Article Contents

Industry Insight: Led Strip Remote Control

The commercial and industrial lighting landscape has undergone a transformative shift with the integration of intelligent control systems, and LED strip remote control technology has emerged as a pivotal innovation in this evolution. Once limited to residential and decorative applications, LED strip lighting with remote control functionality is now a cornerstone in modern commercial and industrial environments—ranging from retail spaces and hospitality venues to manufacturing facilities and cold storage warehouses. The demand for energy efficiency, flexible illumination design, and remote operational management has driven the adoption of controllable LED systems that offer precise dimming, color tuning, and scheduling capabilities. In these critical applications, compliance with international safety and performance standards is non-negotiable. Products bearing ETL and CE certifications ensure reliability, electrical safety, and adherence to rigorous North American and European regulatory requirements—essential for facility managers and lighting designers specifying solutions for large-scale installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this advancement, delivering high-performance LED lighting solutions tailored for commercial and industrial use. With over two decades of engineering expertise, Beauty STC combines robust product design, stringent quality control, and full compliance with global standards to meet the demanding needs of professional lighting applications. The company’s LED strip remote control systems reflect this commitment—offering seamless integration, durable construction, and certified performance that support smarter, safer, and more sustainable lighting infrastructures across industries.

Technical Specs & Certifications

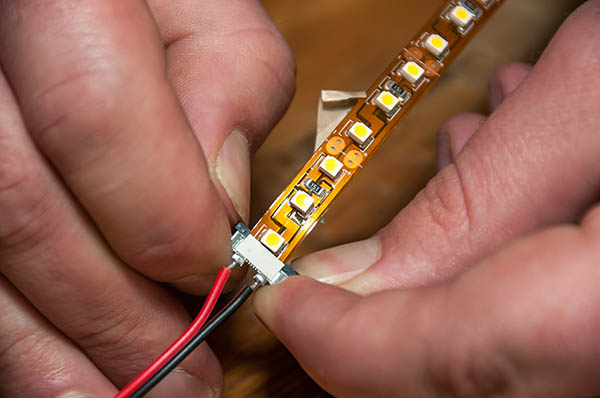

The term “LED strip remote control” refers to two distinct but complementary components: the LED flexible strip itself and the wireless remote control unit used to operate it. Technical specifications must be addressed separately for each element, as lumens per watt and CRI are properties of the LED strip, while IP ratings apply to both the strip and the remote. Beauty STC rigorously engineers both components to exceed industry standards, ensuring reliability and performance consistency across all manufacturing batches.

For the LED strip, Beauty STC achieves a typical efficacy range of 120–140 lumens per watt at 25°C ambient temperature, depending on the specific LED density and color temperature selected. This high efficiency is maintained without compromising color quality, as all strips targeting professional applications are engineered for a minimum CRI of 92 (Ra) and R9 >50, verified using calibrated spectroradiometers per ANSI C78.377 standards. Our proprietary phosphor formulation and strict binning process ensure consistent color accuracy across rolls, critical for retail, photography, and high-end residential installations where true color representation is non-negotiable. Unlike competitors who may sacrifice efficacy for CRI, Beauty STC’s thermal management design—including optimized copper PCB thickness and thermal interface materials—minimizes lumen depreciation even at elevated drive currents.

IP ratings are application-dependent but consistently implemented with robust materials. Indoor strips (e.g., under-cabinet lighting) carry IP20 certification with flame-retardant PVC backing. For damp or outdoor use, Beauty STC offers IP65-rated strips featuring a seamless silicone overmolding process that eliminates air gaps, preventing moisture ingress at solder points—a common failure point in lesser strips. Our premium IP67/IP68 variants undergo 1,000-hour salt spray testing and include double-layered conformal coating on all electronic components, ensuring reliability in marine or high-humidity environments. The silicone jacketing maintains flexibility down to -40°C, avoiding cracking during installation in cold climates.

The remote control units are engineered for durability with an IP44 rating as standard, protecting against splashed water and dust ingress during typical indoor use. RF remotes (433MHz or 2.4GHz) provide 15-meter range through walls, while IR variants include precision optical filters to prevent false triggering. All remotes use industrial-grade ABS housings with UV stabilizers to resist yellowing, and button mechanisms rated for 100,000 cycles. Beauty STC’s quality control extends to final assembly: every strip undergoes 24-hour burn-in testing at 1.2x rated voltage, with spectral output and waterproofing validated batch-by-batch. This commitment to traceable quality—evidenced by our ISO 9001-certified production lines and in-house photometric lab—ensures that the lumen maintenance (L70) exceeds 50,000 hours even in challenging environments, directly supporting client ROI through reduced maintenance and energy costs.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and scalability to serve both domestic and international markets.

