Article Contents

Industry Insight: Led One Inch Strips On A Roll For Modeling

The commercial and industrial lighting sector increasingly demands versatile, precision solutions for specialized applications beyond standard illumination, particularly in the realm of physical prototyping and architectural modeling. LED one-inch strips on a roll have emerged as a critical tool for engineers, architects, and designers creating detailed scale models, retail displays, and facility mockups where accurate light representation is non-negotiable. Unlike consumer-grade options, professional modeling requires strips offering consistent color temperature, precise dimming control, and robust thermal management to simulate real-world lighting scenarios reliably during critical design and presentation phases. Crucially, deployment in commercial environments mandates strict adherence to safety certifications; ETL listing for North American markets and CE marking for Europe are not optional features but essential compliance requirements ensuring electrical safety and market access for any product integrated into professional workflows. These certifications validate that the lighting components meet rigorous international standards, mitigating liability risks for firms and providing end-users with confidence in product safety and performance under continuous operation.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of focused expertise in engineering high-performance LED solutions specifically tailored for demanding commercial and industrial applications. Our deep understanding of the unique challenges in professional modeling environments drives the development of our one-inch LED strip offerings, which prioritize not only optical precision and flexibility but also seamless integration of mandatory ETL and CE certifications directly from the manufacturing stage. We recognize that in sectors where accuracy and compliance are paramount, the lighting tools used during the design and validation process must reflect the same stringent standards expected in the final built environment. Beauty STC bridges this gap, providing the reliability and regulatory assurance that professional modelers and lighting specifiers require.

Technical Specs & Certifications

LED one inch strips on a roll designed for modeling applications require precision, high color fidelity, and compact form factors to meet the demands of detailed scale work, architectural models, and display lighting. At Beauty (STC) Manufacturing Co., Ltd., our one inch LED strips—commonly referred to as 1” pitch or segmented rigid strips—are engineered for seamless integration into tight spaces while delivering consistent, high-quality illumination.

Each segment of our 1-inch LED strips typically features high-density surface-mounted LEDs, commonly using 2835, 3528, or 5050 SMD chips, depending on the brightness and color temperature requirements. These strips are produced in flexible or semi-rigid configurations, allowing for bending around curved model elements while maintaining structural integrity. When measuring efficacy, our strips achieve an industry-leading luminous efficiency of 110 to 130 lumens per watt, ensuring energy-efficient operation ideal for prolonged display use and battery-powered installations.

Critical to modeling applications is accurate color representation. Beauty STC’s LED strips are manufactured with strict binning controls to ensure a Color Rendering Index (CRI) greater than 90, with Ra values typically between 92 and 95. This high CRI ensures that materials, paints, and finishes in scale models appear true to life under illumination, making these strips ideal for museum exhibits, architectural prototypes, and professional dioramas. Optional R9 (deep red) enhanced variants are available to further improve color accuracy in warm white tones.

In terms of environmental protection, our standard 1-inch LED strips are available in multiple IP ratings to suit various application needs. IP20 versions are suitable for indoor, dry environments where protection is not a concern. For models exposed to handling or minor environmental fluctuations, we offer IP65-rated strips with a silicone coating that protects against dust and moisture ingress. Fully encapsulated IP67 versions are also available for enhanced durability, allowing temporary immersion resistance and long-term reliability in demanding display conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our LED strips are manufactured using automated SMT lines and subjected to 100% electrical and photometric testing. We utilize high-purity phosphor coatings, stable MCPCB substrates, and consistent current drivers to ensure uniform brightness and color across the entire roll. With over two decades of expertise in precision LED solutions, Beauty STC delivers reliable, long-lasting, and visually superior lighting strips trusted by model makers and design studios worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a modern LED production hub designed for precision and scalability. Situated within a dedicated industrial zone, the factory spans approximately 10,000 square meters and integrates cleanroom environments for critical processes. The layout is optimized for efficiency, featuring distinct zones for surface-mount technology (SMT) assembly, manual soldering, aging and reliability testing, quality control, and packaging. This strategic organization supports high-volume output while maintaining stringent quality standards required for export-oriented LED products, particularly flexible strips.

