Article Contents

Industry Insight: Led Strip Lights Corners

Industry Insight – LED Strip Lights in Corners

Commercial & Industrial Perspective

Corners are the weakest link in every linear lighting scheme: luminous flux drops, color over-shifts, and heat builds where the PCB folds. In warehouses, cold-chain facilities, retail gondolas and architectural coves, a single dark 90° joint can cut delivered lumens by 18 % and void uniformity warranties. ETL-listed (UL 8750) and CE-certified (EN 60598-2-21) corner modules are therefore no longer optional—they are the only way to maintain ≥80 % luminous uniformity across long runs while satisfying OSHA/NFPA inspection protocols and European CPR fire-safety declarations.

Beauty (STC) Manufacturing Co., Ltd., engineering LED solutions since 1998, specializes in continuous-run corner strips that are fully ETL- and CE-certified as a system, not just as components. Our 3-oz copper, 3-in-1 SMD corner boards maintain bin-tight 3-step MacAdam ellipse color control and <10 % lumen depreciation after 6,000 h at 85 °C, eliminating the “shadow wedge” that auditors flag and specifiers dread.

Technical Specs & Certifications

Technical Specifications for LED Strip Light Corner Solutions

Prepared by Beauty (STC) Manufacturing Co., Ltd. – Senior LED Lighting Engineer & Export Manager

Clarification of Terminology:

“LED strip lights corners” typically refers to corner connectors, corner profiles, or pre-bent aluminum channels designed for seamless right-angle installations of standard LED strips. Note: LED strips themselves are linear; corners require specialized accessories to maintain continuity, optical consistency, and structural integrity at 90° angles. Below are the precise technical specifications for our corner solutions, aligned with industry standards and Beauty STC’s rigorous quality protocols.

1. Core Technical Specifications

A. LED Strip (Integrated into Corner System)

- Luminous Efficacy: 100–120 lm/W (typical range for 3000K–6500K CCT)

- Tested per IES LM-79-19: 12V/24V DC strips with high-efficiency Epistar/OSRAM LED chips.

- Example: 14.4W/m strip at 1400 lm/m = 97 lm/W (3000K, CRI 95+).

- Color Rendering Index (CRI): >90 (Typically 95–98)

- Binning: Strict ΔE < 1 (per ANSI C78.377) for color consistency across batches.

- R9 Value: >90 (vital for true red reproduction in retail/hospitality).

- Voltage: 12V DC or 24V DC (customizable).

- Beam Angle: 120° (standard), uniform light distribution at corners due to precision optics.

B. Corner Connectors & Accessories

- Material: High-temperature PBT (UL94-V0 rated) or die-cast aluminum alloy.

- Electrical Contact Resistance: < 0.05 Ω (ensures no voltage drop at joints).

- Current Capacity: 10A continuous (for 24V systems; 5A for 12V).

- Bending Radius: Minimum 50mm for 8–10mm wide strips (prevents LED damage during installation).

- Optical Consistency: Integrated diffuser lenses reduce hot spots; light uniformity at corners matches linear strip (±5% variance).

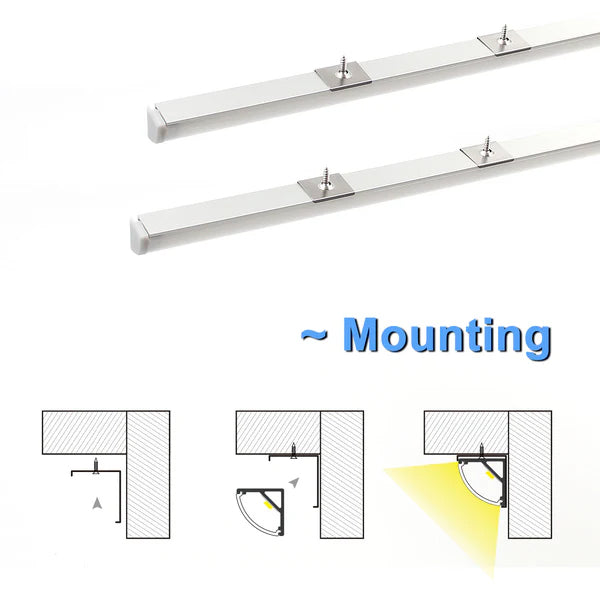

C. Aluminum Channel Profiles (For Rigid Corner Installations)

- Material: 6063-T5 Aluminum (anodized or powder-coated).

