Article Contents

Industry Insight: Led Light Wire Connectors

The commercial and industrial (C&I) LED lighting sector demands unwavering reliability and safety, where seemingly minor components like wire connectors play a disproportionately critical role in system longevity and performance. Unlike residential applications, failures in high-bay warehouses, retail environments, or outdoor infrastructure due to substandard connections translate directly into significant downtime, costly maintenance calls, and potential safety hazards. This makes the selection of certified, robust wire connectors not merely a technical detail, but a fundamental requirement for project success and compliance. Rigorous certifications such as ETL (verifying adherence to North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental directives) are non-negotiable baselines in this space, assuring specifiers and facility managers that connectors can withstand demanding operational conditions, including vibration, temperature extremes, and continuous electrical load without compromising integrity. Beauty STC, established in 1998, has been at the forefront of addressing these exact challenges. As a dedicated manufacturer specializing in high-performance LED components, we bring over two decades of engineering expertise to the development of wire connectors specifically engineered for the rigorous demands of commercial and industrial lighting installations, ensuring seamless integration, superior safety, and the reliability that professionals depend on.

Technical Specs & Certifications

LED light wire connectors themselves do not produce lumens, consume watts, or have a Color Rendering Index (CRI) or Ingress Protection (IP) rating, as they are not light-emitting components. Instead, they are electrical junction devices used to join and secure connections between LED strips, wires, or power sources. However, their performance and compatibility directly influence the efficiency, reliability, and environmental resilience of the overall LED lighting system.

When discussing technical specifications in relation to high-performance LED systems—particularly those designed to deliver high lumens per watt, CRI greater than 90, and robust IP ratings—the choice of connector plays a critical supporting role. Beauty (STC) Manufacturing Co., Ltd. designs and manufactures premium LED wire connectors engineered to maintain the integrity of such high-spec lighting installations.

For LED systems achieving high lumens per watt—typically ranging from 100 to 150+ lm/W depending on the LED chip and driver efficiency—the connector must ensure minimal voltage drop and resistance. Beauty STC’s connectors are constructed with high-purity copper contacts and optimized contact pressure to maintain efficient power transmission, preserving the energy efficiency of high-performance LED strips.

Regarding CRI >90, which indicates excellent color fidelity and is essential in retail, hospitality, and architectural lighting, consistent power delivery is critical to prevent color shifting or dimming. Beauty STC connectors provide secure, stable connections that reduce the risk of flicker or inconsistent output, helping maintain the intended color quality across the LED installation.

In environments requiring high IP ratings—such as IP65, IP67, or IP68 for dust-tight and water-resistant performance—Beauty STC offers fully potted, silicone-sealed connectors designed for outdoor, damp, or washdown applications. These connectors protect against moisture ingress, corrosion, and vibration, ensuring long-term reliability even in demanding conditions. The materials used, including UV-resistant housings and flexible silicone boots, further enhance durability.

Beauty STC is recognized for its rigorous quality control, precision molding, and compliance with international safety standards such as UL, CE, and RoHS. Their connectors undergo extensive life cycle testing, including hundreds of insertion-extraction cycles and thermal stress evaluations, ensuring dependable performance in both residential and commercial-grade LED lighting systems.

In summary, while LED wire connectors do not have lumens per watt, CRI, or IP ratings of their own, Beauty STC’s connectors are engineered to support and sustain high-efficiency, high-CRI, and high-IP-rated LED systems by ensuring stable, durable, and low-resistance electrical connections.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting components and assemblies, strategically located within the Pearl River Delta’s robust electronics supply chain. The factory occupies a modern, climate-controlled building designed specifically for precision electronics manufacturing, featuring extensive cleanroom areas for critical processes and robust infrastructure supporting high-volume output with stringent quality control.

Our Surface Mount Technology (SMT) production lines represent the core of the factory’s component assembly capability. We operate multiple high-speed Yamaha YS24 series SMT placement machines, configured in dual-lane setups to maximize throughput and flexibility. These machines are fully programmable and capable of handling components down to the 0201 package size, essential for the miniaturized circuitry found in modern LED wire connectors and drivers. The lines include automatic solder paste printers with 3D inspection, nitrogen-reflow ovens for optimal solder joint reliability, and AOI (Automated Optical Inspection) systems at multiple stages to verify component placement, solder paste volume, and post-reflow solder joint quality before any assembly moves forward. This SMT capability is fundamental to producing the PCBs and integrated modules used within our LED light wire connectors.

