Article Contents

Industry Insight: Led Tape Light Power Supply

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and compliance with stringent safety standards. Among the critical components enabling modern LED lighting systems, the LED tape light power supply plays a pivotal role in ensuring reliable, stable, and long-term performance. As buildings, factories, retail spaces, and warehouses increasingly adopt flexible LED tape lighting for task, accent, and ambient illumination, the demand for high-quality, code-compliant power supplies has surged. In this context, certifications such as ETL and CE have become essential benchmarks, verifying that power supply units meet North American and international safety, electromagnetic compatibility, and performance requirements.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation in LED power solutions, delivering robust and certified drivers tailored for demanding commercial and industrial environments. With a steadfast commitment to engineering excellence and regulatory compliance, Beauty STC has established itself as a trusted partner for lighting professionals seeking reliable, code-compliant power supplies that support the seamless integration of LED tape lighting into large-scale applications.

Technical Specs & Certifications

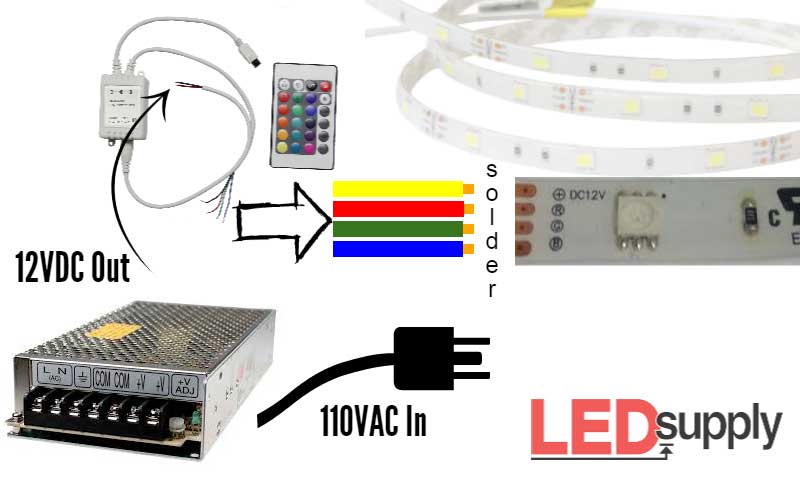

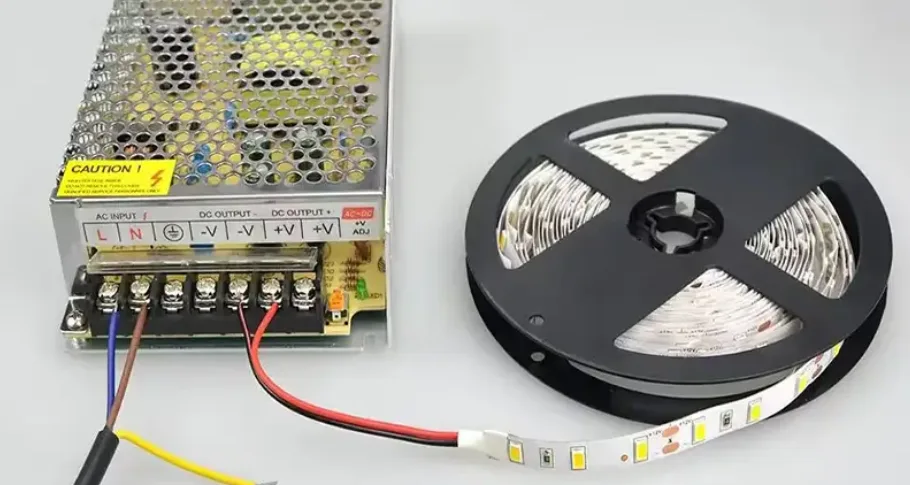

LED tape light power supplies, also known as LED drivers, are critical components for system performance and longevity, but it’s essential to clarify a fundamental point: lumens per watt (lm/W) and Color Rendering Index (CRI) are specifications of the LED tape itself, not the power supply. The power supply’s role is to convert incoming AC line voltage (e.g., 120V/230V AC) to the stable, low-voltage DC (typically 12V or 24V) required by the LED tape. Its efficiency impacts the overall system lm/W, but it does not generate light or influence CRI directly.

The primary technical specifications for an LED tape light power supply relevant to your query focus on efficiency, compatibility, protection, and environmental rating. Beauty STC power supplies are engineered to maximize the performance of high-quality LED tapes, including those achieving >90 CRI and high lm/W. Key specs include:

Power supply efficiency, measured as a percentage, indicates how effectively it converts AC input power to usable DC output power, minimizing energy loss as heat. Beauty STC specifies high-efficiency drivers, typically exceeding 88-92% efficiency (e.g., meeting or exceeding DoE Level VI or EU CoC Tier 2 standards). This high efficiency directly contributes to the overall system lm/W figure. For instance, a 90 lm/W LED tape powered by an 85% efficient driver results in a system efficiency of approximately 76.5 lm/W, whereas the same tape with a 92% efficient Beauty STC driver achieves about 82.8 lm/W. Selecting a high-efficiency driver is crucial for realizing the full lm/W potential of the LED tape.