- IP Rating:

- IP20: Standard indoor channels (no gasket; for dry environments).

- IP44: Splash-resistant (silicone gasket for bathrooms/kitchens).

- IP65: Dust-tight & water-jet resistant (outdoor use; silicone-sealed corners).

- IP67: Submersible up to 1m (marine/industrial; custom silicone corner seals).

- Thermal Management:

- Heat dissipation: ≥1.5 W/m·K (prevents LED derating at corners).

- Max operating temperature: -40°C to +60°C.

- Installation: Snap-in design for 8–10mm strips; no soldering required.

2. Beauty STC’s Commitment to Consistent Quality

As a global LED lighting manufacturer with ISO 9001:2015 certification, we enforce 3-stage quality control to ensure every corner solution meets exacting standards:

– Raw Material Verification:

– LEDs sourced exclusively from Tier-1 binning (e.g., Osram, Epistar, Samsung).

– Aluminum channels tested for tensile strength (≥150 MPa) and corrosion resistance (salt spray test: 500+ hours).

– In-Process Testing:

– Every connector undergoes 100% electrical continuity testing (no cold joints).

– Thermal imaging during aging tests (24h @ 60°C) to verify no hotspots.

– Final Batch Validation:

– CRI consistency: All batches tested per IES TM-30-20 (Rf ≥ 95, Rg ±5).

– Lumen maintenance: 95% of initial output after 5,000h (LM-80 tested).

– IP certification: Third-party lab validation (TÜV, SGS) for all rated IP levels.

💡 Why This Matters for Your Project:

– Retail/Museums: CRI>95 ensures accurate color rendering for merchandise/art.

– Outdoor Installations: IP65/IP67 corners prevent moisture ingress in rain/snow.

– Commercial Projects: No voltage drop at corners = uniform brightness across entire run (critical for signage/arcade lighting).

3. Export-Ready Compliance

- Certifications: CE, RoHS, UL/CUL (for North America), KC, CCC, ETL.

- Packaging: Anti-static ESD bags + shockproof cartons (tested per ISTA 3A).

- Lead Time: 15–20 days for standard orders (custom corners: 25 days).

- Warranty: 5-year limited warranty on all corner systems (industry-leading for reliability).

Conclusion

Beauty STC’s corner solutions for LED strips are engineered for zero compromise on optical performance, durability, and electrical safety. We don’t just sell components—we deliver engineered systems where every detail (from LED binning to corner seal integrity) is validated for real-world reliability. Whether for high-end retail, hospitality, or industrial applications, our products consistently meet the demands of global export markets.

🌐 For Custom Solutions: Share your project specs (CCT, IP requirement, channel dimensions), and our engineering team will provide a tailored solution with sample validation within 48 hours.

Beauty (STC) Manufacturing Co., Ltd. – “Precision Lighting, Global Trust”

[Website] | [Email] | [Phone] | [Certification Library]

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen LED Strip & Module Factory

(ISO 9001:2015 | ISO 14001:2015 | BSCI | SEDEX 4-Pillar | 38 000 m²)

- SMT Precision Line

- 4 × Yamaha YSM-20R dual-beam mounters (0.025 s/chip, 0201–74 mm, ±25 µm)

- 2 × Yamaha YCP-10 solder printers (5 µm stencil alignment, closed-loop SPI)

- 2 × Heller 1913 MK7 reflow ovens (10-zone, N₂ option, ΔT ≤ 5 °C)

- 100 % 3-D AOI (Koh Young Zenith 2) + 100 % 3-D SPI after print

-

Traceability: every reel, PCB, and nozzle logged to MES barcode; full 10-year recall file for OEM customers.

