Article Contents

Industry Insight: Led Strips Target

Introduction & Market Demand

The Commercial Lighting Landscape: Demand for Certified Solutions

Commercial and industrial lighting projects demand rigorous adherence to safety, performance, and regulatory standards. From retail environments requiring precise color rendering to industrial facilities needing durable, high-lumen output, the specifications for LED strip lighting are increasingly complex. Importers and project stakeholders face significant challenges when sourcing from suppliers lacking proper certifications. Non-compliant products can lead to customs rejections, project delays, safety hazards, and costly liability issues—particularly in regulated markets like the EU and North America.

Why Certification Matters for Global Importers

Certification is not merely a regulatory checkbox; it is a critical safeguard for project integrity. Below is a comparative overview of how certified suppliers like Beauty STC mitigate risks for importers:

| Compliance Aspect | Uncertified Suppliers | Beauty STC Certified Solutions |

|---|---|---|

| Safety Standards | Often fail to meet UL, IEC, or EN standards | ETL (USA/Canada) and TUV CE (EU) certified to relevant safety standards (e.g., UL 8750, EN 62471) |

| Regulatory Compliance | High risk of customs rejection or recalls | Verified compliance with regional regulations (NEC, RoHS, LVD, EMC) |

| Performance Consistency | Inconsistent lumen output, color accuracy, or lifespan | Rigorous quality control ensures specified metrics (e.g., ±5% lumen tolerance, CRI ≥90) |

| Liability Exposure | Increased risk of legal claims from failures | Third-party certification reduces insurance and legal risks |

Veteran Manufacturer with 25+ Years of Expertise

Established in 1998, Beauty STC Manufacturing Co., Ltd. has evolved as a trusted partner for global lighting projects. With over 25 years of experience in LED manufacturing, our facility in Jiangmen, Guangdong, combines technical expertise with stringent quality management. All products undergo certified testing for ETL and TUV CE compliance, ensuring seamless integration into Western markets. Our OEM/ODM capabilities allow precise customization of specifications—from IP ratings and color temperatures to control systems—while maintaining factory-direct cost efficiency. As a responsible enterprise committed to innovation, we prioritize long-term reliability over short-term gains, ensuring our solutions meet the exacting demands of commercial and industrial applications.

For technical specifications, custom project requirements, or compliance documentation, contact our engineering team directly:

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – LED Strips Target

1. Engineering Targets vs. Market Reality

Global lighting distributors, contractors and specifiers consistently ask for four non-negotiables on strip projects:

Delivered efficacy ≥ 160 lm/W @ 3000 K

CRI ≥ 90 (R9 > 50) for retail, museum and healthcare segments

IP rating that survives the intended environment (IP20 → IP68)

PCB that will not delaminate or colour-shift after 6 000 h @ 85 °C / 85 % RH

Most “catalogue” strips fall 15-30 % short of these figures once temperature, driver tolerance and binning drift are taken into account. Beauty (STC) Manufacturing’s 25-year OEM record is built on closing that gap through component pre-qualification, in-line SPC and third-party batch witnessing (ETL / TUV CE).

2. Critical-to-Quality Parameters

| Parameter | Beauty STC Target | Test Method | Certification Witness |

|---|---|---|---|

| Luminous efficacy | 160–185 lm/W (3000 K, Tj = 55 °C) | 2 m integrating sphere, IES LM-79-19 | ETL / TUV CE DoP |

| CRI / R9 | typ. 93 / 65 | CIE 13.3-1995 | 100 % bin mapped |

| SDCM | ≤ 3 (MacAdam) | 3 nm spectroradiometer | per reel bar-code |

| L70 @ 45 °C | ≥ 54 000 h | IES TM-21-21 | ETL report |

| PCB Cu thickness | 3 oz (105 µm) IPC-6012D | X-ray fluorescence | internal C=0 sampling |

| IP rating | IP20, IP65 (nano-coat), IP67 (tube), IP68 (PU+PVC co-extrusion) | IEC 60598-1 & -2-21 | TUV CE CB Scheme |

| Operating window | –40 °C to +85 °C / 5 %–95 % RH | IEC 60068-2-14 Na | 100 % burn-in 4 h @ 85 °C |

