Article Contents

Industry Insight: Led Strip Corner Connector

In commercial and industrial lighting applications, precision, durability, and seamless integration are paramount—especially when designing continuous LED strip runs across complex architectural features. The LED strip corner connector has emerged as a critical component in modern lighting installations, enabling clean, reliable connections at 90-degree angles and other angular transitions without compromising light uniformity or system integrity. Engineered to meet the rigorous demands of professional environments, high-quality corner connectors ensure stable electrical performance, reduce installation time, and maintain the aesthetic continuity essential in retail spaces, office buildings, warehouses, and industrial facilities.

Compliance with international safety and performance standards is non-negotiable in these settings. Leading solutions are ETL and CE certified, verifying adherence to North American and European safety regulations, respectively. These certifications provide assurance to contractors, facility managers, and designers that the components will perform reliably under demanding conditions while meeting code requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED connectivity solutions for over two decades. Specializing in high-performance connectors and accessories for commercial and industrial lighting systems, Beauty STC combines precision engineering with rigorous quality control to deliver products trusted by professionals worldwide. With a commitment to durability, safety, and seamless integration, Beauty STC continues to set the benchmark for reliability in LED strip lighting infrastructure.

Technical Specs & Certifications

LED strip corner connectors are mechanical and electrical interface components designed to join flexible LED strips at 90-degree angles, not light-emitting elements themselves. Consequently, specifications such as lumens per watt (lm/W) and Color Rendering Index (CRI) do not apply to the connector. These metrics are inherent properties of the LED strip’s diodes, phosphor formulation, and driver circuitry. A high CRI >90 and optimal lm/W are achieved through the LED strip design, not the connector. The connector’s role is to maintain electrical continuity and mechanical stability without degrading the strip’s performance.

The primary technical specifications for LED strip corner connectors relate to electrical compatibility, mechanical design, and environmental protection. Electrical compatibility requires matching the connector to the strip’s voltage (typically 12V or 24V DC), pin configuration (e.g., 2-pin, 4-pin for RGB), and conductor width. Mechanically, precision-molded housings ensure secure strip retention and consistent 90-degree alignment, while high-conductivity phosphor bronze contacts with gold plating minimize resistance and prevent oxidation. Strain relief features are critical to prevent wire pull-out during installation or thermal cycling.

IP ratings are highly relevant for corner connectors in demanding environments. Standard non-waterproof connectors carry an IP20 rating, offering basic protection against finger contact but no moisture resistance. For wet or outdoor applications, Beauty STC manufactures IP65-rated corner connectors featuring silicone gaskets that seal the strip entry points, and IP67-rated variants with fully potted internal contacts capable of withstanding temporary submersion. It is essential to note that the overall system’s IP rating depends on the LED strip’s own rating and proper installation of all components.

At Beauty STC, our corner connectors exemplify rigorous quality standards through precision injection molding with UL94 V-0 flame-retardant materials, contact plating with 0.3μm gold over nickel for superior conductivity and corrosion resistance, and 100% functional testing for continuity and insulation resistance. We implement strict dimensional controls to ensure perfect strip alignment without stressing solder joints, and our strain relief mechanisms undergo 50N pull-force validation. This commitment prevents voltage drop, flicker, or failure points that could compromise the LED strip’s specified lm/W output or CRI performance, ensuring the lighting system maintains its engineered photometric integrity throughout its operational life.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from strong logistical support and access to a skilled manufacturing workforce. The facility is designed to support efficient, large-scale production while maintaining strict quality control standards.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise and reliable assembly of LED components. These SMT machines ensure high-speed placement of LEDs, resistors, capacitors, and other surface-mount devices onto flexible and rigid printed circuit boards used in LED strips. The automated SMT process enhances consistency, reduces human error, and supports high-volume output, making it ideal for both standard and custom LED strip manufacturing.

To ensure product durability and performance, the Jiangmen factory implements comprehensive aging and reliability testing procedures. Completed LED strips and related components undergo extended burn-in tests under controlled temperature and humidity conditions. These aging tests typically run for 24 to 72 hours to identify early failures, verify thermal stability, and confirm consistent light output and color consistency. Additional quality checks include waterproof testing for IP-rated products, electrical safety inspections, and mechanical stress testing for connectors and flexible circuits.

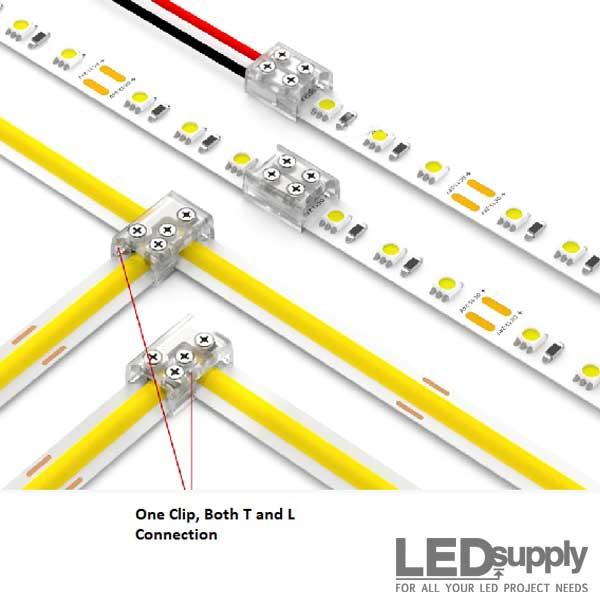

Beauty STC has strong OEM capabilities and can customize a wide range of LED lighting accessories, including the ‘LED strip corner connector’. This specialized connector is designed to maintain seamless electrical continuity and mechanical stability when LED strips are installed around corners or in angled configurations. The company supports OEM partners by offering custom designs in terms of connector angle (e.g., 90-degree, 45-degree), housing material, plating finish, pin configuration, and compatibility with various LED strip types (e.g., 2835, 5050, SK6812). Clients can also request branding, packaging, and labeling according to their specifications.