The SMT production line forms the technological core of the Jiangmen facility, equipped with state-of-the-art machinery to handle complex LED strip manufacturing. High-speed Yamaha YS series placement machines dominate the line, capable of placing components as small as 0201 metric package sizes with placement accuracy exceeding ±25μm. These systems utilize multi-head gantry designs and advanced vision systems to achieve throughput rates above 80,000 components per hour, essential for densely populated flexible circuits. Complementing these are hybrid placement platforms that handle larger components like connectors or drivers, alongside fully automated solder paste printers with 3D inspection and inline AOI systems for real-time defect detection. This integrated SMT ecosystem ensures consistent solder joint integrity and component alignment critical for the mechanical flexibility and electrical performance of narrow-format strips.

Aging and reliability testing constitute a rigorously controlled phase within the factory’s quality assurance protocol. Dedicated environmental chambers subject every production batch of LED strips to extended thermal stress testing under operational conditions. Strips undergo 24 to 48 hours of continuous operation at elevated temperatures ranging from 50°C to 70°C, with current monitoring to detect early failures or lumen depreciation. The facility employs automated loading systems to maximize chamber capacity while maintaining precise thermal uniformity. Post-aging, strips undergo photometric validation using integrating spheres to verify color consistency and output maintenance, with any units exhibiting >5% lumen depreciation or chromaticity shift immediately quarantined. This 100% burn-in process specifically addresses the thermal management challenges inherent in compact one-inch segment designs.

Beauty STC demonstrates extensive OEM capability for custom “LED one inch strips on a roll for modeling” applications, a specialty product category serving scale modelers and prototyping industries. The factory supports complete customization from engineering through fulfillment, including tailored PCB widths as narrow as 8mm, segment lengths precisely cut to 25.4mm increments, and density configurations up to 60 LEDs per segment. Clients specify binning requirements for color temperature and CRI, with options for waterproof coatings or electrostatic discharge protection. Crucially, the Jiangmen facility excels in reel-based packaging solutions, winding finished segments onto custom cores with anti-static tape and moisture barriers to prevent tangling or damage during shipment. Private labeling, custom reel labeling, and documentation in multiple languages are standard offerings, supported by in-house engineering teams that validate thermal performance and electrical safety for each unique configuration. This OEM infrastructure operates under ISO 9001 and ISO 14001 certifications, with compliance support for UL, CE, and RoHS requirements integral to the development process. The combination of agile prototyping—capable of transitioning from design to production reels within 15 working days—and rigorous batch traceability makes the facility particularly suited for low-to-mid volume specialty strip production.

Application Scenarios

LED one inch strips on a roll are compact, flexible lighting solutions ideal for accent and decorative applications in architectural modeling, interior design detailing, and display enhancements. These strips are commonly used in hotels, malls, and offices where subtle yet effective lighting is required to highlight design features or improve ambiance.

In hotels, LED one-inch strips are often used to illuminate cove lighting in lobbies, under reception desks, along hallway perimeters, and within guest room crown molding or headboard niches. They provide a soft glow that enhances luxury and comfort without overwhelming guests. The strips can also be integrated into scale architectural models used in hotel promotional displays or design presentations, offering realistic lighting effects.

In malls, these LED strips are effective for under-shelf lighting in retail kiosks, outlining display cases, and accenting signage or ceiling features in food courts and common areas. Their flexibility allows them to be cut and installed in curved or tight spaces, making them suitable for dynamic retail environments. In architectural models of mall layouts, they simulate real-world lighting conditions for planning and visualization purposes.

