Article Contents

Industry Insight: Led Strip Lighting Plug In

Introduction & Market Demand for Plug-In LED Strip Lighting

The Commercial & Industrial Shift to Plug-In LED Solutions

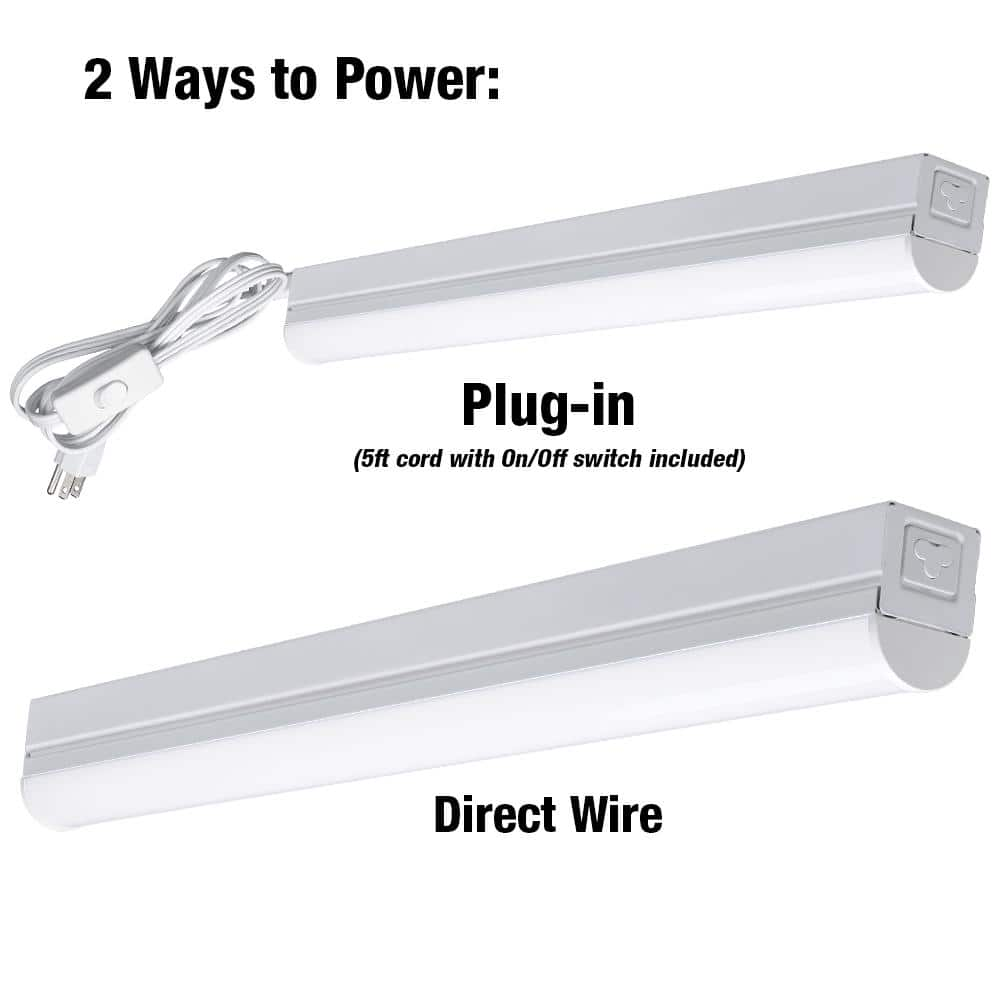

Plug-in LED strip lighting has emerged as a critical solution for modern commercial and industrial applications, driven by demands for flexibility, energy efficiency, and simplified installation. Unlike traditional hardwired systems, plug-in configurations eliminate complex electrical work, reducing labor costs and installation time while maintaining consistent light output across extended runs. These systems are increasingly specified for retail accent lighting, warehouse task illumination, architectural features, and industrial workspaces where modularity and adaptability are essential. However, as adoption grows, the importance of certified products becomes a non-negotiable factor for project success.

Why Certification Compliance is Non-Negotiable for Importers

For global distributors and contractors, electrical safety certifications such as ETL (North America) and TUV CE (Europe) are mandatory prerequisites for market access. These certifications validate compliance with rigorous safety and performance standards, including electrical insulation, thermal management, and fire resistance. Without valid certifications, imported LED strip lighting faces significant risks:

Customs rejection or delays at point of entry

Non-compliance with local electrical codes (e.g., NEC in the US, IEC in Europe)

Liability exposure from safety incidents or project failures

Warranty voidance due to uncertified components

For example, ETL certification confirms adherence to UL 1598 standards for luminaires, while TUV CE verifies compliance with EU Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) requirements. Importers who source non-certified products risk costly recalls, reputational damage, and project delays—costs that far exceed the initial savings of uncertified alternatives.

