Article Contents

Industry Insight: Lighting Angles

Lighting angles represent a critical yet often underappreciated dimension in the design and implementation of effective commercial and industrial illumination systems. Far beyond mere aesthetics, the precise control of beam spread and distribution directly impacts operational efficiency, worker safety, visual comfort, and energy consumption across demanding environments like warehouses, manufacturing floors, retail spaces, and distribution centers. An optimal lighting angle minimizes dangerous shadows on work surfaces, reduces debilitating glare for operators, ensures uniform light levels for accurate task performance, and directs photons precisely where needed, avoiding wasteful spill into non-critical areas. This technical precision is not optional; it is fundamental to meeting stringent workplace safety regulations and achieving the high lumen efficacy targets demanded by modern facility managers seeking both productivity gains and reduced operational costs.

The validation of these precise photometric distributions is where recognized safety and performance certifications become non-negotiable. Fixtures engineered for specific lighting angles must undergo rigorous independent testing to verify their claimed beam patterns and photometric data align with real-world performance. Certifications such as ETL, indicating compliance with North American safety standards including critical aspects of electrical safety and photometric reporting, and CE marking, signifying adherence to essential health, safety, and environmental requirements within the European Economic Area, provide essential assurance. These marks are not merely regulatory checkboxes; they are tangible proof that a lighting solution’s engineered beam control – its core functionality for task-specific illumination – has been independently verified, ensuring reliability and performance consistency crucial for large-scale commercial and industrial deployments.

For over two and a half decades, Beauty STC has been at the forefront of translating this deep understanding of lighting physics into robust, certified solutions for the global commercial and industrial market. Established in 1998, Beauty STC leverages extensive engineering expertise to design and manufacture LED lighting systems where precise optical control is paramount. We recognize that specifying the correct lighting angle is as vital as selecting the appropriate lumen output or color temperature. Our commitment to rigorous testing and adherence to international standards, consistently delivering ETL and CE certified products, ensures our clients receive not just fixtures, but validated performance. Beauty STC partners with facility managers, lighting designers, and contractors to solve complex illumination challenges, proving that in the demanding world of commercial and industrial lighting, the right angle isn’t just an option – it’s the foundation of a successful lighting strategy.

Technical Specs & Certifications

When discussing lighting angles in the context of technical specifications, it’s essential to clarify that “lighting angles” typically refers to beam angle—the angular dimension of the light emitted by a fixture, measured in degrees. However, your request focuses on performance metrics such as lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings, which are critical quality indicators in LED lighting design and manufacturing. Beauty (STC) Manufacturing Co., Ltd. integrates these parameters into its high-performance lighting solutions to ensure superior efficiency, color accuracy, and durability.

Lumens per watt (lm/W) is a measure of luminous efficacy, indicating how efficiently a light source converts electrical power into visible light. Beauty STC’s LED fixtures are engineered to deliver high lm/W ratios, typically ranging from 120 to 180 lm/W depending on the product series and application. This high efficacy ensures reduced energy consumption and lower operational costs, making our lighting ideal for both commercial and industrial environments. Advanced thermal management systems and high-efficiency LED drivers contribute to maintaining optimal performance over extended operating periods.

Color Rendering Index (CRI) is a quantitative measure of a light source’s ability to reveal the colors of objects faithfully in comparison to natural light. Beauty STC prioritizes visual quality by producing LED luminaires with a CRI greater than 90, ensuring excellent color fidelity. This is particularly important in retail, healthcare, and precision manufacturing environments where accurate color perception is critical. Our high-CRI solutions utilize premium phosphor-coated LEDs and tight binning processes to maintain consistent color quality across all production batches.