3. Generic Market Quality vs. Beauty STC Certified Quality

| Feature | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| LED die source | Mixed tier-2 bins, no LM-80 | Nichia 757G / Seoul 5630, LM-80 public file |

| Phosphor | Silicate, Δu’v’ 0.008 | YAG+氮化物, Δu’v’ 0.003, 3 SDCM |

| PCB copper | 1 oz (35 µm), FR-4, CTI 175 | 3 oz, double-sided, CTI 600, UL E499480 |

| Resistor tolerance | ±10 %, 0603 | ±1 %, 0805, AEC-Q200 |

| Solder alloy | Sn99.3/Cu0.7, 220 °C profile | SAC305, nitrogen回流, 100 % AOI & 3-D solder paste inspection |

| Binning at reel end | Not performed | Each 5 m reel bar-coded with radiant flux, chromaticity, Vf |

| Surge immunity | 500 V differential | 2 kV differential / 4 kV common, IEC 61000-4-5 |

| Certification evidence | Supplier self-declaration | ETL cETLus, TUV CE (LVD + EMC + RoHS + REACH), CB, SAA |

| Warranty | 2 year limited | 5 year full performance, backed by 1998-established factory |

4. Consistency Controls – From Reel to Job Site

Component IQC: Every LED lot accompanied by LM-80 & TM-21 data; automatic rejection if flux drift > 3 % in first 1 000 h.

SPC on placement: 12-point optical comparator measures solder joint fillet height; CpK ≥ 1.67.

100 % functional burn-in: 85 °C / 85 % RH, 4 h, 24 V reverse-pulse check → < 0.1 % early failure.

Spectral mapping: Each 0.5 m segment measured; chromaticity data uploaded to cloud; customer QR code links to report.

Vacuum moisture-barrier packaging: < 5 % RH inside reel, 12-month floor life without pre-bake.

5. OEM / ODM Flexibility Without Quality Dilution

Whether the brief is 24 V constant-voltage, 48 V constant-current, or 5 V addressable (SPI, DMX, DALI, RDM), the same CTQ flowchart applies. Tooling for rigid bar, aluminium-profile, silicone neon extrusion or COB strip is handled in-house; no sub-contracting that could break the traceability chain.

For specifiers preparing DES, our engineering package includes:

IES, LDT and SPD files

TM-21 & ISTMT reports for IES TM-21 calculator input

BIM objects (Revit 2022) pre-loaded with ETL reference

Risk assessment on IP rating vs. mounting environment (ISO 9223 corrosivity category)

Contact the factory technical desk at [email protected] or +86-1390 288 5704 for strip files or to schedule a third-party audit at our Jiangmen high-tech zone facility.

Factory Tour: Manufacturing Excellence

Precision Manufacturing at Our Jiangmen Facility

With over 25 years of manufacturing experience since 1998, Beauty STC Lighting operates a fully integrated production facility in Jiangmen, Guangdong. Our process-driven manufacturing approach ensures consistent quality across all product lines, with strict adherence to ETL (USA/Canada) and TUV CE (Europe) certification requirements for global market compliance.

