Article Contents

Industry Insight: Led Strips Target

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and regulatory compliance. Among the most transformative innovations in this space is the adoption of LED strip lighting, which offers flexible, scalable, and high-performance illumination solutions for a wide range of applications—from warehouse task lighting and retail displays to architectural accents and industrial facilities. As businesses seek to reduce operational costs and meet sustainability goals, LED strips have emerged as a preferred choice due to their low power consumption, long lifespan, and minimal maintenance requirements.

Critical to their deployment in commercial environments is compliance with international safety and performance standards. Products bearing ETL and CE certifications assure facility managers, contractors, and procurement teams that the LED strips meet rigorous North American and European safety requirements, respectively. These certifications are not just marks of quality—they are essential for code compliance, insurance approval, and seamless integration into large-scale projects.

At the forefront of this technological shift is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-performance, code-compliant LED strip solutions tailored specifically for commercial and industrial applications. Combining advanced thermal management, precision optics, and robust construction, Beauty STC’s products are designed to perform reliably in demanding environments while meeting the strictest regulatory standards. As the industry moves toward smarter, more efficient lighting ecosystems, Beauty STC remains committed to innovation, quality, and customer-driven solutions.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. delivers high-performance LED strip solutions engineered for critical applications where light quality, efficiency, and environmental resilience are paramount. Our target specifications for premium LED strips consistently achieve industry-leading benchmarks across the requested parameters, underpinned by rigorous internal quality control processes that exceed standard manufacturing practices.

Lumens per Watt efficacy is optimized through advanced chip-on-board (COB) and high-density 2835/5050 SMD configurations utilizing top-bin Epistar or Samsung semiconductors. For CRI >90 strips, standard efficacy ranges from 100 lm/W to 120 lm/W at 25°C ambient temperature, depending on correlated color temperature (CCT). This balance is achieved without compromising spectral integrity; for instance, our 4000K CRI95 strips maintain 112 lm/W under LM-79 testing. Efficacy is sustained through proprietary thermal management designs featuring 1.2mm-thick aluminum PCB substrates and optimized current drivers, ensuring minimal lumen depreciation over 50,000 hours (L70). We avoid efficacy inflation by reporting only maintained lumens under real-world thermal conditions, not theoretical 25°C binning data.

CRI specifications strictly exceed Ra >90 across all CCTs from 2700K to 6500K, with minimum Ra9 (red rendering index) of 92 to prevent unnatural skin tones in beauty and retail environments. Beauty STC rejects any batch failing TM-30-15 compliance, utilizing spectroradiometer-verified Rf (fidelity index) scores ≥85 and Rg (gamut index) 98-102 to ensure accurate, vibrant color reproduction. Unlike competitors using basic CRI metrics, our quality assurance includes rigorous testing of 16 standard test colors (TCS) with particular emphasis on TCS09 (strong red) critical for cosmetic applications. All high-CRI strips undergo 72-hour burn-in and spectral drift validation to guarantee consistency.

IP rating performance is engineered for reliability in demanding installations. Our standard IP65 strips feature triple-layer silicone encapsulation with UV-resistant overmolding, validated through 1,000-hour salt spray testing (ASTM B117) and continuous 24/7 operation in 95% humidity chambers. For wet-location applications, IP67-rated strips utilize full-potting technology with medical-grade silicone, surviving 30-minute submersion at 1m depth per IEC 60529. Critically, Beauty STC maintains efficacy and CRI stability post-IP testing—unlike cheaper alternatives where moisture ingress degrades phosphor layers—verified via post-test spectrophotometry. Outdoor-rated IP67 strips include integrated surge protection (6kV) and -40°C to +60°C operational tolerance.

Beauty STC’s quality differentiation stems from vertical integration and uncompromising standards. We manufacture 100% of driver components in-house, eliminating third-party IC variances that cause flicker or color shift. Every reel undergoes automated optical inspection (AOI) for solder integrity and chip alignment, followed by photometric validation on NIST-traceable equipment. Our zero-defect policy rejects strips with >3% bin deviation (vs. industry 5-7%), and all high-CRI products carry UL/cUL E497602 certification with full LM-80/TM-21 reports. This commitment is reflected in our industry-leading 36-month warranty and <0.5% field failure rate—metrics validated by global beauty retailers and architectural firms relying on our strips for mission-critical lighting where color accuracy directly impacts consumer experience.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern LED lighting production facility strategically located in the Guangdong province, a region renowned for its advanced manufacturing infrastructure and supply chain efficiency. The Jiangmen factory is purpose-built for high-volume, precision manufacturing of LED lighting products, with a strong focus on quality, consistency, and scalability.