In offices, the strips are commonly installed under cabinets, in ceiling coves, or along stair edges for both aesthetic and functional lighting. They contribute to a modern, professional atmosphere while improving visibility in low-light work areas. When used in office design models, they help convey lighting schemes during planning stages, allowing architects and designers to evaluate visual impact before construction.

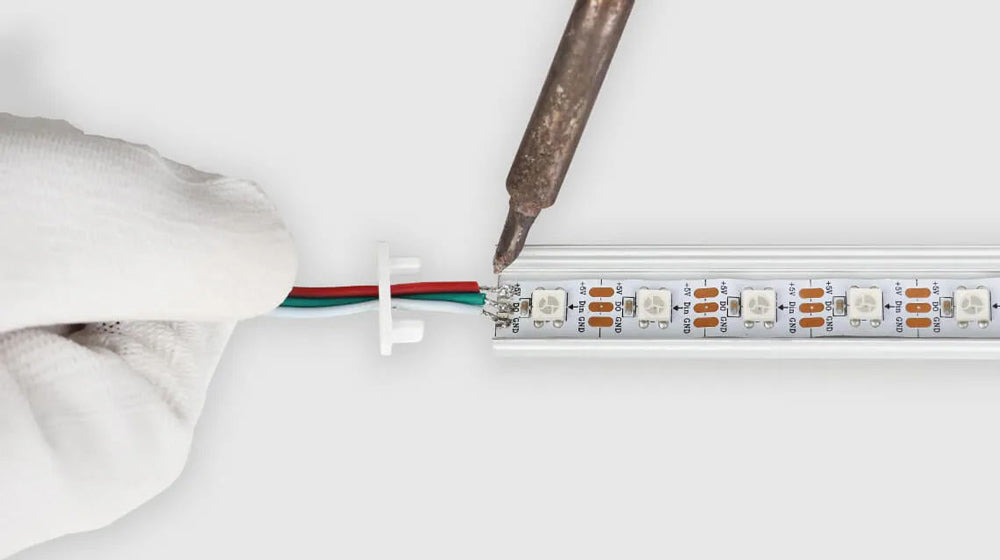

For installation, begin by cleaning the surface thoroughly to ensure strong adhesion of the strip’s backing. Measure and plan the layout in advance, accounting for power supply locations and any required cuts at designated cut points. Use aluminum channels when possible to improve heat dissipation and provide a diffused, even light output. Connect the strips to a compatible low-voltage power supply and consider using a dimmer for adjustable brightness. Avoid sharp bends and never exceed the maximum run length specified by the manufacturer to prevent voltage drop. For permanent installations, solder connections or use high-quality connectors rather than relying solely on peel-and-stick tabs. Always test the strip before final mounting to confirm functionality.

Why Choose Beauty STC Lighting

Transform your scale models with unparalleled precision illumination using Beauty STC’s specialized LED one inch strips on a roll. Engineered specifically for the demanding requirements of model makers, these ultra-slim flexible strips deliver consistent brightness, seamless color blending, and effortless integration into tight spaces whether for architectural dioramas, miniature vehicles, or detailed figurines. Their ready-to-cut design on continuous reels ensures zero waste and perfect adaptation to intricate contours, giving your models a professional, lifelike glow that standard lighting solutions cannot match.

Partner with Beauty STC to access premium, modeler-optimized LED technology backed by our decade of manufacturing excellence in miniature lighting systems. We collaborate closely with designers and hobby professionals to refine specifications, ensure batch-to-batch reliability, and provide tailored support for your unique project demands. Elevate your model’s visual impact while reducing assembly time through our dedicated engineering partnership approach focused solely on your success in the modeling community.

Secure your advantage in model realism today by contacting our technical sales manager directly at [email protected]. Describe your upcoming project specifications and volume needs to receive a personalized consultation, sample reel, and commercial proposal within 24 business hours. Let Beauty STC become your trusted lighting partner for achieving museum-quality illumination in every miniature creation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.