Article Contents

Industry Insight: Led Strip Light

The LED strip light has emerged as a transformative solution in commercial and industrial lighting, offering unmatched flexibility, energy efficiency, and design adaptability. As businesses increasingly prioritize sustainable operations and cost-effective lighting systems, LED strip lights have become the preferred choice for applications ranging from warehouse illumination and retail accent lighting to architectural highlighting and task lighting in manufacturing environments. Their low-profile design and scalable configuration allow for seamless integration into a wide array of settings, while advancements in thermal management and lumen output ensure long-term reliability and performance under demanding conditions.

Compliance with international safety and performance standards is critical in commercial deployments, and leading LED strip light solutions are now routinely certified to ETL and CE standards—ensuring electrical safety, electromagnetic compatibility, and adherence to North American and European regulatory requirements. These certifications not only instill confidence among facility managers and contractors but also facilitate global market access and code compliance.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, delivering high-performance LED lighting solutions tailored for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC combines rigorous quality control, innovative thermal and optical design, and full compliance with ETL and CE standards to provide reliable, long-lasting LED strip lighting trusted by professionals worldwide.

Technical Specs & Certifications

LED strip light specifications require careful consideration of photometric, chromatic, and environmental parameters to ensure performance meets application demands. At Beauty STC Manufacturing Co., Ltd., our engineering rigor ensures each specification is validated through stringent in-house and third-party laboratory testing.

Lumens per Watt (lm/W) efficacy represents the core energy efficiency metric, indicating visible light output per unit of electrical power consumed. Our standard high-CRI LED strips achieve 100-120 lm/W under optimal thermal management at 25°C ambient temperature and nominal drive current. This range accounts for the inherent trade-off between high color rendering and efficiency; achieving CRI >90 necessitates spectral broadening that typically reduces peak efficacy by 10-15% compared to standard CRI 80 strips. Efficacy is dynamically influenced by operating conditions—higher drive currents increase lumen output but reduce lm/W due to droop effects, while inadequate thermal dissipation from improper mounting on aluminum channels can degrade efficiency by up to 20%. Beauty STC optimizes this balance through precision binning of Epistar and Samsung LEDs, proprietary phosphor formulations, and copper-core flexible PCBs with 2oz copper weight to maximize heat dissipation.

Color Rendering Index (CRI) values exceeding 90 are non-negotiable for applications demanding true-to-life color representation, such as retail displays, beauty salons, and photography studios. Our Ra >90 strips consistently achieve R9 (saturated red) >50 and R12 (saturated blue) >45—critical indicators often omitted in misleading specifications—to ensure vibrant, accurate rendering of skin tones and colored objects. This performance is validated using Konica Minolta CA-410 spectroradiometers per ANSI C78.377 standards, with spectral power distributions showing balanced emission across the visible spectrum. Unlike budget strips that artificially inflate CRI through narrow-band blue peaks, Beauty STC’s multi-phosphor LEDs undergo 100% spectral verification during production, guaranteeing consistent color fidelity across reel-to-reel batches.

IP ratings define ingress protection against solids and liquids, directly impacting installation versatility and longevity. Beauty STC offers three certified variants: IP20 for dry indoor use (basic silicone coating), IP65 for damp environments (conformal silicone encapsulation resisting low-pressure water jets), and IP67 for temporary submersion (fully potted construction with welded end caps). Crucially, IP65/67 ratings apply only when installed with our proprietary waterproof connectors and sealed within compatible profiles—field failures often stem from improper termination, not strip defects. All encased strips undergo 72-hour salt spray testing (ASTM B117) and thermal cycling (-40°C to +85°C) to prevent delamination. Beauty STC’s quality differentiation lies in this systems approach: we supply not just strips but validated installation ecosystems, including aluminum channels with integrated diffusers that maintain thermal performance while achieving rated IP protection.

Beauty STC’s commitment to quality transcends datasheet claims through multi-stage verification. Every production batch undergoes LM-80 lifetime testing (minimum 6,000 hours), with L70 projections exceeding 50,000 hours at 40°C case temperature. Our strips feature 99.99% oxygen-free copper traces, eliminating the brittle tin-plated alloys common in lower-tier products that cause early failure. Rigorous 100% automated optical inspection (AOI) catches micro-solder defects, while accelerated life testing at 85°C/85% RH ensures reliability in tropical climates. This engineering discipline—rooted in ISO 9001-certified processes and UL/cETL certification for all standard products—ensures our high-CRI strips deliver sustained performance where competitors’ offerings degrade prematurely due to substandard materials and inadequate validation protocols.

