Article Contents

Industry Insight: Led Line

The commercial and industrial lighting sector continues to evolve with increasing demand for energy-efficient, durable, and code-compliant solutions. At the forefront of this transformation is LED linear lighting—commonly referred to as LED line lighting—offering superior performance, long service life, and sleek design integration across warehouses, manufacturing facilities, office buildings, and retail spaces. As facility managers and lighting designers prioritize sustainability and operational cost savings, the need for reliable, certified products has never been greater. LED line systems that carry key safety and performance certifications such as ETL and CE are now standard requirements, ensuring compliance with North American and international regulations while guaranteeing electrical safety, photometric accuracy, and environmental resilience.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been a trusted innovator in the LED lighting industry for over two decades. Specializing in high-performance commercial and industrial LED solutions, Beauty STC combines advanced thermal management, optical engineering, and robust construction to deliver linear lighting systems that meet the rigorous demands of modern facilities. With a strong commitment to quality and compliance, all Beauty STC LED line products are ETL and CE certified, reflecting adherence to the highest standards in safety, reliability, and energy efficiency. As the market continues to shift toward smarter, more sustainable lighting infrastructures, Beauty STC remains a strategic partner for specifiers, contractors, and facility operators seeking proven performance and lasting value.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance linear LED lighting systems primarily for architectural, commercial, and high-end residential applications. Our ‘LED line’ products, such as the LumaLine series, are engineered to exceed industry benchmarks for efficiency, color fidelity, and environmental resilience. Key technical specifications are detailed below with a focus on your requested parameters.

Lumens per Watt (lm/W) efficiency is a core priority in our thermal and optical design. Our standard linear fixtures achieve 140–160 lm/W under real-world operating conditions at 25°C ambient temperature, using standard 4000K CCT LEDs. This range accounts for driver losses and optical components. Higher efficacy up to 165 lm/W is attainable with our premium 3000K or 4000K options using Samsung LM301B or Nichia NV4L E272B mid-power LEDs, coupled with optimized passive extrusion heat sinks maintaining junction temperatures below 75°C. Critical to this performance is our proprietary thermal management system, which ensures sustained output without lumen depreciation even in 55°C ambient environments, as validated by TM-21 lifetime projections. Driver efficiency consistently exceeds 92% across our range, minimizing system-level energy loss.

Color Rendering Index (CRI) performance is non-negotiable in our quality standard. All architectural linear products maintain a minimum CRI of 92, with R9 (saturated red) values exceeding 50, ensuring vibrant and accurate color representation critical for retail, healthcare, and hospitality settings. This is achieved through stringent LED binning using multi-phosphor high-CRI chips and rigorous in-line spectroradiometric testing. We further validate color consistency with TM-30-15 metrics, typically achieving Rf > 85 and Rg > 100, guaranteeing both fidelity and gamut balance. Every production batch undergoes spectrometer verification against ANSI C78.377 chromaticity requirements, with deviations held within a 3-step MacAdam ellipse.

IP ratings are rigorously applied based on application requirements. Indoor architectural lines carry IP20 as standard, with gasketed lens options for IP40 in dry locations. Our outdoor and wet-location linear systems are rated IP66 or IP67, achieved through seamless silicone gasketing at all joints, encapsulated drivers, and marine-grade aluminum housings. The IP67 variants undergo 30-minute submersion testing at 1 meter depth per IEC 60529, with zero ingress. Crucially, our IP67 designs maintain thermal performance through vented heat sinks with hydrophobic membranes, preventing condensation while allowing convection—addressing a common flaw in sealed competitive products. All outdoor fixtures include UV-stable polycarbonate lenses resistant to yellowing.

