Article Contents

Industry Insight: Led Tape Corner Connectors

In the evolving landscape of commercial and industrial lighting, precision, reliability, and seamless integration are paramount. LED tape corner connectors have emerged as critical components in achieving clean, continuous lighting runs across complex architectural contours and tight junctions. These connectors ensure robust electrical continuity and mechanical stability when installing flexible LED strips around corners, columns, and structural transitions—common challenges in retail spaces, warehouses, office environments, and manufacturing facilities. As demand grows for energy-efficient and low-maintenance lighting solutions, the performance and safety certifications of these components are under increasing scrutiny. Industry-standard compliance, particularly ETL and CE markings, has become essential, ensuring that products meet rigorous North American and international safety, electromagnetic compatibility, and performance requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED connectivity and power distribution solutions. With over two decades of experience, Beauty STC has built a reputation for engineering high-quality, code-compliant components trusted by lighting professionals across commercial and industrial sectors. Their LED tape corner connectors exemplify this commitment—combining durable materials, secure contact design, and certification to ETL and CE standards for safe, long-term operation in demanding environments. As buildings become smarter and lighting layouts more intricate, Beauty STC continues to deliver the reliable infrastructure needed to support modern LED applications with confidence and precision.

Technical Specs & Certifications

LED tape corner connectors are passive mechanical and electrical interface components designed specifically to join flexible LED strips at directional changes, such as 90-degree or 45-degree turns. It is critical to clarify that these connectors themselves do not generate light and therefore possess no inherent lumens per watt (lm/W) or Color Rendering Index (CRI) specifications. These photometric properties are exclusively characteristics of the LED tape or module being connected. Beauty STC’s corner connectors are engineered to preserve the performance integrity of high-quality LED tapes meeting stringent lm/W and CRI >90 requirements, but the connectors are not the source of these metrics.

The primary technical function of a corner connector is to ensure reliable electrical continuity and mechanical stability at the bend point without damaging the LED tape’s circuitry. Beauty STC’s connectors achieve this through precision-machined phosphor bronze or beryllium copper contacts with triple-layer gold plating (typically 0.3–0.5μm), ensuring contact resistance below 0.03Ω per pin. This minimizes voltage drop and thermal stress, which is essential for maintaining the consistent light output and efficiency of the connected LED tape. For instance, when used with Beauty STC’s high-efficiency LED tapes (which routinely achieve 130–150 lm/W at 3000K with CRI >90 and R9 >50), the connector prevents localized power loss that could otherwise reduce system efficacy below target specifications.

IP ratings for corner connectors are determined by their sealing methodology and material composition, directly impacting the overall system’s environmental resilience. Beauty STC offers two certified IP-rated solutions: IP65-rated connectors utilize a dual-seal design with integrated silicone gaskets and UV-stable polycarbonate housings, suitable for protected outdoor or high-moisture indoor environments like kitchens or retail displays. For fully submersible or harsh outdoor applications, our IP67-rated connectors feature a one-piece overmolded TPU jacket with laser-welded seams, tested to withstand 1 meter of water immersion for 30 minutes without ingress. Crucially, these ratings apply only when the connector is correctly installed with compatible IP-rated LED tape and properly sealed end caps—Beauty STC provides detailed installation protocols to ensure system-level compliance.

Beauty STC’s quality differentiation lies in rigorous validation beyond industry standards. Every corner connector batch undergoes 100% automated continuity and insulation resistance testing, followed by accelerated lifecycle validation (5,000+ thermal cycles from -40°C to +85°C) and pull-force verification exceeding 15N. Unlike generic alternatives, our connectors are co-engineered with proprietary LED tapes to prevent micro-cracking in the tape’s flexible PCB during installation, a common failure point that degrades CRI consistency over time. All materials comply with UL94 V-0 flammability ratings and RoHS 3, with traceable lot documentation for critical projects. This systems-level approach ensures that when Beauty STC specifies CRI >90 and high lm/W performance for an LED tape solution, the corner connectors actively contribute to sustaining those metrics throughout the product’s lifespan, rather than becoming a point of failure.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility strategically located within one of China’s key manufacturing hubs. The Jiangmen plant is fully equipped to support high-volume, precision manufacturing of LED lighting products, including flexible LED strips and associated components such as corner connectors.

The factory features state-of-the-art Surface Mount Technology (SMT) production lines that ensure accurate and efficient placement of LED components onto flexible printed circuits. These SMT machines are automated and calibrated for high-speed assembly with tight tolerances, enabling consistent quality and reliability in every batch. The integration of advanced pick-and-place machines, reflow soldering systems, and automated optical inspection (AOI) equipment ensures that LED tape products meet strict performance and durability standards.

To guarantee long-term reliability, the Jiangmen facility conducts comprehensive aging tests on both finished LED tapes and components such as corner connectors. Products undergo extended operational testing under controlled thermal and electrical conditions, simulating real-world usage over prolonged periods. This aging process helps identify early failure points and ensures that only robust, high-performance products leave the factory.