While the power supply does not determine CRI, its stability and low ripple current are vital for maintaining consistent light output and color quality from high-CRI LED tapes. Instability or excessive ripple can cause flicker or slight color shifts, undermining the >90 CRI specification of the tape. Beauty STC power supplies incorporate robust filtering and precision regulation circuitry to deliver exceptionally stable DC output with ripple current typically kept below 5%, ensuring the LED tape operates at its specified color quality and lumen output over its lifespan. Our drivers are rigorously tested with high-CRI LED modules to guarantee compatibility and performance stability.

IP (Ingress Protection) rating is a critical specification for both the power supply and the LED tape, defining resistance to dust and moisture. Beauty STC offers a comprehensive range of power supplies with various IP ratings to match installation environments. For indoor dry locations, IP20 rated drivers (basic protection against finger contact) are suitable. For damp locations like bathrooms or covered outdoor areas, IP65 or IP67 rated drivers are essential, providing full dust protection and resistance to water jets or temporary immersion. Beauty STC’s sealed, potting compound-filled IP67 drivers are designed for harsh environments, ensuring reliable operation even when mounted outdoors or in high-moisture areas alongside compatible IP67 or IP68 LED tape. The specific IP rating required depends entirely on the physical location of the power supply unit itself within the installation.

Beauty STC’s commitment to quality is paramount in our power supply manufacturing. All drivers undergo stringent in-house testing protocols exceeding IEC/EN 61347-1 and 61347-2-13 safety standards, including 100% production line testing for critical parameters like output voltage stability, short-circuit protection, and thermal performance. We utilize premium components, including high-temperature capacitors and robust PCB layouts, ensuring reliable operation at full load across the specified ambient temperature range (typically -25°C to +60°C or higher for industrial variants). Our drivers feature comprehensive protection mechanisms: short circuit, overload, overvoltage, and over-temperature shutdown. This focus on durability, safety, and consistent performance ensures Beauty STC power supplies provide a stable foundation for high-efficiency, high-CRI LED tape systems, minimizing field failures and supporting the long operational life expected from professional lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province, China. The factory is strategically situated within the Pearl River Delta region, known for its robust electronics and lighting supply chain, enabling efficient sourcing of materials and timely delivery of finished products.

The production floor is centered around advanced Surface Mount Technology (SMT) lines, which are critical for the precise and high-speed assembly of LED tape light power supplies and other electronic components. These SMT machines include fully automated pick-and-place systems, reflow soldering ovens, and automated optical inspection (AOI) units. This automation ensures consistent soldering quality, high component placement accuracy, and reliable performance of the final products. The SMT lines are capable of handling a wide range of component sizes and packaging types, supporting both small-batch custom orders and large-scale mass production.

To ensure long-term reliability, Beauty STC implements comprehensive aging and burn-in testing procedures. Finished power supplies for LED tape lights undergo rigorous aging tests under elevated temperatures and full-load conditions for durations typically ranging from 4 to 24 hours. These tests help identify early-life failures and verify thermal stability, output consistency, and overall durability. Additional quality assurance measures include electrical performance testing, insulation resistance checks, and environmental testing such as humidity exposure and thermal cycling.

Beauty STC has strong OEM and ODM capabilities, particularly in the development and manufacturing of customized LED tape light power supplies. The company supports clients in designing power solutions tailored to specific voltage, current, dimming functions (including 0-10V, DALI, and TRIAC), efficiency requirements, and form factors. With in-house engineering teams experienced in power electronics and thermal management, Beauty STC can provide full turnkey services—from circuit design and PCB layout to certification support (such as CE, UL, CCC, and TUV) and packaging. This makes the Jiangmen factory a reliable partner for brands seeking high-quality, customized power supply solutions integrated into LED lighting systems.

