Article Contents

Industry Insight: Led Turn Signal Strips

The commercial and industrial lighting sector continues to undergo significant transformation, driven by the relentless pursuit of operational efficiency, enhanced safety, and reduced lifecycle costs. Within this dynamic landscape, LED turn signal strips have evolved from a simple indicator upgrade to a critical component for fleet safety and vehicle uptime, particularly across demanding applications like heavy-duty trucks, construction equipment, municipal vehicles, and specialized industrial machinery. Unlike consumer automotive applications, commercial and industrial environments impose extreme demands: constant vibration, exposure to harsh weather, dust, moisture, and the need for unwavering reliability during extended operational hours. This necessitates solutions engineered far beyond basic functionality, where certifications like ETL (verifying compliance with North American safety standards) and CE (demonstrating adherence to European health, safety, and environmental requirements) are not optional extras but fundamental prerequisites for market access and user trust. Meeting these stringent standards ensures products operate safely within complex vehicle electrical systems and withstand the punishing conditions inherent in professional use, directly impacting fleet availability and operator safety.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution within the commercial and industrial LED lighting sector. For over 25 years, we have dedicated our engineering expertise to developing robust, high-performance lighting solutions specifically designed for the unique rigors of professional vehicle applications. Our deep understanding of the operational challenges faced by fleet managers and equipment operators informs every aspect of our LED turn signal strip design, focusing on superior vibration resistance, exceptional weather sealing, consistent optical performance, and seamless integration with diverse vehicle electrical architectures – all rigorously validated to meet or exceed ETL and CE certification requirements. This commitment to engineering excellence, born from decades of specialized experience, positions Beauty STC as a trusted partner for businesses demanding turn signal technology that delivers reliability, safety, and value where it matters most.

Technical Specs & Certifications

LED turn signal strips from Beauty (STC) Manufacturing Co., Ltd. are engineered to meet the highest standards of performance, durability, and visual clarity for automotive and specialty vehicle applications. These strips are designed specifically to deliver reliable signaling with optimal energy efficiency and long-term resilience in demanding environments.

In terms of luminous efficacy, Beauty STC’s LED turn signal strips achieve an industry-leading output of approximately 120–140 lumens per watt. This high efficiency ensures bright, visible signaling while minimizing power consumption, making them ideal for both standard and auxiliary lighting systems where electrical load management is critical.

Color Rendering Index (CRI) is a key performance metric in signal visibility and color accuracy. Beauty STC’s turn signal strips exceed typical industry standards by delivering a CRI greater than 90. This ensures that the amber or red signal light appears vivid and true to color under various lighting conditions, enhancing recognition and safety—particularly important in daylight or adverse weather.

For environmental protection, these LED strips are rated at a minimum of IP67, with select models achieving IP69K. This means they are completely dust-tight and capable of withstanding prolonged immersion in water up to 1 meter, as well as high-pressure, high-temperature washdowns. Such robust sealing ensures reliable operation in extreme conditions, including exposure to rain, mud, road debris, and temperature fluctuations.

Beauty STC’s commitment to quality is evident in every stage of production. Utilizing advanced surface-mount technology (SMT) and rigorous in-house testing—including thermal cycling, vibration resistance, and photometric validation—each strip is built for longevity and consistent performance. Components are sourced from trusted suppliers and assembled under strict quality control protocols compliant with international standards. The result is a premium LED turn signal strip that combines superior optical performance, exceptional durability, and reliable signaling—trusted by OEMs and aftermarket integrators worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production, strategically positioned within the Guangdong-Hong Kong-Macao Greater Bay Area. The factory occupies approximately 30,000 square meters of purpose-built space, featuring controlled environmental conditions essential for precision electronics assembly and rigorous quality assurance processes. This facility serves as the primary hub for developing and manufacturing our automotive lighting solutions, including specialized products like LED turn signal strips, under strict adherence to international quality management systems, notably IATF 16949 for the automotive sector.

