Article Contents

Industry Insight: Led Tape Light Switch

The Critical Role of Certified LED Tape Light Switches in Commercial Applications

Market Demand Drivers for Quality Control Systems

Commercial and industrial lighting projects demand precision-engineered control solutions that align with evolving technical and regulatory requirements. As projects scale in complexity—integrating smart building systems, energy efficiency mandates, and stringent safety protocols—reliability becomes non-negotiable. Distributors and project managers consistently encounter challenges with uncertified or low-quality LED tape light switches, including:

Flicker-free dimming performance required for healthcare, education, and retail environments where visual comfort directly impacts user experience.

Compatibility with 4-6 wire light engines for seamless integration with modern LED drivers and multi-voltage systems (12V/24V).

Regional compliance adherence to avoid customs rejections, project delays, or legal liabilities.

Scalable performance consistency across thousands of fixtures in large-scale deployments, where inconsistent switching causes system-wide failures.

These challenges underscore the need for manufacturing partners who prioritize technical rigor over cost-cutting compromises.

Why ETL and CE Certifications Are Non-Negotiable for Importers

For global lighting distributors, certifications are not optional—they are foundational to risk mitigation and market access. Products lacking ETL (USA/Canada) or TUV CE (Europe) certification face:

Customs and regulatory barriers: Non-compliant shipments are routinely rejected at ports, incurring costly delays or destruction.

Liability exposure: Electrical failures in uncertified products void insurance claims and expose importers to legal action under local electrical codes (e.g., NEC in the U.S., IEC in Europe).

Reputational damage: Projects delayed or compromised by faulty components erode trust with end-users and architects.

ETL certification validates compliance with UL 61058-1 for switch safety and performance in North American markets, while TUV CE confirms adherence to EN 61058-1, EMC directives, and RoHS restrictions in Europe. These certifications are independently verified through rigorous testing—ensuring products meet the exacting standards required for commercial applications.

Beauty STC: 25+ Years of Certified Manufacturing Excellence

Since 1998, Beauty STC Manufacturing has delivered compliant, high-performance lighting solutions to over 50 countries. Our factory-direct model eliminates middlemen, ensuring traceable quality control from raw materials to final testing. All products undergo third-party validation for ETL and TUV CE compliance, providing distributors with confidence in every shipment.

| Specification | Detail |

|---|---|

| Certifications | ETL (UL 61058-1), TUV CE (EN 61058-1, RoHS compliant) |

| Voltage Options | 12V DC, 24V DC (customizable) |

| Dimming Compatibility | 0-10V, PWM, DALI, phase-cut (OEM configurable) |

| IP Rating | IP20 (standard), IP65/IP67 (optional) |

| Operating Temperature | -20°C to +50°C |

| OEM Capabilities | Custom enclosures, labeling, voltage configurations, dimming protocols, and compliance packages |

Our commitment to “Be a responsible enterprise, Be a caring person” and “Passionate, and Innovation” ensures every component is engineered for longevity, safety, and seamless integration into commercial lighting systems. With 25+ years of experience in Western-market compliance and OEM/ODM expertise, Beauty STC provides distributors with a single-source partner for reliable, certified LED control solutions—backed by technical support and rigorous quality assurance.

Contact our engineering team to discuss project-specific requirements: [email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

H2 Technical Specifications & Quality Standards

LED Tape-Light Switch Assemblies – Factory-Direct Parameters

Beauty (STC) has manufactured low-voltage control hardware since 1998; every tape-light switch leaves our Jiangmen plant with full ETL (US/Canada) and TUV CE files, ready for distributor stock with no re-testing.

