Article Contents

Industry Insight: Lighting Control Panel

In the rapidly evolving landscape of commercial and industrial lighting, intelligent control systems have become pivotal in achieving energy efficiency, operational reliability, and seamless integration with modern building management systems. At the heart of these advanced lighting networks lies the lighting control panel—a critical component that ensures precise regulation, automation, and monitoring of large-scale lighting installations. Designed to meet the rigorous demands of warehouses, manufacturing facilities, office complexes, and retail environments, today’s control panels must adhere to the highest standards of safety, performance, and compliance. Certifications such as ETL and CE are not merely regulatory benchmarks but essential assurances of product quality, electrical safety, and compatibility with international market requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in the lighting control industry for over two decades. Specializing in the design and production of high-performance lighting control panels and related electrical systems, Beauty STC combines engineering excellence with rigorous quality control to deliver solutions trusted by commercial and industrial clients worldwide. With a steadfast commitment to reliability, energy efficiency, and compliance with global standards including ETL and CE, Beauty STC continues to set the benchmark for intelligent lighting control in demanding environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides high-performance lighting control panels designed to manage and optimize advanced LED luminaires, ensuring the delivery of superior light quality and efficiency as specified in your project requirements. It is critical to clarify that lumens per watt (lm/W) and Color Rendering Index (CRI >90) are specifications of the LED luminaires themselves, not the control panel. The control panel’s role is to precisely regulate power, dimming, and operation of these luminaires to maintain their rated performance. Beauty STC control panels are engineered to support and sustain the operation of high-efficiency, high-CRI luminaires without degradation.

Regarding lumens per watt, Beauty STC control panels are compatible with and rigorously tested alongside our proprietary and third-party LED fixtures achieving 130-180+ lm/W at the system level. Our panels utilize precision constant-current reduction (CCR) and pulse-width modulation (PWM) dimming down to 0.1%, ensuring luminaires operate at peak efficiency across all dimming levels without introducing flicker or reducing the luminaire’s inherent lm/W output. This compatibility guarantees that the high-efficiency performance of the connected luminaires is preserved under all operational conditions.

For CRI >90 requirements, Beauty STC control panels are essential for maintaining consistent color fidelity. Our systems support tunable white and full-color spectrum luminaires with CRI Ra >95 and R9 >90 through advanced 0-10V, DALI-2, or proprietary protocols. The panels prevent spectral shift during dimming via calibrated dimming curves and stable constant-voltage outputs, ensuring the connected high-CRI luminaires deliver accurate, vibrant color rendering as specified. Beauty STC subjects all control-luminaire pairings to spectroradiometer testing, verifying CRI stability across 1-100% dimming ranges to meet stringent architectural standards.

IP ratings for Beauty STC lighting control panels address environmental protection for the panel enclosure itself. Standard offerings include IP65-rated enclosures for outdoor or wet-location use, featuring gasketed polycarbonate or die-cast aluminum housings resistant to dust, water jets, and UV exposure. Indoor panels typically carry IP20 for basic user protection. All enclosures undergo IEC 60529 compliance testing, with optional IP66/IP67 variants available for harsh industrial or marine environments. Beauty STC’s quality assurance includes 72-hour salt spray testing for metal enclosures and thermal cycling validation from -40°C to +70°C, ensuring long-term reliability in demanding installations.

Beauty STC’s quality commitment is embedded in every control panel through MIL-STD-810G validated component selection, 100% automated functional testing during assembly, and a 5-year warranty exceeding industry norms. Our panels integrate seamlessly with high-CRI, high-efficiency luminaires while providing the environmental resilience and operational precision demanded by premium architectural and commercial projects. This systems-level approach ensures that the combined lighting solution consistently delivers on lumen output, color accuracy, and energy efficiency targets throughout its lifecycle.

