Article Contents

Industry Insight: Led Strip Connector

In the rapidly evolving landscape of commercial and industrial lighting, LED strip connectors have emerged as critical components in ensuring efficient, reliable, and scalable illumination systems. As facilities increasingly adopt flexible and energy-efficient LED strip lighting for applications ranging from warehouse task lighting to architectural accenting, the demand for high-quality, code-compliant connectors has grown significantly. These connectors not only simplify installation and reduce labor costs but also maintain the integrity of electrical connections in demanding environments—where durability, safety, and performance are non-negotiable.

Compliance with international safety standards such as ETL and CE has become essential for manufacturers and specifiers alike, ensuring that LED strip connectors meet rigorous requirements for electrical safety, fire resistance, and long-term reliability. In this context, trusted suppliers play a pivotal role in delivering products that combine innovation with regulatory adherence.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing LED interconnection solutions for over two decades. With a strong engineering foundation and a commitment to quality, Beauty STC designs and manufactures a comprehensive range of UL/ETL- and CE-certified LED strip connectors tailored for commercial and industrial applications. Their products are engineered to support seamless integration, high current capacity, and environmental resilience—making them a preferred choice for lighting professionals who demand performance, safety, and longevity in mission-critical installations.

Technical Specs & Certifications

LED strip connectors themselves do not possess lumens per watt (lm/W) or Color Rendering Index (CRI) specifications, as these metrics are inherent properties of the LED light source within the flexible strip, not the mechanical or electrical interface component. It is crucial to distinguish between the performance characteristics of the LED strip and the functional role of the connector. Beauty STC designs and manufactures connectors specifically to preserve the strip’s rated performance without degradation. Connectors are evaluated based on electrical continuity, mechanical reliability, ingress protection, and compatibility with the strip’s specifications.

Lumens per watt is a measure of the LED strip’s luminous efficacy, determined by the LED chips, driver efficiency, and thermal management. A high-quality connector must minimize voltage drop and power loss at the connection point to ensure the strip operates at its specified lm/W. Beauty STC connectors utilize high-conductivity phosphor bronze or brass contacts with gold plating, achieving contact resistance below 10 milliohms. This design ensures voltage drop across the connector remains under 0.1V at rated current, preventing efficacy loss and maintaining the strip’s published lm/W output. Poorly engineered connectors can cause significant power dissipation as heat, directly reducing system efficiency and lumen maintenance.

CRI values above 90 indicate excellent color fidelity, essential for applications like retail lighting or beauty salons where accurate skin tone and product color representation are critical. While the connector does not generate light or influence CRI intrinsically, it must not introduce inconsistencies in current delivery that could cause chromaticity shifts along the strip run. Beauty STC connectors feature precision-machined contacts ensuring uniform current distribution across all LED channels. This prevents localized dimming or color temperature variations that might occur with inferior connectors exhibiting uneven contact pressure or corrosion, thereby safeguarding the strip’s CRI >90 performance throughout the installation.

IP ratings for LED strip connectors define their resistance to dust and moisture ingress, directly impacting system longevity and safety in demanding environments. Beauty STC offers connectors rated IP65, IP67, and IP68, validated through rigorous third-party testing per IEC 60529 standards. IP65 connectors feature robust silicone seals protecting against low-pressure water jets, suitable for indoor damp locations. IP67 variants withstand temporary submersion up to 1 meter for 30 minutes, while IP68 models are rated for continuous submersion under manufacturer-specified conditions, often exceeding 1.5 meters depth. All sealed connectors undergo 100% automated pressure decay testing during production to guarantee integrity. Unsealed (IP20) versions are available for dry indoor use but lack environmental protection.

Beauty STC’s commitment to quality is evident in every connector. We utilize automotive-grade materials including flame-retardant UL94 V-0 polycarbonate housings and corrosion-resistant contacts. Each unit undergoes 100% electrical testing for continuity and insulation resistance, followed by a 4-hour burn-in at elevated temperature to identify early failures. Our manufacturing adheres to ISO 9001 standards with traceable component sourcing, and all critical connectors carry UL/cUL or CE certification. Unlike generic alternatives prone to contact oxidation or seal failure, Beauty STC connectors maintain stable performance over 50,000 mating cycles and 50,000 hours of operational life, ensuring the LED system consistently delivers its rated lumens, CRI, and IP protection throughout the installation’s lifespan. This reliability minimizes field failures and maintenance costs, particularly vital in professional lighting applications where downtime is unacceptable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting components and systems, with a strong emphasis on quality control, efficiency, and scalability.

The production floor is integrated with advanced Surface Mount Technology (SMT) lines that enable precise and automated placement of electronic components onto printed circuit boards (PCBs). These SMT machines are high-speed, multi-functional units capable of handling a wide range of component sizes and densities, ensuring consistent soldering accuracy and throughput. The SMT process is supported by automated optical inspection (AOI) systems to verify component placement and solder joint quality, minimizing defects and enhancing product reliability.

A critical part of the quality assurance process at the Jiangmen facility is the comprehensive aging test procedure. After assembly, LED strips and related components undergo rigorous aging tests under controlled thermal and electrical conditions. These tests typically run for 24 to 72 hours at elevated temperatures and full power loads to identify early-life failures and ensure long-term performance stability. The data collected during aging is used to fine-tune production parameters and maintain consistent product quality.