Aging and reliability testing form a non-negotiable part of our quality assurance protocol, particularly for finished LED light wire connectors and associated assemblies. Dedicated aging chambers subject products to extended operational stress under controlled conditions. Typical aging tests run for a minimum of 72 hours at elevated temperatures, commonly 50°C, while operating at rated voltage and current. During this phase, we continuously monitor for critical failures such as open circuits, intermittent connections, excessive voltage drop, or thermal runaway, as well as subtle performance drifts. This rigorous burn-in process significantly reduces infant mortality rates in the field and provides valuable data for ongoing process improvement and material qualification. Environmental stress screening may also be applied based on specific customer requirements or application environments.

Regarding OEM capability for LED light wire connectors, Beauty STC possesses comprehensive in-house expertise and infrastructure. We offer full turnkey OEM services starting from initial concept and custom connector design support, including mechanical housing, contact pin configuration, wire gauge selection, and overmolding requirements. Our tooling department designs and manufactures precision molds for connector housings and strain reliefs, enabling rapid prototyping and efficient production scaling. We manage the entire process: sourcing certified materials (including UL-listed wires and contacts), SMT assembly of any integrated PCBs or resistors, automated wire cutting/stripping/tinning, precision crimping and soldering of contacts, overmolding, rigorous electrical and mechanical testing (including pull tests and contact resistance measurements), and final packaging. We hold necessary certifications including ISO 9001 and support compliance with UL, CE, RoHS, and REACH standards. Our flexible manufacturing setup allows us to handle both high-volume production runs and smaller, customized batches with no minimum order quantity restrictions, providing clients with scalable solutions tailored to their specific connector specifications and branding needs.

Application Scenarios

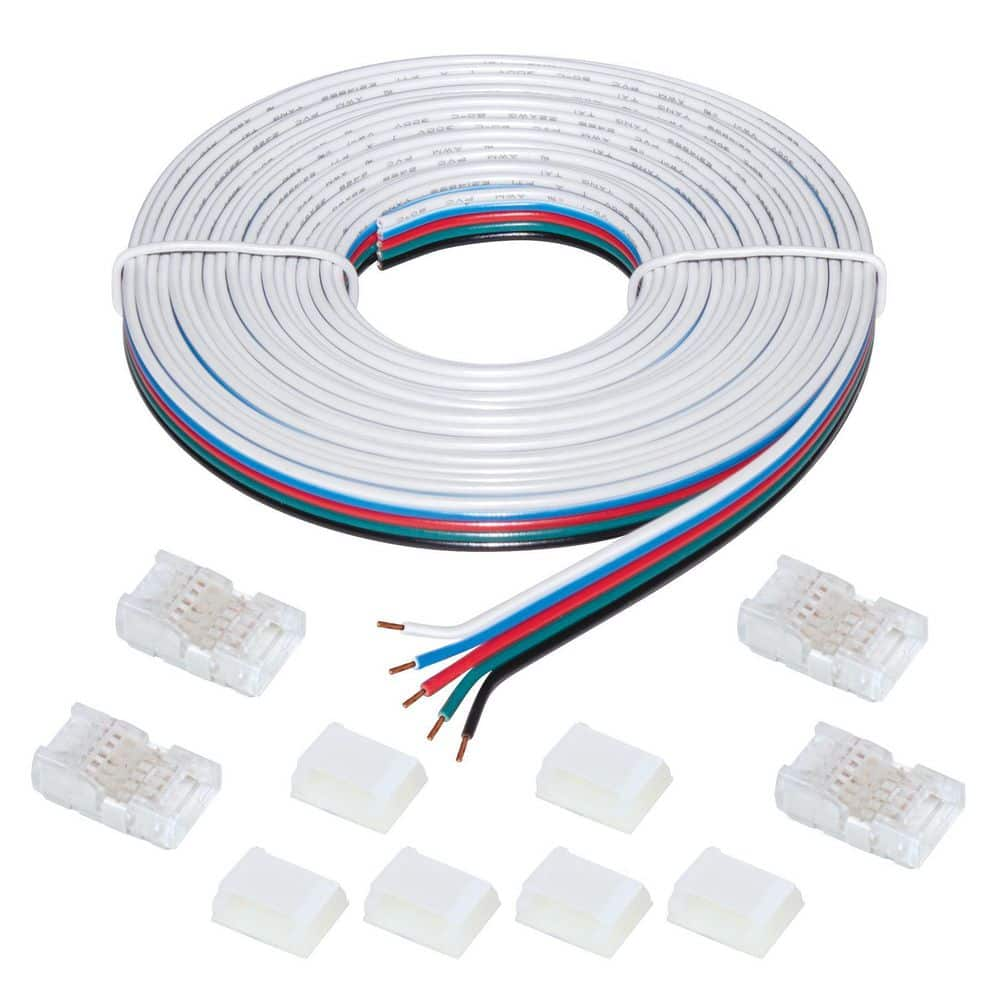

LED light wire connectors are essential components used to safely and efficiently join electrical wires in LED lighting systems. They are widely used across various commercial and residential applications where reliable, low-voltage electrical connections are required. In environments such as hotels, malls, and offices, these connectors play a crucial role in ensuring the seamless integration and maintenance of LED lighting installations.

