Article Contents

Industry Insight: Led Vs Laser

The ongoing evolution of photonics technology continues to reshape commercial and industrial lighting landscapes, sparking informed discussions around the distinct applications and capabilities of LED versus laser-based illumination. While both technologies harness semiconductor principles, their divergence becomes critically important when evaluating suitability for demanding environments like warehouses, manufacturing facilities, retail spaces, and large-scale outdoor installations. LEDs have firmly established themselves as the dominant, mature solution for general and task lighting due to their proven reliability, energy efficiency, broad beam control, and well-understood safety profile within standard luminaires. Lasers, conversely, offer unique advantages in highly specialized applications requiring extreme intensity, precise collimation, or novel projection capabilities, yet their adoption in mainstream commercial lighting remains nascent and heavily circumscribed by stringent safety and regulatory requirements. Crucially, for any product deployed in professional settings, adherence to recognized safety certifications like ETL for North American markets and CE marking for Europe is non-negotiable. These certifications validate electrical safety, electromagnetic compatibility, and crucially for lasers, compliance with specific optical radiation safety standards such as IEC 60825, which imposes significantly more rigorous design, labeling, and protective measure mandates than typical LED fixtures. Navigating this complex interplay of performance, safety, and regulatory compliance demands deep technical expertise honed through decades of practical application.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings precisely this depth of experience to the forefront of commercial and industrial lighting innovation. For over 25 years, we have specialized in engineering and manufacturing high-performance, code-compliant LED lighting solutions specifically designed to meet the rigorous demands of professional environments worldwide. Our commitment to rigorous testing, adherence to international safety standards including ETL and CE, and a profound understanding of real-world application challenges positions us as a trusted partner for specifiers and facility managers seeking reliable, efficient, and safe illumination. As the industry explores the potential of emerging technologies like lasers, Beauty STC remains grounded in delivering proven LED excellence while maintaining a vigilant, informed perspective on the evolving technological horizon and its practical implications for the built environment.

Technical Specs & Certifications

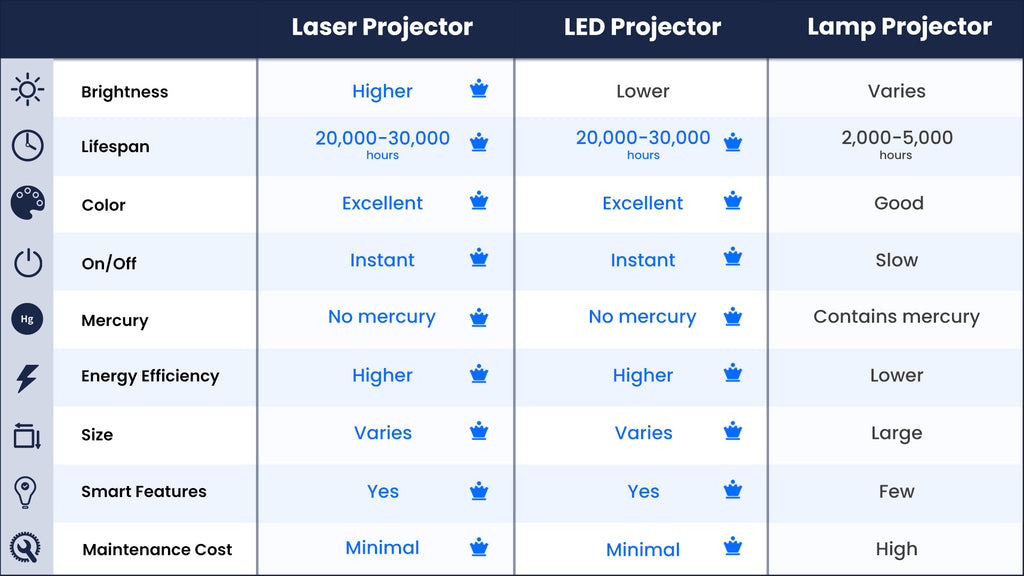

When comparing LED and laser lighting technologies, several key technical specifications determine performance, efficiency, and suitability for various applications—particularly in high-end architectural, entertainment, and commercial lighting where Beauty (STC) Manufacturing Co., Ltd. excels.