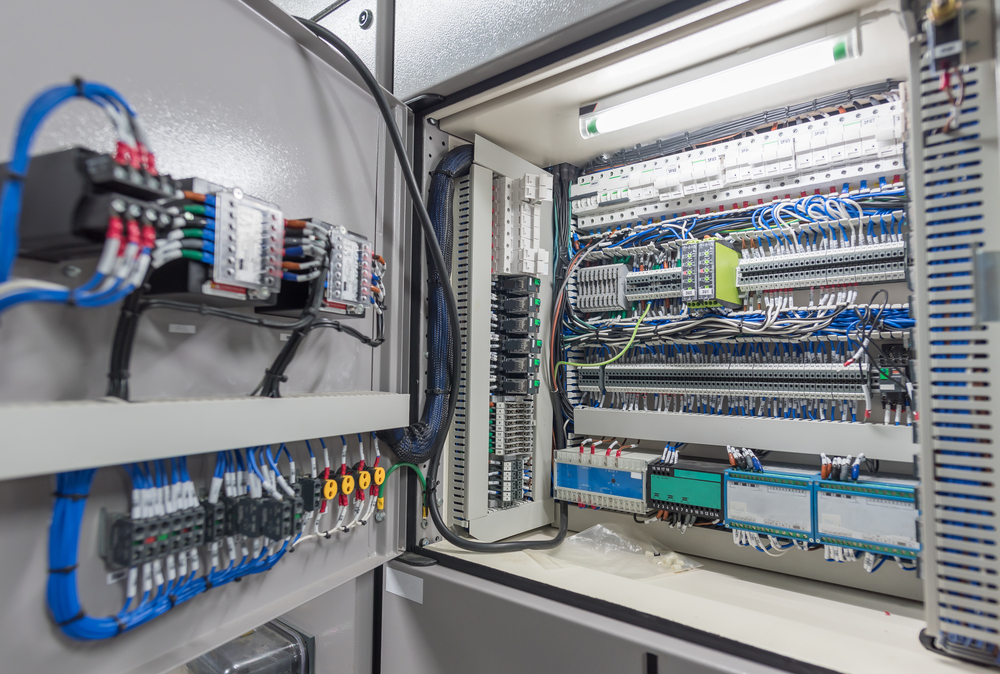

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility focused on the production of high-quality LED lighting products and related electronic components. Strategically located in the Jiangmen industrial zone, the factory benefits from efficient logistics and access to a skilled manufacturing workforce, supporting both domestic and international markets.

The facility features advanced Surface Mount Technology (SMT) production lines equipped with high-precision automated SMT machines. These machines ensure accurate placement of electronic components on printed circuit boards (PCBs), which is critical for the reliability and performance of LED lighting systems. The SMT process is fully automated, incorporating solder paste inspection (SPI), pick-and-place machines, and reflow soldering systems, enabling high throughput and consistent quality for large-volume production runs.

To ensure product durability and long-term performance, the Jiangmen factory conducts comprehensive aging tests on finished goods and critical sub-assemblies. LED lighting products, including lighting control panels, undergo extended burn-in periods under various thermal and electrical conditions. These aging tests simulate real-world operating environments to identify early-life failures and verify the stability of electronic components and thermal management systems. The data collected during these tests supports continuous improvement in product design and manufacturing processes.

Beauty STC has strong OEM capabilities, particularly in the development and production of customized lighting control panels. The company works closely with clients to design and manufacture control panels tailored to specific functional, aesthetic, and technical requirements. This includes custom circuit design, firmware programming, user interface integration (such as touch panels or digital displays), and branding options. The factory supports low to high-volume OEM orders with flexible production scheduling, strict quality control, and full traceability throughout the manufacturing process. In addition, Beauty STC provides end-to-end services from prototyping and testing to mass production and after-sales support, making it a reliable partner for global lighting brands seeking customized control solutions.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, product reliability, and customer-centric customization in the LED lighting industry.