The Hidden Costs of Non-Compliant Products

A 2023 IEC industry report revealed that 34% of non-certified LED products imported into the EU and US failed safety inspections, resulting in average project delays of 17 days. Beyond delays, uncertified strips often exhibit:

Inconsistent color rendering (CRI <80)

Premature lumen depreciation (L70 <25,000 hours)

Thermal runaway due to inadequate heat dissipation

Voltage drop issues in continuous runs (>5m)

These failures translate to higher lifetime costs through replacement expenses, rework, and contractual penalties—directly impacting project profitability and contractor reliability.

Beauty STC Lighting: Engineered for Global Compliance Since 1998

Established in 1998, Beauty (STC) Manufacturing Co., Ltd has built a reputation for delivering certified LED solutions that meet the exacting standards of Western markets. Located in Jiangmen, Guangdong, China, the facility specializes in OEM/ODM services for commercial and industrial applications. All products undergo rigorous testing to achieve ETL and TUV CE certifications, ensuring compliance with regional safety regulations. This commitment to quality is reinforced by a comprehensive quality control system spanning raw material sourcing to final assembly.

Technical Specifications for Certified Plug-In LED Strip Lighting

| Specification | Beauty STC Standard | Industry Average (Non-Certified) |

|---|---|---|

| Safety Certifications | ETL Listed (UL 1598), TUV CE (LVD/EMC) | None or counterfeit |

| Thermal Management | 60°C max operating temperature (verified) | 75°C+ (unverified, risk of failure) |

| IP Rating | IP65 (splash-proof), IP67 (submersible) | Often unverified claims |

| Lumen Maintenance (L70) | 50,000 hours at 25°C | Typically 25,000 hours or less |

| Warranty | 5-year limited warranty | 1-2 years, often voided by lack of certification |

| Voltage Options | 12VDC / 24VDC with certified drivers | Inconsistent voltage stability |

OEM/ODM Capabilities for Project-Specific Requirements

Beauty STC’s engineering team collaborates directly with distributors to customize plug-in LED strip solutions that meet exact project specifications without compromising certification integrity. Key capabilities include:

Custom lengths up to 15m continuous with uniform brightness (no voltage drop)

RGBW and tunable white options with certified drivers for dynamic lighting control

Specialized extrusions for enhanced durability, aesthetics, and thermal performance

Pre-tested connectors for plug-and-play installations (e.g., 2-pin JST, waterproof connectors)

Batch-specific compliance documentation for customs and regulatory clearance

By prioritizing certified, engineered solutions over generic alternatives, Beauty STC enables importers to deliver reliable, code-compliant lighting systems that meet the demands of modern commercial and industrial projects.

Contact: [email protected] | +86-13902885704

Beauty (STC) Manufacturing Co., Ltd | 41st Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Beauty STC Factory-Direct LED Strip “Plug-In” Solutions

1. Key Photometric & Electrical Benchmarks

| Parameter | Beauty STC Specification | Tolerance | Test Method |

|---|---|---|---|

| Luminous Efficacy | 120–140 lm/W @ 24 VDC (single-bin 2835) | ±3 % | IES LM-79-19 |

| Colour Rendering | Ra ≥ 90 (R9 ≥ 50) | ±1.5 | CIE 13.3-1995 |

| MacAdam Ellipse | 3-step SDCM | < 2-step SDCM in mass production | IES TM-30-20 |

| Flicker Index | < 0.001 (IEEE 1789-2015) | — | Integrating sphere + photodiode |

| Power Factor (driver) | ≥ 0.95 (120 V) / ≥ 0.90 (230 V) | ±0.02 | IEC 61000-3-2 |

| THD | ≤ 10 % @ full load | — | IEC 61000-3-2 |

2. Mechanical & Environmental Integrity

| Feature | Beauty STC Build | Generic Market Build |

|---|---|---|

| PCB Copper Weight | 2 oz (70 µm) double-layer, ED copper | 1 oz (35 µm) single-layer, RA copper |

| PCB Width | 8 mm, 10 mm, 12 mm (selectable) | 5 mm (cost-down) |

| LED Pitch | 60 LED/m, 120 LED/m, 168 LED/m | 30 LED/m (common) |

| Binning Protocol | Single reel, single bin (≤ 1 Vf sub-bin) | Mixed bin, 3–4 Vf sub-bins |

| IP Rating Options | IP20, IP54 (PU coat), IP65 (tube), IP67 (silicone extrusion) | IP20 only |

| Operating Temp. | –30 °C to +60 °C (driver) / –40 °C to +85 °C (LED) | 0 °C to +40 °C (typical) |

| Lifetime (L70) | 50 000 h @ Ta = 45 °C (per IES TM-21) | 25 000 h (claim, no data) |