Beauty STC has robust OEM (Original Equipment Manufacturer) capabilities, particularly for LED strip connectors. The company supports custom design and manufacturing of connectors tailored to specific client requirements, including variations in pitch, voltage rating, waterproofing (such as IP65 or IP67-rated housings), and compatibility with different LED strip types (e.g., 5050, 2835, or high-density strips). The OEM process includes mold development, material sourcing, in-house tooling, and full assembly, all managed under strict quality standards. Clients can provide specifications or samples, and Beauty STC’s engineering team will develop compliant, reliable connector solutions with fast turnaround for prototyping and mass production.

Overall, the Jiangmen factory combines advanced automation, stringent testing, and flexible manufacturing to serve both domestic and international markets with high-quality, customized LED connectivity solutions.

Application Scenarios

LED strip connectors serve as critical junction points enabling flexible and efficient installation of LED strip lighting systems across commercial environments. They are not standalone lighting solutions but essential components for creating continuous runs, navigating corners, or facilitating maintenance in areas where direct soldering is impractical. Their primary role is to ensure reliable electrical continuity and mechanical stability between segments of LED strip or between strips and power sources/drivers.

In hotels, LED strip connectors are indispensable for creating seamless ambient lighting in lobbies, corridors, and guest room coves where long, uninterrupted runs are required. They allow installers to route strips around structural obstructions like door frames or ceiling beams without visible breaks, maintaining the desired aesthetic flow. Connectors are also vital behind reception desks for under-counter illumination and within architectural millwork where modular assembly simplifies installation during renovations. Particular attention must be paid to connectors in high-moisture areas such as spa treatment rooms or poolside bars, where IP67-rated waterproof connectors prevent corrosion and failure.

Malls heavily utilize LED strip connectors for dynamic signage illumination, display window highlights, and cove lighting in high-ceiling atriums. The constant foot traffic and potential for vibration near escalators or moving walkways demand robust mechanical strain relief on every connection. Retail storefronts rely on connectors to link multiple strip segments within lightboxes, ensuring even illumination across large graphic panels. When installing in mall environments, prioritize connectors with metal housings and screw terminals over friction-fit types to withstand thermal cycling from HVAC systems and occasional physical contact from maintenance staff.

Offices deploy LED strip connectors primarily for under-cabinet task lighting in workstations, conference room cove accents, and perimeter ceiling reveals to reduce glare while maintaining ambient brightness. The frequent reconfiguration of office layouts makes connectors essential for creating demountable sections that can be easily relocated during workspace updates. In server rooms or equipment closets, connectors with high-temperature ratings (105°C) are mandatory due to ambient heat, while administrative areas benefit from low-profile connectors that remain invisible behind suspended ceiling grids.

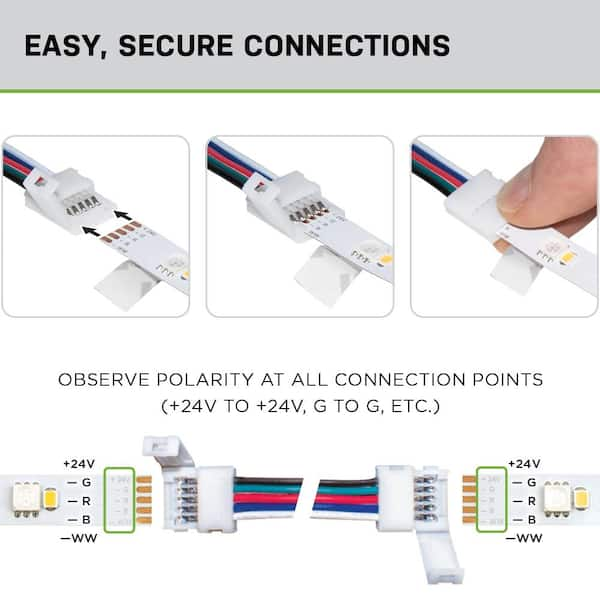

Installation requires strict adherence to electrical safety and mechanical best practices. Always disconnect power at the circuit breaker before handling any components and verify with a multimeter. Match connector polarity precisely to the strip markings—reversed polarity instantly damages LEDs. For permanent installations, apply strain relief clips within 50mm of each connector to prevent wire pull-out, especially where strips traverse expansion joints or flexible mounting surfaces. In high-vibration zones like mall escalator handrails, use screw-terminal connectors instead of push-in types and secure all wire leads with cable ties to structural elements. Before sealing any connector with silicone or placing it within a channel, conduct a 15-minute operational test under full load to detect intermittent faults. Never exceed the connector’s rated amperage—typically 5A for standard types—and for continuous runs exceeding 5 meters, inject power at multiple points using separate connectors to avoid voltage drop. Finally, in concealed spaces like office ceiling plenums, ensure all connectors meet local fire codes with UL 94 V-2 or higher flammability ratings.

Why Choose Beauty STC Lighting

Looking for reliable and high-quality LED strip connectors? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our precision-engineered connectors ensure seamless installations and long-lasting performance across a wide range of applications. As your manufacturing partner, we offer competitive pricing, custom solutions, and consistent quality control to meet your specific project needs.

To learn more or discuss your requirements, contact us today at [email protected]. Let Beauty STC power your next lighting project with innovation and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.