Beauty STC’s quality commitment is systemic, not incremental. We enforce ISO 9001-certified processes from chip procurement to final assembly, including 100% automated photometric testing and 100% burn-in validation at 45°C for 48 hours. Our LEDs are sourced exclusively from Tier-1 suppliers with LM-80+ reports, and we conduct in-house TM-21 lifetime validation showing L70 > 50,000 hours at 55°C ambient. Field reliability data from global installations demonstrates a failure rate below 0.5% at 36 months, attributable to over-engineered thermal pathways, conformal-coated PCBs, and surge-protected drivers meeting IEC 61000-4-5 standards. This holistic approach ensures every linear fixture delivers the promised lm/W, CRI, and IP performance throughout its operational life, without compromise.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province—a strategic location known for its robust industrial infrastructure and proximity to key supply chain networks in the Pearl River Delta. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products, with a strong emphasis on precision, efficiency, and reliability throughout the manufacturing process.

At the core of the production line is a fully automated SMT (Surface Mount Technology) system. The factory is equipped with advanced high-speed SMT machines capable of accurately placing small LED components and other electronic parts onto PCBs (printed circuit boards). These SMT lines are calibrated for consistent performance and support a wide range of LED lighting products, including flexible LED strips, rigid bars, and compact modules. The use of automated optical inspection (AOI) ensures that each board is thoroughly checked for placement accuracy and soldering quality, minimizing defects and enhancing overall product reliability.

To ensure long-term performance and durability, the factory implements rigorous aging tests as part of its quality control protocol. Completed LED lighting products undergo extended burn-in periods—typically 24 to 72 hours—under controlled temperature and electrical load conditions. This aging process helps identify early failures, verifies thermal management performance, and confirms the stability of light output and color consistency. In addition to aging, products are subjected to various environmental and electrical tests, including humidity resistance, IP rating verification, and surge protection testing, depending on the product specifications.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, particularly for LED linear lighting solutions. The company supports customized development of LED lines, including tailored lengths, color temperatures (from 2200K to 6500K), CRI values (up to 98), lumen outputs, beam angles, and housing designs. Clients can specify materials such as aluminum profiles, diffusers (PC or PMMA), and even smart control integrations like DALI, 0-10V, or Bluetooth/Zigbee compatibility. The engineering team works closely with partners from concept to mass production, offering design for manufacturing (DFM) feedback, prototyping, and full-scale production support.

Overall, the Jiangmen factory combines advanced automation, stringent quality assurance, and flexible customization to deliver reliable, high-performance LED lighting solutions for global markets. Its integrated manufacturing ecosystem enables Beauty STC to serve a diverse range of clients, from lighting brands to architectural specifiers, with scalable and efficient OEM services.