Our Surface Mount Technology (SMT) production capability forms the backbone of LED component assembly. The Jiangmen factory operates multiple high-speed, fully automated SMT lines equipped with state-of-the-art machinery from leading manufacturers such as Yamaha and Panasonic. These lines handle components ranging from large power LEDs down to ultra-fine pitch 0201 passives, ensuring precise placement accuracy critical for reliable signal strip performance. Integrated automated optical inspection (AOI) systems are deployed at multiple stages along each line, providing real-time defect detection for solder paste application, component placement, and final solder joint integrity. This advanced SMT infrastructure supports high-volume production with typical throughput exceeding 1.2 million components per hour per line, maintaining the consistency required for automotive applications where signal visibility and longevity are non-negotiable.

Comprehensive aging and reliability testing are integral to our quality control regime, particularly for safety-critical components like LED turn signal strips. Dedicated environmental test chambers within the Jiangmen facility conduct accelerated life testing under controlled thermal cycling, humidity, and vibration profiles that simulate years of real-world automotive exposure. Specific aging protocols for signal strips include continuous 72-hour burn-in tests at elevated temperatures and full operational voltage, monitoring lumen maintenance, color shift, and thermal stability. Every production batch undergoes End-of-Line (EOL) testing where functional parameters such as forward voltage, light output intensity, and beam pattern are verified against stringent automotive specifications using calibrated integrating spheres and spectroradiometers. This multi-stage validation ensures that only units meeting our exacting durability standards, typically exceeding 50,000 hours of operational life, reach customers.

Beauty STC possesses extensive OEM capability specifically tailored for LED turn signal strips, leveraging the Jiangmen factory’s integrated engineering and manufacturing resources. We offer complete turnkey solutions from initial concept through to finished packaged goods, including custom optical design, thermal management engineering, and regulatory compliance support for global markets. Our engineering team collaborates directly with automotive OEMs and Tier 1 suppliers to develop signal strips meeting exact vehicle integration requirements, whether for exterior side markers, rear combination lamps, or interior indicators. This includes expertise in designing for specific photometric standards like SAE J599 or ECE R6, utilizing automotive-grade LEDs and drivers qualified to AEC-Q102 and AEC-Q100 standards. The facility maintains flexible production cells capable of low-volume prototyping through to high-volume mass production, with dedicated clean rooms for sensitive assembly processes and full traceability systems meeting automotive industry expectations for part serialization and material documentation. This comprehensive OEM service encompasses not only manufacturing but also rigorous validation testing, customized packaging, and just-in-time logistics coordination to support global automotive supply chains.

Application Scenarios

LED turn signal strips are not typically used in commercial interior environments such as hotels, malls, or offices. These lighting products are specifically designed for use in transportation and safety applications—most commonly in vehicles, industrial equipment, traffic control systems, and construction or utility vehicles. Their primary function is to provide visible directional signaling or hazard indication in outdoor or vehicular contexts.

In settings like hotels, malls, and offices, general illumination, accent lighting, or decorative LED strips are more appropriate choices. Using LED turn signal strips in these spaces would not serve a functional purpose and may not comply with building or electrical codes related to interior lighting.

However, if you are referring to flexible LED strips used for decorative or architectural accent lighting—sometimes mistakenly called “turn signal strips”—then their application in hotels, malls, and offices becomes relevant. In that case, here are appropriate uses and installation tips:

In hotels, LED strips can be used under reception desks, in corridors, within cove lighting in lobbies, or to highlight architectural features in guest rooms and event spaces. They help create ambient lighting and enhance the guest experience.

In malls, LED strips are effective for illuminating signage, display windows, stair treads, or ceiling coves in common areas. They add visual interest and guide foot traffic with subtle, modern lighting.

In offices, LED strips can be installed under cabinets, above ceiling tiles, or along workstation partitions to provide indirect lighting that reduces glare and improves visual comfort.

