crucially, specifying lighting solutions that consistently deliver the required photometric performance necessitates adherence to rigorous international safety and performance standards, with ETL certification for the North American market and CE marking for Europe being non-negotiable prerequisites for facility managers and lighting specifiers. Beauty STC Manufacturing Co., Ltd., established in 1998, leverages over 25 years of dedicated expertise in LED lighting engineering to address these complex challenges. We specialize in developing high-performance, compliant commercial and industrial luminaires where accurate lumen-to-lux conversion, robust construction, and guaranteed certification are engineered into every product, enabling our global partners to illuminate spaces with confidence and efficiency.

Technical Specs & Certifications

Lumen Lux is a high-performance LED lighting product line engineered and manufactured by Beauty (STC) Manufacturing Co., Ltd., designed to deliver superior illumination with exceptional energy efficiency and reliability. The technical specifications of the Lumen Lux series reflect Beauty STC’s commitment to precision engineering and premium quality in commercial and industrial lighting applications.

The Lumen Lux fixtures achieve an outstanding luminous efficacy ranging from 130 to 160 lumens per watt, depending on the model and configuration. This high lumens/watt ratio ensures significant energy savings compared to conventional lighting systems, making Lumen Lux ideal for facilities aiming to reduce operational costs and meet sustainability targets. The efficiency is achieved through the use of high-grade SMD LED chips and advanced driver technology that optimizes power consumption while maintaining consistent light output.

A defining feature of the Lumen Lux series is its excellent color rendering capability, with a Color Rendering Index (CRI) greater than 90. This high CRI ensures accurate and vibrant color representation, which is critical in environments such as retail spaces, art galleries, healthcare facilities, and precision manufacturing areas where true color perception is essential. The consistent color temperature options—ranging from 3000K to 6500K—further enhance visual comfort and adaptability across different applications.

In terms of environmental protection and durability, Lumen Lux fixtures are available with IP65 and IP66 ratings, offering complete protection against dust ingress and powerful water jets. This makes them suitable for both indoor and outdoor use, including harsh environments such as warehouses, parking garages, food processing plants, and industrial facilities exposed to moisture and contaminants. Some models are also rated for use in wet locations and meet stringent IK08 impact resistance standards for added resilience.

Beauty STC upholds rigorous quality control throughout the manufacturing process, incorporating automated optical testing, thermal management validation, and long-term reliability testing. All Lumen Lux products are RoHS compliant, LM-79 and LM-80 certified, and backed by a comprehensive warranty, underscoring the company’s confidence in product longevity and performance. With a focus on innovation, durability, and customer satisfaction, Beauty STC continues to set industry benchmarks in LED lighting technology through the Lumen Lux series.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production. Strategically located within the Pearl River Delta region, this factory benefits from strong infrastructure, skilled labor availability, and proximity to key supply chains and ports. The Jiangmen site is purpose-built for efficient, high-volume LED luminaire manufacturing, featuring a clean, organized production floor designed to ISO 9001 standards, ensuring a controlled environment critical for electronic assembly and optical performance.

The Surface Mount Technology (SMT) production line forms the backbone of LED module fabrication at the Jiangmen plant. It is equipped with multiple high-speed, precision SMT machines, primarily from leading brands such as Yamaha and Siemens. These machines handle components ranging from tiny 0201 resistors and capacitors to larger LED packages and drivers with exceptional placement accuracy, typically within ±25 microns. The lines operate with high throughput, capable of placing hundreds of thousands of components per hour, and incorporate automated optical inspection (AOI) systems both pre and post-reflow soldering. This rigorous AOI process immediately identifies and corrects placement errors, solder bridges, or missing components, ensuring the foundational electronic assemblies meet stringent quality benchmarks before moving to subsequent stages.

Aging and reliability testing are critical non-negotiables at the Jiangmen facility, reflecting Beauty STC’s commitment to product longevity. Every batch of finished luminaires undergoes comprehensive aging tests within dedicated environmental chambers. Standard aging protocols involve operating products at elevated temperatures, typically 50-60°C, and often at 100% rated voltage, for a minimum duration of 48 to 72 hours. During this extended burn-in period, sophisticated monitoring systems track key parameters including lumen output stability, color consistency (CCT), power consumption, and thermal performance. Any unit exhibiting significant flux depreciation, color shift, or electrical anomaly during this phase is automatically flagged and removed from the shipment. This proactive stress testing significantly reduces field failures and ensures only units demonstrating stable performance under simulated long-term operation reach the customer.