Application Scenarios

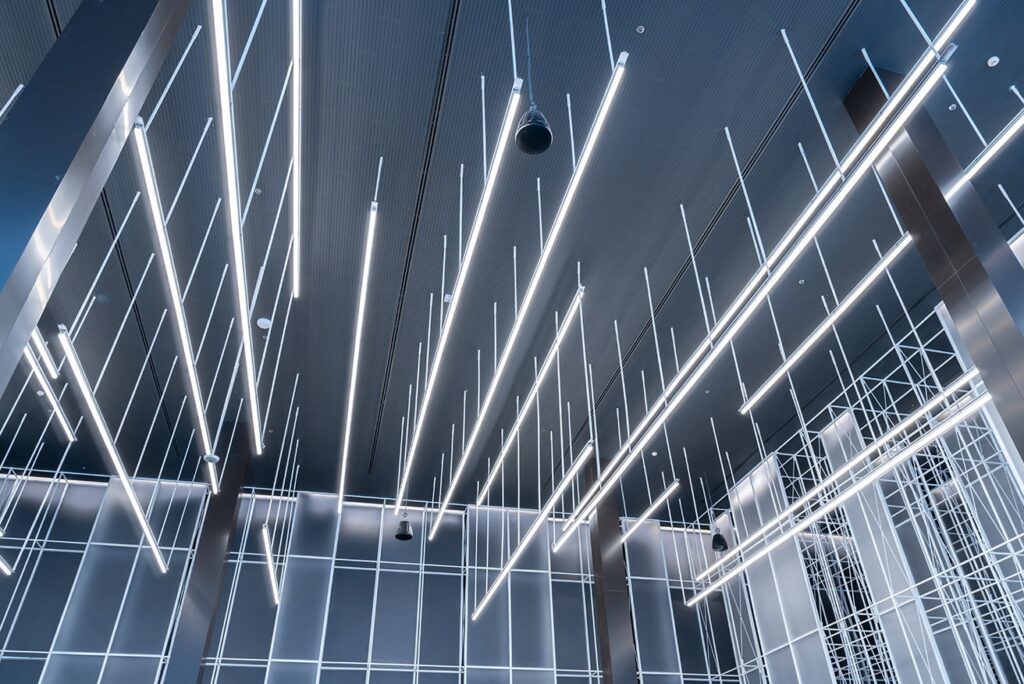

LED line lighting offers versatile solutions across hospitality, retail, and corporate environments due to its flexibility, energy efficiency, and ability to create both functional and atmospheric effects. In hotels, LED lines excel in lobbies for cove lighting along ceilings or reception desks to establish a warm, welcoming ambiance without harsh glare. Guest room applications include subtle under-cabinet lighting in minibars, indirect headboard illumination for relaxation, and step lighting within closets or bathrooms for safety. Hallways benefit significantly from LED lines installed within handrails or floor coves for gentle wayfinding, while pools and spas utilize waterproof IP68-rated lines for underwater edge lighting or perimeter cove effects. Vanity mirror perimeters in high-end bathrooms also leverage LED lines for shadow-free illumination.

Malls present opportunities for dramatic architectural enhancement and retail impact. Vertical LED lines within tall atriums draw the eye upward, emphasizing height and modernity. Retail storefronts and window displays employ narrow-profile LED lines to highlight merchandise edges or create dynamic backlighting effects, with color-tunable options adapting to seasonal promotions. Escalator safety is improved through integrated handrail lighting and step tread illumination. Corridors utilize linear runs along ceilings or columns for consistent, glare-free illumination guiding foot traffic, while food courts implement them above seating areas to define zones with varying color temperatures. Temporary event installations often feature color-changing LED lines for immersive thematic experiences.

Office environments prioritize both productivity and well-being. Under-cabinet task lighting at workstations reduces eye strain during focused work, while perimeter cove lighting in conference rooms provides adjustable ambient illumination suitable for presentations or collaborative sessions, often incorporating brand colors. Reception areas achieve a professional yet inviting feel through LED lines integrated into feature walls or reception desks. Break rooms and lounge zones use warmer temperature lines to encourage relaxation, and structural elements like columns or dropped ceilings gain visual interest through strategic linear accents that define space without overwhelming occupants.

Critical installation considerations begin with selecting fixtures rated for the specific environment IP65 for damp indoor areas like hotel bathrooms, IP67 or IP68 for submerged pool applications, and appropriate thermal management for enclosed spaces. Voltage drop must be meticulously calculated for long runs exceeding 5 meters; solutions include higher input voltage systems 24V or 48V over 12V, strategic power injection points every 5-10 meters, and using thicker gauge wiring. Thermal management is non-negotiable aluminum channels with sufficient mass and ventilation slots prevent lumen depreciation and color shift, especially in recessed coves. All wiring must comply with local electrical codes with certified low-voltage drivers housed in accessible locations. Waterproof connections require silicone-filled butt connectors or IP68-rated junction boxes in wet zones. Always conduct full system testing before final concealment to verify color consistency, dimming performance, and absence of flicker. Precise layout planning ensures seamless visual continuity with overlapping channel sections and concealed end caps to avoid dark spots or visible hardware.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED line solutions from Beauty STC. As a trusted manufacturer in the industry, we deliver reliable, energy-efficient, and innovative LED products tailored to meet diverse commercial and industrial needs. Partner with Beauty STC to benefit from our technical expertise, scalable production, and global support. For collaboration opportunities or product inquiries, contact us at [email protected] and take the next step toward superior lighting performance.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.