Article Contents

Industry Insight: Led Strip Stick

In the evolving landscape of commercial and industrial lighting, LED strip sticks have emerged as a cornerstone solution for energy-efficient, durable, and versatile illumination. Designed to meet the rigorous demands of warehouses, manufacturing facilities, retail environments, and transportation hubs, LED strip sticks offer superior lumen output, extended lifespans, and minimal maintenance requirements compared to traditional fluorescent and HID lighting systems. With increasing emphasis on regulatory compliance and safety, products bearing ETL and CE certifications are now essential, ensuring adherence to North American and international electrical standards, respectively.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance LED solutions tailored for industrial applications. The company’s LED strip sticks combine robust construction, advanced thermal management, and strict quality control to perform reliably in demanding environments. Backed by ETL and CE certifications, Beauty STC’s products are engineered to meet global safety and performance benchmarks, making them a preferred choice for contractors, facility managers, and lighting designers seeking dependable, code-compliant lighting systems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED strip sticks engineered for demanding applications where color fidelity, efficiency, and environmental resilience are critical. Our technical specifications reflect a commitment to exceeding industry benchmarks while ensuring long-term reliability.

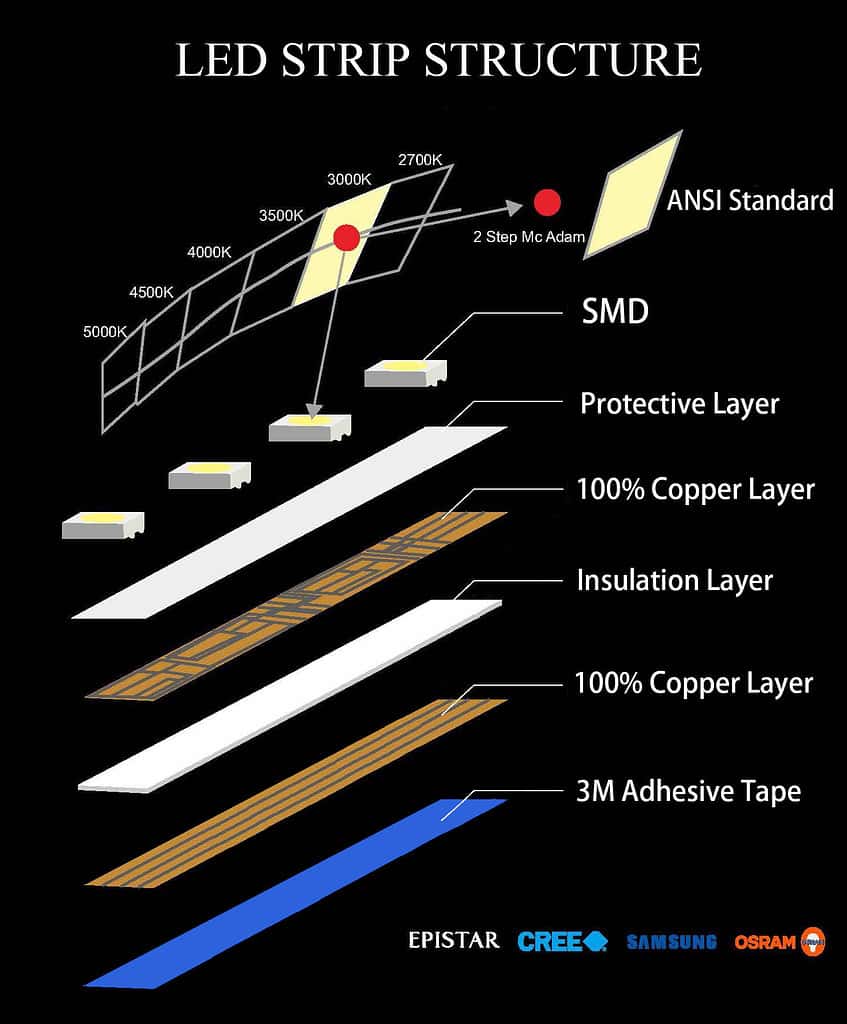

Lumens per Watt (Efficacy) is a core focus in our LED strip stick development. We achieve typical efficacies ranging from 120 to 140 lumens per watt for standard CCT options (3000K to 4000K) under optimal thermal management conditions. This performance is realized through the strategic use of high-bin SMD 2835 or 5050 LEDs paired with precisely calibrated constant-current drivers operating at 70% to 80% of maximum rated current. It is important to note that real-world efficacy varies based on ambient temperature, drive current, and thermal interface quality. Our strips incorporate aluminum PCB substrates to minimize thermal resistance, ensuring sustained output and preventing lumen depreciation from overheating. Competitive products often cite higher lab-only efficacy figures at non-sustainable drive currents; Beauty STC prioritizes stable, field-validated performance over inflated peak numbers.

Color Rendering Index (CRI) consistently exceeds 90 (Ra ≥ 90) across our premium strip stick portfolio, with extended spectrum models achieving Ra > 95. We utilize multi-phosphor LED technology to ensure high fidelity across all critical color bands, including strong R9 (saturated red) values typically above 50 and R12 (saturated blue) values exceeding 45. This is essential for applications like retail merchandising, art galleries, and high-end residential spaces where accurate color perception is non-negotiable. Unlike budget alternatives that may prioritize high CRI through narrow spectral tuning at the expense of R9, our phosphor formulations deliver balanced spectral power distribution. Each production batch undergoes spectroradiometric validation using calibrated integrating sphere systems to guarantee CRI compliance before shipment.

