Article Contents

Industry Insight: Led Strip Corner

In the evolving landscape of commercial and industrial lighting, LED strip corners have emerged as a critical solution for seamless illumination in architectural coves, structural joints, and design transitions. These specialized components ensure continuity in lighting runs around 90-degree bends and complex geometries, delivering both aesthetic precision and functional performance in environments ranging from retail spaces and office buildings to manufacturing facilities and cold storage warehouses. As energy efficiency and durability become paramount, the demand for compliant, high-quality LED corner solutions has intensified—driving the need for products that meet rigorous safety and performance standards such as ETL and CE certifications. These marks not only signify adherence to North American and European regulatory requirements but also reassure facility managers and contractors of reliability, electrical safety, and long-term operational stability.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leader in developing high-performance, code-compliant LED strip systems tailored for demanding commercial and industrial applications. The company’s LED strip corners reflect this commitment—combining precision bend technology, robust materials, and full regulatory compliance to ensure flawless integration into modern lighting designs. As the industry moves toward smarter, more sustainable illumination, Beauty STC continues to set the standard for quality, reliability, and technical excellence in every corner illuminated.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. approaches the specification of flexible LED strip lighting solutions designed for corner installations, commonly referred to as “LED strip corners,” with rigorous engineering standards. It is critical to clarify that “LED strip corner” typically describes the application of standard flexible LED strips bent or routed around architectural corners, often utilizing specialized corner connectors or mounting channels, rather than a distinct product category. Our focus remains on ensuring the underlying LED strip and its associated components meet demanding performance criteria for such applications.

Luminous efficacy, measured in lumens per watt (lm/W), is a key efficiency metric. Beauty STC’s high-performance flexible LED strips suitable for corner installations consistently achieve 120-140 lm/W under real-world operating conditions at 25°C ambient temperature. This range is attainable while maintaining high color quality, utilizing premium Epistar or Samsung 5050 LED packages driven at optimal currents. Efficacy is measured per IES LM-79 standards, factoring in the full system including the driver, and represents a balance between high output, thermal management, and longevity. Strips designed for corner use often employ 24V DC configurations to minimize voltage drop across bends, which inherently supports maintaining higher efficacy throughout the run compared to 12V alternatives over similar distances.

Achieving a Color Rendering Index (CRI) greater than 90, specifically targeting R9 (saturated red) values above 50 and incorporating TM-30 fidelity index (Rf) values of 85+, is a core quality pillar for Beauty STC. We utilize phosphor-converted LEDs with tightly binned chromaticity (within 3-5 MacAdam steps) to ensure color consistency, especially critical in continuous runs around corners where visible shifts are unacceptable. Our standard high-CRI strips for architectural and retail applications consistently deliver CRI >95 and R9 >90, utilizing multi-phosphor blends. This commitment to spectral quality is non-negotiable for applications where accurate color representation is essential, such as in high-end retail displays or hospitality environments featuring corner cove lighting.

IP ratings are paramount for corner installations, particularly in environments exposed to moisture, dust, or requiring washdown. Beauty STC offers flexible strips in IP20 (basic indoor), IP65 (protected against low-pressure water jets and dust), and IP67 (protected against temporary immersion) variants. Crucially, achieving the rated IP protection at corners requires more than just the strip’s inherent rating; it demands properly rated corner connectors and end caps compatible with the strip’s silicone jacket. Our IP65 and IP67 solutions utilize fully encapsulated strips within flexible silicone tubing, paired with proprietary molded silicone corner connectors that maintain the environmental seal integrity around bends, preventing moisture ingress points that commonly cause failure at directional changes. Beauty STC rigorously tests these corner assemblies per IEC 60529 standards, ensuring the entire run, including bends, meets the specified IP rating.

