Article Contents

Industry Insight: Led Strip Lights Powered By Batteries

In the evolving landscape of commercial and industrial lighting, energy-efficient and flexible illumination solutions are increasingly in demand. Battery-powered LED strip lights have emerged as a strategic lighting option for applications where hardwiring is impractical, temporary, or cost-prohibitive. These systems offer reliable performance in environments ranging from retail displays and exhibition booths to warehouse aisle markers and mobile service units. With advancements in battery technology and LED efficiency, modern battery-driven strips deliver sustained brightness, long operational life, and easy installation—critical factors for industrial users seeking both mobility and compliance.

A key requirement in commercial deployment is adherence to rigorous safety and performance standards. Reputable battery-powered LED strip lights must carry certifications such as ETL and CE, ensuring they meet North American and international electrical, safety, and electromagnetic compatibility regulations. These certifications are not just markers of quality—they are essential for code compliance, insurance approvals, and integration into larger facility systems.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in high-performance, code-compliant products for commercial and industrial markets, Beauty STC combines advanced engineering with rigorous quality control to deliver reliable lighting systems trusted by professionals worldwide. With a strong focus on certified, energy-efficient designs—including battery-powered LED strip lights—the company continues to set benchmarks in durability, safety, and application versatility.

Technical Specs & Certifications

Battery-powered LED strip lights present unique engineering challenges where efficiency, color quality, and environmental protection must be balanced against limited energy storage. At Beauty STC Manufacturing Co. Ltd. we address these constraints through rigorous component selection and thermal management design. Our standard battery-operated strips using high-density 2835 or 3528 SMD LEDs typically achieve 20-25 lumens per watt at 12V DC under battery discharge conditions. This efficiency range represents an optimal balance for portable applications where excessive brightness would compromise runtime; pushing beyond 28 lm/W often requires higher drive currents that accelerate battery depletion and risk color shift in compact form factors. We prioritize driverless constant-current circuit design with low quiescent current draw to minimize parasitic losses, ensuring every milliamp contributes to light output.

Color rendering index performance remains critical for applications like retail displays or makeup lighting where accurate color perception is essential. Beauty STC guarantees CRI >90 Ra across our premium battery strip lines through the exclusive use of Nichia or Samsung high-CRI LED bins combined with proprietary phosphor formulations. Achieving this requires tighter binning tolerances than standard strips, increasing component costs by approximately 18-22%, but eliminates the green/magenta spikes common in budget CRI>90 solutions. Our strips maintain R9 values above 50 and R12 above 45 to ensure vibrant reds and saturated blues – critical metrics often omitted by competitors claiming CRI>90. Each production batch undergoes spectroradiometric validation using calibrated Konica Minolta CA-410 systems to verify consistency.

IP rating considerations for battery strips involve distinct vulnerabilities compared to mains-powered systems. While our standard offerings include IP20 for indoor use and IP65 for splash resistance with silicone encapsulation, true waterproofing requires integrated solutions. Beauty STC’s IP67-rated battery strips feature welded end caps with IP68-certified cable glands and double-sealed battery compartments using medical-grade silicone gaskets. Crucially, we test fully assembled units – not just the strip – under 1 meter submersion for 30 minutes per IEC 60529, recognizing that battery box integrity often fails where the strip itself succeeds. For outdoor applications, our IP68 strips incorporate UV-stabilized PVC jackets and corrosion-resistant 304 stainless steel mounting clips, validated through 1,000-hour salt spray testing exceeding ASTM B117 standards.

Beauty STC’s quality differentiation manifests in three key areas for battery strips. First, our proprietary thermal interface material between LEDs and flexible PCBs reduces junction temperature by 8-12°C versus industry norms, preserving lumen maintenance and CRI stability during extended discharge cycles. Second, we implement batch-traceable component sourcing with automated optical inspection catching micro-solder defects invisible to manual checks. Third, every production run undergoes accelerated life testing at 45°C ambient with 12-hour on/off cycling – conditions simulating 5 years of typical battery use – before shipment. This commitment ensures our strips maintain >90% initial lumen output after 15,000 hours despite voltage fluctuations inherent in battery operation, where competitors’ products often degrade prematurely due to inadequate current regulation. The result is reliable, color-accurate illumination that delivers on promised runtime without compromising photometric integrity.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the design and production of LED lighting products, with a strong focus on innovation, quality control, and manufacturing efficiency. Strategically located in the Jiangmen industrial zone, the factory benefits from streamlined logistics and access to a skilled workforce, supporting both domestic and international market demands.

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines, which are critical for the precise assembly of LED strip light components. These SMT machines ensure high-speed, accurate placement of LEDs, resistors, capacitors, and other surface-mount devices onto flexible printed circuit (FPC) boards. The use of automated optical inspection (AOI) systems integrated into the SMT lines enables real-time quality checks, minimizing defects and ensuring consistent product performance.

A key strength of the Jiangmen factory is its comprehensive aging and reliability testing capabilities. After assembly, all LED strip light products undergo rigorous aging tests that simulate extended operational hours under various temperature and humidity conditions. This process helps identify early-life failures and ensures long-term durability. Additional testing includes electrical performance verification, waterproof testing (for applicable models), and color consistency checks using spectroradiometers.