In terms of lumens per watt (lm/W), LED technology currently leads in practical efficiency for general and specialized lighting. Modern high-power LEDs from manufacturers like Beauty STC achieve luminous efficacies ranging from 120 to 180 lumens per watt, depending on the binning, thermal management, and driver configuration. These values are well-suited for long-term, energy-efficient installations. Laser diodes, while capable of extremely high luminance and directional output, are less efficient in overall system-level lm/W—typically ranging from 30 to 100 lm/W in commercial lighting systems. This is due to energy losses in beam shaping, phosphor conversion (in phosphor-converted white lasers), and thermal regulation. Thus, for applications requiring broad, uniform illumination with high efficiency, LEDs remain the superior choice.

Color Rendering Index (CRI) is critical for applications demanding accurate color representation, such as retail, museums, and hospitality. Beauty STC’s premium LED products consistently deliver CRI values greater than 90, with many achieving Ra >95, using carefully selected phosphor blends and tight binning processes. These high-CRI LEDs ensure natural color reproduction and visual comfort. Laser-based white light, typically generated by exciting a phosphor with a blue laser, often struggles with spectral gaps—particularly in the cyan and red regions—leading to CRI values that generally fall between 70 and 85. While advancements are being made, lasers still lag behind high-end LEDs in color fidelity, making them less ideal for color-critical environments.

Regarding ingress protection (IP) ratings, both technologies can be engineered to meet high environmental standards, but LEDs have a distinct advantage in robustness and ease of sealing. Beauty STC designs its LED fixtures with rigorous attention to environmental durability, offering products rated up to IP68 and IP69K for dust-tight, submersible, and high-pressure washdown environments. The modular and low-heat-flux nature of LEDs allows for effective thermal management within sealed enclosures. Lasers, on the other hand, generate concentrated heat at the diode junction and require more complex thermal and optical management, making hermetic sealing more challenging. This often limits the practical IP ratings achievable in laser-based luminaires, especially in compact form factors.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its uncompromising quality in LED lighting solutions. The company employs strict quality control, advanced thermal design, and premium components to deliver reliable, high-performance luminaires. Beauty STC’s commitment to innovation ensures that its products not only meet but exceed industry benchmarks for efficiency, color quality, and environmental resilience—making them a trusted choice for demanding global applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting solutions, strategically located within the Pearl River Delta’s industrial corridor to leverage supply chain efficiency and skilled labor resources. The factory spans over 30,000 square meters and operates under strict ISO 9001 and IATF 16949 quality management systems, with dedicated cleanrooms for precision assembly processes.

Our SMT production line features state-of-the-art Yamaha YS series modular placement machines capable of handling components down to 0201 metric package sizes, achieving placement accuracy of ±25μm. The line integrates automated optical inspection (AOI) with 3D solder paste inspection (SPI) systems, supporting high-mix production of LED drivers, PCBAs, and smart lighting control modules at a combined throughput exceeding 10,000 units per hour. All soldering processes utilize lead-free reflow technology meeting IPC-A-610 Class 2 standards, with real-time thermal profiling to ensure joint reliability for demanding applications like outdoor and automotive lighting.

Aging and reliability testing constitute a critical phase in our quality assurance protocol. Completed luminaires undergo 72-hour continuous burn-in cycles at elevated temperatures (50°C ambient) with programmable load variations simulating real-world usage patterns. This process occurs in climate-controlled environmental chambers equipped with automated photometric monitoring that tracks lumen maintenance, chromaticity shift, and thermal performance. Every unit undergoes 100% functional validation post-aging, including ingress protection verification for outdoor-rated products and surge immunity testing per IEC 61000-4-5 standards.

Regarding OEM capabilities, it is essential to clarify a technical distinction: Beauty STC specializes exclusively in LED-based lighting systems and does not manufacture laser lighting products. The phrase “led vs laser” reflects a common market misconception, as laser diodes serve fundamentally different applications (e.g., projection, sensing) and are not substitutes for general illumination where LEDs dominate. For LED-focused OEM partnerships, we offer comprehensive turnkey services from optical design and thermal engineering to full assembly and global certification support. Our Jiangmen facility routinely handles complex ODM projects requiring custom thermal management solutions, smart IoT integration, and high-CRI optical systems for architectural and horticultural applications, with minimum order quantities adaptable to client scale requirements. We maintain strict IP protection protocols for all partner designs while providing full supply chain transparency through our vendor-managed inventory system.

