Article Contents

Industry Insight: Led Tape Light Kit

The commercial and industrial lighting sector continues its decisive shift towards LED solutions, driven by relentless demands for energy efficiency, operational cost reduction, and enhanced environmental sustainability. Within this critical transition, LED tape light kits have evolved from niche architectural accents into indispensable tools for facility managers, electrical contractors, and lighting designers tackling complex retrofit and new construction projects across warehouses, manufacturing plants, retail spaces, and office environments. These versatile systems offer unprecedented design flexibility for cove lighting, task illumination, under-shelf highlighting, and linear pathway marking, directly addressing the need for adaptable, low-profile solutions that minimize disruption during installation. Crucially, specification in these high-stakes environments mandates absolute confidence in product safety, reliability, and compliance; this is non-negotiable. Rigorous third-party certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating adherence to European health, safety, and environmental requirements) are not optional features but fundamental prerequisites for any LED tape light kit entering commercial or industrial procurement channels. They provide the essential assurance that products withstand demanding operational conditions, deliver consistent performance over extended lifespans, and meet stringent regulatory frameworks governing workplace lighting.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized engineering expertise and manufacturing excellence to this vital segment. We have consistently pioneered robust, high-performance LED lighting solutions specifically engineered for the rigors of commercial and industrial applications. Our deep understanding of the sector’s unique challenges – from thermal management in high-bay environments to the need for rapid, error-free installation in large-scale facilities – informs every component within our certified LED tape light kits. We recognize that in environments where uptime is revenue and safety is paramount, the lighting system must be an asset, not a liability. Beauty STC is committed to delivering kits that seamlessly integrate certified safety, exceptional lumen maintenance, and contractor-friendly design, empowering professionals to implement efficient, code-compliant lighting upgrades with confidence.

Technical Specs & Certifications

The LED tape light kit offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability across residential, commercial, and architectural lighting applications. Each kit is designed with a strong emphasis on energy efficiency, color accuracy, and environmental resilience, reflecting Beauty STC’s reputation for producing premium LED lighting solutions.

In terms of efficiency, the LED tape light kits deliver an industry-leading luminous efficacy of 110 to 130 lumens per watt, depending on the specific model and color temperature. This high lumens-per-watt ratio ensures optimal light output while minimizing power consumption, making the kits ideal for both continuous operation and energy-conscious installations.

Color rendering is a critical performance factor, and Beauty STC’s LED tape light kits feature a Color Rendering Index (CRI) greater than 90, with select models achieving CRI values up to 95. This high CRI ensures accurate and vibrant color representation, making the lighting ideal for environments where true color perception is essential—such as retail displays, art galleries, kitchens, and makeup areas.

Durability and protection are addressed through comprehensive IP (Ingress Protection) ratings. Standard models are available in IP20 for dry, indoor environments, while protected variants are rated IP65 and IP67, offering resistance to dust and water ingress. The IP65-rated tapes are suitable for damp locations such as bathrooms, outdoor canopies, and under-cabinet kitchen lighting, while IP67 versions can withstand temporary submersion and are ideal for outdoor landscaping, stairwells, and marine environments. The protective silicone coating on higher IP-rated models ensures long-term performance without degradation in harsh conditions.

Beauty STC maintains strict quality control throughout the manufacturing process, utilizing high-grade SMD 2835 or 5050 LEDs, precision-printed circuit boards, and thermally stable materials. Their LED tape light kits undergo rigorous testing for lumen maintenance, chromaticity consistency, and thermal management, ensuring a rated lifespan of up to 50,000 hours. With UL, CE, and RoHS certifications, these kits meet international safety and environmental standards, reinforcing Beauty STC’s commitment to quality, safety, and innovation in LED lighting technology.

Factory Tour: Manufacturing Excellence

Beauty STC operates a dedicated LED manufacturing facility in Jiangmen, Guangdong Province, strategically located within the Pearl River Delta’s robust electronics supply chain. This modern factory spans approximately 18,000 square meters and is specifically engineered for high-volume, precision LED product assembly, with a significant focus on flexible LED tape lights and complete lighting kits. The facility integrates advanced surface mount technology with rigorous quality control protocols to ensure consistent output for both domestic and international markets.