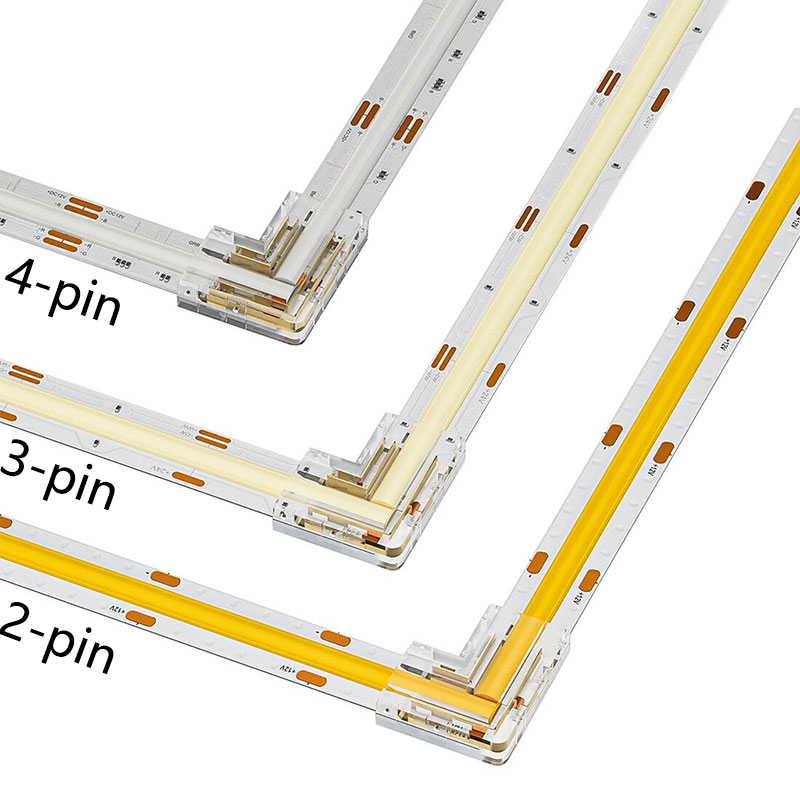

Beauty STC has strong OEM capabilities and supports customized manufacturing for clients worldwide. This includes the design and production of specialized accessories like LED tape corner connectors—used to join LED strips at various angles while maintaining electrical continuity and mechanical stability. The company can customize these connectors in terms of configuration (e.g., 90-degree, T-junction, or flexible swivel types), pin count, housing material, and branding, to suit specific project or product requirements.

With in-house mold design, tooling, and engineering support, Beauty STC’s Jiangmen factory provides end-to-end OEM services—from prototyping and testing to mass production and packaging—ensuring flexibility, fast turnaround, and adherence to international quality standards.

Application Scenarios

LED tape corner connectors serve a critical function in commercial lighting installations where flexible LED tape must navigate directional changes while maintaining electrical continuity and mechanical integrity. Their primary application across hotels, malls, and offices centers on seamless transitions around architectural features where bending the tape beyond its minimum radius would cause damage or inconsistent light output. In hotels, these connectors are indispensable for creating uninterrupted cove lighting in lobbies and corridors, particularly where plaster moldings meet walls or ceilings. They also enable precise illumination of vanity mirror perimeters in guest bathrooms and under-bed lighting systems where tight 90-degree turns are required without visible gaps. For retail environments like malls, corner connectors prove essential in illuminated signage frameworks, display case edging, and feature walls where dynamic angular designs demand clean transitions between vertical and horizontal planes. Their use ensures consistent brightness around promotional kiosks and storefront displays without the dark spots that occur when tape is improperly bent. Office installations rely heavily on these components for under-cabinet task lighting in reception areas, along the tops of glass partitions in open-plan layouts, and within suspended ceiling coves where multiple directional changes occur in confined spaces.

Installation requires meticulous attention to detail to prevent premature failure. Always disconnect power at the circuit breaker before handling any components, as commercial lighting systems often operate at line voltage. Verify polarity alignment between the tape’s positive and negative markings and the connector’s corresponding terminals—reversed polarity instantly damages LEDs. When preparing the tape ends, use sharp scissors to cut precisely at the designated scissor icon marks; jagged cuts cause poor contact. For snap-in connectors, ensure the tape is fully seated until an audible click occurs, then gently tug to confirm retention. Solderless push-fit types require inserting the tape straight into the connector without angling, followed by securing the locking lever. Critical strain relief must be implemented: never let the connector bear mechanical load. Anchor the tape 10-15mm before the connector using aluminum channel clips or adhesive-backed cable ties, allowing slack for thermal expansion. In high-traffic areas like hotel corridors or mall walkways, encapsulate connections with clear silicone sealant rated for LED use to prevent dust ingress and vibration damage. Avoid overtightening screws on screw-terminal connectors, as this crushes the tape’s copper pads. Finally, conduct a 15-minute operational test before concealing the assembly—commercial projects often discover failures only after drywall or trim installation, leading to costly rework. Remember that corner connectors introduce slight voltage drop; for runs exceeding 5 meters, position connectors closer to the power source rather than at the tape’s far end to maintain uniform brightness.

Why Choose Beauty STC Lighting

Looking for reliable LED tape corner connectors? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED lighting solutions. Our high-quality corner connectors ensure seamless installations and superior performance for any project. To learn more or place an order, contact us today at [email protected] and let Beauty STC be your preferred lighting partner.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.