Article Contents

Industry Insight: Led Tape Dimmer

The commercial and industrial lighting landscape continues to evolve with a growing emphasis on energy efficiency, design flexibility, and intelligent control systems. Among the most transformative innovations in this space is the LED tape dimmer, a critical component enabling precise light output management in architectural cove lighting, high-end retail displays, industrial workspaces, and large-scale hospitality environments. As facility managers and lighting designers demand greater control over ambiance and energy consumption, high-performance dimmers compatible with low-voltage LED tape systems have become essential. These devices not only enhance user experience but also extend the lifespan of LED installations when properly matched and certified.

In this context, compliance with international safety and performance standards such as ETL and CE is non-negotiable. These certifications ensure that LED tape dimmers meet rigorous requirements for electrical safety, electromagnetic compatibility, and operational reliability—key considerations in mission-critical commercial environments. With the proliferation of substandard products in the market, specifying certified components has become a priority for engineers and contractors aiming to deliver durable, code-compliant lighting solutions.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED control technology for over two decades. Renowned for engineering excellence and a deep commitment to quality, Beauty STC develops robust, certified dimming solutions tailored for demanding commercial and industrial applications. Their LED tape dimmers are designed to integrate seamlessly with a wide range of low-voltage LED systems while maintaining compliance with ETL and CE standards, offering specifiers and installers confidence in performance, safety, and long-term reliability.

Technical Specs & Certifications

The term “LED tape dimmer” refers to a control device, not the light source itself. A dimmer regulates power to an LED tape light strip but does not produce light. Therefore, specifications like lumens per watt (lm/W) and Color Rendering Index (CRI) apply exclusively to the LED tape light source, not the dimmer. IP ratings may apply to both components depending on design, but are critical for the tape installation environment. Beauty STC designs and manufactures both high-performance LED tapes and compatible dimmers as part of integrated lighting solutions. Below are the relevant technical specifications focused on the LED tape light source, as implied by your query, alongside context for dimmer compatibility and Beauty STC’s quality assurance.

LED tape light sources from Beauty STC consistently achieve luminous efficacy in the range of 120 to 140 lumens per watt for standard 24VDC high-density tapes under optimal thermal management and drive conditions. This efficiency range represents the current industry benchmark for premium architectural and commercial grade LED tapes, balancing high output with thermal stability. Efficacy is measured at 25°C ambient temperature using calibrated integrating spheres per IES LM-79 standards. Actual system efficacy can be influenced by dimmer selection, as inefficient dimming methods or incompatible drivers may reduce overall system efficiency by 5-15%. Beauty STC dimmers are engineered to minimize this loss, maintaining >95% of the tape’s native efficacy when paired correctly.

Color fidelity is a core strength of Beauty STC LED tapes. All tapes marketed for architectural, retail, and high-end residential applications maintain a minimum CRI (Ra) of 95, with R9 (saturated red) values typically exceeding 90. This exceeds your specified CRI >90 requirement and ensures accurate, vibrant color rendition critical for applications like retail merchandising, art galleries, and hospitality. CRI values are rigorously verified using spectroradiometers per ANSI C78.377, with batch testing documentation available. Tapes undergo accelerated life testing to confirm CRI stability over 50,000 hours, preventing the color shift common in lower-tier products. Beauty STC achieves this through proprietary phosphor blends and tight binning controls on Samsung and Epistar LEDs.

IP ratings for Beauty STC LED tapes are application-specific and clearly defined per product line. IP65-rated tapes feature robust silicone encapsulation for protection against dust and low-pressure water jets, suitable for outdoor canopy lighting or semi-exposed architectural coves. IP67 tapes withstand temporary immersion up to 1 meter for 30 minutes, ideal for landscape lighting or under-cabinet kitchen installations where splash exposure occurs. For demanding wet locations like pool perimeters or marine environments, Beauty STC offers IP68-certified tapes tested to 5 meters submersion for continuous operation. All encapsulated tapes undergo 100% post-production IP verification via pressure decay testing, not just sample checks. The dimmer units themselves, typically installed in dry locations, carry IP20 ratings but are housed in UL-listed metal or polycarbonate enclosures with thermal management features.

Beauty STC’s quality commitment is embedded in every production stage. Our Shenzhen facility implements ISO 9001-certified processes with reel-to-reel automated optical inspection (AOI) catching micro-defects invisible to manual checks. LED bins are controlled to a 3-step MacAdam ellipse for color consistency, and every tape reel undergoes 4-hour burn-in testing at full power before shipment. We utilize military-grade silicone for encapsulation with UV stabilizers preventing yellowing, and our copper PCBs feature 2oz copper thickness for superior heat dissipation compared to industry-standard 1oz. Third-party certifications include UL 8750, CE, RoHS, and ERP compliance, with photometric reports traceable to NIST standards. This rigorous approach ensures not only meeting but sustaining the specified lm/W, CRI, and IP performance throughout the product lifecycle, reducing field failures and maintaining lighting quality for end-users. System compatibility is guaranteed through Beauty STC’s dimmer-tape validation matrix, preventing flicker or reduced output when using our recommended control solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, vertically integrated facility specializing in the production of LED lighting solutions, including LED tape lights and associated control components such as LED tape dimmers. The facility is strategically located within the Pearl River Delta, a region known for its advanced manufacturing infrastructure and supply chain efficiency.

