Article Contents

Industry Insight: Led Strip Warm Light

The demand for LED strip lighting with warm light output has seen significant growth across commercial and industrial sectors, driven by the need for energy-efficient, versatile, and aesthetically pleasing illumination solutions. In environments ranging from retail spaces and hospitality venues to warehouses and manufacturing facilities, warm white LED strips (typically 2700K–3000K) are increasingly favored for enhancing visual comfort, creating inviting atmospheres, and improving worker well-being without compromising on performance. As facility managers and lighting designers prioritize both functionality and ambiance, warm light LED strips offer a balanced solution—delivering high lumen efficacy, long operational life, and seamless integration into architectural and structural designs.

Compliance with international safety and performance standards is critical in commercial and industrial applications. Reputable LED strip products are routinely certified to meet ETL and CE standards, ensuring electrical safety, electromagnetic compatibility, and reliability under rigorous operating conditions. These certifications are not just regulatory requirements—they are markers of product quality and consistency, especially in large-scale installations where performance uniformity and maintenance intervals directly impact operational efficiency.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance LED strip solutions, Beauty STC combines advanced thermal management, precision optics, and robust construction to serve the evolving needs of commercial and industrial clients worldwide. With a strong commitment to engineering excellence and regulatory compliance, the company delivers ETL- and CE-certified warm light LED strips that offer superior color rendering, consistent output, and long-term durability—making them a trusted choice for professionals who demand reliability and quality in demanding environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance LED strips designed specifically for warm light applications requiring exceptional color fidelity and reliability. Our warm white LED strips strictly adhere to a correlated color temperature (CCT) range of 2700K to 3000K, ensuring a consistent, inviting ambiance free from unwanted cool undertones. Regarding lumens per watt (lm/W), our premium warm light strips achieve an efficacy range of 100-110 lm/W at 2700K under standard operating conditions (25°C ambient, 24V DC drive). This performance is engineered through the strategic selection of high-efficiency, multi-die 2835 or 5050 SMD LEDs combined with optimized driver circuitry. It is critical to understand that pushing efficacy significantly beyond 110 lm/W at 2700K while maintaining CRI >90 is physically constrained by the Stokes shift loss inherent in converting blue pump light to deep red wavelengths; Beauty STC prioritizes balanced performance over inflated lm/W claims that compromise color quality or longevity.

Achieving and sustaining a Color Rendering Index (CRI) exceeding 90, including a minimum R9 value of 50 for robust red rendition, is a core engineering focus at Beauty STC. Our warm light strips utilize proprietary tri-phosphor or quad-phosphor blends applied to high-brightness blue LED chips. Each production batch undergoes rigorous spectral binning to ensure tight chromaticity consistency (within a 3-step MacAdam ellipse) and guaranteed CRI >90 across the entire reel. This meticulous process, coupled with advanced optical encapsulation using high-purity silicone instead of cheaper epoxy, prevents phosphor degradation and color shift over time, ensuring the warm light output remains true and vibrant throughout the product’s lifespan. Independent third-party LM-79 testing reports are available to verify these CRI specifications.

IP rating selection is application-dependent, and Beauty STC offers warm light strips across the spectrum to meet diverse environmental demands. For standard dry indoor installations (e.g., cove lighting, cabinetry), our IP20 strips provide optimal thermal management and lumen output. For damp locations like bathrooms or kitchens, IP65-rated strips feature a continuous silicone coating over the LEDs and PCB, protecting against water splashes and dust ingress while maintaining high thermal conductivity. For fully exposed outdoor or submerged applications (e.g., pool perimeters, landscape lighting), our IP67 and IP68 strips utilize a robust dual-layer silicone extrusion process, fully encapsulating the PCB and connectors to withstand temporary submersion or prolonged wet conditions. It is essential to note that higher IP ratings, particularly IP67/IP68, involve additional material layers which can reduce the effective lumen output by 8-12% compared to an equivalent IP20 strip; Beauty STC provides precise lumen maintenance data sheets reflecting these environmental ratings.