H3 Key Electrical & Photometric Data (12 V & 24 V Platforms)

| Parameter (switch + 5 m tape load) | Beauty STC Certified Range | Generic Market Spread | Test Method / Reference |

|---|---|---|---|

| System efficacy (incl. driver loss) | 130–150 lm/W @ 24 V | 90–110 lm/W | IES LM-79-19 |

| CRI | ≥ 90 (R9 > 50) | 80–85 typical | CIE 13.3 |

| Flicker per cent (120 Hz) | ≤ 1 % (SVM ≤ 0.2) | 5–15 % | IEEE 1789 |

| Switch standby draw | < 0.15 W | 0.3–0.5 W | IEC 62301 |

| In-rush current limit | ≤ 35 A for 200 µs | 60–100 A | ETL surge ring-wave |

| PCB copper weight | 2 oz (70 µm) double layer, 7 mil track/space | 1 oz, 5 mil | IPC-6012D |

| Flame rating | UL 94 V-0 | HB or V-2 | UL bench test |

| IP rating (switch housing) | IP20 standard, IP44 & IP65 with potted PCB | IP20 only | IEC 60529 |

| Operating T-case | –30 °C … +60 °C | –20 °C … +50 °C | ETL chamber |

| Lifetime (switch FET) | 50 000 on/off cycles @ full 5 A | 20 000 cycles | IEC 60669-2-1 |

| Certifications on file | ETL cETL, TUV CE, RoHS, REACH | Self-declared | – |

H3 PCB & Component Consistency Controls

- Same-batch SMT: 100 % AOI + 5 % X-ray on BGA/QFN driver ICs.

- Copper thickness checked eddy-current on every 0.5 m² panel; rejects if < 65 µm.

- Thermal cycling –40 °C↔+125 °C, 200 cycles, solder-joint cross-section before lot release.

- CCT binning within 3 SDCM for all LEDs driven by the switch; MacAdam ellipse report shipped with each carton.

- 4 kV common-mode surge test post-potting for IP44/65 variants; ensures outdoor tape-switch reliability.

H3 OEM/ODM Flexibility

Output form factor: PCB-only, snap-in rail, or enclosed wall-box.

Dimming protocol: 0-10 V, PWM, DALI-2, or Casambi-ready upon request.

Custom silk-screen / laser-mark without MOQ when ordered with matching LED tape.

All paperwork (ISTMT, TM-21, SDS, BIS, RCM) supplied in distributor’s language set.

For quotations or technical files, email [email protected] or call +86-1390-288-5704.

Factory Tour: Manufacturing Excellence

Precision Manufacturing & OEM Capabilities

State-of-the-Art Production Facility in Jiangmen

Established in 1998, Beauty STC Lighting’s Jiangmen facility operates within the Jianghai District High-tech Industrial Zone. Our 25+ years of manufacturing expertise is supported by fully automated production lines designed for precision and scalability. Key equipment includes:

12 automated SMT assembly lines with 0.01mm component placement accuracy

Reflow soldering ovens and wave soldering systems

Automated Optical Inspection (AOI) for real-time solder joint validation

Integrated testing stations for electrical and optical performance

All production processes adhere to documented quality protocols, ensuring consistency across high-volume orders for global markets.

Rigorous Quality Assurance Protocols

Every product undergoes a multi-stage QC process to meet international standards and client specifications:

Thermal Aging Tests: 48-hour continuous operation at 40°C ambient with ±10% voltage fluctuations to validate stability under real-world conditions.

Certification Compliance: ETL (USA/Canada) and TUV CE (Europe) testing for electrical safety, EMC, and thermal performance at each production stage.

Optical Consistency: Spectrophotometer measurements (Konica Minolta) ensure color consistency (ΔE <1.0) across all CCT ranges.

Environmental Testing: IP rating verification (IP20 to IP67), humidity resistance, UV exposure, and temperature cycling tests for durability.

