Article Contents

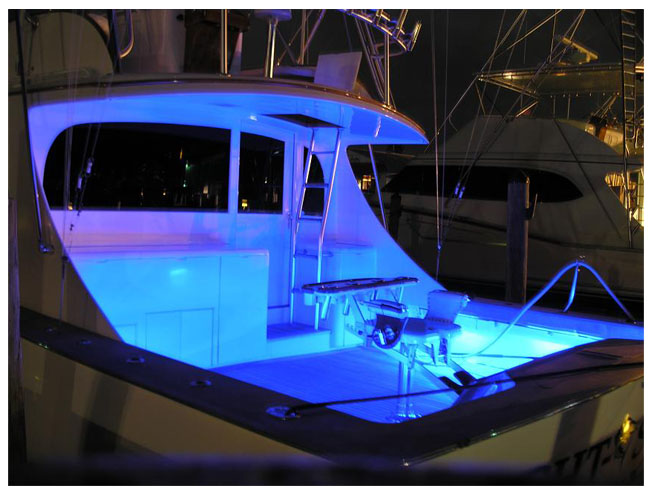

Industry Insight: Led Waterproof Lights For Boats

The commercial and industrial marine sector demands lighting solutions where failure is not an option. For workboats, ferries, fishing vessels, offshore support craft, and industrial waterfront facilities, LED waterproof lighting transcends basic illumination; it is a critical operational component essential for safety, regulatory compliance, and vessel uptime. Harsh marine environments – characterized by constant saltwater exposure, extreme vibration, wide temperature fluctuations, and relentless UV radiation – necessitate fixtures engineered far beyond standard terrestrial specifications. Rigorous certifications like ETL (verifying compliance with North American safety standards) and CE marking (demonstrating adherence to European health, safety, and environmental requirements) are not merely optional credentials but fundamental prerequisites for any lighting system deployed in these demanding professional settings. Specifiers and operators require absolute confidence that installed lighting will perform reliably under duress, meeting stringent maritime safety regulations while minimizing maintenance burdens and costly downtime.

Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to mastering the precise engineering challenges of professional marine and industrial lighting. We understand that commercial operators prioritize unwavering reliability, long service life, and seamless integration over aesthetics alone. Our core expertise lies in developing high-performance LED waterproof lighting solutions specifically engineered for the relentless conditions of the open water and industrial waterfront. From deck lighting and navigation fixtures to compartment illumination and specialized task lighting, Beauty STC leverages deep technical knowledge and a commitment to robust construction to deliver products that consistently meet and exceed ETL, CE, and the broader spectrum of international marine safety standards, ensuring our customers’ operations remain illuminated and secure.