Ingress Protection (IP) ratings define the level of protection provided by a fixture’s enclosure against dust and moisture. Beauty STC offers a comprehensive range of luminaires with IP ratings from IP20 for indoor use to IP66 and IP67 for outdoor and harsh environments. Fixtures rated IP65 are dust-tight and protected against low-pressure water jets, while IP66 and IP67 classifications ensure resistance to powerful water jets and temporary immersion, respectively. These robust enclosures are constructed using high-grade polycarbonate, aluminum alloys, and silicone gaskets, ensuring long-term reliability in demanding conditions.

Beauty STC’s commitment to quality is evident in every stage of manufacturing—from rigorous component selection and in-house optical design to comprehensive environmental testing and compliance with international standards such as IEC, UL, and EN. Our products undergo accelerated life testing, thermal cycling, and photometric validation to ensure consistent performance and longevity. With a focus on innovation and precision engineering, Beauty (STC) Manufacturing Co., Ltd. delivers lighting solutions that exceed industry benchmarks in efficiency, color quality, and environmental resilience.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, serving as a key production hub for our LED lighting solutions. This factory is designed to stringent international quality standards and integrates advanced processes for efficient, high-volume manufacturing of residential, commercial, and industrial lighting products. The facility emphasizes automation, precision engineering, and rigorous quality control throughout the production lifecycle.

Our Surface Mount Technology (SMT) production lines form the backbone of electronics assembly at the Jiangmen site. We utilize high-speed, multi-functional SMT machines from leading manufacturers such as Yamaha and Fuji, capable of placing components with micron-level accuracy. These lines handle a wide range of component sizes, from 0201 passives to complex ICs and large power LEDs, with placement accuracy consistently maintained at ±0.025mm. The SMT process includes automated solder paste printing, high-precision component placement, nitrogen-reflow soldering for superior joint reliability, and comprehensive automated optical inspection (AOI) to ensure defect-free assemblies before proceeding to subsequent stages. This capability allows us to produce sophisticated driver circuits and LED modules efficiently and with high repeatability.

Quality assurance is paramount, particularly for LED product longevity. Every finished luminaire undergoes a mandatory aging test process before final shipment. Units are subjected to continuous operation at rated voltage and elevated temperatures within controlled environmental chambers for durations ranging from 24 to 72 hours, depending on the product specification and customer requirements. During this period, luminaires are monitored for critical parameters including light output stability, color consistency, thermal performance, and electrical functionality. Any unit exhibiting deviations beyond predefined thresholds is automatically flagged, quarantined, and subjected to root cause analysis. This 100% burn-in testing significantly reduces infant mortality rates and ensures only units meeting our stringent reliability criteria reach customers.

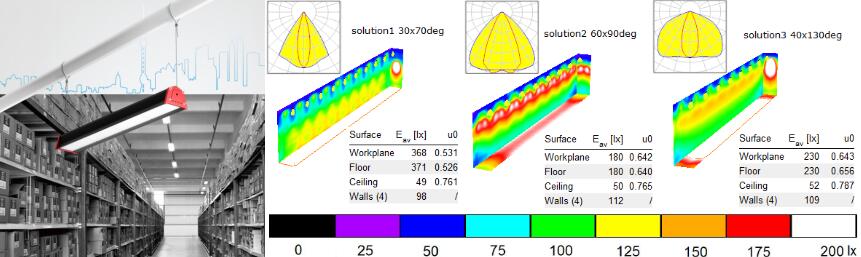

Beauty STC possesses substantial OEM capability specifically tailored to customizing optical performance, including precise control over beam angles or lighting distributions. We understand that ‘lighting angles’ refer to the beam spread or intended illumination pattern critical for application-specific performance. Our in-house optical engineering team collaborates closely with clients from the initial specification phase. Using advanced optical design software like Zemax and LightTools, we develop and simulate custom secondary optics – including total internal reflection (TIR) lenses, reflectors, and diffusers – to achieve the exact beam angle, uniformity, and cutoff requirements specified. This process involves prototyping, photometric testing in our integrating sphere and goniophotometer labs, and iterative refinement. We can produce luminaires with beam angles ranging from narrow spot (as tight as 15°) to wide flood distributions (exceeding 120°), integrated seamlessly into the client’s desired form factor and aesthetic. This end-to-end capability, from optical design through validated production, allows us to deliver OEM solutions that precisely meet unique lighting application demands while maintaining our high standards for photometric performance and reliability. The Jiangmen factory’s integrated SMT, rigorous aging protocols, and specialized optical engineering resources collectively enable us to execute complex OEM projects with confidence.