Beauty STC possesses robust OEM capabilities specifically tailored for clients requiring customized lighting solutions measured in lumen output and lux levels. The Jiangmen factory is fully equipped to handle end-to-end OEM projects, from initial concept and optical design through to mass production and branded packaging. Engineering teams work closely with clients to define precise photometric requirements, whether it’s achieving a specific lumen package for a downlight, a targeted lux level at a work surface for task lighting, or uniform distribution for area illumination. Utilizing advanced optical simulation software and in-house integrating sphere and goniophotometer labs, the team validates designs to meet exact lumen and lux specifications. The production process, including the SMT lines and final assembly, is seamlessly adapted for client-specific Bill of Materials (BOMs), mechanical designs, and driver configurations. Full branding services encompass custom labeling, packaging design, and documentation, all while maintaining the rigorous quality control and aging test protocols applied to Beauty STC’s own products. This comprehensive OEM service ensures clients receive reliable, specification-compliant lighting products under their own brand, backed by the manufacturing expertise of the Jiangmen facility.

Application Scenarios

The term “lumen lux” refers to two distinct but related photometric units—lumens measure the total amount of visible light emitted by a source, while lux measures the amount of light (lumens) falling on a surface per square meter (1 lux = 1 lumen/m²). Understanding the appropriate lumen and lux levels is critical when designing lighting for different environments such as hotels, malls, and offices to ensure comfort, functionality, and energy efficiency.

In hotels, lighting plays a vital role in creating ambiance and enhancing guest experience. Public areas such as lobbies and reception desks typically require 100–200 lux for a welcoming yet functional atmosphere, while corridors may need 50–100 lux. Guest rooms benefit from layered lighting—general lighting at around 100–150 lux, complemented by task lighting (e.g., reading lamps at 300–500 lux near beds or desks) and accent lighting for décor. Bathrooms should have 200–300 lux, especially around mirrors. Use dimmable LED fixtures to allow guests to adjust lighting according to mood and time of day.

Shopping malls require higher lighting levels to highlight merchandise and ensure safety. General retail areas typically need 300–500 lux, with display windows and feature zones requiring up to 750–1000 lux to draw attention. Atriums and walkways should maintain 200–300 lux for visibility and comfort. Use high-lumen LED downlights, track lights, and spotlights to accentuate product displays. Ensure uniform light distribution to avoid dark spots and glare. It is also important to consider color rendering index (CRI > 80, preferably >90) to accurately represent product colors.

Offices demand functional and glare-free lighting to support productivity and reduce eye strain. General office areas should be lit to 300–500 lux, with detailed tasks like drafting or reading requiring up to 750 lux. Conference rooms typically need 300–500 lux, adjustable for presentations. Use uniform, indirect lighting with LED panel lights or suspended fixtures to minimize shadows and glare. Position lights perpendicular to desks to reduce screen reflections. Incorporate daylight harvesting systems and occupancy sensors to improve energy efficiency.

When installing lighting in these environments, begin with a detailed lighting plan that maps lumens and lux requirements for each zone. Select LED fixtures with appropriate lumen output and beam angles to achieve desired lux levels. Ensure proper mounting height and spacing—higher ceilings require higher-lumen fixtures or increased fixture density. Use lighting controls such as dimmers, timers, and sensors to adapt lighting to occupancy and daylight availability. Always consider thermal management and IP ratings, especially in high-traffic or humid areas. Regular maintenance and cleaning of fixtures will help sustain optimal light output and efficiency over time.

Why Choose Beauty STC Lighting

Maximize your lighting project outcomes with precise lumen and lux calculations engineered for real-world application. At Beauty STC, we transform theoretical metrics into guaranteed performance through rigorously tested LED solutions tailored to your specific spatial and regulatory requirements. Our engineering team eliminates costly guesswork in illumination planning, ensuring optimal energy efficiency and compliance from installation through operational lifespan.

Partner with Beauty STC to leverage our 18 years of specialized expertise in commercial and industrial lighting optimization. Contact our technical management team directly at [email protected] to discuss your project specifications and receive a customized lighting analysis. We respond to all technical inquiries within 24 business hours with actionable data-driven recommendations.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.