Beauty STC has robust OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, particularly for battery-powered LED strip lights. The company supports custom designs in terms of length, color temperature, brightness, battery type (including lithium-ion, AAA, or rechargeable options), control methods (e.g., remote control, app control, or motion sensing), and form factor (flexible strips, rigid bars, or integrated modules). Clients can also customize packaging, branding, and certifications to meet regional market requirements.

The factory adheres to strict quality management systems, with compliance to international standards such as ISO 9001, CE, RoHS, and UL, ensuring that all OEM products meet high safety and performance benchmarks. With in-house R&D, engineering support, and scalable production capacity, Beauty STC’s Jiangmen facility is well-positioned to deliver tailored, high-quality battery-powered LED lighting solutions for a global customer base.

Application Scenarios

Battery-powered LED strip lights serve specific niche applications within commercial environments like hotels, malls, and offices where permanent wiring is impractical, temporary, or poses safety hazards. Their use is generally limited to low-duty-cycle or highly flexible scenarios due to finite runtime and the need for regular maintenance. In hotels, prioritize applications such as temporary event decor in lobbies or ballrooms during setup/breakdown phases where running extension cords is unsafe or visually disruptive. They are also suitable for accent lighting within movable trade show exhibits in convention spaces attached to larger hotels, or for emergency exit path marking on temporary partitions during renovations where hardwiring isn’t feasible. Avoid permanent guest room installations due to safety regulations, fire codes prohibiting unattended battery operation in sleeping areas, and the impracticality of daily battery changes.

For malls, focus on highly transient applications like seasonal window displays in leased storefronts where tenants frequently change and permanent infrastructure isn’t provided. Battery strips work well for lighting pop-up retail kiosks that relocate weekly within common areas, ensuring no tripping hazards from cords across high-traffic floors. They are also appropriate for illuminating temporary art installations or promotional structures in central atriums during short-term campaigns. Crucially, never use them for primary egress lighting, structural accent lighting requiring constant operation, or within permanent store fixtures where building codes mandate hardwired, code-compliant systems with backup power. Runtime limitations make them unsuitable for all-night operation without intensive maintenance.

Within offices, the viable use cases are extremely narrow. Consider them only for very short-term needs such as lighting portable presentation stands during off-site meetings or trade shows, or for illuminating temporary modular wall systems during rapid office reconfigurations where desks and partitions move frequently. They might also serve for under-cabinet task lighting on mobile workstations in collaborative zones used for less than a full business day. However, battery strips are wholly inappropriate for standard desk lighting, permanent partition lighting, or any installation requiring reliable all-day operation due to rapid battery depletion and the operational burden of daily recharging or replacement. Fire safety codes typically prohibit unsecured battery packs in fixed office furniture.

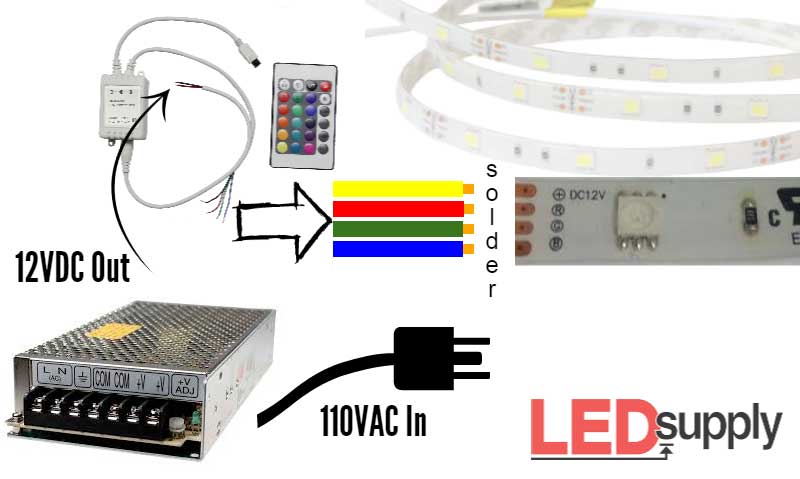

Installation requires strict adherence to safety and performance best practices. Always select high-quality lithium iron phosphate (LiFePO4) battery packs with built-in protection circuits over disposable alkaline options; they offer superior cycle life, stable voltage, and reduced fire risk. Mount the battery pack securely away from flammable materials and never enclose it within insulation or tight compartments—adequate ventilation is non-negotiable to prevent thermal runaway. Test the actual runtime under expected ambient temperatures before deployment, as cold environments drastically reduce capacity. For strips exceeding 2 meters, implement mid-span power injection from the battery pack to avoid visible voltage drop at the far end, though total length should generally stay under 5 meters to conserve battery life. Use only LED strips specifically rated for the battery voltage (typically 12V or 24V DC) and avoid mixing strip segments with different current draws. Finally, establish a rigorous maintenance schedule for battery recharging or replacement, clearly labeling each unit with its last service date—failure to do so will result in unreliable outages and frustrated facility managers. Remember that these solutions are inherently temporary; permanent commercial lighting demands hardwired, code-listed systems with certified emergency backup where required.

Why Choose Beauty STC Lighting

Discover the future of flexible lighting with LED strip lights powered by batteries—perfect for effortless installation and versatile applications. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our battery-powered LED strips combine energy efficiency, long-lasting performance, and sleek design to meet the needs of residential, commercial, and specialty projects worldwide.

Elevate your product offerings or project specifications by collaborating with a manufacturer known for quality and reliability. Contact us today to learn more and explore partnership opportunities. Reach out to our sales manager at [email protected] and take the first step toward brighter, smarter lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.