Beauty STC’s quality commitment is embedded throughout the product lifecycle. We utilize German- or Japanese-sourced drivers with >90% efficiency and 50,000+ hour lifespans (L70/B50 per TM-21), ensuring stable power delivery critical for consistent output around corners. All high-CRI strips undergo 100% burn-in testing at elevated temperatures (45°C) for 48 hours, with automated optical inspection verifying lumen output, chromaticity, and CRI before shipment. Our silicone extrusion process for IP-rated strips ensures uniform thickness and adhesion, preventing delamination at flex points. The result is a corner installation solution that maintains uniform brightness, color consistency, and environmental resilience, backed by a comprehensive 5-year warranty reflecting our confidence in reliability. This engineering discipline ensures that Beauty STC LED strips perform flawlessly in demanding corner applications where inferior products often exhibit color shift, hot spots, or premature failure.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and fully equipped LED lighting production facility designed to support high-volume manufacturing with strict quality control. Strategically located in the Jiangmen industrial zone, the facility leverages advanced automation and streamlined processes to ensure consistent product performance and reliability.

The factory features multiple high-speed SMT (Surface Mount Technology) production lines equipped with state-of-the-art machines from leading manufacturers. These SMT lines are capable of precise placement of LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED strip lights. The machines operate with high accuracy and throughput, supporting a wide range of strip light designs, including high-density and low-profile configurations. Automated optical inspection (AOI) systems are integrated into the SMT process to detect placement errors and soldering defects in real time, ensuring superior assembly quality.

After SMT assembly, LED strips undergo rigorous aging tests as part of the factory’s quality assurance protocol. Strips are powered continuously for 24 to 72 hours under controlled temperature and humidity conditions to identify early failures and verify long-term stability. Electrical performance, color consistency, and thermal behavior are monitored throughout the aging process. This step is critical in delivering reliable products, especially for applications requiring sustained operation.

Beauty STC has strong OEM capabilities and can customize LED strip solutions to meet specific client requirements. For products such as the ‘LED strip corner’—a specialized design used to seamlessly illuminate inside or outside corners—the company offers tailored engineering support. This includes custom PCB bending designs, connector integration, housing solutions, and thermal management to ensure optimal light distribution and mechanical fit. Clients can specify parameters such as color temperature, IP rating, voltage, and length, and Beauty STC handles the entire process from prototyping to mass production. With in-house tooling, molding, and packaging resources, the Jiangmen factory is well-equipped to deliver OEM orders efficiently and at scale.

Application Scenarios

LED strip corners serve a critical function in commercial lighting by enabling seamless transitions where linear runs meet perpendicular surfaces. This application is essential for maintaining visual continuity and achieving professional-grade illumination in high-traffic environments. In hotels, LED strip corners are most effectively deployed within architectural coves of lobbies and reception areas to create expansive ambient washes that guide guest movement. They are equally valuable behind headboards in guest rooms for indirect backlighting, around curved reception desks to highlight branding, and along pool deck edges where waterproof strips navigate tight turns. The key is eliminating visible gaps at joints to preserve the illusion of a single, uninterrupted light source which enhances perceived space quality.

For malls and retail centers, LED strip corners become indispensable at entrance canopies where strips wrap structural beams to welcome visitors, within illuminated signage boxes requiring precise 90-degree bends around letter contours, and along suspended feature ceilings in food courts where strips follow geometric patterns. Department store display fixtures frequently use corner installations to highlight product edges without shadowing, while escalator handrails often incorporate bent strips for safety guidance. The challenge here lies in maintaining consistent brightness through bends—a critical factor for brand image—where poor corner execution creates distracting dark spots that undermine the premium shopping experience.

Office environments leverage LED strip corners primarily for functional integration within modern workspace designs. They appear under suspended ceiling baffles to provide indirect task lighting in open-plan areas, around monitor backlighting in executive suites for reduced eye strain, and within partition walls of collaborative zones to define spaces subtly. Conference room tables with integrated strips require flawless corner connections for video conference aesthetics, while reception desk perimeters use them to create a floating effect. Thermal management becomes paramount here since confined corners in office furniture can trap heat, accelerating lumen depreciation if not properly addressed during installation.

