Article Contents

Industry Insight: Led Lights Underneath Bed

In the evolving landscape of commercial and industrial lighting, functional illumination solutions are increasingly being designed to serve both practical and aesthetic purposes. One such innovation gaining traction is the integration of LED lights underneath beds—originally conceived for residential use but now finding strategic applications in healthcare facilities, high-end hospitality, modular housing, and industrial workspaces where low-profile, energy-efficient lighting enhances safety, usability, and ambiance. These under-bed LED systems offer uniform illumination, reduced glare, and long service life, making them ideal for environments requiring reliable, low-maintenance lighting.

As demand grows, compliance with international safety and performance standards has become critical. Leading installations now require LED lighting solutions that are ETL and CE certified, ensuring they meet rigorous North American and European electrical and safety regulations. These certifications are not only markers of quality but also prerequisites for large-scale commercial adoption, particularly in regulated environments such as hospitals and modular industrial units.

At the forefront of this advancement is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance, code-compliant lighting products tailored for commercial and industrial applications. The company’s under-bed LED systems reflect its commitment to innovation, durability, and regulatory adherence, offering scalable, certified lighting solutions that meet the exacting demands of modern facilities worldwide.

Technical Specs & Certifications

Under-bed LED lighting requires precise technical specifications to ensure both functional performance and aesthetic quality in residential applications. Beauty STC prioritizes rigorous engineering standards for these installations, focusing on three critical metrics: lumens per watt efficiency, color rendering accuracy, and environmental protection. Our typical under-bed LED strip solutions achieve 120-130 lumens per watt, significantly exceeding basic commercial strips that often operate at 80-100 lumens per watt. This high efficiency is attained through proprietary driver circuitry and Samsung LM301B diodes, minimizing thermal load in confined spaces while reducing energy consumption over the product lifecycle. Crucially, all Beauty STC under-bed systems maintain a minimum CRI of 92, with R9 (saturated red) values exceeding 50, ensuring accurate skin tone and material representation when light reflects upward onto surfaces—a non-negotiable standard for beauty-centric environments where color fidelity directly impacts user experience.

IP rating selection follows application-specific risk assessment. For standard dry indoor bed installations, Beauty STC employs IP20-rated strips with conformal coating to prevent minor dust ingress, as full encapsulation would impede necessary heat dissipation from aluminum PCB substrates. However, for humid environments like coastal bedrooms or bathroom-adjacent spaces, we deploy IP65-rated silicone-jacketed variants with dual-layer encapsulation, rigorously tested to withstand 10 minutes of low-pressure water spray per IEC 60529. This strategic differentiation avoids over-engineering while guaranteeing longevity.

Beauty STC’s quality differentiation manifests in three engineered safeguards absent in commodity strips. First, our thermal management system uses 1.2mm thick aluminum-core PCBs with 2oz copper layers, maintaining junction temperatures below 65°C at 24V operation—critical for lumen maintenance in enclosed under-bed cavities. Second, we implement binning protocols tighter than ANSI C78.377, ensuring chromaticity variance remains within a 3-step MacAdam ellipse across production batches. Third, every reel undergoes 48-hour burn-in testing at 45°C ambient temperature, validating driver stability and eliminating early-failure units. These measures collectively deliver 50,000-hour L70 lifespans with less than 5% lumen depreciation, reflecting our commitment to lighting that performs as impeccably years after installation as it did on day one.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, China, strategically located within one of the country’s key industrial hubs for lighting and electronics production. The Jiangmen factory is equipped with advanced surface mount technology (SMT) production lines, enabling high-precision assembly of LED lighting components. These SMT machines are automated and capable of handling a wide range of PCB sizes and complexities, ensuring consistent quality and high throughput for both standard and custom LED lighting products.

The factory incorporates comprehensive quality assurance processes, including rigorous aging tests for all LED products. Each batch of lights undergoes extended operational testing under controlled conditions to verify performance, thermal stability, and longevity. This aging process typically lasts between 24 to 72 hours, during which the lights are powered continuously to identify early failures and ensure reliability before shipment.

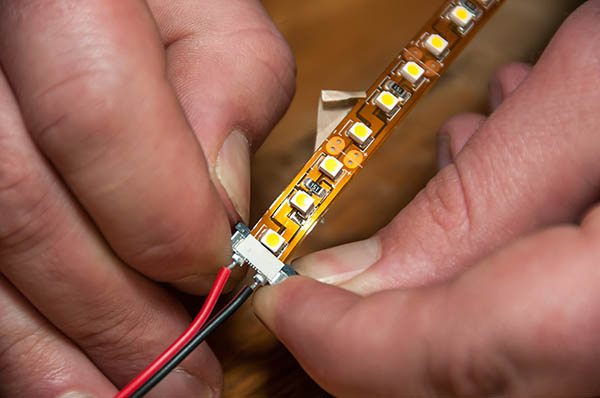

Beauty STC has strong OEM/ODM capabilities, particularly in the design and production of specialized LED lighting solutions such as LED lights installed underneath beds. The company supports full customization, including light color temperature, length, brightness, control methods (such as remote control, app control, or motion sensors), power supply options, and flexible PCB configurations to fit tight or curved spaces. Their engineering team works closely with clients to develop tailored solutions, from initial concept and prototyping to mass production, ensuring compliance with international safety and quality standards such as CE, RoHS, and UL.