The factory is equipped with state-of-the-art Surface Mount Technology (SMT) production lines, which ensure high-precision placement of electronic components on printed circuit boards (PCBs). These SMT machines enable rapid and consistent assembly of driver circuits, control modules, and other electronic parts essential for LED tape dimmers. Automated optical inspection (AOI) systems are integrated into the SMT process to verify component placement and solder quality, ensuring high reliability and minimal defect rates.

Quality assurance is a core focus at the Jiangmen facility. Completed LED tape dimmers undergo rigorous aging tests, typically lasting 4 to 8 hours under elevated temperatures and full load conditions. This process helps identify early-life failures and ensures long-term performance and durability. Additional tests include electrical safety checks, signal stability verification, and compatibility testing with various LED tape types and dimming protocols such as PWM, 0-10V, or DALI, depending on the product design.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, allowing clients to customize LED tape dimmers in terms of form factor, electrical specifications, control interfaces (e.g., remote control, app-based, or wall-mounted), and branding. The company supports low to high-volume production runs and offers full turnkey services, including PCB design, component sourcing, assembly, testing, packaging, and logistics. This flexibility makes Beauty STC a preferred partner for brands seeking reliable, high-quality, and differentiated LED control solutions.

Application Scenarios

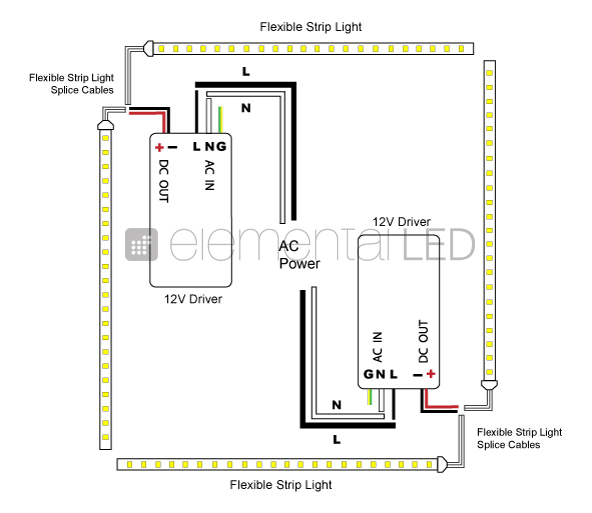

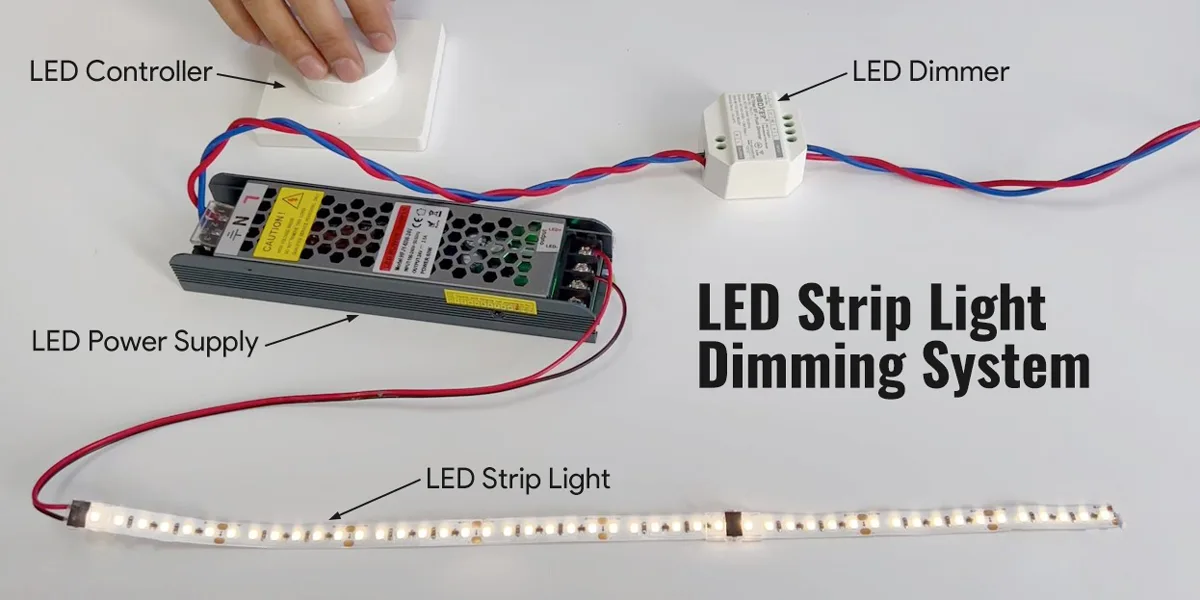

LED tape dimmers are essential control devices for managing the brightness of LED tape light installations across various commercial environments. It is important to clarify that the term “LED tape dimmer” typically refers to a compatible dimming controller or driver designed specifically for LED tape systems, not a standalone dimmer switch for the tape itself. The dimming functionality is usually integrated into the constant voltage or constant current LED driver powering the tape, or managed via an external dimming module compatible with the tape’s power supply. Below are the primary applications in hotels, malls, and offices, followed by critical installation considerations.

In hotel settings, LED tape dimmers are extensively used to create adaptable ambiance and enhance guest experience. Key applications include guestroom cove lighting where dimming allows transition from bright task lighting to soft relaxation levels, particularly around headboards or under cabinets. Lobby and reception areas utilize dimmable tape in architectural coves and feature walls to adjust lighting intensity from vibrant daytime presentations to intimate evening atmospheres. Corridors and elevator lobbies employ subtle dimming for nighttime courtesy lighting, reducing energy use while maintaining safe egress. High-end suites and spas leverage dimmable tape in vanity mirrors and wet areas for customizable lighting during grooming or treatments, though strict IP67-rated tape and drivers must be used in moisture-prone zones.

