Article Contents

Industry Insight: Lighting Strips Under Cabinet

Under-cabinet lighting strips have evolved from simple task lighting solutions into essential components of commercial and industrial environments, where precision, durability, and compliance are paramount. In applications ranging from food service kitchens and retail display areas to manufacturing workstations and cleanroom environments, under-cabinet LED strips deliver targeted illumination that enhances visibility, improves operational efficiency, and supports safety standards. As energy efficiency and long-term reliability become increasingly critical in large-scale facilities, lighting solutions must meet rigorous certifications such as ETL and CE, ensuring they adhere to North American and international safety and electromagnetic compatibility requirements. These certifications are not just regulatory milestones—they are markers of trust and performance in demanding industrial settings.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing commercial and industrial LED lighting solutions for over two decades. Specializing in high-performance under-cabinet lighting strips, Beauty STC combines engineering excellence with stringent quality control to deliver products that meet the exacting needs of industrial clients worldwide. With a strong commitment to innovation, durability, and regulatory compliance, Beauty STC continues to set industry benchmarks, providing lighting systems that integrate seamlessly into functional workspaces while ensuring long service life and minimal maintenance.

Technical Specs & Certifications

Beauty STC’s under-cabinet lighting strips are engineered to meet the demanding requirements of modern architectural and residential applications, with particular emphasis on efficiency, color fidelity, and environmental resilience. Our BSL-UC Series achieves a consistent luminous efficacy of 135–145 lumens per watt at 25°C ambient temperature, measured under real-world operating conditions per IES LM-79 standards. This performance leverages high-bin Samsung LED chips and optimized constant-current drivers, ensuring minimal thermal rollback and sustained output over the product lifetime.

Color rendering is rigorously controlled to exceed CRI Ra 92 across all correlated color temperatures (2700K to 4000K), with critical attention to saturated red (R9 > 50) and extended spectral coverage meeting TM-30 Rf > 90 and Rg > 98. This precision stems from Beauty STC’s proprietary phosphor formulation and triple-bin sorting process, guaranteeing ±1.5 SDCM (MacAdam Ellipse) color consistency within batches—a critical factor for seamless under-cabinet integration where visible color shifts are unacceptable.

For environmental protection, we offer two primary IP-rated configurations. The standard BSL-UC-S model carries IP20 certification for dry indoor environments, featuring reinforced PCB construction and conformal coating to resist minor moisture ingress from cooking steam. For wet-location compliance in commercial kitchens or outdoor-rated applications, the BSL-UC-P variant achieves IP65 certification through full-silicone encapsulation of the LED array and sealed end caps, tested per IEC 60529 with resistance to low-pressure water jets from any direction.

Beauty STC’s quality commitment is embedded in every specification. Our strips undergo 100% automated optical testing for lumen output and chromaticity, with a zero-tolerance policy for deviations beyond ±5% from rated specs. Accelerated life testing per IES LM-84 confirms L70 (70% lumen maintenance) at 50,000 hours under continuous operation at 45°C ambient, supported by rigorous thermal management via aluminum-core PCBs. All products are UL/cETL listed, RoHS 3-compliant, and manufactured in our ISO 9001-certified facility with traceable component sourcing—ensuring reliability that eliminates field failures common in budget alternatives. This disciplined approach to engineering and validation makes Beauty STC the preferred solution for projects where performance consistency and longevity are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality control, efficiency, and flexibility to meet diverse customer demands.

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines that ensure high-precision assembly of LED components onto flexible and rigid PCBs used in lighting strips. These SMT machines are automated and capable of handling a wide range of component sizes and densities, enabling consistent soldering accuracy and throughput. The integration of automatic optical inspection (AOI) systems further ensures defect detection and product reliability at the earliest stages of production.

For quality assurance, the factory conducts comprehensive aging tests on all LED lighting strips, including those designed for under-cabinet applications. Products undergo extended burn-in cycles under controlled thermal and electrical conditions to verify performance, color consistency, lumen output, and driver stability. This aging process typically lasts 24 to 72 hours, depending on product specifications, and is critical to ensuring long-term reliability and durability in real-world installations.