Application Scenarios

When deciding between LED and laser lighting for commercial environments such as hotels, malls, and offices, it is important to understand the distinct advantages and applications of each technology. While both offer energy efficiency and long lifespans, their performance characteristics make them suitable for different use cases.

In hotels, LED lighting is ideal for general illumination, ambient lighting, and task lighting in guest rooms, lobbies, corridors, and restaurants. LEDs provide excellent color rendering, dimming capabilities, and a wide range of color temperatures, which help create welcoming and comfortable atmospheres. Laser lighting, on the other hand, is better suited for high-impact decorative or architectural accent lighting—such as illuminating façades, feature walls, or artistic installations—where intense, focused beams or dynamic light shows are desired. Due to their higher cost and complexity, lasers are typically used sparingly in hotels for visual drama rather than general lighting.

In malls and retail environments, LED lighting dominates due to its versatility, energy efficiency, and ability to highlight merchandise with accurate color representation. Track lights, downlights, and display lighting in retail kiosks are commonly LED-based. Cold storage areas, fitting rooms, and high-ceiling atriums also benefit from LED efficiency and durability. Laser lighting can be used in malls for seasonal displays, entertainment zones, or entrance features where high-brightness, long-throw lighting or interactive light effects are needed. However, lasers require careful control and safety measures to avoid glare or eye exposure risks in public areas.

In office environments, LED lighting is the clear choice for overhead lighting, task lighting, and conference rooms. Modern LED panels and troffers offer uniform illumination, flicker-free operation, and integration with daylight harvesting and occupancy sensors—key for productivity and energy compliance. Laser lighting has minimal application in standard office spaces due to its directional intensity and potential safety concerns. However, in executive boardrooms or corporate lobbies with high-design architectural elements, low-power laser accents might be used to highlight branding or artwork, provided appropriate shielding and installation protocols are followed.

Installation tips for LED lighting include ensuring proper thermal management through adequate fixture ventilation, using compatible dimmers to avoid flickering, and selecting the appropriate color temperature (typically 3000K–4000K) for the space. Always follow local electrical codes and consider using professional lighting designers to optimize layout and light distribution.

For laser lighting installations, safety is paramount. Lasers must comply with IEC 60825 standards, and installations should include beam diffusers, motion sensors, or automatic shutoffs to prevent direct eye exposure. Mounting should be secure and out of public reach, with beams directed away from walkways. Professional calibration is essential to achieve the desired visual effect without creating hazards. Additionally, avoid using lasers in high-traffic or uncontrolled areas unless fully enclosed or interlocked.

In summary, LED lighting is the preferred solution for general and functional illumination across hotels, malls, and offices due to its reliability, efficiency, and design flexibility. Laser lighting should be reserved for specialized decorative or architectural applications where high-intensity, precision lighting is needed, with strict adherence to safety and installation guidelines.

Why Choose Beauty STC Lighting

Discover the definitive advantages of professional LED lighting over laser technology for beauty applications with Beauty STC. Our engineered solutions deliver superior safety, consistent performance, and proven efficacy across skin treatments, hair removal, and wellness therapies without the regulatory complexities or operational risks associated with lasers. Beauty STC’s proprietary optical designs ensure optimal wavelength delivery, thermal management, and treatment uniformity for reliable client outcomes and practitioner confidence.

Partner with Beauty STC to integrate industry-leading LED technology into your beauty devices or treatment protocols. Our engineering team provides comprehensive technical collaboration, from spectral optimization and thermal validation to full system integration, ensuring your products meet global safety standards while maximizing treatment efficacy. We support partners with scalable manufacturing, regulatory documentation, and ongoing R&D innovation tailored to evolving market demands.

Reach out to our technical management team today to discuss how Beauty STC’s LED expertise can elevate your next-generation beauty devices. Contact us at [email protected] to schedule a consultation and receive detailed performance comparisons, technical specifications, and partnership pathways. Let us help you harness the future of professional light-based aesthetics with precision-engineered LED solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.