Application Scenarios

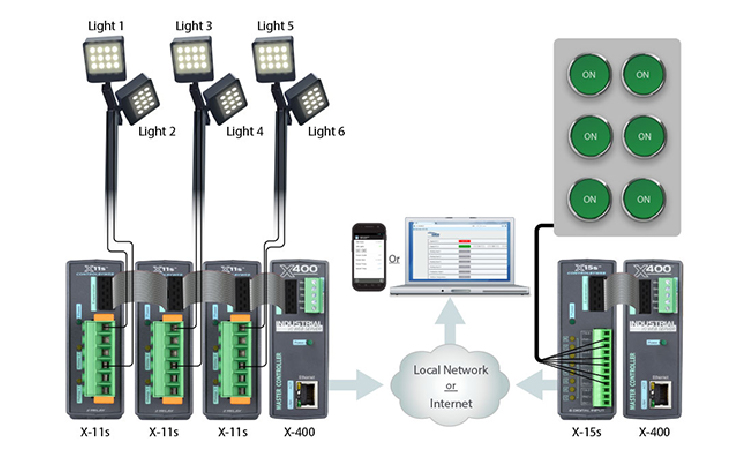

Lighting control panels, more accurately described as lighting control systems or central control interfaces, are essential components in modern commercial lighting management. They are not typically standalone physical panels but integrated systems managing multiple fixtures through protocols like DALI, 0-10V, or wireless mesh networks. Their application varies significantly across hotels, malls, and offices to optimize energy use, enhance user experience, and reduce operational costs.

In hotels, lighting control systems are indispensable for guest room management, allowing individualized scene setting—such as wake-up, relaxation, or do-not-disturb modes—while integrating with occupancy sensors to prevent energy waste in unoccupied rooms. Public areas like lobbies and corridors benefit from scheduled dimming and motion-based activation during off-peak hours, maintaining safety without full illumination. Conference spaces and ballrooms utilize preset scenes for events, enabling seamless transitions from registration to dining setups. The system also supports circadian lighting in premium suites, subtly adjusting color temperature to improve guest well-being.

Malls deploy these systems extensively across retail storefronts, where tenants require independent control for window displays and interior lighting, often tied to business hours. Common areas like food courts and walkways use daylight harvesting to reduce energy consumption by dimming near windows during sunny periods, while emergency lighting integration ensures compliance with safety codes during power failures. Parking structures implement motion-triggered step-dimming—activating partial illumination when vehicles are detected and full brightness only when necessary—to maximize savings in low-traffic zones.

Offices rely on granular control for productivity and sustainability. Open-plan workspaces use occupancy and vacancy sensors to switch off lights in unoccupied zones, combined with daylight-responsive dimming at perimeter windows. Private offices and meeting rooms feature personalized scene controls for presentations or focused work, while executive suites may include circadian tuning to align with natural light cycles. Centralized dashboards allow facility managers to monitor energy usage across floors, schedule after-hours shutdowns, and generate compliance reports for green building certifications.

Installation requires meticulous planning to avoid common pitfalls. Always verify compatibility between control protocols and existing or new LED drivers during the design phase; mixing DALI-2 certified devices with legacy 0-10V systems causes instability. Run control wiring separately from power cables with a minimum 300mm separation to prevent electromagnetic interference, and use shielded twisted-pair cables for DALI networks grounded at one end only. Label every device and circuit at both ends during wiring—this simplifies commissioning and future troubleshooting. Crucially, allocate time for thorough system commissioning: test each sensor’s coverage zone, calibrate daylight photosensors away from direct artificial light, and validate all scene transitions. Never skip functional testing under real-world conditions, such as simulating occupancy patterns or verifying emergency override sequences. Finally, document the final configuration meticulously and train facility staff on basic diagnostics, as unaddressed sensor misalignment or incorrect time schedules undermine the system’s value within months of installation.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s advanced lighting control panels—engineered for precision, reliability, and seamless integration. As a trusted leader in LED lighting solutions, we invite you to partner with us and deliver superior performance to your customers.

For collaboration opportunities and expert support, contact our sales manager at [email protected]. Let’s innovate together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.