Custom OEM/ODM Solutions

We provide end-to-end OEM/ODM services tailored to global market requirements. Our in-house engineering team supports custom design, prototyping, and production for specialized applications. Key customizable parameters for LED tape products include:

| Parameter | Standard Options | Customizable Range |

|---|---|---|

| Length | 5m standard reels | 0.5m increments (max 50m per reel) |

| CCT | 2700K, 4000K, 5000K | 2400K–6500K (±50K) |

| CRI | Ra80, Ra90 | Ra80–98 |

| IP Rating | IP20 (indoor), IP65 (outdoor) | IP20–IP67 |

| Packaging | Standard retail boxes | Custom branding, materials, labeling |

All OEM projects include full documentation, compliance testing, and traceability from raw materials to finished goods. We support private labeling, custom packaging, and integration of proprietary control systems for seamless compatibility with existing lighting ecosystems.

For detailed specifications or project consultations, contact our engineering team at [email protected] or +86 13902885704.

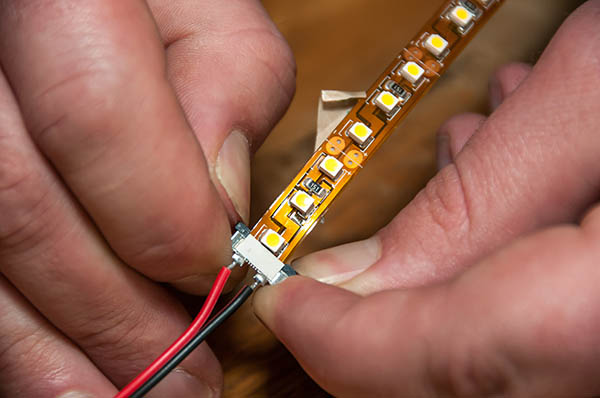

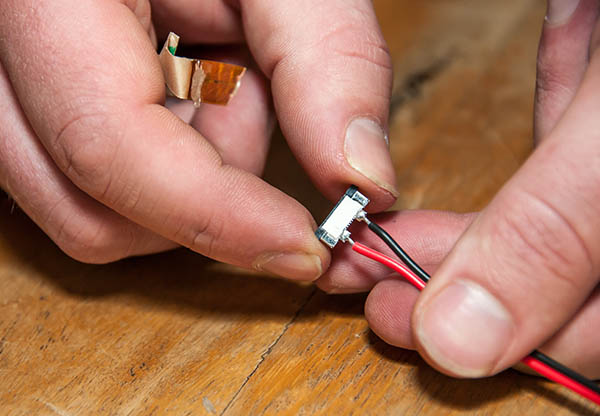

Installation & Application Scenarios

Application Scenarios for LED Tape Light Switches

(Industrial-grade, ETL/TUV CE certified, factory-direct since 1998)

H2 | Where Spec-Grade Tape Light Switches Add Value

| Segment | Key Lighting Task | Switching/Dimming Challenge Solved by Beauty STC Certified Gear |

|---|---|---|

| 4 & 5-star hotels | 24 h cove, headboard, vanity accent | 0–10 V or DALI flicker-free dimming to 0.1 %; ETL-listed for North-America FF&E schedules |

| Shopping malls | 100 m+ continuous retail façade | 230 V relay panel + 24 VDC local switch; TUV CE verified for EU CPR fire routes |

| Corporate offices | Human-centric linear over workstations | Casambi-ready switch/dimmer; <1 % THD keeps PoE networks clean |

| High-end residences | Curved stair profile, toe-kick | Plenum-rated 24 VDC driver + slave switch; UL 2108 recognized for US inspections |

| Exterior façades | Pixel-mapping RGBW tape | IP67 DMX512 RDM switch; galvanic isolation passes 4 kV surge per EN 61547 |

| Cold-chain warehouses | -30 °C freezer aisle | Low-temp driver -40 °C start; switch mounted in heated electrical room |