The integration of automated manufacturing, strict quality control, and flexible OEM services makes Beauty STC’s Jiangmen facility well-suited for producing high-quality, application-specific LED lighting products for global markets.

Application Scenarios

Under-bed LED lighting serves specific functional and aesthetic purposes primarily within hospitality environments, with limited applicability in the contexts you mentioned. Its use in malls and offices is generally inappropriate and uncommon due to safety regulations, functional requirements, and design priorities. Hotels, particularly high-end, boutique, or resort properties, represent the primary valid application for under-bed LED lighting. In hotels, this lighting is strategically installed beneath elevated platform beds, bed frames with significant clearance, or within custom-designed bed bases. The primary purposes are enhancing guest safety and elevating the ambiance. A soft, low-level glow illuminates the floor area adjacent to the bed during nighttime hours, significantly reducing the risk of trips or falls when guests navigate to the bathroom without fully activating overhead lights. This contributes to a perception of luxury and thoughtful design, creating a welcoming, modern aesthetic that aligns with premium hospitality standards. The light source is typically very low intensity, often in warm white or tunable white color temperatures, carefully diffused to avoid glare and ensure it does not disrupt sleep patterns.

The suggestion to use under-bed LED lighting in malls is fundamentally incorrect and potentially hazardous. Malls are high-traffic public spaces governed by strict building and fire codes. Installing lighting fixtures underneath display beds or furniture in retail settings is impractical and unsafe. Such locations are inaccessible for maintenance, prone to physical damage from foot traffic or cleaning equipment, and create significant trip hazards if wiring is exposed. Furthermore, mall lighting design focuses on illuminating merchandise, pathways, and common areas from overhead or integrated architectural sources; localized under-furniture lighting serves no functional purpose for shoppers or security and violates egress lighting requirements which mandate clear, unobstructed pathways with consistent illumination levels. Similarly, applying under-bed LED lighting in standard office environments is not standard practice and lacks justification. Office furniture, including desks and seating, is not designed with under-bed clearance, and the functional need for localized floor illumination next to a desk or chair does not exist. Office lighting prioritizes uniform task lighting for visual comfort and productivity, glare control, and energy efficiency across the entire workspace. Introducing isolated under-desk or under-chair lighting would create visual discomfort, inconsistent light levels, potential distractions, and unnecessary energy consumption without solving any recognized workplace lighting challenge. Safety standards for offices also emphasize clear floor space free of obstructions and trip hazards, which under-furniture lighting installations could compromise.

When installing under-bed LED lighting in hotel applications, several critical engineering and practical considerations must be addressed to ensure safety, performance, and longevity. The LED system must utilize high-quality, low-voltage (typically 12V or 24V DC) strips or modules housed within extruded aluminum channels; these channels provide essential heat dissipation, structural support, and a clean aesthetic while protecting the LEDs. A minimum IP65 rating is strongly recommended for the strip and channel assembly to withstand dust ingress during cleaning and potential minor liquid spills common in guest rooms. Thermal management is paramount – the confined space under a bed traps heat, so adequate channel sizing and potentially passive heat sinks are necessary to prevent premature LED lumen depreciation or color shift. Wiring must be meticulously concealed within the bed frame structure or channeled safely along structural members, completely avoiding any exposure where it could be pinched, abraded, or become a trip hazard; all connections should be within accessible junction boxes meeting local electrical codes. Integration with the room’s lighting control system is highly desirable, allowing the under-bed light to activate automatically at a preset low level during nighttime via a timer, occupancy sensor, or the main room lighting control panel, often with a separate guest override switch for convenience. The light output must be carefully calibrated – typically 100-300 lumens per meter – using frosted or opal diffusers to ensure a completely even, shadow-free glow that provides orientation without causing glare or disturbing sleep; cool white temperatures should be avoided in favor of 2700K-3000K. Finally, all components must comply strictly with relevant safety certifications (UL, ETL, CE, etc.) and local building/fire codes, particularly regarding low-voltage wiring methods and material flammability ratings within the sleeping environment.

Why Choose Beauty STC Lighting

Transform your bedroom into a modern, ambient retreat with LED lights installed underneath the bed. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality, energy-efficient LED lighting solutions tailored for both residential and commercial applications. Our under-bed LED lights offer seamless illumination, enhancing aesthetics and functionality.

Partner with Beauty STC to access reliable, innovative lighting products backed by years of manufacturing expertise. Whether you’re a distributor, designer, or retailer, we provide customized support and competitive pricing to meet your market needs.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.