Article Contents

Industry Insight: Led On 12V

The commercial and industrial lighting sector is increasingly recognizing the strategic advantages of 12V DC LED systems as a core solution for demanding applications. Moving beyond traditional line-voltage installations, 12V LED technology offers significant benefits in safety, efficiency, and design flexibility, particularly in environments like parking structures, warehouses, cold storage facilities, and wet locations where reduced electrical risk is paramount. This low-voltage approach minimizes arc-fault hazards, simplifies integration with renewable energy sources and battery backups, and enables more compact, versatile fixture designs. However, the critical nature of these installations demands absolute reliability and adherence to stringent safety standards. Compliance with certifications such as ETL (verifying adherence to North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) is not optional; it is the essential foundation for market acceptance, liability protection, and ensuring long-term operational integrity in professional settings. For over 25 years, Beauty STC Manufacturing Co., Ltd. has been a trusted innovator and manufacturer in this space, leveraging our deep expertise since 1998 to engineer robust, certified 12V LED lighting solutions specifically engineered to meet the rigorous demands of commercial and industrial projects worldwide.

Technical Specs & Certifications

When referring to LED lighting operating on a 12V DC power supply—commonly used in automotive, marine, RV, and low-voltage architectural applications—the technical specifications are critical for performance, efficiency, and reliability. At Beauty (STC) Manufacturing Co., Ltd., our 12V LED products are engineered to deliver superior optical quality, energy efficiency, and environmental resilience.

Lumens per Watt (lm/W) is a key metric for evaluating the energy efficiency of LED lighting. Beauty STC’s 12V LED solutions typically achieve an efficacy range of 90 to 110 lumens per watt, depending on the specific product and optical configuration. This high efficiency ensures minimal power consumption while maintaining bright, consistent illumination—ideal for battery-powered or off-grid applications where energy conservation is essential.

Color Rendering Index (CRI) is another critical factor, especially in environments where accurate color representation is required, such as retail displays, hospitality settings, or makeup and grooming areas. Beauty STC ensures that all high-CRI 12V LED products feature a CRI greater than 90, with many offerings exceeding 95. This results in natural, vibrant lighting that closely replicates daylight, enhancing visual clarity and comfort.

Ingress Protection (IP) ratings define the level of protection against dust and moisture, which is vital for durability in demanding environments. Beauty STC provides a range of 12V LED products with IP ratings from IP65 to IP68. An IP65 rating indicates complete dust protection and resistance to low-pressure water jets, making it suitable for outdoor or damp indoor locations. For fully waterproof performance in submerged or high-moisture conditions, our IP68-rated 12V LED strips and fixtures offer continuous protection against water ingress, even under prolonged submersion.

Beauty STC’s commitment to quality is reflected in our rigorous manufacturing standards, use of premium components—such as high-grade SMD LEDs and stable constant-current drivers—and comprehensive testing for thermal management, electrical safety, and long-term reliability. Our 12V LED products undergo aging tests, humidity resistance evaluations, and color consistency checks to ensure uniform performance across batches. With over two decades of expertise in LED innovation, Beauty (STC) Manufacturing Co., Ltd. delivers lighting solutions that combine efficiency, precision, and durability for professional and consumer applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant hub for our LED lighting production, strategically located within one of China’s key industrial regions to leverage robust supply chain infrastructure and skilled labor. The Jiangmen factory is purpose-built for high-volume, precision LED manufacturing, featuring cleanroom environments and advanced production lines dedicated to ensuring product consistency and quality. This facility serves as a core operational center for both domestic and international markets, supporting our commitment to engineering excellence and scalable production capacity.

The SMT production lines within the Jiangmen factory are equipped with state-of-the-art high-speed surface mount technology machines from leading global manufacturers such as Yamaha and Siemens. These machines deliver exceptional placement accuracy, typically within ±25μm, essential for handling the miniature components used in modern LED drivers and control circuits. The lines are configured to process a wide range of component sizes, from ultra-small 0201 passives to larger integrated circuits and connectors, ensuring flexibility for diverse product designs. Automated optical inspection (AOI) systems are integrated directly after the reflow soldering stage, providing real-time verification of component placement, solder joint integrity, and potential defects, which is critical for the thermal management and electrical reliability of LED assemblies operating on low-voltage DC systems.

Aging testing is a non-negotiable phase in our quality assurance protocol at the Jiangmen facility, rigorously applied to every production batch of 12V DC LED products. Units undergo continuous operation under full electrical load for a minimum of 48 to 72 hours within precisely controlled environmental chambers, maintaining temperatures typically between 50°C and 60°C to accelerate stress conditions. During this period, critical parameters such as lumen maintenance, chromaticity stability, drive current consistency, and thermal performance are continuously monitored using calibrated photometric and electrical test equipment. Any unit exhibiting performance drift beyond our stringent internal thresholds during aging is automatically flagged for root cause analysis and corrective action, ensuring only units demonstrating proven operational stability proceed to final packaging. This comprehensive burn-in process significantly reduces infant mortality rates in the field.