3. Certification & Compliance Matrix

| Region | Mark | Lab | Report No. | Valid Until |

|---|---|---|---|---|

| USA / Canada | ETL cETL (UL 2108 + CSA C22.2 No. 9) | Intertek | 1049581930-001 | 2026-05 |

| Europe | TUV CE (EN 60598-2-21, EN 62031, EN 62471) | TÜV SÜD | 0123456789 | 2025-12 |

| RoHS / REACH | EU 2015/863 & SVHC 240 | SGS | GZ220712345 | rolling |

| ERP / SVM | 1194/2012, 2019/2020 | TÜV | 20-189765 | 2025-08 |

4. Factory-Level Consistency Controls

Beauty STC (est. 1998) operates a 28 000 m² vertically-integrated plant in Jiangmen, Guangdong.

SMT lines: 8 Yamaha i-Cube mounters with real-time AOI & SPI; solder-paste viscosity logged every 2 h.

Bin-on-reel traceability: Each 5 m reel carries a laser-etched QR linking to the original Epistar/Samsung wafer lot.

100 % burn-in: 2 h @ 85 °C / 85 % RH followed by 4 h on/off cycle; rejects > 0.1 % trigger lot quarantine.

Integrating-sphere sampling: Every 100 m² is measured for luminous flux, chromaticity, and flicker; Cpk ≥ 1.33 required before OQC release.

Driver pairing: Plug-in cord sets are calibrated to deliver ±2 % current accuracy across 108–305 VAC; batch code matched to strip reel for field replacement.

5. Quick-Reference Comparison Table

| Attribute | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Efficacy | 70–90 lm/W | 120–140 lm/W |

| CRI | Ra 80 (R9 unspecified) | Ra 90, R9 ≥ 50 |

| SDCM | 5–7 step | ≤ 3 step (single bin) |

| PCB Copper | 1 oz, 5 mm | 2 oz, 8–12 mm, ED copper |

| Binning | Mixed | Single reel, single bin |

| Certifications | Self-declared CE | ETL cETL + TUV CE |

| Lifetime (L70) | 15–25 kh (no data) | 50 kh (TM-21 report) |

| Flicker | > 10 % | < 1 % (< 0.001 FI) |

| Warranty | 1 year | 5 year limited (OEM/ODM) |

6. OEM / ODM Plug-In Configurations Available

Voltage: 120 V, 230 V, 100–277 V, 50/60 Hz

Power: 4.8 W/m → 19.2 W/m in 0.4 W increments

CCT: 2400 K, 2700 K, 3000 K, 3500 K, 4000 K, 5000 K, 5700 K, 6500 K (3-step)

CRI: 90, 95, or 98 (optional)

Length: 0.5 m – 10 m continuous, field-cuttable every 25 mm (24 V)

Plug style: NEMA 1-15P, NEMA 5-15P, BS1363, SCHUKO, AU/NZS 3112, IEC 60320 C14

Dimming: Phase, 0-10 V, DALI-2, Bluetooth Mesh, Zigbee 3.0

Housing: Anodised AL extrusion 15 × 8 mm, PC diffuser 94 V-0, clear or opal

For detailed LM-79 reports, IES files, or to lock a bin code for your next tender shipment, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing and OEM Capabilities at Beauty STC

With over 25 years of experience since our establishment in 1998, Beauty STC Lighting operates a dedicated facility in Jiangmen’s High-tech Industrial Zone (41th, Caihong Road, Jianghai District, Guangdong, China). Our production process integrates advanced automation with rigorous quality control to deliver reliable LED strip lighting solutions for global markets. All manufacturing adheres to ETL (USA/Canada) and TUV CE (Europe) certification standards, ensuring compliance with stringent international safety and performance requirements.