IP Ratings for our LED strip sticks are rigorously defined by construction and application. Standard flexible strips without encapsulation are rated IP20 for indoor dry locations. For environments requiring moisture or dust resistance, we offer variants with silicone coating (IP65) or full silicone extrusion (IP67). Rigid aluminum-channel-integrated strip sticks achieve IP65 when end caps and connectors are properly sealed, while fully potted versions in continuous silicone housings reach IP68 for temporary submersion. Crucially, Beauty STC emphasizes that the IP rating applies only to the strip itself under controlled factory testing; field performance depends entirely on correct installation, including waterproof connectors and sealed termination points. We explicitly warn against installing even IP67-rated strips in constantly submerged or high-condensation scenarios without additional protective measures, as thermal cycling can compromise seals over time.

Beauty STC’s quality differentiation lies in systemic engineering rigor. We reject the industry practice of sourcing commodity LEDs and assembling basic strips. Instead, we control the entire value chain: our LEDs are binned for chromaticity consistency (within a 3-step MacAdam ellipse), drivers undergo 100% burn-in testing, and aluminum PCBs feature 1.0mm thick substrates for superior heat dissipation compared to competitors’ 0.8mm or FR4 alternatives. All products comply with UL 8750 and IEC 62471 photobiological safety standards, with third-party certification documentation available. Most significantly, our thermal management protocols—validated through 5,000-hour LM-80 testing—ensure lumen maintenance of L70 > 50,000 hours at 25°C ambient, directly addressing the primary failure mode in LED systems. This holistic approach to quality prevents the premature color shift and output decay common in strips that prioritize initial cost over sustained performance.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility dedicated to the production of high-quality LED lighting products. Strategically located in the Jiangmen Jianghai District, the factory benefits from excellent logistical access and a skilled regional workforce, supporting efficient manufacturing and export operations.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise assembly of LED components onto flexible and rigid printed circuit boards. These SMT machines ensure high-speed, high-accuracy placement of LEDs, resistors, capacitors, and other surface-mounted devices, allowing for consistent product quality and reliability. The automated soldering and reflow processes further enhance production efficiency and minimize defects, meeting international standards for electronic manufacturing.