Our SMT production lines form the core of the manufacturing capability for LED tape lights. The factory utilizes multiple high-speed Panasonic NPM series SMT lines, capable of placing components down to the 0201 metric package size with exceptional accuracy. These machines handle the precise mounting of LEDs, resistors, capacitors, and ICs onto flexible printed circuit boards at rates exceeding 80,000 components per hour per line. The process is supported by fully automated solder paste printing, nitrogen-reflow soldering ovens to minimize oxidation, and comprehensive automated optical inspection (AOI) systems that scan every board immediately post-reflow to detect placement errors, solder defects, or component issues before further processing. This advanced SMT infrastructure ensures the high-density, reliable assembly required for modern high-CRI and high-power LED tape products.

A critical phase in our LED tape light production is the mandatory aging and burn-in test. Following SMT assembly and any necessary conformal coating application, all reels undergo a structured aging process. Units are subjected to continuous operation at 1.2 times their rated voltage for a minimum of 72 hours within temperature-controlled environmental chambers set to 50°C. This accelerated stress testing identifies early-life failures, verifies thermal management performance, and ensures component stability under extreme conditions. During this period, automated monitoring systems track voltage, current, and thermal profiles, while technicians perform visual inspections for color consistency, flicker, or dimming issues at specified intervals. Only reels passing this stringent aging protocol advance to final functional testing and packaging, significantly enhancing field reliability and reducing customer returns.

