Article Contents

Industry Insight: Led Tape Light Manufacturers

The commercial and industrial lighting sector continues to evolve with a strong emphasis on energy efficiency, durability, and compliance with international safety standards. Among the most transformative innovations in this space is the widespread adoption of LED tape lighting—compact, flexible, and highly versatile solutions that offer uniform illumination for architectural coves, under-cabinet applications, signage, and industrial workspaces. As demand grows for reliable, code-compliant lighting systems, manufacturers must meet rigorous certifications such as ETL and CE, ensuring products adhere to North American and European safety and performance requirements. These certifications are not just regulatory benchmarks but critical differentiators in competitive bidding and project specifications.

Established in 1998, Beauty (STC) Manufacturing Co., Ltd. has emerged as a trusted leader in the LED tape light industry, serving commercial and industrial clients worldwide. With over two decades of engineering expertise, Beauty STC combines advanced thermal management, robust construction, and strict quality control to deliver high-performance lighting solutions that meet and exceed ETL and CE standards. From large-scale manufacturing facilities to corporate office environments, Beauty STC’s LED tape lights provide consistent, long-lasting illumination with the reliability demanded by professional installations.

Technical Specs & Certifications

LED tape light manufacturers must adhere to stringent technical specifications to meet high-performance applications, particularly where efficiency, color fidelity, and environmental resilience are critical. Lumens per Watt (lm/W) serves as the primary metric for energy efficiency, with premium manufacturers targeting 120–150 lm/W for standard 24V DC tapes under optimal thermal management. Achieving values consistently above 140 lm/W requires advanced chip-on-board (COB) technology, high-efficiency drivers, and optimized thermal substrates to minimize lumen depreciation. Lower-cost alternatives often fall below 100 lm/W due to inferior LEDs or inadequate heat dissipation, directly impacting operational cost savings over the product lifecycle.

Color Rendering Index (CRI) values exceeding 90 are non-negotiable for applications demanding true-to-life color representation, such as retail displays, art galleries, and high-end residential spaces. However, reputable manufacturers go beyond a basic CRI >90 claim by ensuring high R9 (saturated red) values above 50 and maintaining a TM-30-15 fidelity index (Rf) above 80. This prevents the common industry pitfall of artificially inflated CRI through excessive green spectrum emphasis, which distorts skin tones and warm colors. Rigorous spectral analysis and binning of LEDs are essential to sustain consistent color quality across production batches, avoiding visible variations in continuous installations.

IP Ratings define environmental protection levels, with IP20 being standard for dry indoor use. For demanding installations, IP65 (dust-tight and low-pressure water jets) suits covered outdoor or commercial kitchens, while IP67 (temporary submersion up to 1m for 30 minutes) or IP68 (continuous submersion beyond 1m, typically 3m for 72 hours) is mandatory for landscape lighting, pools, or marine environments. Critical to authentic IP68 certification is the use of fully potted flexible PCBs with marine-grade silicone encapsulation, not merely conformal coatings, to prevent moisture ingress during thermal cycling. Many manufacturers misrepresent IP ratings; true compliance requires third-party validation per IEC 60529 standards with documented testing protocols.

At Beauty STC, we exceed these benchmarks through vertically integrated engineering. Our flagship COB tape series delivers 142–148 lm/W at 2700K–4000K, verified by independent labs under LM-79 testing. We achieve CRI >95 with R9 >90 and Rf >85 through proprietary phosphor blends and tight MacAdam Step 3 binning, supported by full spectral data reports. For environmental resilience, our IP68 tapes undergo 1,000-hour salt spray testing and 10,000-cycle thermal shock validation (−40°C to +85°C), exceeding IEC 60598 standards. Every reel is 100% tested for continuity and color consistency, backed by a 50,000-hour L70 warranty and UL/cUL certification. This commitment to measurable performance—never marketing claims—ensures our tapes perform reliably in the world’s most demanding architectural and commercial projects. For project-specific validation, our engineering team provides custom photometric reports and accelerated life testing data.