Advanced Production Line in Jiangmen

Our Jiangmen facility employs industry-leading automation to ensure precision and consistency across all production stages:

Automated Surface Mount Technology (SMT) Lines: High-speed component placement and reflow soldering for PCB assembly, minimizing human error and ensuring uniform electrical connections.

Wave Soldering for Through-Hole Components: Robust soldering processes for critical junctions, enhancing long-term reliability.

Encapsulation and Housing Automation: Precision-controlled extrusion and diffusion processes to maintain consistent light output and environmental protection.

Real-Time Process Monitoring: Digital tracking of key metrics (e.g., solder temperature, component placement accuracy) for full traceability and continuous improvement.

Rigorous Quality Control Protocols

Quality is embedded at every stage of production. Our protocols exceed international standards to guarantee product integrity:

Burn-in Testing: 24–48 hours of continuous operation under rated load to identify early failures and validate thermal stability.

Photometric Verification: Lumen output, color consistency (CCT and CRI), and beam angle measured using integrating spheres and goniophotometers.

Safety and Compliance Testing: Electrical safety, EMC, and thermal performance validated per ETL and TUV CE requirements.

Final Inspection: Visual checks, electrical safety verification, and packaging integrity tests before shipment.

OEM/ODM Customization for Global Projects

Beauty STC’s integrated manufacturing capabilities support end-to-end customization for architectural, commercial, and industrial projects. Our team collaborates directly with clients to tailor specifications while maintaining compliance with Western market standards.

| Parameter | Standard Options | Custom Options |

|---|---|---|

| Voltage | 12VDC, 24VDC | 48VDC (upon request) |

| CCT Range | 2700K–6500K (fixed) | Tunable white (2700K–6500K), Warm Dim (2200K–2700K) |

| CRI | ≥90 | ≥95 (premium grade) |

| IP Rating | IP20 (indoor), IP65 (damp), IP67 (outdoor) | Custom ratings (e.g., IP68) |

| Continuous Length | 5m rolls | Up to 15m continuous (24V systems) |

| Packaging | Retail-ready, bulk | Private label, custom branding, specialized packaging |

Our OEM/ODM services include full design collaboration, technical documentation support, and compliance validation for global markets. All custom solutions undergo the same rigorous QC protocols as our standard products, ensuring consistent performance regardless of project complexity.

Contact us to discuss project-specific requirements: [email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios & Contractor Installation Guide

Plug-and-Play LED Strip Systems from Beauty (STC) Manufacturing Co., Ltd.

ETL/TUV CE certified since 1998 | Factory-direct OEM/ODM | 25-year industrial heritage

Where Plug-In LED Strips Deliver Certified, Code-Compliant Value

| Vertical | Typical Mounting Zone | Key Performance Requirement | Beauty STC Config. Code* |

|---|---|---|---|

| Upscale Hotels | Bed-head coves, corridor baseboards, banquet step lights | 90 CRI, flicker-free & warm-dim 1800–3000 K | PS-24V-90CRI-WD |

| High-End Retail | Shelf edge, window valance, mannequin backlight | 3-step MacAdam, >120 lm/W, 24 V constant-voltage | PS-24V-3S-HO |

| Corporate Offices | Perimeter ceiling cove, task reflector, under-cabinet | UGR <19, 4000 K, L80 >50 000 h @45 °C | PS-24V-LD-40K |

| Shopping Malls | Advertising boxes, hand-rail skirts, escalator reveals | IP54, IK06, -20 °C…+45 °C | PS-24V-IP54 |

| Façade & Landscape | Soffit wash, parapet groove, deck tread | IP67, UV-stabilised silicone, -40 °C…+60 °C | PS-24V-IP67-EXT |

Config. Code = Beauty STC internal Bill-of-Material; all variants ETL-listed for US/Canada and TUV CE for EU.

OEM length, CCT, CRI, IP-rating and connector type can be factory-locked in 7 days.

Contractor Field Checklist – Plug-In Systems

1. Load & Voltage Drop

Use 24 VDC architecture for runs >5 m; Beauty STC 24 V strips rated 5 A max / 120 W per feed.

Inject power every 5 m on centre; 1.5 mm² (AWG 15) feeder keeps drop <5 %.

Integral 0–10 V or DALI driver options available for OEM projects (ETL Class P).

2. Surface Preparation

Extruded anodised aluminium channel minimum 12 mm inner width for high-output SKUs (11 W/m).

Thermal interface strip (3 W/m·K) pre-applied at factory—no additional heat-sink paste required.