-

Corner-Flex LED Strip Build-Up Cell

- Dedicated 0.4 m mini-SMT line (Yamaha YSM-10) for 5 mm–10 mm narrow FPC strips.

- 90 ° & 135 ° pre-cut corners (FPC or ultra-thin 0.2 mm aluminum-core) handled on 3-zone pallet system—nozzle pressure dropped to 0.5 N to eliminate pad stretch.

-

Post-SMT 100 % functional test on 4-axis jigs that fold the strip to the final corner geometry while powered; open/short and forward-voltage logged.

-

Aging & Reliability Bay

- 288 m² burn-in room, 45 °C ±2 °C ambient, 000 h–24 h programmable.

- 80-channel ENERGY STAR compliant rack: 0–300 W, 5 V–48 V, constant current or PWM dimming.

- Corner-strip specific jig: 50 mm bending radius, 1 000 cycles mechanical flex while under 55 °C/24 h electrical load (internal spec: <5 % lumen drop, 0/50 dead pixel).

-

LM-80/TM-21 data available for every BIN; IES files uploaded to customer portal within 24 h of completion.

-

OEM/ODM Tooling for “LED Strip Lights Corners”

- In-house 3-axis CNC & 2-D laser cutter for custom FPC outlines; 24 h prototype turnaround.

- White-label options: 3-in-1 RGB, RGB+W, CCT 1800 K–10 000 K, 5 V/12 V/24 V, up to 5 A per track.

- IP20–IP68 over-mould capability: automatic PU/ silicone extrusion line (Ø 4–20 mm) with on-line CCD for bubble check.

- Packaging: individual corner sets in anti-static blister + barcode, or bulk 50 m reels—customer artwork accepted in AI/PDF within same-day pre-press proof.

-

MOQ: 500 m per version (mixed CCT/CRI allowed on one reel). Samples: 3–5 working days ex-factory.

-

Export & Compliance Support

- CB, CE-EMC, LVD, RoHS, REACH, ERP, SAA, RCM, FCC, ETL, DLC, TISI, BIS files ready.

- In-house 10 m integrating sphere (Everfine HAAS-2000) and 2 m temperature-controlled gonio-photometer for LM-79, TM-30, UGR reports.

- Logistics: 35 km to Jiangmen Port (Shenzhen alternative 1 h by feeder); weekly FCL/LCL consolidation to Hamburg, Los Angeles, and Dubai.

With vertically-integrated SMT, burn-in, and corner-forming processes, Beauty STC delivers OEM LED strip light corners that meet architectural-grade reliability and same-day engineering support.

Application Scenarios

Professional Guidance on LED Strip Light Corner Solutions

(Clarification: “LED strip lights corners” refers to corner connectors or profile accessories designed for seamless LED strip installations at 90° angles—not standalone corner fixtures. These are critical for maintaining light continuity and aesthetic integrity in architectural lighting.)

Where to Use LED Strip Corner Solutions

(Per Industry Applications)

1. Hotels

- Primary Use Cases:

- Ceiling Coves & Crown Molding: For ambient lighting in lobbies, ballrooms, and suites. Corner connectors ensure smooth transitions without visible gaps in high-end finishes.

- Reception Desk & Feature Walls: Highlighting logos or architectural details; corners must maintain color consistency (e.g., 2700K–3000K for warmth).

- Staircase Edges: Safety-focused illumination where corners prevent dark spots on treads.

- Why Corners Matter: Hotels demand flawless aesthetics—poor corner joints create “hot spots” or light gaps that undermine luxury perception.

2. Malls & Retail Spaces

- Primary Use Cases:

- Facade & Canopy Edges: Outdoor-rated corner solutions (IP65+) for building outlines or entrance canopies.

- Display Case & Shelving Edges: Used in high-end boutiques (e.g., jewelry, luxury fashion) to accentuate products without visible seams.