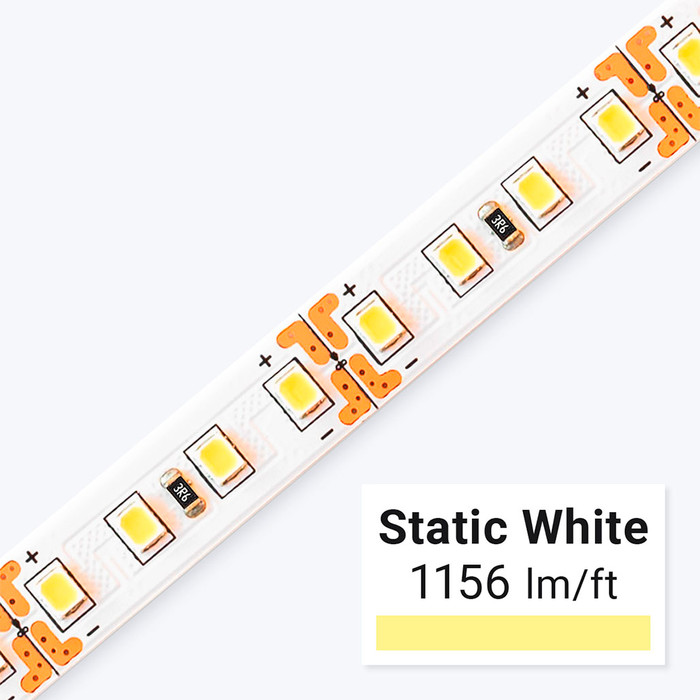

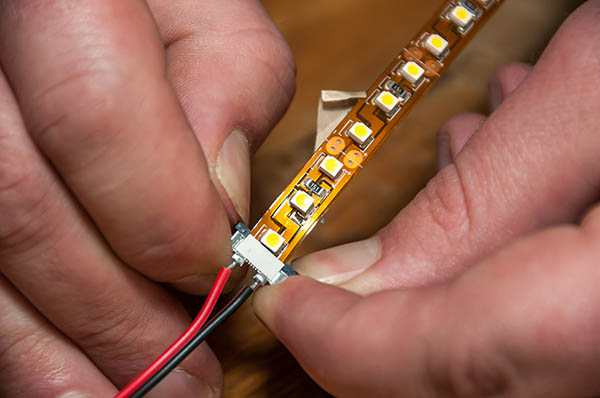

When installing LED strips in any of these environments, ensure the power supply matches the voltage requirement of the strip—typically 12V or 24V DC. Use compatible LED drivers and connectors to avoid flickering or damage. Always follow local electrical codes and consider using dimmable drivers for greater control over lighting ambiance.

For long runs, inject power at multiple points to prevent voltage drop, which can cause dimming at the far end of the strip. Use aluminum channels to dissipate heat and protect the LEDs, especially in high-usage areas. Make sure all wiring is concealed and secured properly to maintain a clean, professional appearance.

Finally, select the appropriate color temperature—such as 2700K to 3000K for warm, inviting spaces in hotels, or 4000K to 5000K for brighter, more focused environments in offices and retail areas. Choose high CRI (Color Rendering Index) strips (80 or above) to ensure accurate color representation, especially in retail or hospitality settings.

Why Choose Beauty STC Lighting

Elevate your vehicle lighting systems with Beauty STC’s premium LED turn signal strips, engineered for superior performance, reliability, and compliance with global automotive standards. Our advanced strips deliver instant illumination, exceptional longevity, and precise beam control, ensuring optimal visibility and safety while enhancing vehicle aesthetics. Partner with Beauty STC to integrate cutting-edge, rigorously tested LED solutions that meet stringent SAE and ECE regulations, reduce maintenance costs, and provide seamless customization for OEM or aftermarket applications. Contact our engineering team today at [email protected] to discuss your specific requirements and discover how our turn signal strips can exceed your expectations. Include “LED Turn Signal Partnership Inquiry” in your subject line for immediate attention.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.