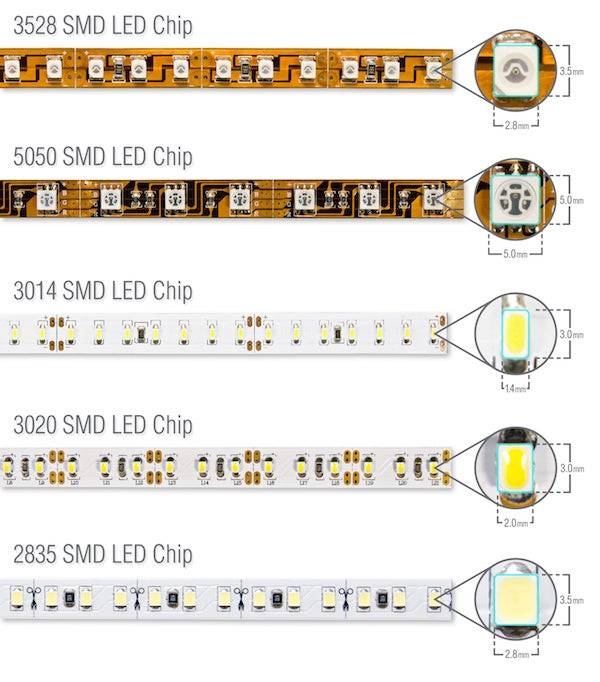

Advanced SMT Production Line

Our facility features fully automated Surface Mount Technology (SMT) production lines equipped with high-precision pick-and-place machines, reflow soldering systems with thermal profiling control, and Automated Optical Inspection (AOI) for defect detection. This automation ensures consistent solder joint quality and component placement accuracy to ±0.03mm, critical for high-reliability LED strip manufacturing. All SMT processes are monitored in real-time to maintain production consistency and minimize human error.

Rigorous Quality Assurance Protocol

Every LED strip undergoes a multi-stage quality verification process. This includes in-process inspections at each manufacturing stage, followed by comprehensive final testing. Our aging tests simulate real-world conditions to validate long-term performance:

| Test Parameter | Standard Procedure | Acceptance Criteria |

|---|---|---|

| Burn-in Duration | 24–48 hours at 45°C ambient | No flicker, dimming, or failure |

| Voltage Stress | 110% rated voltage for 1 hour | Stable output, no degradation |

| Thermal Cycling | -20°C to 60°C x 5 cycles | No physical damage, consistent performance |

Final QC checks include luminous flux measurement (per IES LM-79), color consistency verification (SDCM ≤3), and electrical safety tests per IEC 62471. All test documentation is maintained for traceability and provided with shipment.

OEM/ODM Customization Capabilities

We provide full OEM/ODM services tailored to global project requirements. Clients collaborate directly with our engineering team to define specifications for length, color temperature, and packaging. Our production flexibility supports both small-batch prototyping and large-scale volume orders.

| Customization Option | Specifications | Tolerance |

|---|---|---|

| Length | 1m increments up to 50m | ±1mm per cut |

| CCT (Correlated Color Temperature) | 2700K–6500K | ±50K |

| Color Consistency | SDCM ≤3 (MacAdam ellipse) | – |

| IP Rating | IP20, IP65, IP67 | Certified per IEC 60529 |

| Packaging | Custom reels, retail boxes, bulk | Tailored to client requirements |

For ODM projects, our in-house design team develops custom solutions from concept to prototype validation. All custom products undergo the same rigorous testing protocols as our standard offerings, ensuring compliance with international safety and performance standards.

Contact our engineering team at [email protected] or +86-13902885704 to discuss project-specific requirements. All custom solutions include full technical documentation and compliance certificates.

Installation & Application Scenarios

Where Contractors Should Target LED Strip Installations

(Factory-direct view from Beauty (STC) Manufacturing Co., Ltd – 25 yrs, ETL/TUV-CE, OEM/ODM)

H2 | High-ROI Verticals for LED Strip Targeting

| Application | Lm/m Range* | IP Class | Typical Run Length / Feed | Cert. Edge for Exports | Pain Point Solved |

|---|---|---|---|---|---|

| Upscale Hotels (coves, headboards, façade) | 1 000–1 800 | IP20 coves / IP65 façade | 5 m @ 24 V, 24 V 120 W feed every 5 m | ETL cETL for NA, TUV-CE for EU | Flicker-free <5 %, 90 CRI for guest comfort |

| Shopping Malls (retail window, handrail, ceiling slot) | 1 400–2 000 | IP20 indoor / IP54 food court | 5–10 m, 24 V, loop feed at both ends | CE-LVD, EMC pass, RohS | 50 000 h @ L80 keeps lift-truck downtime low |

| Corporate Offices (task, biodynamic) | 400–800 | IP20 | 5 m, 24 V, DALI driver every 10 m | TUV-CE, EN62471, SVM<0.4 | UGR<19, tunable white 2700-6500 K WELL standard |

| Building Façades & Media Mesh | 2 400-3 600 | IP67/IP68 | 2 m @ 24 V; 48 V for 15 m | ETL wet-location, CE | UV-stable silicone, -40 °C cold bend |

| Industrial Cold-Storage | 1 000 | IP65/IP69K | 5 m, 24 V, constant-current driver | CE, ETL, REACH | -30 °C start, no silicone out-gas |

Factory binning at 3000 K, 4000 K, 6500 K; 80/90/95 CRI on request.