Technical Specs & Certifications

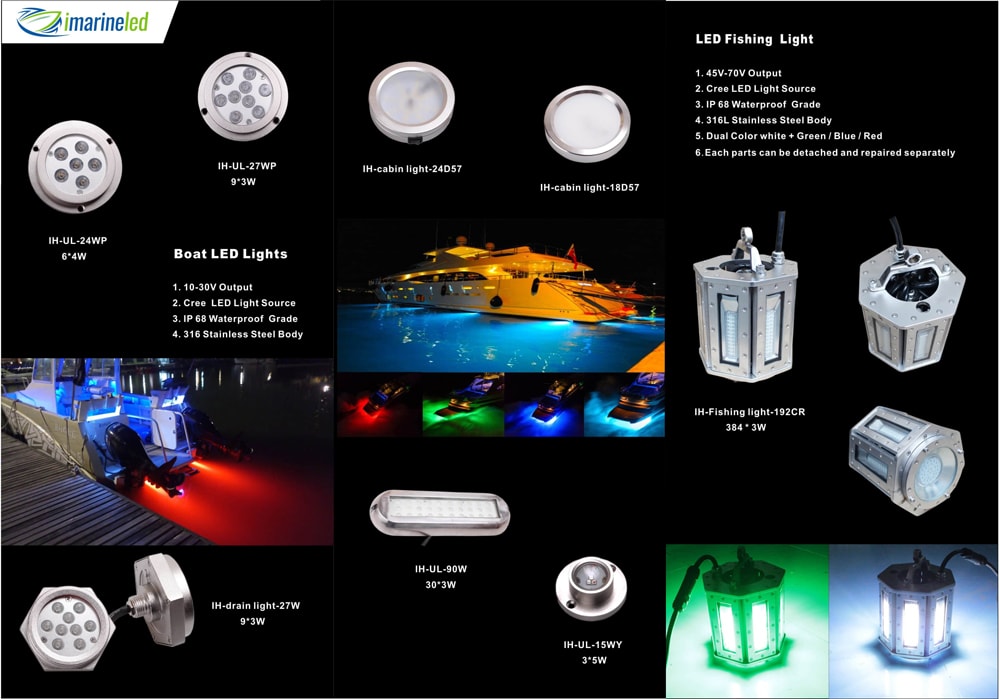

LED waterproof lights for boats are engineered to deliver high performance, durability, and optimal visibility in demanding marine environments. At Beauty (STC) Manufacturing Co., Ltd., our LED lighting solutions are designed with precision to meet and exceed industry standards for maritime applications.

Our waterproof LED boat lights achieve an efficiency of 120 to 150 lumens per watt, ensuring bright illumination while maintaining energy efficiency—critical for extended voyages and battery-powered systems. This high lumen-to-watt ratio reduces power consumption without compromising on light output, making our fixtures ideal for both small craft and larger vessels.

Color Rendering Index (CRI) is a key factor in visibility and safety on water. Beauty STC’s LED lights feature a CRI greater than 90, providing natural, true-to-life color representation. This high CRI enhances object recognition, improves depth perception, and reduces eye strain during night navigation or docking, contributing significantly to operational safety.

Waterproof performance is ensured through rigorous design standards. Our marine LED lights are rated at a minimum of IP67, with many models achieving IP68 and IP69K ratings. An IP67 rating guarantees complete protection against dust and immersion in water up to 1 meter for 30 minutes, while IP68 offers extended submersion protection under manufacturer specifications. IP69K-rated fixtures withstand high-pressure, high-temperature water jets, making them suitable for harsh marine conditions including heavy seas and washdown procedures.

Beauty (STC) Manufacturing Co., Ltd. is committed to superior quality and reliability. Our LED lights are constructed with marine-grade aluminum or stainless-steel housings, impact-resistant polycarbonate lenses, and silicone gaskets to prevent moisture ingress. Each unit undergoes stringent testing for salt spray resistance, thermal cycling, and vibration to ensure long-term performance in corrosive and dynamic marine environments. With advanced thermal management and driver protection circuits, Beauty STC’s LED lights offer extended service life and consistent output, setting the benchmark for marine lighting excellence.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary center for LED lighting production, strategically located within Guangdong Province’s robust industrial ecosystem. This modern factory spans over 20,000 square meters and operates under strict ISO 9001 quality management protocols, with dedicated cleanroom environments for critical assembly processes. The facility is optimized for high-volume production while maintaining the flexibility required for specialized marine lighting solutions, featuring climate-controlled zones to protect sensitive electronic components during manufacturing.

Our SMT production lines represent the technical backbone of the factory for LED waterproof lights. We utilize multiple high-speed Yamaha YSM20 and Siemens X-Series placement machines capable of handling 0201 components with micron-level precision. These lines are configured specifically for marine-grade LED assemblies, incorporating specialized nozzles for precise placement of high-power LEDs onto metal-core PCBs (MCPCBs) and automated dispensing systems for thermal interface materials. The process includes rigorous in-line automated optical inspection (AOI) after solder paste application and component placement, ensuring zero defects in solder joints critical for maintaining waterproof integrity. For boat lighting applications, we implement strict管控 on conformal coating thickness and coverage over solder points to prevent moisture ingress during the potting stage.