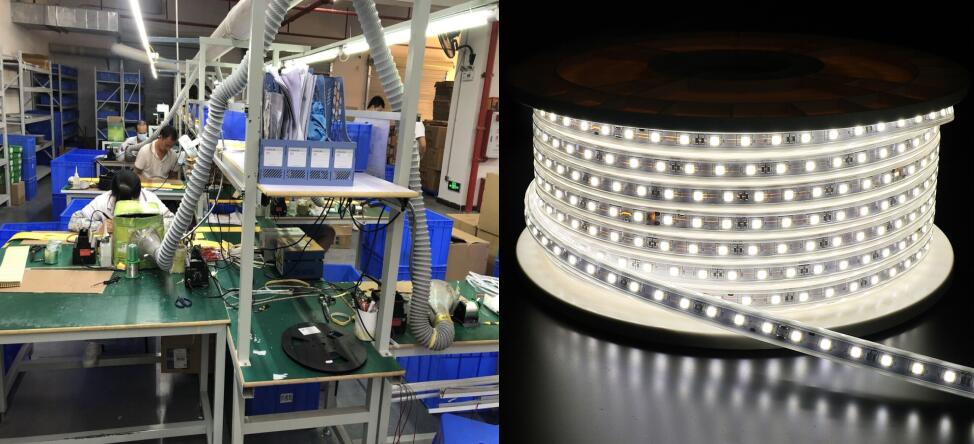

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility specializing in the production of LED lighting solutions, with a strong focus on high-quality LED tape lights. Strategically located in the Jiangmen industrial zone, the factory benefits from excellent logistics access and a skilled manufacturing workforce, enabling efficient production and timely delivery for both domestic and international markets.

The manufacturing floor is equipped with advanced Surface Mount Technology (SMT) production lines, which are critical for the precise and reliable assembly of LED components onto flexible printed circuit boards. These SMT machines include high-speed pick-and-place units, precision solder paste printers, reflow ovens with nitrogen environments, and automated optical inspection (AOI) systems. This advanced automation ensures consistent component placement, excellent solder joint quality, and minimal defects, which are essential for the performance and longevity of LED tape lights.

To guarantee product reliability and durability, the Jiangmen factory implements rigorous aging and quality testing procedures. Completed LED tape light reels undergo extended aging tests, typically operating at full power for 24 to 48 hours under controlled temperature and humidity conditions. This process helps identify early failures and ensures that only stable, high-performing products are shipped to customers. Additional testing includes waterproof performance checks (for IP-rated tapes), color consistency evaluation using spectrometers, and electrical safety testing in compliance with international standards such as CE, RoHS, and UL.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities tailored specifically for LED tape light manufacturers and brand partners. The company supports custom solutions including different color temperatures, LED densities (e.g., 30, 60, 120 LEDs per meter), special waterproofing (IP20, IP65, IP67), custom lengths, and private labeling. The engineering team works closely with clients to develop specifications, create prototypes, and scale to mass production with full documentation and quality control. The factory also supports custom packaging, branding, and compliance certification assistance, making it a comprehensive partner for businesses looking to launch or expand their LED lighting product lines.

Overall, the Jiangmen facility reflects Beauty STC’s commitment to innovation, quality, and flexibility in serving the global LED lighting market.

Application Scenarios

LED tape light manufacturers serve critical roles in commercial lighting projects across hotels, malls, and offices, providing tailored solutions that meet the specific functional and aesthetic demands of each environment. In hotels, LED tape lighting is extensively used for creating ambiance in lobbies, hallways, and guest rooms, particularly under cabinetry, within cove ceilings, along stair edges for safety, and behind headboards or mirrors to enhance luxury and wayfinding. Malls leverage these products for dynamic retail displays, accentuating product features in shop windows, illuminating signage, defining architectural elements in common areas, and creating visually engaging pathways to draw foot traffic. Offices utilize LED tape lighting for task lighting under desks or cabinets, enhancing modern aesthetics in reception areas, providing subtle under-cabinet illumination in break rooms, and integrating into suspended ceiling systems for uniform, glare-free ambient light that supports productivity and well-being.

Installation requires careful attention to detail to ensure longevity and optimal performance. Always begin by verifying the LED tape’s specifications match the intended environment, particularly its IP rating for moisture resistance in areas like hotel bathrooms or mall food courts, and its color temperature and CRI for accurate color rendering in retail settings. Proper thermal management is non-negotiable; install tape lights within aluminum mounting channels to dissipate heat effectively, preventing premature lumen depreciation and color shift, especially in enclosed spaces like coves or under cabinets. Avoid sharp bends or kinks during installation as these can damage internal circuits—maintain the manufacturer’s specified minimum bending radius. Ensure all connections are secure and waterproofed if exposed to humidity, using connectors rated for the tape’s voltage and environment. For large-scale deployments across multiple floors in hotels or expansive mall atriums, consistent batch production from a single manufacturer is essential to avoid visible color variance; coordinate closely with the manufacturer to secure tape from the same production run. Finally, integrate compatible dimming systems and drivers from the outset, confirming compatibility with building management systems in offices or sophisticated control systems in high-end hotels to enable seamless scene setting and energy savings. Partnering with an experienced LED tape light manufacturer ensures access to technical support for complex installations and guarantees performance standards are met across the entire project lifecycle.

Why Choose Beauty STC Lighting

Looking for reliable LED tape light manufacturers? Partner with Beauty STC, a trusted leader in high-quality LED lighting solutions. With years of expertise in design, engineering, and manufacturing, we deliver premium LED tape lights tailored to your project needs. From residential to commercial applications, our products combine performance, durability, and innovation. Contact us today to discuss your requirements and elevate your lighting projects. Email [email protected] to connect with our team and start a successful partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.