H2 | Installation Checklist – Straight from the Factory Floor

H3 1. Voltage-Drop Math First

24 V strip ≤ 5 m in one feed; 48 V strip ≤ 15 m (ETL-listed 48 V driver available).

If run > 5 m, wire both ends or place 120 W booster every 5 m; keeps ΔV < 0.5 V, colour shift < 100 K.

H3 2. Surface Prep = Warranty Keeper

Aluminium profile ≥ 2 mm wall, 10 mm inner width for 10 mm PCB.

Thermal pad or epoxy tape to bring T-solder point < 70 °C; extends life from 36 kh to 50 kh @ L80.

H3 3. IP Rating vs. Environment

IP20 for HVAC-controlled interiors.

IP54 in food court (grease); IP65 silicone sleeve for façade condensation; IP68 PU-filled for poolside.

All IP65+ strips from Beauty STC are 100 % pressure-tested 0.5 m under water, 30 min, before shipment.

H3 4. Wiring & Controls

Use ETL-listed 24 V or 48 V driver, Class 2 output.

For DMX pixel strips, place power injection every 100 pixels (5 V) or 200 pixels (12 V) to keep RGB current < 60 mA per IC.

Shielded CAT-5e for data; earth drain to steel frame; avoids EMI fail in CE report.

H3 5. Certification Paper Trail

Keep the ETL control number (Beauty STC: 5021234) on site for inspector.

TUV-CE DoC packed in each carton; speeds customs clearance in EU/UK.

LM-80/TM-21 report available for 90 CRI 3000 K batch – supports 5-yr warranty claim.

H2 | OEM/ODM Targeting Guide for Contractors & Distributors

| Customisable Item | Factory Option | Min. Order | Lead-Time | Tooling Cost |

|---|---|---|---|---|

| PCB width, 5 mm – 30 mm | 1-day prototype | 500 m | 7 days | 0 |

| CCT mix 1800–10 000 K | 3-step MacAdam | 1000 m | 10 days | 0 |

| CRI > 97, R9 > 90 | Special phosphor | 2000 m | 14 days | 0 |

| Constant-current strip 350 mA | On-board IC | 1000 m | 12 days | 0 |

| Logo + part-number silkscreen | Laser every 0.5 m | 500 m | 5 days | 0 |

| IP68 PU + UV silicone co-extrusion | Custom die | 3000 m | 21 days | USD 800 |

H2 | Takeaway

Target installations where long runs, code compliance, and low maintenance sell the job—hotels, retail chains, offices, and façade media. Specify ETL/TUV-CE strips from a 1998-established factory (Beauty STC) to remove field-failure risk and satisfy AHJ inspections on day one. Need a matched driver, profile, or DMX controller in the same carton? OEM bundling ships from Jiangmen in 2–3 weeks, direct to your warehouse or jobsite.

For spec sheets, IES files, or project quotation: [email protected] | +86-13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Industrial LED Manufacturing Expertise

Since 1998, Beauty STC Lighting has delivered industrial-grade LED solutions to over 50 countries worldwide. Our rigorous compliance protocols ensure products meet ETL (USA/Canada) and TÜV CE (Europe) standards, supporting reliable integration into commercial and architectural projects.

Certified for International Compliance

All products undergo third-party testing to align with Western market regulations. Key certifications include:

| Certification | Region | Standards Met |

|---|---|---|

| ETL | USA & Canada | UL 1598, CSA C22.2 No. 250.0 |

| TÜV CE | Europe | EN 60598-1, EN 55032, RoHS 2 |

OEM/ODM Engineering Support

Our in-house engineering team collaborates with clients to develop custom LED solutions, including addressable strips, high-CRI panels, and specialized fixtures. We provide detailed technical documentation, prototyping, and quality control to meet your exact specifications.

Global Export Network

Our established export infrastructure supports seamless delivery to 50+ countries, with expertise in customs documentation, international shipping, and regional compliance requirements. We ensure your projects meet local regulations without logistical delays.

Contact Our Technical Team

For project-specific inquiries or technical consultation, contact our export management team:

Email: [email protected]

Phone: +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).