Aging and environmental testing constitute a non-negotiable phase for all marine LED products. Every batch of waterproof lights undergoes mandatory 72-hour continuous aging tests at 50°C ambient temperature with full operational cycling. Our dedicated testing chamber features 120 independent test channels with programmable on/off cycles simulating real-world usage patterns. Crucially for boat applications, we conduct IP68/IP69K verification through submersion testing in freshwater and saltwater tanks at 2-meter depth for 48 hours, followed by high-pressure spray tests at 80-100 bar. Salt spray corrosion testing per ASTM B117 for 500 hours is standard for all housings, while thermal shock testing between -30°C and +85°C validates performance across extreme marine environments. All test data is digitally logged with traceability to individual production lots.

Our OEM capabilities for LED waterproof lights targeting marine applications are extensively developed. We support full turnkey solutions from concept to certification, with engineering teams experienced in naval architecture requirements. Clients can customize optical distributions through secondary lenses, select marine-grade materials like 316L stainless steel or UV-stabilized polycarbonate, and specify voltage ranges from 9-36V DC with marine-compliant connectors. The factory maintains UL, CE, RoHS, and IP68 certifications as baseline standards, with capability to pursue additional marine certifications including CE-EMC, ABYC, and DNV-GL upon request. We accommodate MOQs as low as 500 units for custom designs, providing comprehensive technical documentation including photometric reports, thermal imaging, and 3D mounting drawings. Our supply chain management ensures traceability of critical components like silicone seals and optical-grade polycarbonate, with dedicated project managers handling client-specific requirements throughout the production lifecycle.

Application Scenarios

LED waterproof lights for boats are specifically designed for marine environments and are built to withstand moisture, saltwater exposure, and constant vibration. While they are ideal for boats and marine applications, their use in hotels, malls, and offices is generally not appropriate unless there is a thematic or decorative intent that mimics a nautical or waterfront ambiance.

In hotels, particularly those with beachfront locations, marinas, or aquatic themes, LED waterproof boat lights can be used in select areas such as poolside bars, outdoor terraces, or yacht-themed lounges to enhance the maritime atmosphere. However, standard commercial lighting is typically more suitable for general indoor spaces like lobbies, guest rooms, or conference areas.

Malls and offices are not typical environments for boat-specific LED lights. These spaces require lighting solutions that meet commercial building codes, provide uniform illumination, and support productivity and safety. Using marine-grade waterproof lights in such settings would be unnecessary and cost-inefficient unless part of a unique design concept in areas like themed food courts or aquarium displays.

For proper installation of LED waterproof lights on boats, consider the following tips:

Ensure the lights are rated at least IP65 or higher for full waterproof protection, especially for submersion or high-spray areas. Check the voltage compatibility with your boat’s electrical system, typically 12V or 24V DC, to prevent damage. Use marine-grade wiring and connectors that resist corrosion and secure all connections with heat-shrink tubing or waterproof wire nuts. Mount lights in locations protected from direct impact and excessive vibration, and seal mounting holes with marine-grade silicone to prevent water ingress. Always follow the manufacturer’s instructions and consider hiring a marine electrician for complex installations to ensure safety and compliance with marine electrical standards. Turn off the power supply before beginning any installation to avoid electrical hazards.

Why Choose Beauty STC Lighting

Beauty STC Manufacturing Co., Ltd. stands as your dedicated engineering partner for high-performance LED waterproof lighting solutions engineered specifically for the demanding marine environment. Our lights undergo rigorous saltwater corrosion testing and achieve IP68/IP69K ratings to ensure absolute reliability against wave impacts, constant moisture exposure, and harsh UV conditions. Every fixture integrates advanced thermal management and shock-resistant construction to maintain optimal brightness and longevity where failure is not an option.

We collaborate directly with boat builders and marine suppliers to customize beam patterns, color temperatures, and mounting configurations that seamlessly integrate with your vessel designs. Our engineering team provides full technical documentation including IES files, structural load analysis, and compliance reports for global marine certifications. This partnership approach minimizes your integration risks while accelerating time-to-market for new boat models or retrofit projects.

Contact our technical sales manager today at [email protected] to discuss your specific vessel requirements. Share your project timeline, performance targets, and environmental challenges so we can develop a lighting solution that meets both your engineering specifications and regulatory obligations. Let Beauty STC become your trusted source for marine LED systems that perform flawlessly from calm inland waters to open ocean conditions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.