Beauty STC’s commitment to quality is embedded in every stage of manufacturing. We implement stringent incoming material inspection for LED chips, phosphors, and substrates, sourced exclusively from Tier-1 suppliers. Our automated SMT lines operate under ISO 9001-certified processes with 100% AOI (Automated Optical Inspection) post-placement. Critical to warm light performance is our thermal management design; we utilize 2oz or 4oz copper PCBs with thermal vias to ensure junction temperatures remain low, directly contributing to sustained lumen output and CRI stability over 50,000 hours (L70/B50). All strips undergo 100% aging and photometric testing, with serialized batch traceability. Beauty STC strips comply with UL 8750, CE, and RoHS standards, and our quality control protocols consistently achieve failure rates below 0.3%, ensuring our warm light solutions deliver reliable, high-fidelity illumination for demanding architectural and residential projects.

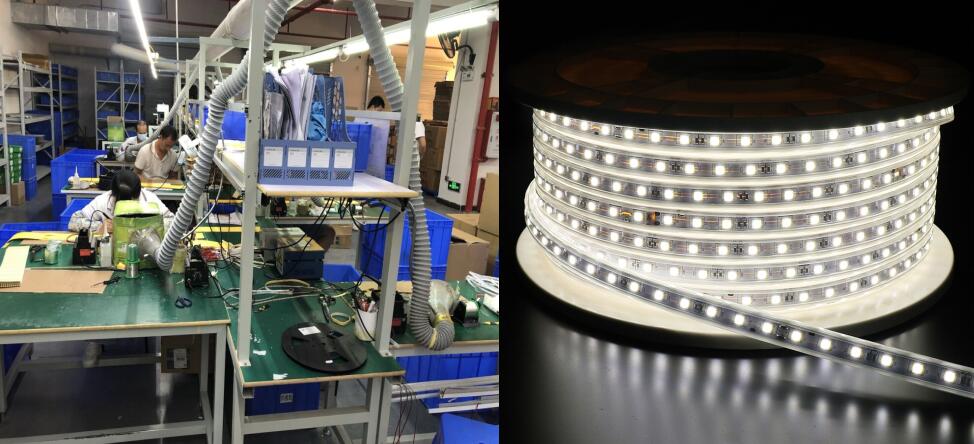

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, China. The factory is strategically located within a major industrial zone, providing efficient access to supply chains, logistics, and skilled labor. Spanning a substantial production area, the Jiangmen facility is designed for high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control and process automation.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which ensure high-speed and high-accuracy placement of LED components onto flexible and rigid PCBs. The factory utilizes multiple high-efficiency SMT lines equipped with automatic optical inspection (AOI) systems to detect soldering defects and component misplacement in real time. This level of automation guarantees consistent product quality and supports the production of compact, high-density LED strips, including the popular ‘led strip warm light’ series.

To ensure long-term reliability, every batch of LED strips undergoes rigorous aging tests within the facility. These tests simulate extended operation under elevated temperatures and continuous power loads, typically lasting 24 to 72 hours. During aging, performance metrics such as light output, color consistency, and thermal behavior are closely monitored. Only products that pass these tests move to final packaging, ensuring customers receive durable and stable lighting solutions.

Beauty STC has robust OEM (Original Equipment Manufacturing) capabilities tailored specifically for LED lighting products, including customized warm light LED strips. The company supports clients in designing product specifications such as color temperature (typically 2700K–3000K for warm white), CRI (Color Rendering Index), voltage (12V or 24V), IP rating (from IP20 to IP68), and cuttable lengths. Clients can also request custom branding, packaging, and labeling. With in-house R&D, engineering, and tooling support, Beauty STC efficiently handles small pilot runs as well as large-scale OEM orders, maintaining flexibility and fast turnaround times.