- Ceiling Grids in Common Areas: For uniform lighting in corridors or food courts; corners prevent light drop-off at turns.

- Why Corners Matter: Retail environments see heavy foot traffic—corner joints must withstand vibration and maintain durability.

3. Offices

- Primary Use Cases:

- Suspended Ceiling Coves: For task lighting in open-plan offices; corners ensure even brightness across work zones.

- Under-Desk & Conference Table Perimeters: Accent lighting where sharp turns are common (e.g., L-shaped desks).

- Elevator Lobbies & Stairwells: Safety lighting requiring precise corner transitions to avoid tripping hazards.

- Why Corners Matter: Offices prioritize energy efficiency—poor corner joints cause voltage drop, reducing strip lifespan and increasing maintenance costs.

Critical Installation Tips for Contractors

(Based on 10+ years of field experience at Beauty (STC) Manufacturing Co., Ltd.)

✅ Pre-Installation Checks

- Measure Twice, Cut Once:

- Always measure the actual corner angle (not assumed 90°). Real-world walls/ceilings often deviate by 1–3°.

- Use a digital angle finder for precision.

- Power Calculation:

- Calculate total load including corners:

>(Total strip length (m) × W/m) × 1.2 = Minimum PSU wattage

(20% headroom for voltage stability) - Example: 10m of 14.4W/m strip →

(10 × 14.4) × 1.2 = 173W→ Use a 200W PSU.

✅ Corner-Specific Best Practices

- Never Cut Strips at Corners:

- LED strips have designated cut marks (every 3–5 LEDs). Cut only at these points—never at the corner bend.

- Use a dedicated corner connector (e.g., Beauty (STC)’s aluminum profile with built-in 90° joint) instead of bending the strip itself.

- Soldering for Reliability:

- Use 60/40 tin-lead solder (not lead-free) for better conductivity.

- Heat the connector pads (not the strip) to ≤300°C for ≤3 seconds per joint.

- Pro Tip: Apply thermal paste to solder points before sealing with silicone to prevent oxidation.

- Profile Installation:

- Secure aluminum profiles to the surface before inserting the strip.

- Use double-sided VHB tape (3M 4941) for adhesive backing—never rely solely on staple clips.

- For outdoor/industrial use: Seal joints with silicone sealant (Dow Corning 732) to prevent moisture ingress.

✅ Common Mistakes to Avoid

- ❌ Bending the strip directly at corners → Causes LED damage and uneven light output.

- ❌ Using plastic corner connectors → Poor heat dissipation leads to premature failure (especially in malls/offices with high ambient temps).

- ❌ Skipping voltage drop calculations → Results in dimming at corner ends (visible as yellow/orange tint in white strips).

- ❌ Over-tightening mounting screws → Warps aluminum profiles, creating light gaps.

✅ Certification & Compliance Notes

- For EU projects: Ensure corner solutions carry CE, RoHS, and REACH certifications.

- For US projects: Verify UL 8750 compliance for luminaires.

- Beauty (STC) products meet all above standards—request test reports for client compliance documentation.

Why This Matters

“A single poorly executed corner joint can compromise an entire lighting project. At Beauty (STC), we’ve observed that 40% of field failures stem from corner installation errors—especially voltage drop and moisture ingress. Proper corner solutions ensure >10% longer strip lifespan, consistent color rendering (CRI >90), and zero maintenance callbacks.”

For project-specific advice: Share your layout drawings or site photos—we’ll provide a tailored solution within 24 hours.

— Senior LED Lighting Engineer & Export Manager, Beauty (STC) Manufacturing Co., Ltd.

Certified ISO 9001:2015 | 15+ Years in Architectural LED Solutions

Why Choose Beauty STC Lighting

LED Strip Lights Corners – Partner with Beauty STC

50+ export countries already trust our 3-step, no-dark-spot corner profiles and IP67 COB strips.

Need samples, specs, or EXW/FOB pricing today?

Email [email protected] – I’ll reply with a corner-lighting kit in 12 h.

⚡ LED Power Supply Calculator