H2 | Contractor Field Notes – What We Tell Our OEM Partners

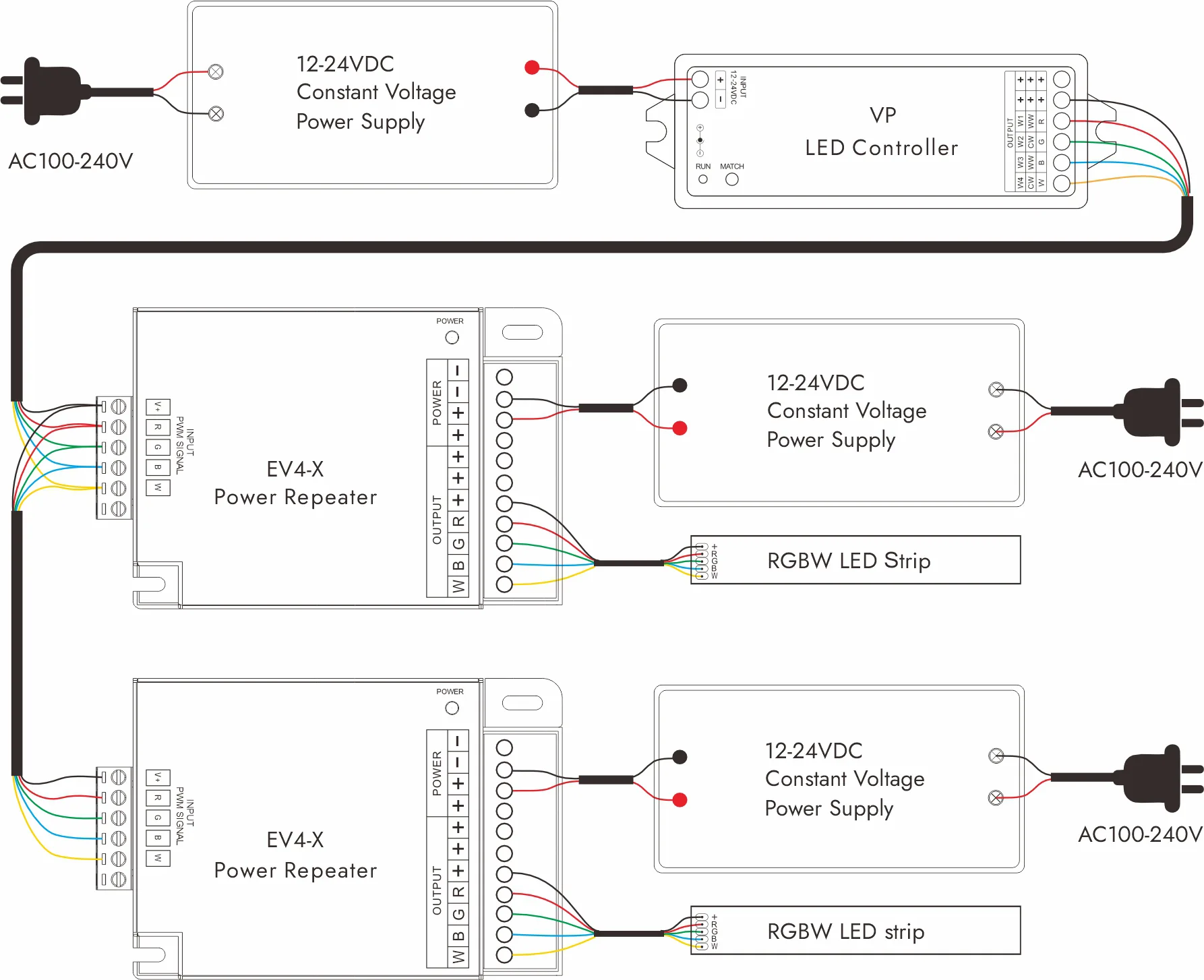

H3 | 1. Voltage Class & Cable Routing

12 V vs 24 V vs 48 V: For runs >5 m use 24 V to keep copper gauge ≤1.5 mm² and current <5 A per circuit.

Separate Class 2 tape conductors from mains in rigid metallic conduit (NEC 411) or H05Z-K red sheath (HD 603).

Beauty STC switch housings are double-insulated; earth wire not required, saving 30 % install time.