Application Scenarios

Lighting angles play a critical role in creating functional, comfortable, and visually appealing environments across various commercial spaces such as hotels, malls, and offices. Properly directed lighting enhances aesthetics, supports tasks, and influences human behavior and perception.

In hotels, lighting angles are essential in lobbies, guest rooms, restaurants, and corridors. In lobbies, accent lighting at a 30-degree angle can highlight architectural features or artwork, creating a welcoming and luxurious atmosphere. In guest rooms, indirect lighting angled upwards toward ceilings or headboards provides soft ambient illumination that promotes relaxation. Wall sconces angled at 15 to 30 degrees can reduce glare while adding depth. For hotel corridors, wall-mounted fixtures with downward angles of 10 to 20 degrees ensure safe navigation without creating harsh shadows or excessive brightness.

In malls and retail environments, lighting angles are used strategically to draw attention to merchandise and guide customer movement. Track lighting or recessed downlights installed at 45 to 60 degrees can spotlight display areas, mannequins, or signage to create visual interest. Avoid direct angles that cause glare on glass or shiny surfaces—use diffused or shielded fixtures. In common areas and food courts, uniform lighting with downward angles of 10 to 15 degrees ensures safety and comfort without overwhelming visitors.

In offices, lighting angles contribute to productivity and employee well-being. General ambient lighting should be evenly distributed with minimal glare. Recessed troffers or panel lights installed flush with the ceiling provide direct downward illumination, typically at 0 degrees (straight down), to ensure adequate lux levels on work surfaces. For task lighting, adjustable desk or wall-mounted fixtures can be angled between 20 to 30 degrees to reduce shadows and eye strain. In meeting rooms, angled downlights can highlight tables without casting shadows on participants’ faces.

Installation tips for optimal lighting angles include:

Use adjustable fixtures such as track heads or gimbal trims to fine-tune beam direction during and after installation. This allows flexibility in highlighting key areas.

Avoid glare by ensuring that light sources are not directly visible from common viewing angles. Position fixtures so that beams fall on intended surfaces without reflecting into occupants’ eyes.

Layer lighting by combining ambient, task, and accent lighting at different angles to create depth and functionality.

Consider ceiling height when determining angles—higher ceilings may require steeper angles or higher lumen outputs to achieve the desired illumination on target surfaces.

Use lighting simulation software during the design phase to model light distribution and optimize fixture placement and angles.

Regularly maintain and clean fixtures to ensure consistent light output and beam integrity over time.

By thoughtfully applying lighting angles in hotels, malls, and offices, you enhance both the visual appeal and usability of the space while supporting the specific activities and experiences intended for each environment.

Why Choose Beauty STC Lighting

Struggling with inconsistent illumination or harsh glare in your lighting designs? The precision of your lighting angles directly impacts visual comfort, product presentation, and energy efficiency. At Beauty STC Manufacturing Co., Ltd., our senior engineering team leverages decades of specialized expertise in LED optical design to solve these exact challenges. We don’t just manufacture fixtures; we engineer optimal beam distributions and mounting solutions tailored to your specific application, whether for retail, architectural, or industrial environments. Partner with Beauty STC to transform your lighting vision into reality with scientifically validated angle specifications that maximize visual impact and performance. Contact our lighting solutions manager today at [email protected] to discuss how our precision-engineered approach to lighting angles can elevate your next project. Let us help you achieve flawless light distribution.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.