At the heart of the production line are advanced SMT (Surface Mount Technology) machines, which enable precise and automated placement of electronic components onto printed circuit boards used in LED strips and control systems. These SMT lines are fully automated, featuring high-speed pick-and-place machines, reflow soldering ovens, and automated optical inspection (AOI) systems to ensure component accuracy and solder joint integrity. This level of automation supports consistent product quality and high throughput, essential for meeting large-scale OEM demands.

The factory incorporates comprehensive aging and reliability testing procedures as part of its quality assurance protocol. Completed LED strip assemblies, including those with integrated remote control functionality, undergo rigorous aging tests—typically operating at full power for extended periods under controlled thermal and electrical conditions. This process helps identify early-life failures and ensures long-term performance and durability. Additional testing includes waterproof verification, color consistency checks, and signal stability testing for remote-controlled products.

Beauty STC has robust OEM and ODM capabilities, particularly for customized LED strip and remote control solutions. The company supports clients in developing tailored products, including custom PCB designs, specific color temperatures, dimming protocols (such as 2.4G RF, infrared, or Bluetooth), and proprietary remote control interfaces. Clients can also brand the products with their own logos and packaging, supported by in-house design and engineering teams that assist from prototype to mass production.

Overall, the Jiangmen factory combines advanced manufacturing technology, stringent quality control, and flexible customization options, making Beauty STC a reliable partner for OEM clients seeking high-quality, competitively priced LED lighting solutions with integrated remote control features.

Application Scenarios

LED strip remote controls find strategic application across hospitality, retail, and commercial environments, enhancing functionality and user experience when implemented correctly. Within hotels, remote controls are primarily deployed in guest rooms for under-cabinet lighting in minibars, cove lighting within headboards or wall niches, and accent lighting in bathrooms or vanity areas, allowing guests to adjust ambiance without reaching for wall switches. Lobby and corridor installations often utilize remotes for decorative cove lighting or feature walls, enabling staff to shift color temperatures or dim levels for different times of day or events. In high-end suites, remotes manage layered lighting scenes combining strips with other fixtures.

Malls leverage LED strip remotes extensively for dynamic visual merchandising and environmental control. Retail storefronts use them to highlight product displays with tunable white or RGB strips above showcases, where store staff adjust lighting to complement merchandise changes. Common areas employ remotes for architectural cove lighting along escalators, ceilings, or columns, facilitating quick adjustments for holidays or promotions. Food court zones utilize remotes to modify strip lighting under seating booths or counters, creating distinct atmospheres during peak versus off-peak hours. Critical installation zones like stairwells or emergency exit paths may use remotes for non-essential decorative strips, ensuring safety lighting remains independent.

Office environments benefit from remotes in specific collaborative and flexible workspaces. Meeting rooms frequently feature strips under tables or behind presentation screens, allowing presenters to dim ambient light via remote without interrupting flow. Hot-desking areas use remotes for task lighting under shelving or within partitioned work nooks, giving employees personal control. Executive offices and lounge zones implement remotes for RGBW strips in feature walls or coves, enabling mood adjustments for focus or relaxation. Conference center pre-function areas utilize remotes to transition strip lighting between registration and event modes.

Installation requires meticulous planning to ensure reliability. Always verify the remote system type—IR remotes demand direct line-of-sight between transmitter and receiver, making them unsuitable for enclosed coves, while RF remotes offer greater flexibility but require channel coordination in dense installations. Position receivers away from electromagnetic interference sources like transformers or HVAC units, and never conceal them behind metal surfaces which block signals. For large zones, group strips into logical circuits matching intended scenes rather than physical location—for instance, all hospitality headboard strips on one channel—even if this requires additional wiring runs. Conceal receivers within accessible junction boxes near the strip start point, never embedding them in inaccessible plenums. Crucially, integrate remote-controlled strips into the building management system where possible; standalone remotes are impractical for enterprise control, so use RF systems with central gateways that allow remote scheduling or overrides via facility management software. Always test signal range with final finishes in place, as drywall or glass can attenuate RF signals, and provide clear operational documentation to facility staff highlighting channel assignments and reset procedures.

Why Choose Beauty STC Lighting

Upgrade your lighting experience with high-quality LED strip remote controls designed for seamless performance and precision control. At Beauty STC, we specialize in advanced LED lighting solutions tailored to meet the demands of residential, commercial, and industrial applications. Our LED strip remote controls offer reliable functionality, intuitive design, and compatibility with a wide range of lighting systems.

Partner with Beauty STC to access innovative products, consistent quality, and expert technical support. As a trusted manufacturer, we are committed to delivering lighting solutions that enhance efficiency and customer satisfaction.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.