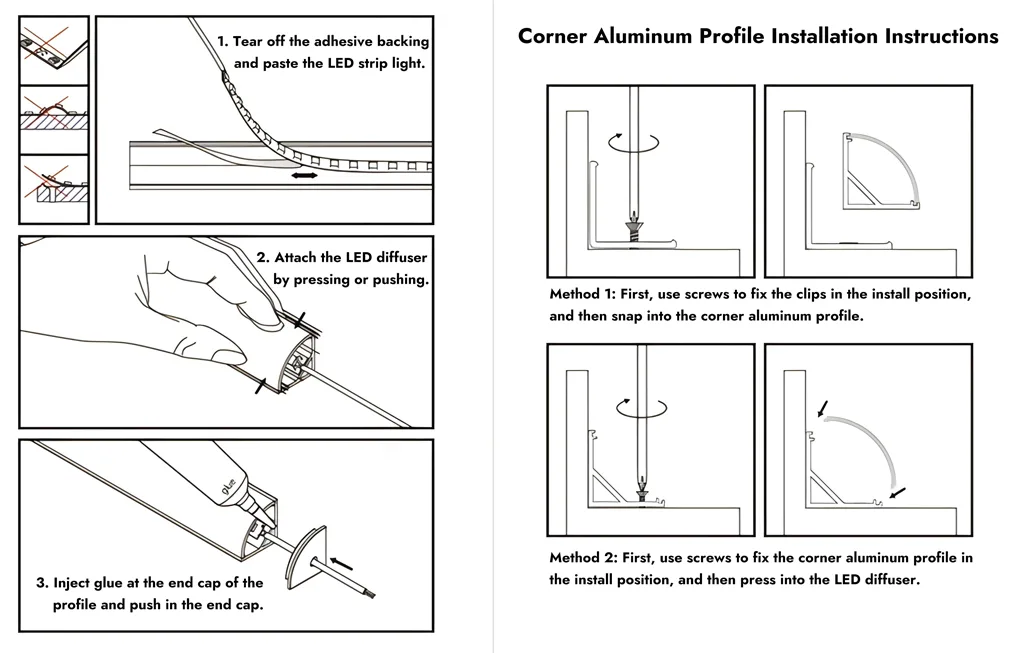

Installation demands meticulous attention to detail regardless of venue. Always prepare surfaces with isopropyl alcohol to remove oils before applying adhesive, as commercial environments experience higher vibration and temperature fluctuations than residential settings. When bending strips, never exceed the manufacturer’s specified minimum bending radius—typically 20-30mm for flexible PCBs—to prevent solder joint fractures. For true 90-degree corners, use purpose-built corner connectors rather than forcing the strip, ensuring electrical contacts align perfectly to avoid voltage drop. In high-ceiling mall installations, pre-test corner sections at ground level since accessibility for repairs is difficult. Crucially, maintain a 2-3mm expansion gap between strips at corners to accommodate thermal expansion in large-scale deployments where temperature swings occur between business hours and overnight. Always verify color consistency across multiple reels during installation, as batch variations become glaringly obvious at corner transitions in uniformly lit spaces. Finally, document all corner connection points in as-built drawings—this saves significant troubleshooting time during facility maintenance cycles.

Why Choose Beauty STC Lighting

Looking to enhance your LED strip lighting projects with seamless corner solutions? Partner with Beauty STC, a trusted name in innovative LED lighting technology. Our high-quality LED strip corners are designed for durability, precision, and effortless installation, making them ideal for residential, commercial, and industrial applications.

As a leading manufacturer, we offer competitive pricing, custom solutions, and reliable support to meet your specific needs. Whether you’re a distributor, contractor, or lighting designer, we’re ready to help you deliver outstanding results.

Contact us today to start a successful partnership. Email our sales team at [email protected] and discover how Beauty STC can power your next lighting project with quality and confidence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.