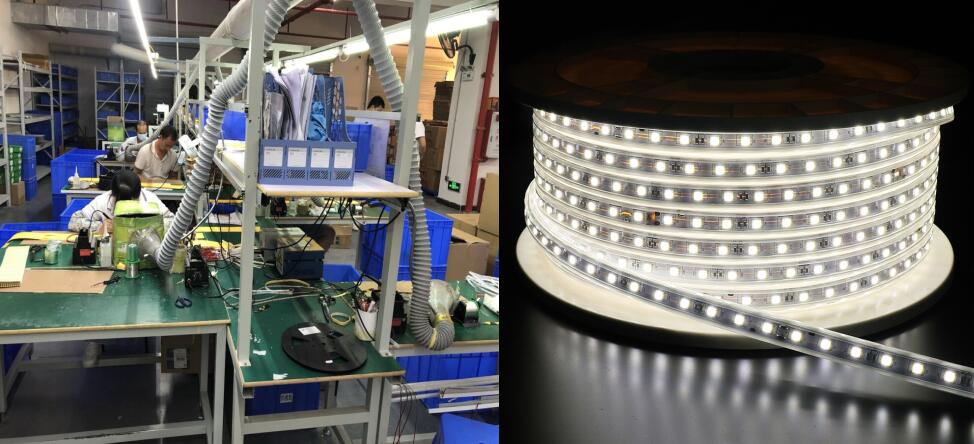

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is fully equipped to support high-volume, precision manufacturing of LED lighting products, with a particular focus on LED strip lights. The facility integrates advanced automation, rigorous quality control processes, and flexible production lines to serve both domestic and international markets.

At the core of the factory’s production capability are state-of-the-art SMT (Surface Mount Technology) lines. These high-speed SMT machines are capable of accurately placing small LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED strip light manufacturing. The SMT process is fully automated, ensuring consistent soldering quality, high placement accuracy, and efficient throughput. Multiple SMT lines operate in parallel, allowing for rapid turnaround and scalability to meet large order volumes.

Following PCB assembly, the factory conducts comprehensive aging tests as part of its quality assurance protocol. Completed LED strip lights undergo extended burn-in periods—typically 24 to 72 hours—under controlled temperature and voltage conditions. This aging process helps identify early-stage failures, ensures product stability, and verifies performance under continuous operation. Additional testing includes waterproof testing for relevant models, luminance and color consistency checks, and electrical safety inspections.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities tailored specifically for LED strip lights. The company supports custom solutions including different color temperatures, IP ratings, PCB lengths and layouts, special diffusers, branding with custom labels or packaging, and integration with various control systems (e.g., 2.4G RF, WiFi, DMX). Clients can collaborate with Beauty STC’s engineering team from concept to mass production, benefiting from in-house PCB design, tooling, and prototyping services. The factory also complies with international standards such as CE, RoHS, and UL, enabling seamless export to global markets.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to quality, innovation, and flexibility, making it a reliable manufacturing partner for branded lighting companies and distributors seeking high-performance, customizable LED strip light solutions.

Application Scenarios

LED strip lighting offers versatile solutions across commercial environments when applied strategically. In hotels, prioritize guest experience through subtle illumination in lobbies via cove lighting to create welcoming atmospheres, under-bar counters for ambient glow, and within guest room crown molding for adjustable mood lighting. Corridors benefit from low-level step lighting integrated into handrails or baseboards for safety without disrupting sleep cycles, while vanity mirrors in bathrooms gain functional task lighting with color temperature options. Pool and spa areas utilize waterproof strips for underwater effects or perimeter highlighting, enhancing both safety and aesthetics.

For malls, focus on driving retail engagement and navigation. Install strips beneath display cases to accentuate merchandise without glare, within signage channels for vibrant branding visibility, and along escalator handrails for directional guidance. Feature walls in common areas gain depth through layered backlighting, while fitting rooms achieve true-color representation with high-CRI strips at 4000K. Parking structures require robust IP67-rated strips in stairwells and ramps for consistent illumination, reducing dark spots while maintaining energy efficiency during low-traffic hours.

Office applications should balance productivity and well-being. Implement under-cabinet task lighting at workstations to reduce screen glare, avoiding direct desk illumination. Conference rooms gain sophistication through perimeter cove lighting that supports video calls without harsh shadows. Reception desks use discreet strips for logo highlighting, while server rooms benefit from cool-white strips with emergency backup for maintenance access. Always pair with daylight sensors in perimeter offices to minimize energy use.

Installation demands rigorous attention to detail in commercial settings. Verify local electrical codes before commencement, ensuring all components carry necessary certifications like UL or CE for the region. Thermal management is non-negotiable—aluminum channels must be used for runs exceeding 16 feet, with thermal paste applied between strips and channels in high-ambient-temperature zones like kitchens or server rooms. Address voltage drop by injecting power every 16-32 feet depending on strip density, using 18-gauge wire for main feeds. Waterproof installations require fully potted strips with silicone end caps, never relying solely on IP ratings for submerged applications. Conceal all wiring within raceways or building cavities; exposed cables violate fire codes in most jurisdictions. Finally, conduct photometric testing post-installation to confirm uniformity—commercial projects demand less than 10% lumen variation across continuous runs to avoid visible hotspots. Always document circuit loading calculations for facility management handover.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED strip lights from Beauty STC. As a trusted manufacturer, we deliver reliable, energy-efficient, and customizable lighting solutions for residential, commercial, and industrial applications. Partner with Beauty STC to benefit from competitive pricing, consistent product performance, and dedicated support.

To start a collaboration or request a product catalog, contact our sales manager today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.