Our OEM capabilities for 12V DC LED solutions are a cornerstone service offered from the Jiangmen factory, designed to support clients requiring custom integration into automotive, marine, RV, or specialized low-voltage architectural applications. We provide full engineering collaboration, starting from initial concept refinement through to mass production, including custom PCB layout modifications, driver circuit adaptation for specific 12V input tolerances or dimming protocols, tailored thermal management solutions, and bespoke mechanical housing design. The facility holds relevant international certifications including IEC, UL, and CE, ensuring OEM products meet global regulatory requirements. We accommodate flexible order volumes with competitive MOQs, offer comprehensive labeling and packaging customization, and maintain strict IP confidentiality protocols. Our engineering team works closely with OEM partners to validate designs against application-specific environmental and performance criteria, ensuring seamless integration and reliability of the ‘LED on 12V’ solution within the client’s end product.

Application Scenarios

LED lighting on 12V DC systems is increasingly being adopted in commercial and hospitality environments such as hotels, malls, and offices due to its energy efficiency, safety, and compatibility with modern low-voltage power systems. Here’s where and how it is best applied, along with essential installation tips.

In hotels, 12V LED lighting is ideal for accent and ambient lighting applications. It is commonly used in guest room cove lighting, under-cabinet lighting in minibars, wardrobe illumination, and bathroom mirror lighting. The low voltage enhances safety in areas with higher humidity, such as bathrooms, and allows for flexible design with dimmable and color-tunable options to create a relaxing atmosphere. 12V LEDs are also suitable for use in emergency lighting systems due to their compatibility with battery backup solutions.

Malls benefit from 12V LED lighting in display and feature lighting. Retail storefronts, signage backlighting, and decorative architectural highlights often use 12V strips or spotlights for precise control and minimal heat output. The low voltage reduces electrical risks in high-traffic public areas and allows for discreet installation in tight or sensitive spaces. Additionally, 12V systems integrate well with centralized power supplies, enabling efficient maintenance and consistent performance across large installations.

In office environments, 12V LED lighting supports modern, minimalist designs. It is frequently used for task lighting under shelves or desks, in partition walls, and for indirect ceiling coves that reduce glare and create a comfortable work atmosphere. The use of 12V systems also aligns with sustainable building standards, as they can be powered by renewable sources or integrated into smart building systems with centralized DC power distribution.

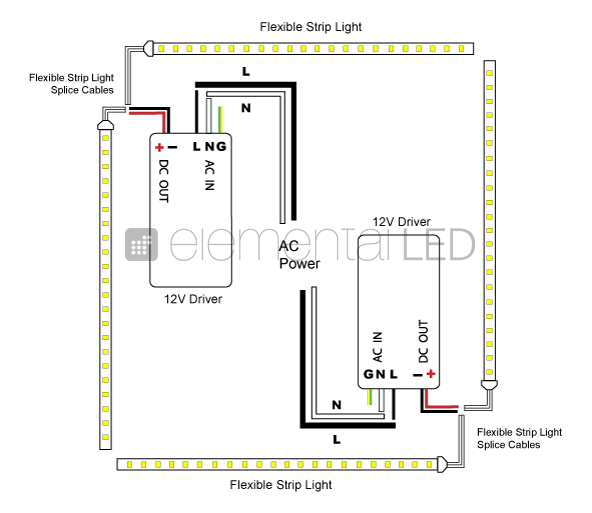

When installing 12V LED lighting, several best practices should be followed. First, always use a properly rated and adequately sized DC power supply that matches the total load of the LED system, allowing for at least a 20% headroom to prevent overheating. Voltage drop is a critical consideration over long cable runs—use thicker gauge wires or inject power at multiple points to maintain consistent brightness, especially with LED strips. Ensure all connections are secure and insulated to prevent short circuits, and use connectors or soldered joints instead of twisting wires together.

It is also important to verify compatibility between the LED product and the driver or power supply, particularly with dimming systems. Use constant voltage 12V DC drivers for standard strips and ensure any control systems (such as DALI or 0-10V) are properly interfaced through compatible converters. Finally, follow local electrical codes and safety standards, and consider using Class 2 or SELV (Safety Extra Low Voltage) compliant systems where required for added protection.

By applying these guidelines, 12V LED installations in hotels, malls, and offices can deliver reliable, efficient, and aesthetically pleasing lighting solutions.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with Beauty STC’s precision-engineered 12V LED solutions designed for optimal performance, safety, and energy efficiency in demanding commercial and architectural applications. Our low-voltage systems deliver exceptional reliability and seamless integration while meeting rigorous global safety standards. Partner with Beauty STC to access custom-engineered 12V LED technology backed by decades of manufacturing expertise and dedicated technical support. Reach out to our engineering team today to discuss your specific requirements and elevate your next project. Contact our partnership manager directly at [email protected] to initiate a collaboration.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.