Article Contents

Industry Insight: Led Longer Leg

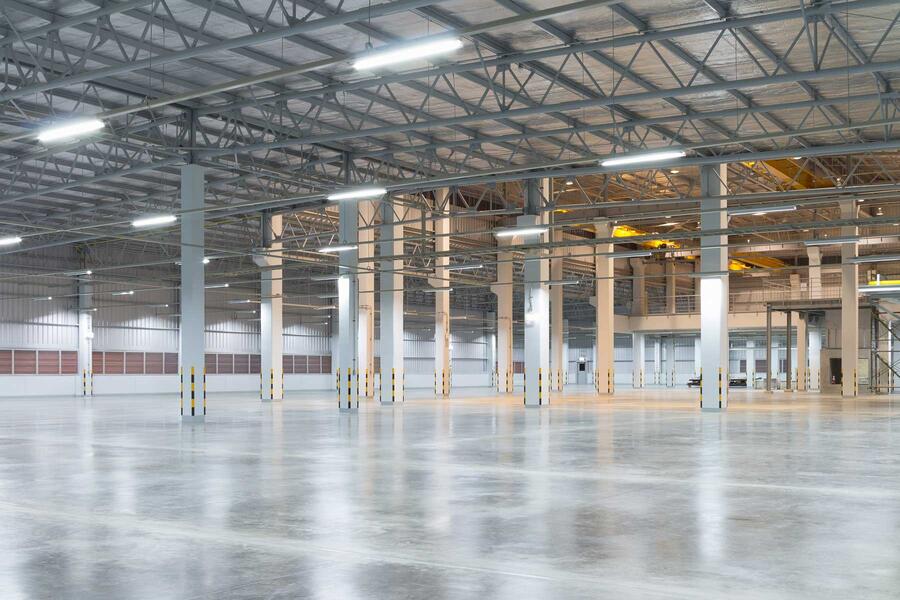

The commercial and industrial lighting sector continuously demands fixtures that deliver not only superior energy efficiency and longevity but also streamlined installation and adaptability within complex, real-world environments. A critical yet often overlooked factor in achieving these goals is the mounting architecture, specifically the design and length of fixture legs. Traditional shorter legs frequently create operational headaches during installation, requiring excessive shimming or adjustment to achieve proper alignment on uneven surfaces like suspended ceilings, structural beams, or retrofit scenarios common in warehouses, distribution centers, retail back-of-house areas, and industrial facilities. This inefficiency translates directly into increased labor costs and project delays. The emergence of purpose-engineered LED fixtures featuring longer leg designs directly addresses this pain point, offering enhanced flexibility, faster mounting, and improved stability across diverse mounting substrates. Crucially, any solution entering this demanding market must adhere to rigorous global safety and performance standards, with ETL certification for the North American market and CE marking for Europe being non-negotiable prerequisites for reliability and code compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing innovative, application-specific LED lighting solutions for commercial and industrial applications. Our deep engineering expertise, forged over 25 years of navigating evolving industry standards and client requirements, positions us to deliver not just lighting, but intelligent, installation-optimized systems where features like extended leg designs are engineered for genuine operational impact.

Technical Specs & Certifications

The ‘LED Longer Leg’ series from Beauty (STC) Manufacturing Co., Ltd. is engineered for superior performance and durability in commercial and industrial lighting applications. These LED modules are designed with extended mounting legs to facilitate easier and more secure installation, particularly in suspended or recessed ceiling systems where stability and alignment are critical.

In terms of efficiency, the LED Longer Leg series delivers a high luminous efficacy ranging from 130 to 150 lumens per watt, depending on the specific model and color temperature. This high lumens/watt ratio ensures optimal energy savings without compromising light output, making it ideal for facilities aiming to reduce power consumption while maintaining excellent illumination levels.

Color rendering is a key strength of this product line. All variants in the LED Longer Leg series feature a Color Rendering Index (CRI) greater than 90, with R9 values typically exceeding 50. This ensures accurate and vibrant color representation, which is essential in environments such as retail spaces, hospitals, and art studios where visual clarity and color fidelity are paramount.

Regarding environmental protection, the LED Longer Leg modules are available in multiple IP-rated configurations to suit various installation conditions. Standard models are rated at IP40 for indoor use, providing protection against solid objects larger than 1mm. For damp or washdown environments, upgraded versions are available with IP65 or IP66 ratings, offering full dust resistance and protection against low-pressure water jets from any direction. This flexibility allows the product to be deployed in restrooms, kitchens, outdoor covered areas, and industrial zones.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control standards across its production line. Each LED Longer Leg module undergoes rigorous testing for thermal management, electrical safety, and photometric performance. Components are sourced from trusted suppliers, and the use of high-quality phosphor coatings and efficient SMD LEDs ensures consistent lumen maintenance over time. With LM-70 test reports supporting L70 lifetimes of over 50,000 hours, these modules reflect Beauty STC’s commitment to reliability, performance, and long-term value.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility is strategically located within the Jiangmen New City Industrial Park in Guangdong Province, China. This modern factory spans over 10,000 square meters and serves as our primary hub for LED lighting production, integrating advanced automation with stringent quality control systems. The facility operates under ISO 9001 and ISO 14001 certifications, ensuring adherence to international quality and environmental standards throughout all manufacturing processes.