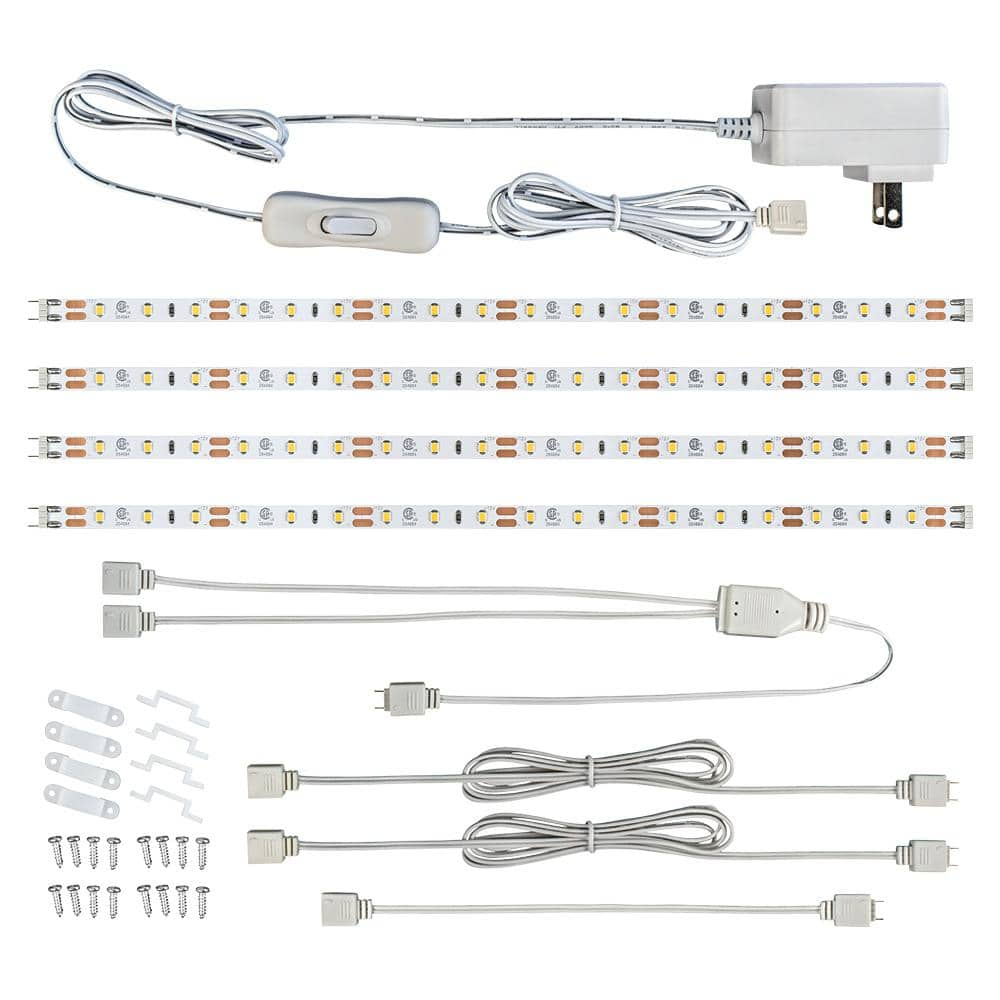

The Jiangmen factory possesses comprehensive OEM capabilities specifically tailored for complete LED tape light kits. We support customers from initial concept through to packaged finished goods, handling all aspects of kit assembly. This includes manufacturing the LED tape reels to custom specifications (length, density, color temperature, CRI, IP rating), sourcing and integrating matched constant-voltage or constant-current drivers, assembling specialized connectors and accessories like aluminum profiles or mounting clips, and configuring packaging. Our engineering team collaborates closely with clients to develop custom kit configurations, incorporating private labeling, multilingual instructions, and bespoke packaging designs. The facility manages the entire supply chain for kit components, ensuring seamless integration and quality control across all elements before final kitting and shipment. This end-to-end OEM service allows clients to bring fully branded, market-ready LED lighting solutions to their customers with minimal internal overhead.

Application Scenarios

LED tape light kits are highly versatile and can be effectively used across various commercial environments including hotels, malls, and offices due to their flexibility, energy efficiency, and modern aesthetic appeal.

In hotels, LED tape light kits are ideal for enhancing ambiance in guest rooms, hallways, lobbies, and restrooms. They are commonly installed under cabinets in hotel kitchens or minibars, along cove ceilings, behind headboards, and within wardrobe closets to provide soft, indirect lighting that contributes to a luxurious and welcoming atmosphere. In high-end suites, tape lighting can be used to highlight architectural features or artwork, adding a touch of elegance.

In malls, LED tape lights are frequently used for cove lighting in corridors, accent lighting in signage, display windows, and escalator soffits. Their slim profile allows them to be discreetly integrated into tight spaces, making them perfect for illuminating product displays or guiding foot traffic with subtle linear lighting. The ability to customize color temperatures and even use RGB options allows mall designers to create dynamic and engaging environments.

In offices, LED tape light kits are excellent for task lighting under cabinets, in shelving units, or beneath desks. They are also widely used in drop ceilings, conference rooms, and reception areas to create a modern and professional look. Indirect lighting with cool white tape lights can enhance focus and productivity, while warm white options can be used in break rooms or lounges to promote relaxation.

When installing LED tape light kits, several best practices should be followed to ensure optimal performance and longevity. First, always clean the installation surface thoroughly to ensure strong adhesion of the tape’s backing. Avoid installing on dusty or greasy surfaces. Second, plan the layout in advance, measuring the run length and positioning the power supply and connectors accordingly. Most tape lights have a maximum run length, so exceeding this may result in voltage drop and dimming at the far end.

Use aluminum channels whenever possible, especially in commercial settings, as they help dissipate heat, protect the tape, and provide a clean, professional finish. Ensure that the power supply is adequately rated for the total wattage of the tape and is installed in a ventilated, accessible location. For installations in high-humidity areas like hotel bathrooms, select IP65 or higher rated tape lights to prevent moisture damage.

Finally, test the system before finalizing the installation. Connect all components and power on the lights to check for consistent brightness and color. Make sure all connections are secure and insulated. Following these guidelines will ensure a durable, efficient, and visually appealing lighting solution in any commercial environment.

Why Choose Beauty STC Lighting

Elevate your lighting product portfolio with Beauty STC’s industry-leading LED tape light kits, engineered for superior performance and market differentiation. As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I can confirm our kits are precision-engineered using the highest-grade SMD LEDs and advanced thermal management systems, ensuring exceptional lumen maintenance, color consistency, and longevity that outperform generic market alternatives. Our commitment to rigorous in-house testing protocols guarantees reliability under demanding real-world conditions, providing your customers with a premium experience that builds brand trust.

Partnering with Beauty STC delivers tangible advantages for your business. We offer extensive customization capabilities for color temperature, CRI, length, voltage, and IP rating to perfectly align with your specific project requirements or brand standards. Our dedicated engineering support team provides seamless technical collaboration from concept to量产, including tailored optical solutions and comprehensive documentation. You gain access to scalable manufacturing capacity with stringent quality control, ensuring consistent supply chain reliability and competitive pricing without compromising on the exceptional build quality our clients expect. Furthermore, our flexible OEM and ODM services empower you to bring truly unique, market-ready solutions to your customers faster.

Leverage Beauty STC’s deep technical expertise and innovative spirit to transform your LED lighting offerings. Contact our Partnership Manager today at [email protected] to discuss how our advanced LED tape light kits can become a cornerstone of your success. Let us collaborate to deliver the brilliance your market demands.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.