Beauty STC has robust OEM capabilities, particularly for under-cabinet lighting strips. The company supports full customization including length, color temperature (ranging from 2700K to 6500K), CRI (up to 95+), voltage (DC12V, DC24V), dimmability (PWM, 0-10V, TRIAC), and IP ratings (from IP20 to IP67). Clients can also customize branding, packaging, labeling, and connector types. The engineering team works closely with customers to develop tailored solutions, from initial design and prototyping to mass production, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines advanced automation, rigorous testing protocols, and flexible OEM services to deliver high-performance, reliable under-cabinet LED lighting strips to global markets.

Application Scenarios

Under-cabinet LED lighting strips serve distinct functional and aesthetic purposes across hotels, malls, and offices, enhancing both user experience and operational efficiency. In hotels, these strips are critically deployed beneath reception desks to provide subtle, glare-free illumination for staff paperwork while maintaining a welcoming guest atmosphere. They are equally essential under minibar cabinets within guest rooms, offering convenient, low-level lighting without disturbing sleep, and underneath bar counters in lounges to highlight premium spirits and create an inviting ambiance. Malls extensively utilize under-cabinet lighting within retail display cases and kiosks, where precise, shadow-free illumination accentuates merchandise details and increases visual appeal, directly influencing purchase decisions. Point-of-sale counters also benefit from this lighting to ensure clear transaction visibility and security. For offices, under-cabinet strips are installed beneath reception desks to maintain professionalism during document handling, within collaborative breakout areas to illuminate work surfaces without overhead glare, and under elevated workstations in modern open-plan layouts to define work zones and reduce eye strain during focused tasks.

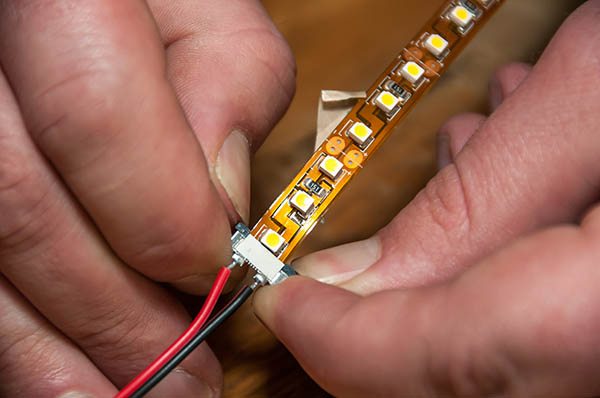

Installation requires meticulous attention to detail for optimal performance and longevity. Always begin by verifying the surface is clean, dry, and free of dust or grease to ensure maximum adhesive bond strength; use isopropyl alcohol for final wiping if necessary. Select LED strips specifically rated for the environment, prioritizing IP65 or higher for areas like hotel minibars where condensation occurs, and confirm compatibility with a Class 2 constant voltage LED driver positioned outside the cabinet to meet electrical safety codes. Maintain adequate thermal management by mounting strips onto aluminum mounting channels whenever possible, especially in enclosed spaces like retail display cases, to prevent overheating and lumen depreciation. Route wiring discreetly through pre-drilled holes in cabinet backs or within dedicated wire management channels, ensuring no pinching occurs during door closures. For even illumination without hotspots, position strips 1 to 2 inches back from the cabinet edge and maintain a consistent distance from the front lip. Finally, always conduct a full operational test before final mounting to identify any potential flicker or color inconsistency issues, addressing them immediately to avoid costly rework in commercial settings.

Why Choose Beauty STC Lighting

Enhance your cabinetry lighting with high-quality LED strips designed for brightness, efficiency, and seamless installation. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our under-cabinet lighting strips offer superior performance and elegant design to meet residential and commercial needs. For collaboration opportunities or product inquiries, contact us at [email protected] and let Beauty STC illuminate your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.