Overall, the Jiangmen factory combines advanced automation, strict quality assurance, and comprehensive OEM services, making Beauty STC a reliable partner for high-quality warm light LED strip production.

Application Scenarios

LED strip warm light, typically defined as 2700K to 3000K correlated color temperature (CCT) with a high CRI (90+), serves distinct purposes across commercial environments by creating inviting, comfortable atmospheres. Its application differs significantly between hotels, malls, and offices due to varying functional and psychological needs.

In hotels, warm LED strips are essential for enhancing guest experience and perceived luxury. Install them discreetly within cove lighting in guest room ceilings to provide soft, shadow-free ambient illumination that aids relaxation without glare. Use them under vanity cabinets in bathrooms for flattering, even task lighting that avoids harsh shadows on faces. Corridor soffits benefit from warm strips to guide guests with a welcoming glow that reduces the institutional feel of long hallways. Lobby feature walls or reception desk perimeters utilize warm strips to highlight architectural elements and create a sense of arrival, directly influencing first impressions. Crucially, avoid cool white light in these areas as it undermines the restful, premium ambiance guests expect.

Malls require strategic warm light deployment to balance retail appeal with navigational clarity. Retail storefronts extensively use warm strips within display cases and shelving to render textiles, cosmetics, and food more naturally and appetizingly, directly impacting purchase decisions. Food court ceilings often incorporate cove lighting with warm strips to stimulate appetite and encourage longer dwell times. Common area handrails or step edges employ low-level warm strips for subtle safety lighting that maintains the space’s upscale aesthetic without the clinical feel of cool white. However, main circulation corridors typically require cooler light for alertness and wayfinding; warm strips here should be limited to accent features like column wraps to avoid disorientation. Consistent color temperature across all warm strips within a mall zone is critical to prevent visual discord between stores.

Offices deploy warm LED strips selectively where human interaction and comfort are prioritized over high-acuity tasks. Reception areas use them behind reception desks or along feature walls to convey approachability and reduce visitor anxiety. Executive office perimeters or bookshelf undersides benefit from warm strips to create a non-institutional, conversational atmosphere during meetings. Break rooms and lounge zones employ warm strips under cabinetry or in ceiling coves to foster social interaction and mental respite. It is vital to avoid installing warm strips as primary task lighting in workstations, as insufficient illuminance and low CCT can cause eye strain and reduce productivity; these areas require cooler, brighter direct lighting. Warm strips here should complement—not replace—functional overhead systems.

Installation demands rigorous adherence to technical best practices regardless of location. Always mount strips within extruded aluminum channels with diffusers; this ensures optimal heat dissipation, prevents premature lumen depreciation, and provides uniform light distribution. Never adhere strips directly to combustible surfaces like drywall or wood. Calculate voltage drop meticulously for runs exceeding 5 meters—use 24V systems for longer installations and inject power at multiple points to maintain consistent brightness. For damp locations like hotel bathrooms or mall food courts, specify IP65-rated strips and silicone-end caps, ensuring all connections are sealed within waterproof junction boxes. Verify dimmer compatibility with the driver type (e.g., 0-10V, DALI) during specification to avoid flicker, and conduct on-site color temperature verification with a spectrometer to guarantee batch consistency. Always follow local electrical codes regarding low-voltage wiring separation from mains power. Proper installation directly impacts system longevity and performance, especially in high-traffic commercial settings where maintenance access is disruptive.

Why Choose Beauty STC Lighting

Discover the perfect ambiance with our premium LED strip warm light solutions designed for both residential and commercial applications. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality, energy-efficient lighting that combines elegance with performance. Our warm light LED strips offer a soft, inviting glow ideal for homes, hotels, retail spaces, and more.

Partner with Beauty STC to access reliable manufacturing, customizable options, and exceptional technical support. Whether you’re looking for standard lengths or tailored specifications, we deliver consistent quality and competitive pricing.

For collaboration opportunities or product inquiries, contact us today at [email protected] and let us illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.