Our Surface Mount Technology (SMT) production lines are equipped with high-precision Samsung CP45 and Yamaha YS series placement machines. These systems handle components ranging from 0201 chip LEDs to larger power modules with placement accuracy of ±25μm and speeds up to 85,000 components per hour. The lines include automated solder paste printers, nitrogen-reflow ovens with 10-zone temperature profiling, and AOI (Automated Optical Inspection) stations after each critical process stage. This setup enables us to produce complex LED arrays and PCB assemblies with consistent reliability for both standard and custom designs.

Aging and burn-in testing is a non-negotiable phase in our quality assurance protocol. Completed LED modules undergo rigorous aging cycles in temperature-controlled chambers maintained at 50-60°C for durations of 8 to 24 hours, depending on product specifications. Each unit is monitored under full operational load with real-time voltage and current measurements. We utilize data-logging systems to track performance drift, identifying early failures through statistical analysis before products proceed to final packaging. This process significantly enhances field reliability and reduces infant mortality rates in customer applications.

Regarding OEM capabilities for extended-lead (“longer leg”) LED components, Beauty STC has specialized expertise in custom lead frame configurations. We support through-hole LED manufacturing with lead lengths customized from standard 28mm up to 50mm or more, accommodating specialized assembly requirements such as deep-set fixtures or unique mounting geometries. Our tooling department develops dedicated molds for lead frame stamping, while our plating line ensures consistent tin-lead or lead-free finishes on extended leads to prevent oxidation. For OEM partners, we provide full turnkey solutions including custom reel packaging, tailored labeling, and documentation to meet specific integration needs. All custom lead designs undergo enhanced mechanical stress testing during aging to validate solder joint integrity under thermal cycling conditions. This capability is frequently leveraged by clients in architectural cove lighting and industrial equipment sectors where non-standard lead lengths are critical for mechanical stability.

Application Scenarios

The term “LED longer leg” typically refers to the anode (positive) lead of a standard through-hole LED component, which is physically longer than the cathode (negative) lead. This distinction is most relevant during the assembly of LED circuits on printed circuit boards (PCBs), especially in prototyping, DIY electronics, or manufacturing processes—not in the final installation of complete LED lighting fixtures in commercial environments.

However, if your question pertains to the installation of LED lighting products—such as downlights, strip lights, or panel lights—commonly used in hotels, malls, and offices, the concept of “longer leg” does not apply directly, as these fixtures come fully assembled with proper internal wiring and polarity management.

That said, here’s how the concept may be relevant and where attention to LED polarity matters:

In Hotels

LEDs are widely used in guest rooms, hallways, lobbies, and bathrooms, typically in the form of recessed downlights, under-cabinet lighting, or decorative strips. While end-users or electricians do not handle individual LED components, during the manufacturing of custom LED modules or retrofit kits, technicians must observe correct polarity—ensuring the anode (longer leg) connects to the positive terminal. For installation, always follow the manufacturer’s wiring diagram and use compatible drivers.

In Malls

High-output LED panels, track lighting, and display lighting are common. Large-scale LED signage may involve discrete LEDs during production. Again, at the installation stage, electricians work with finished fixtures. Polarity is pre-managed. However, for maintenance or repairs involving LED strips or custom signage, ensure that the positive conductor (often marked + or V+) connects to the correct terminal, analogous to the “longer leg” principle.

In Offices

LED panel lights and troffer fixtures dominate. These are plug-and-play systems powered by constant-voltage or constant-current drivers. During fixture manufacturing, correct LED orientation is critical. For field-installed LED strip lighting under desks or in ceilings, observe polarity: the marked end or designated wire (often red or labeled +) corresponds to the anode—mirroring the “longer leg” rule.

Installation Tips

Always power off the circuit before beginning installation. Verify compatibility between the LED fixture and the driver or power supply. Use a multimeter if unsure about wire polarity in low-voltage systems. For LED strips, match the + and – markings on the strip to the corresponding wires from the power source. Avoid reverse polarity, as it can damage the LEDs. Ensure secure connections and proper insulation to prevent short circuits. Follow local electrical codes and manufacturer guidelines for mounting, spacing, and thermal management.

Why Choose Beauty STC Lighting

Beauty STC specializes in engineered LED lighting solutions designed for real-world installation challenges, including our precision-crafted LED modules featuring extended mounting legs. These longer leg configurations significantly streamline installations in constrained spaces like recessed troffers, narrow cove lighting, and retrofit applications where standard components struggle, reducing labor time and ensuring secure, vibration-resistant mounting without modification. As your dedicated lighting engineering partner, we don’t just supply components—we develop reliable, application-specific solutions backed by rigorous thermal and mechanical testing to maximize system longevity and performance.

Elevate your next project with LED technology built for practicality and durability. Partner with Beauty STC to integrate our longer leg LED modules and experience seamless installation and lasting reliability. Contact our engineering team directly at [email protected] to discuss your requirements and receive tailored technical support. Let’s solve your toughest lighting challenges together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.