To ensure long-term performance and durability, Beauty STC implements comprehensive aging and burn-in tests across its production output. Finished LED strip lights undergo extended operational testing under controlled conditions, typically running at full power for 24 to 72 hours. This process helps identify early failures, verifies thermal management performance, and confirms consistent light output and color stability before products are packaged and shipped.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, particularly for LED strip stick products. The company supports customized solutions including length specifications, color temperature options (such as 2700K to 6500K), RGB and tunable white configurations, IP ratings (from IP20 to IP68), and various voltage requirements (DC12V, DC24V). Clients can also request custom labeling, packaging, and private branding. With in-house engineering and design support, Beauty STC works closely with partners to develop tailored lighting solutions that meet specific market or application needs.

Overall, the Jiangmen factory combines advanced automation, rigorous quality control, and flexible customization to serve global clients in residential, commercial, and industrial lighting sectors.

Application Scenarios

LED strip sticks, which refer to rigid linear LED modules typically housed in aluminum profiles for structural support and heat dissipation, serve distinct purposes across commercial environments. Their primary advantage over flexible tape lies in consistent light output, durability, and professional aesthetics, making them ideal for architectural integration where straight lines and clean finishes are required.

In hotels, LED strip sticks excel in creating ambiance and enhancing guest experience. Install them within cove lighting along corridor ceilings to provide indirect, glare-free wayfinding illumination that maintains a premium feel. They are equally effective under reception desks for a floating effect, behind headboards in guest rooms for subtle night lighting, and within vanity mirrors in bathrooms for even, shadow-free task lighting. For high-end suites, consider integrating them into custom millwork or feature walls to highlight textures without visible fixtures. Always select a high CRI (90+) variant in warm white temperatures (2700K-3000K) to ensure skin tones and décor appear natural, and ensure all channels are powder-coated to match interior finishes for seamless blending.

Malls leverage LED strip sticks for visual merchandising and spatial definition. Use them to illuminate high-value display cases in jewelry or electronics stores, where precise, cool white light (4000K) enhances product details without UV damage. Install them along the perimeters of feature walls in common areas to create dynamic branded backdrops, or embed them within suspended ceiling baffles to define zones without obstructing sightlines. For directional guidance, integrate them into handrails or floor channels at staircases, though ensure these comply with local emergency lighting codes. In food courts, position them under hood canopies to brighten seating areas while avoiding direct view—critical for maintaining a comfortable dining atmosphere. Always verify IP65-rated channels for food service zones to withstand cleaning and humidity.

Offices benefit from LED strip sticks in both functional and design applications. Mount them under suspended cabinet systems in kitchens or pantries to eliminate shadows on countertops, or within bookshelves to showcase awards or literature. For collaborative spaces, install them along the inner edges of acoustic baffles to softly illuminate meeting areas without glare on screens. In executive offices, integrate them into desk credenzas for a refined touch. Prioritize dimmable 3500K-4000K modules to support circadian lighting strategies, and use mounting clips every 300mm to prevent sagging in long runs. Avoid placing strips directly above workstations to minimize reflections on monitors—position them at least 600mm above desktop height.

Installation requires strict adherence to commercial standards. Always secure channels to solid substrates like drywall studs or metal framing using appropriate fasteners; never rely solely on adhesive tape in high-traffic areas. Ensure channels include end caps and diffusers to prevent glare and dust ingress. For runs exceeding 5 meters, feed power from both ends to avoid voltage drop, and use a dedicated circuit with overcurrent protection sized for the total load. In suspended ceilings, maintain minimum 10mm clearance from insulation to prevent overheating. Crucially, all electrical connections must be performed by a licensed electrician per local codes, with low-voltage strips (24V) preferred for safety in accessible areas. Finally, conduct a photometric validation post-installation to confirm uniformity and avoid hotspots that compromise the professional aesthetic these spaces demand.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium LED strip sticks—engineered for performance, durability, and seamless integration. Whether you’re working on architectural highlights, commercial displays, or residential accents, our LED strip sticks deliver consistent, high-quality illumination.

Partner with Beauty STC, a trusted leader in innovative LED solutions. As a manufacturer with years of expertise, we offer customized options, bulk pricing, and dedicated support to meet your project needs.

Take the next step—connect with our sales team today. Email [email protected] to discuss your requirements, request samples, or receive a tailored quote. Let’s light up the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.