For shopping malls, LED tape dimmers serve strategic merchandising and environmental control purposes. Retail storefronts and display windows use dimmable tape to highlight products with adjustable intensity, avoiding glare while drawing attention to featured items. Common areas like food courts and seating zones implement dimming to shift from energetic high-brightness during peak hours to calmer low-level illumination in off-peak times, improving customer dwell time. Feature installations such as column wraps or ceiling canopies in atriums require precise dimming control to synchronize with dynamic lighting scenes or daylight harvesting systems. Back-of-house areas including stockrooms may use basic dimming for task lighting flexibility, though this is less common than in public-facing zones.

Office environments deploy LED tape dimmers primarily for human-centric lighting and energy efficiency. Executive offices and meeting rooms incorporate dimmable tape in cove lighting to support video conferencing with glare-free illumination and adjust for presentations versus collaborative sessions. Open-plan workspaces use tape under partitions or in suspended ceilings with tunable white or dimmable systems to align with circadian rhythms, though full dimming to very low levels is less critical here than in hospitality. Reception and waiting areas benefit from dimming to modulate welcome intensity from professional daytime levels to subdued evening modes. Breakout and wellness rooms often feature fully dimmable tape to create restorative low-light environments, supporting occupant well-being.

Installation requires meticulous attention to compatibility and electrical specifications. Always verify that the LED tape, power supply/driver, and dimming control system share identical dimming protocols such as 0-10V, DALI, PWM, or phase-cut; mismatched components cause flickering, limited range, or failure. Calculate total tape wattage per circuit and ensure the driver’s capacity exceeds this by 20% to prevent overload, especially with long tape runs where voltage drop may necessitate multiple power feeds. For constant voltage systems (12V/24V), use dimmable constant voltage drivers with appropriate dimming input compatibility—never connect tape directly to a standard wall dimmer. Maintain strict separation between low-voltage dimming control wires and mains power cables to avoid interference, routing them in separate conduits where possible. In commercial settings, all components must carry relevant safety certifications like UL, CE, or TÜV, and installations should comply with local electrical codes including circuit protection and emergency lighting requirements. Always conduct thorough low-end dimming tests before finalizing installations, as some tape-driver combinations exhibit instability below 10-20% brightness. Finally, engage qualified electricians for all connections, particularly in high-traffic commercial spaces where safety and reliability are paramount. Beauty (STC) Manufacturing Co., Ltd. recommends using our certified dimmable drivers with integrated compatibility testing for LED tape systems to ensure seamless performance across these demanding applications.

Why Choose Beauty STC Lighting

Looking for a reliable and high-performance LED tape dimmer solution? Partner with Beauty STC, a trusted leader in innovative LED lighting technology. Our advanced dimming systems ensure seamless control, smooth performance, and superior compatibility with a wide range of LED tapes. Whether you’re working on residential, commercial, or architectural projects, Beauty STC delivers precision and quality you can count on.

Take your lighting projects to the next level. Contact us today at [email protected] to discuss your needs and discover how Beauty STC can support your business with tailored dimming solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.