Application Scenarios

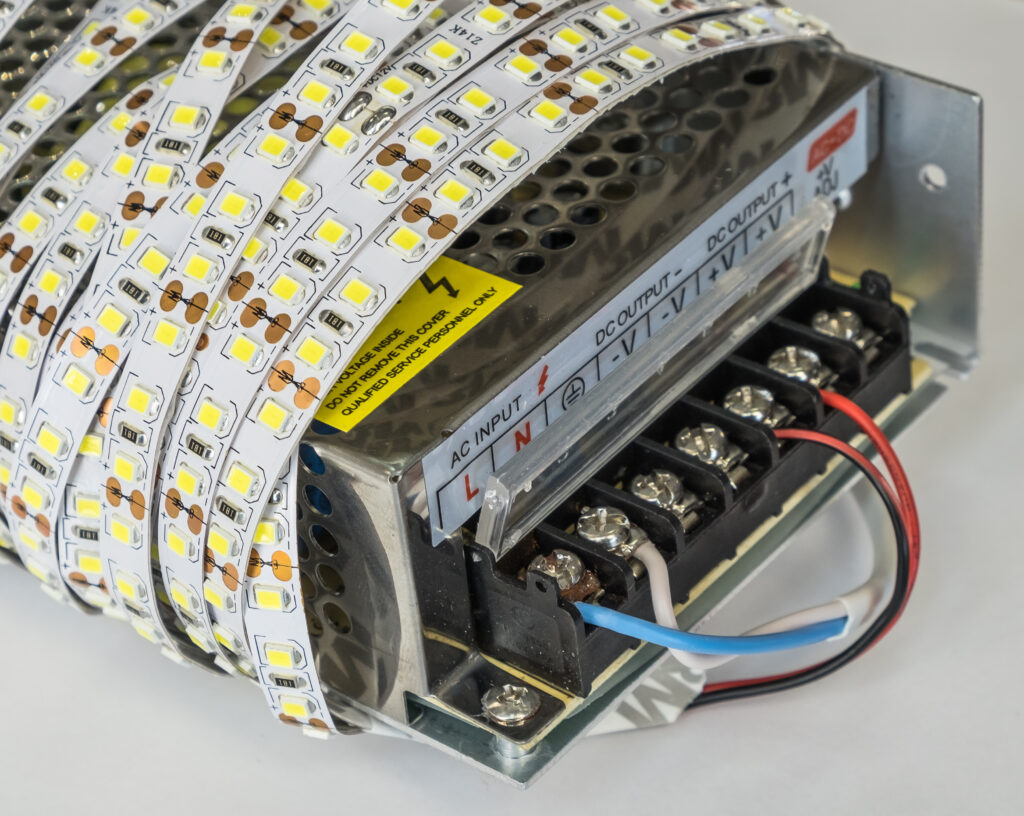

LED tape light power supplies are essential components for converting standard AC line voltage to the low-voltage DC required by flexible LED tape lighting systems. Their application across hotels, malls, and offices focuses on creating ambiance, enhancing functionality, and improving energy efficiency while ensuring safety and reliability. In hotels, these power supplies are predominantly used to drive LED tape in architectural cove lighting within lobbies and corridors to establish a welcoming, indirect glow, under cabinet lighting in minibars and vanity areas for task illumination, behind headboards for subtle night lighting, and within feature walls or reception desks for visual interest. Critical moisture-prone areas like spa treatment rooms or poolside bars require IP67-rated power supplies mounted outside wet zones but within close proximity to the tape to prevent voltage drop. For malls, power supplies are extensively deployed in retail display windows to highlight merchandise with precise, shadow-free illumination, along ceiling perimeters in food courts to create layered lighting without glare, within escalator side panels for safety and branding, and in corridor soffits to guide visitor flow. High-traffic mall environments demand robust thermal management; power supplies must be installed in ventilated metal enclosures away from insulation and grouped with adequate spacing to handle continuous 12+ hour operation without overheating. Offices utilize these drivers for under-desk task lighting to reduce eye strain, within suspended ceiling coves for uniform ambient light, along stair treads for safety, and in partitioned workspaces for customizable personal lighting zones. Conference rooms often employ dimmable power supplies compatible with building management systems to adjust lighting for presentations or video calls.

Installation must prioritize electrical safety and system longevity. Always select a power supply with at least 20% higher wattage capacity than the calculated tape load to prevent thermal stress and ensure stable output over time—this derating is non-negotiable in commercial settings where lights operate extended hours. Mount power supplies in accessible locations compliant with local electrical codes, never concealed within walls or ceilings where heat dissipation is restricted; use DIN rail or bracket mounting in dedicated junction boxes. Maintain strict separation between low-voltage DC wiring and AC mains cables by at least 200mm to avoid electromagnetic interference causing flicker, routing them in separate conduits where possible. Verify all connections are secure and insulated with wire nuts or Wago connectors—loose terminals are a leading cause of field failures. For long tape runs exceeding 5 meters, feed power from both ends or use multiple power supplies to eliminate voltage drop that causes dimming at the far end. Label every power supply clearly with circuit details and tape zone it serves for maintenance efficiency. In humid environments like hotel bathrooms or mall food courts, confirm the power supply’s IP rating matches the location’s requirements and seal conduit entries to prevent moisture ingress. Finally, always power down the circuit during installation and use a multimeter to verify correct DC output before connecting the tape to avoid damaging the LEDs. Beauty (STC) power supplies incorporate over-temperature and short-circuit protection specifically engineered for these demanding commercial applications, ensuring compliance with IEC 61347 standards.

Why Choose Beauty STC Lighting

Looking for a reliable LED tape light power supply solution? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting systems. Our precision-engineered power supplies ensure optimal performance, durability, and safety for all your LED tape light applications. Whether you’re working on residential, commercial, or industrial projects, we provide customized solutions tailored to your needs.

Contact us today to discuss your requirements and discover how Beauty STC can support your business with superior products and professional service. Reach out to our sales manager at [email protected] and take the first step toward a successful partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.