H3 | 2. Switch Location & Derating

Mount wall switch ≥30 cm from shower curb (IP44 zone 2) or use IP65-rated touch panel (our P/N SW-65-DIM).

Derate relay to 80 % when switching electronic drivers; our 16 A ETL relay is factory-tested at 20 A resistive but labelled 16 A for LED loads—no field guesswork.

H3 | 3. Flicker & EMC Compliance

Specify “high-frequency” option (>3 kHz) for camera-equipped spaces (hotels, broadcast studios). Test report available; IEEE 1789 Flicker-free at 100 % and 10 % dim.

Add ferrite bead on 0–10 V line when parallel to 230 V for >10 m; keeps TUV CE emission below CISPR 15 class B.

H3 | 4. Expansion for Future IoT

Leave 20 % spare poles in panel; Beauty STC DALI-2 switches snap onto standard 35 mm DIN rail—no additional back-box.

Firmware update via NFC handset; OEM logo splash screen can be flashed in 30 s on site.

H2 | Quick Specification Matrix – Beauty STC Factory-Direct Switch Family

| Model | Input | Output Signal | Load/Channel | Cert. | Dimming Curve | Wiring |

|---|---|---|---|---|---|---|

| SW-10V-ETL | 110–277 VAC | 0–10 V sink | 50 mA | ETL, FCC | Log-square | 6-way |

| SW-DALI-TUV | 220–240 VAC | DALI-2 | 64 addresses | TUV CE, RoHS | Linear | 2-wire |

| SW-DMX-5R | 24 VDC | DMX512 RDM | 5 A relay | CE, EAC | Custom RGB | 5-pin XLR |

| SW-CAS-2CH | 100–240 VAC | BLE Mesh | 2×4 A relays | CE, RCM | Tunable W | L-N-PE |

All variants integrate with Beauty STC 24 V or 48 V constant-voltage tapes; matched driver-to-switch pairing eliminates compatibility claims.

H3 | Need Project-Specific Switch Schedules?

Email technical drawings to [email protected]. Our Jianghai-based engineering team (25-year track record since 1998) provides OEM silk-screen, custom wire lengths, and matched ETL/TUV CE driver bundles within 10 working days.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your Trusted Manufacturing Partner for Global LED Solutions

Two Decades of Engineering Excellence

Since 1998, Beauty STC Lighting has delivered precision-engineered LED solutions to global markets. Our 25+ years of manufacturing expertise ensures rigorous quality control, consistent performance, and adherence to international standards. Every product undergoes stringent testing to meet the demands of commercial and residential applications.

Global Compliance & Certification Assurance

Our products are certified for direct integration into Western markets, eliminating compliance barriers for distributors and project managers.

| Certification | Region | Key Compliance |

|---|---|---|

| ETL | USA & Canada | UL 1598, cULus safety certification |

| TUV CE | Europe | CE marking, EN 60598, RoHS 2 compliant |

OEM/ODM Capabilities Tailored to Your Specifications

Beauty STC Lighting provides flexible manufacturing solutions for LED tape light projects requiring precise technical specifications. Our capabilities include:

Full customization of voltage, color temperature, and CRI

Custom IP ratings for indoor to harsh environments

Integration with industry-standard control systems

Private labeling and packaging options

| Specification | Options |

|---|---|

| Voltage | 12V DC, 24V DC |

| Color Temperature | 2400K (Warm White) – 5000K (Daylight) |

| CRI | >90 (Standard), >95 (High CRI) |

| IP Rating | IP20 (Indoor), IP65 (Damp/Wet), IP67 (Submersible) |

| Control Compatibility | 0-10V, DALI, PWM, 4-6 wire systems |

Technical Support for Global Projects

With 25+ years of experience, ETL and TUV CE certifications for Western markets, and export experience across 50+ countries, Beauty STC Lighting provides reliable, compliant solutions for commercial and residential lighting projects. Our technical export team is available to support your specifications, documentation needs, and project timelines.

Contact us for detailed product datasheets and project-specific quotations:

[email protected] | +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).