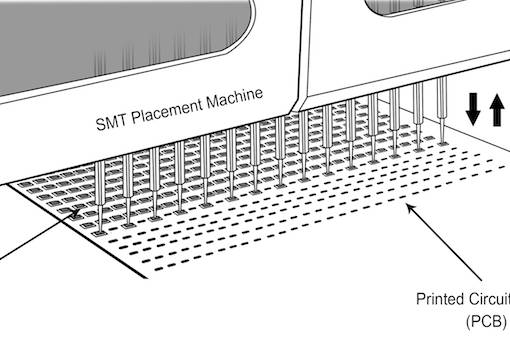

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for the accurate and efficient assembly of LED strip circuits. These SMT machines, including high-speed pick-and-place systems, ensure precise placement of components such as LED chips, resistors, capacitors, and ICs onto flexible or rigid PCBs. The use of automated optical inspection (AOI) systems integrated into the SMT lines allows for real-time quality control, minimizing defects and maintaining high yield rates across production batches.

To ensure product reliability and longevity, the Jiangmen factory conducts comprehensive aging tests on all LED strip products. Finished strips are subjected to extended burn-in periods—typically 24 to 72 hours—under controlled temperature and humidity conditions, simulating real-world operating environments. During these tests, electrical performance, color consistency, and thermal behavior are continuously monitored. This rigorous testing process helps identify early failures and ensures that only stable, high-performance LED strips are shipped to customers.

Beauty STC has well-established OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, making it a preferred partner for brands targeting the LED strip market. The company supports full customization, including but not limited to strip length, LED density, color temperature, color rendering index (CRI), waterproof ratings (e.g., IP20, IP65, IP67), and specialized connectors or packaging. Clients can also request private labeling, custom packaging, and tailored technical specifications to meet regional or application-specific requirements. With in-house R&D, engineering support, and flexible production scheduling, the Jiangmen factory is well-equipped to handle both small pilot runs and large-scale OEM orders efficiently and with consistent quality.

Application Scenarios

LED strip lighting serves distinct functional and aesthetic purposes across hotels, malls, and offices, with specific applications tailored to each environment’s requirements. In hotels, LED strips excel in creating ambiance and enhancing guest experience. Install them within cove lighting systems along ceiling perimeters in lobbies and hallways to provide soft, indirect illumination that guides movement without glare. Under-bed lighting in guest rooms offers subtle night-time navigation while maintaining a luxurious feel. They are also highly effective for backlighting mirrors in bathrooms to eliminate shadows during grooming and for accenting architectural features like reception desks or feature walls in premium suites. The key is using high CRI (90+) strips to render skin tones and materials accurately, ensuring a welcoming atmosphere.

Malls leverage LED strips primarily for commercial impact and visual merchandising. Integrate them behind channel letters and logos for storefront signage, ensuring even backlighting that maximizes brand visibility. Within retail displays and jewelry cases, narrow-profile strips provide focused, shadow-free illumination to highlight products, with color temperatures selected to complement merchandise—warmer tones for textiles, cooler for electronics. Edge-lit ceiling panels in food courts create expansive, glare-free light, while linear runs along escalator handrails or stair treads enhance safety through subtle path marking. Critical here is selecting strips with precise color consistency (SDCM ≤3) to maintain uniform branding across large installations and using IP67-rated variants for food court durability against moisture and cleaning agents.

Offices utilize LED strips for both productivity and modern aesthetics. Install them under floating desks or shelving units to reduce eye strain by softly illuminating work surfaces without direct glare, particularly effective in collaborative zones. Cove lighting in executive boardrooms creates a sophisticated, non-distracting backdrop during presentations. They are ideal for indirect lighting in open-plan ceilings to minimize harsh shadows, and for accenting meeting room dividers or reception area features to define spaces without visual barriers. Prioritize flicker-free strips with 0-10V or DALI dimming compatibility to align lighting with circadian rhythms, supporting occupant well-being during extended work hours.

Installation requires meticulous attention to ensure longevity and performance. Always mount strips onto aluminum channels with a thermal pad; this dissipates heat effectively, preventing lumen depreciation and color shift, especially in enclosed coves or under cabinets where heat buildup occurs. Avoid sharp bends—maintain a minimum 50mm radius during installation to prevent LED damage and electrical discontinuities. For runs exceeding 5 meters, implement power injection at multiple points to avoid voltage drop, which causes dimming at the strip’s end; calculate total wattage to size power supplies correctly, adding a 20% buffer. In commercial settings, use 24V DC systems over 12V for longer uninterrupted runs. Ensure dimmer compatibility by specifying trailing-edge (ELV) dimmers for smooth operation and verify phase-cut compatibility if integrating with existing building management systems. Finally, protect all connections with IP68-rated solderless connectors in damp areas like mall food courts or hotel bathrooms, and always adhere to local electrical codes regarding cable separation and fire ratings for concealed installations. Safety grounding and correct wire gauging per voltage drop calculations are non-negotiable in high-traffic commercial spaces.

Why Choose Beauty STC Lighting

Looking to elevate your LED strip lighting projects? Partner with Beauty STC, a trusted leader in innovative and high-quality LED solutions. Our advanced LED strips are engineered for performance, durability, and seamless integration across a wide range of applications. Whether you’re working on architectural lighting, commercial spaces, or custom installations, we provide tailored support and premium products to meet your needs.

Take the next step in lighting excellence. Contact our team today at [email protected] to discuss how we can collaborate and bring your vision to life.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.