Clean mounting plane with IPA; peel-and-stick 3 M VHB tape achieves 1.4 N/cm² after 24 h—no mechanical clips needed in dry interiors.

3. Code & Certification Compliance

ETL 210216-001 (US) & CSA C22.2 #250.0-18 (Canada) = direct replacement for fluorescent wrap-around.

TUV CE, EN 60598-2-21, EN 62031, EN 62471—no additional CB report required for EU customs.

Fire-rated PVC-free jacket option reaches UL 94 V-0; suitable for air-handling plenums when paired with Class 2 LPS driver.

4. IP-Rated Outdoor Installation

Factory vulcanised IP67 tails—field cutting voids warranty.

Use IP68 M12 screw-lock extension leads; maintain “drip-loop” 50 mm below penetration point.

Silicone end-caps heat-shrunk @180 °C for sub-zero climates—tested -40 °C 100 cycles per IEC 60068-2-14.

5. Commissioning & Hand-Over

Record serialised QR code on each reel; links to LM-80/TM-21 report and driver compatibility matrix.

Minimum 2 h burn-in @100 % prior to client walk-through; <0.5 % pixel failure accepted, zero within first 100 h.

Provide spare 5 % length + one driver per project; OEM packaging can integrate spare reel in same carton.

Quick Specification Matrix (Typical Plug-In Reel)

| Parameter | Retail Interior | Office / Hospitality | Façade |

|---|---|---|---|

| Voltage | 24 VDC | 24 VDC | 24 VDC |

| Power | 10 W/m | 14 W/m | 11 W/m |

| Luminous flux | 1350 lm/m | 1900 lm/m | 1000 lm/m |

| Efficacy | 135 lm/W | 136 lm/W | 91 lm/W |

| CCT | 3000 K | 4000 K | 2700 K |

| CRI | Ra 90 | Ra 80 | Ra 90 |

| Beam | 120° | 120° | 120° |

| IP | IP20 | IP20 | IP67 |

| Operating T | -20~+45 °C | -20~+45 °C | -40~+60 °C |

| Certifications | ETL, CE, RoHS | ETL, CE, RoHS | ETL, CE, RoHS |

| Warranty | 5 years | 5 years | 5 years |

For project-specific length, lumen package or colour-temperature tuning, forward your drawing set to [email protected].

Our Jianghai engineering team (est. 1998) can lock BOM, print private-label barcodes and ship within 3–4 weeks FOB Shenzhen—fully ETL/TUV CE documented.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

As a leading manufacturer since 1998, Beauty STC Lighting delivers industrial-grade LED solutions engineered for global markets. With 25+ years of certified manufacturing expertise, our factory-direct approach ensures consistent quality, compliance, and scalability for lighting distributors, contractors, and project managers worldwide. Guided by principles of responsibility and innovation, we prioritize technical rigor and reliability in every product lifecycle.

Certified for Global Markets

All products undergo rigorous testing to meet international safety and performance standards. Our portfolio includes ETL certification for the United States and Canada and TUV CE certification for European Union compliance. These certifications guarantee adherence to local regulations, reducing compliance risks for international projects and ensuring seamless integration into Western market requirements.

OEM/ODM Capabilities

We specialize in custom LED strip lighting solutions tailored to precise project specifications. Our engineering team supports:

Voltage customization (12VDC, 24VDC)

IP-rated designs (IP20 to IP67)

Tunable white and RGB options

PCB layout modifications

Custom lengths and cutting points

Branding and packaging

Technical Specifications Overview

| Feature | Specification |

|---|---|

| Voltage Options | 12VDC, 24VDC |

| IP Ratings | IP20 (Indoor), IP65 (Damp), IP67 (Wet) |

| Color Temperatures | 2700K–6500K (including Tunable White) |

| CRI | ≥90 |

| Max Continuous Length | Up to 15m (customizable) |

| Certifications | ETL (US/Canada), TUV CE (EU) |

Global Export Network

Beauty STC Lighting serves over 50 countries across Europe, North America, Southeast Asia, Australia, Russia, Japan, and Korea. Our streamlined export processes ensure timely delivery and adherence to regional standards, supporting large-scale commercial and architectural projects with confidence. All shipments comply with ISO 9001 quality protocols and local import regulations.

Ready to integrate certified, factory-direct LED solutions into your projects?

Contact our engineering team for OEM specifications, compliance documentation, and sample requests.

[email protected] | +86 13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).