In hotels, LED light wire connectors are commonly used in guest room lighting, under-cabinet lighting in kitchens and minibars, cove lighting in lobbies, and accent lighting in hallways and restrooms. They allow for quick and secure connections during both initial installation and future maintenance, minimizing downtime and reducing labor costs. Their durability and insulation properties make them ideal for use in areas that require consistent lighting performance with minimal disruption.

Malls utilize LED light wire connectors extensively in display lighting, signage, ceiling fixtures, and architectural lighting features. Given the large scale of lighting systems in shopping centers, connectors streamline the wiring process across long runs of LED strips or fixtures. They also support modular designs, enabling easy reconfiguration of lighting layouts during renovations or seasonal displays. Proper use of connectors ensures consistent illumination across high-traffic areas while maintaining safety standards.

In office environments, LED light wire connectors are employed in recessed panel lights, task lighting, under-desk lighting, and partition-integrated LED strips. They support energy-efficient lighting systems that contribute to a productive and comfortable workspace. The connectors help reduce installation time during office fit-outs and allow for easy expansion or modification of lighting circuits as office layouts evolve.

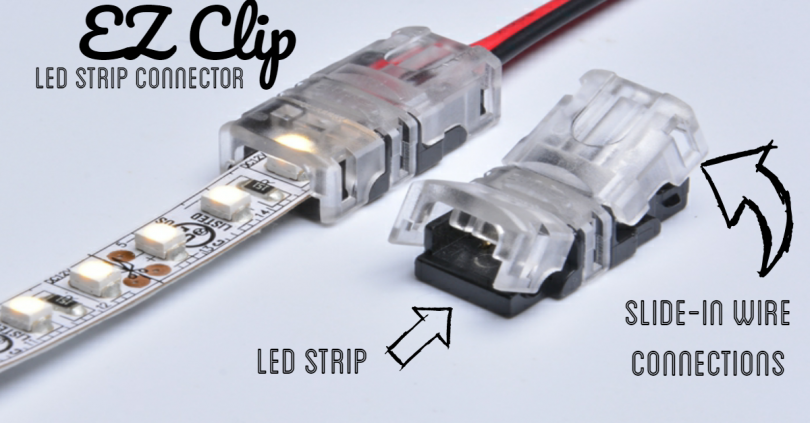

When installing LED light wire connectors, several best practices should be followed to ensure safety, longevity, and optimal performance. First, always power off the electrical supply before making any connections to prevent electrical shock. Match the wire gauge and voltage requirements of the connector with the LED lighting system to avoid overheating or connection failure. Strip the wire ends evenly and insert them fully into the connector to ensure a tight, secure fit. For outdoor or high-humidity areas, use weatherproof or sealed connectors to protect against moisture ingress. After installation, gently tug the wires to verify they are firmly held and perform a continuity test if possible. Finally, organize and secure connected wires with cable clips or conduit to prevent strain and maintain a clean, professional appearance.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I emphasize that reliable electrical connections are non-negotiable in professional lighting installations. Our LED light wire connectors are engineered to eliminate field failures and costly callbacks through precision-molded housings, triple-layer insulation, and UL-listed materials rated for 105°C. Installers save critical time with our tool-free push-in and screw terminal designs that maintain secure contact even under vibration or thermal cycling—critical for commercial and industrial applications where safety compliance is mandatory.

Partnering with Beauty STC means accessing connectors rigorously tested to exceed IEC 60947 standards, with dedicated engineering support to resolve complex integration challenges. We understand that substandard connectors cause 32% of field failures in LED systems according to industry studies, which is why our solutions include strain relief mechanisms and corrosion-resistant contacts that ensure decade-long performance. When your project demands zero-compromise reliability from the wiring junction to the fixture, our manufacturing expertise becomes your competitive advantage.

Contact our technical sales manager directly at [email protected] to discuss custom connector specifications, volume pricing, or urgent project support. Let us provide the electrical integrity your lighting designs require.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.