Overall, the Jiangmen factory combines advanced automation, rigorous quality assurance, and flexible customization to serve both domestic and international markets, making Beauty STC a reliable partner for OEM and ODM projects in the LED lighting industry.

Application Scenarios

LED strip corner connectors serve a specific technical purpose regardless of building type: they enable clean 90-degree directional changes in rigid LED strip installations without damaging the strip’s circuitry. Their application is determined by the fixture geometry, not the venue category. In hotels, they are essential for seamless cove lighting transitions in lobbies or behind reception desks where strips turn corners. Malls require them for precise illumination of display case perimeters and architectural coves in high-traffic zones to maintain visual continuity. Offices utilize them under suspended ceiling reveals, along partition walls, and within custom millwork where strips navigate right angles in task lighting systems. The universal trigger for their use is any sharp internal or external 90-degree bend where physically forcing the strip would fracture copper traces or delaminate components.

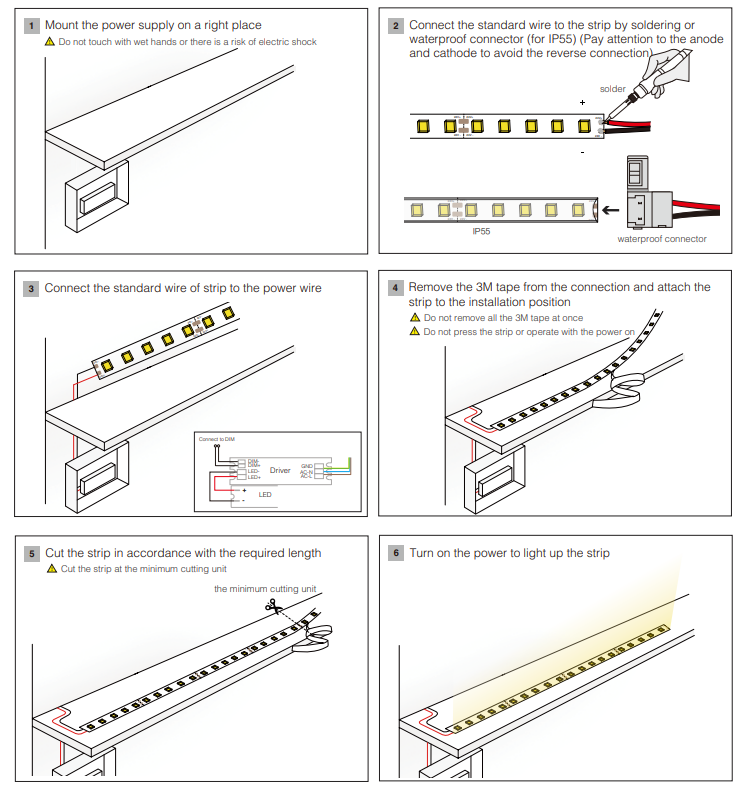

Installation requires strict adherence to electrical and mechanical best practices. Never attempt to bend standard LED strips beyond their minimum bend radius as this cracks solder joints and creates dark spots. Select connectors matching your strip’s width profile exactly—using a 10mm connector on 12mm strip causes poor contact and overheating. Before insertion, power down the circuit and verify strip polarity alignment to prevent reverse-feeding damage. Clean the strip’s contact pads with isopropyl alcohol to remove oils that cause intermittent connections. Apply firm even pressure when seating the strip into the connector until it clicks; partial insertion leads to voltage drop and flickering. For high-lumen density strips in commercial settings, add a second mechanical clamp over the connector body to counter thermal expansion forces that can dislodge strips over time. Avoid overtightening set screws as this crushes flexible PCBs. In environments with significant temperature swings like mall atriums, leave 2-3mm slack at corners to accommodate material contraction. Always test the connection under full load for 15 minutes before final concealment to catch early failure signs like localized heating. Remember that corner connectors introduce a minor voltage drop point—position them symmetrically in long runs to balance light output. Never substitute with soldered joints in field installations as this voids safety certifications and creates fire hazards in plenum-rated spaces.

Why Choose Beauty STC Lighting

Looking to seamlessly connect your LED strip lights around corners? Discover the perfect solution with Beauty STC’s high-quality LED strip corner connectors—engineered for durability, precision, and easy installation. Whether you’re working on residential, commercial, or industrial lighting projects, our connectors ensure a smooth, reliable connection every time.

Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. We specialize in innovative, high-performance products designed to meet the evolving needs of lighting professionals worldwide. Join forces with us to deliver superior lighting experiences to your customers.

For partnership inquiries or product details, contact us today at [email protected]. Let’s illuminate the future—together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.