Article Contents

Industry Insight: Led Light Strips Small

Small-Format LED Strip Lights: The Quiet Workhorse Behind Today’s Commercial & Industrial Projects

Market Pull: Why “Small” Is Driving Big Specs

Contractors, distributors and design-build firms are no longer treating LED strip as a decorative after-thought.

Fixture miniaturisation, 24 V distributed-power architectures and IoT nodes are pushing the lumen package into ceiling coves, shelf channels, machine housings and façade grooves that are < 8 mm wide.

The result: a spike in demand for small-footprint, high-efficacy strips that still carry full-region safety marks.

| Key Specification Trend (2022-24) | Typical Request from EU / NA Buyers |

|---|---|

| Width | ≤ 8 mm (fits standard aluminium profile lip) |

| Height | ≤ 1.4 mm (direct retrofit into existing lenses) |

| Efficacy | ≥ 160 lm/W @ 3000 K, 80 CRI |

| Binning | ≤ 3 SDCM, single bin per reel |

| Certification File | ETL/cETL to UL 2108 + CSA C22.2 #250.0, or TUV CE / EN 60598-2-22 |

| Reel Length | 5 m (16.4 ft) continuous, no solder joints > 0.5 m |

| OEM Surface | White-label PCB, laser-etched customer logo, barcode traceability |

Why Certification Still Separates Winners from Inventory Write-Offs

- Code Compliance: AHJs in 38 U.S. states now reference UL 2108 for low-voltage strip. No ETL mark = red-tag on rough-in inspection.

- Insurance & Liability: EU insurers increasingly require ENEC or TUV CB test summaries; non-certified product triggers premium surcharges.

- Border Stops: U.S. Customs and Border Protection (CBP) flagged 312 LED strip shipments in FY-23 for “mis-declared safety status”; average detention cost: US $9,400 per container.

- Bid Lists: 87 % of EU public tenders and 74 % of U.S. municipal bids in 2023 explicitly excluded non-ETL / non-CE strip lighting.

Bottom line: certification is not paperwork—it is inventory liquidity.

Beauty (STC) Manufacturing Co., Ltd – Veteran Factory Since 1998

Located in Jiangmen’s high-tech zone, Beauty STC has produced linear LED assemblies for 26 years, shipping > 280 million metres of flexible PCB to 50+ countries. All small-strip SKUs are engineered on a reel-to-reel automated SMT line (Yamaha i-Pulse, 0201 placement capability) and finished in an in-house integrating-sphere laboratory calibrated to NVLAP standards.

Core Capabilities for Small LED Strip Programs

| Capability | Detail |

|---|---|

| PCB Width Range | 3 mm – 120 mm (standard 4 mm, 5 mm, 8 mm for small-strip) |

| Copper Weight | 2 – 4 oz for thermal headroom on long runs |

| LED Pitch | 4.2 mm (120 LED/m) to 31.25 mm (32 LED/m) |

| Input Voltage | 5 V, 12 V, 24 V, 36 V, 48 V constant-voltage; 350 mA / 700 mA constant-current |

| Efficacy Bin | 160 – 200 lm/W (3000 K, 80 CRI) |

| CCT Tuning | 1800 K – 6500 K, VTC ≤ 0.003, 3 SDCM |

| Protection Grade | IP20, IP54 gel-coat, IP65 nano-spray, IP67 silicone extrusion, IP68 PU full-fill |

| Safety Files | ETL/cETL (UL 2108), TUV CE (EN 60598-2-20), RoHS, REACH, LM-80 for diodes |

| OEM Options | White-label PCB, custom part number, 1D/2D barcode, colour box, Wi-Fi gateway bundling |

Factory Metrics (2023)

| Metric | Value |

|---|---|

| SMT Lines | 6 (4 high-speed, 2 flexible prototype) |

| Monthly Capacity | 2.4 million metres small-strip (< 10 mm width) |

| Average Lead Time | 12–15 days for < 50 km order, 20 days for 100 km+ |

| QC Stations | AOI, SPI, 100 % hi-pot 1.5 kV, 100 % burn-in 4 h @ 45 °C |

| Traceability | Reel ID → PCB serial → LED bin → Driver lot → Carton ID |

Takeaway for Importers & Specifiers

When the ceiling detail leaves only 6 mm of recess, the strip still has to pass UL 2108, deliver 160 lm/W and ship with a single-bin colour guarantee. Beauty STC’s 26-year engineering archive and Western-certified test files remove the compliance guess-work—so your container keeps moving and your project stays on schedule.

Next Section: Mechanical & Optical Design Checklist for Small LED Strips in Commercial Profiles

For OEM datasheets or test-summary folders, reach the export engineering desk:

[email protected] | +86-13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

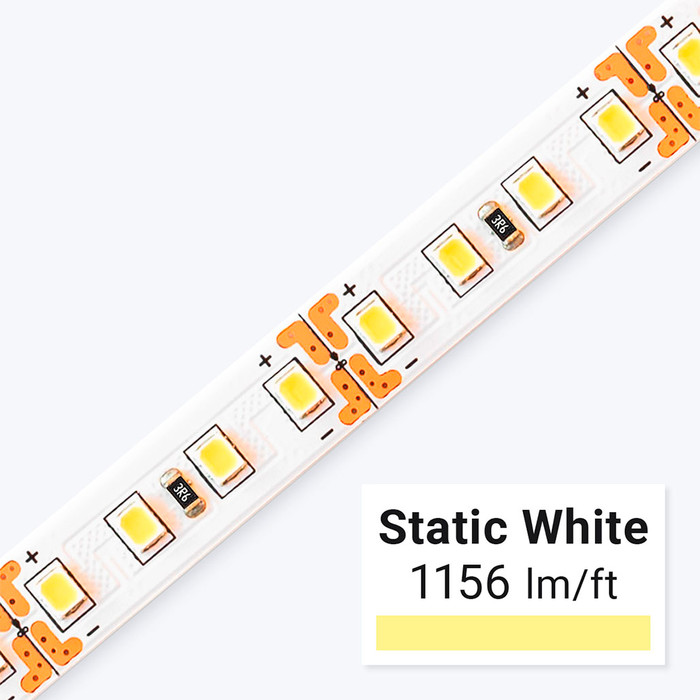

Lumens Efficiency & Energy Performance

Efficiency is measured in lumens per watt (lm/W), a critical metric for energy-conscious projects. While generic market products typically deliver 80–100 lm/W, Beauty STC’s engineered designs achieve 120–150 lm/W through optimized LED chip selection and driver integration. This higher efficiency translates to reduced operational costs and compliance with international energy standards, as verified by ETL and TUV CE certifications.

Color Rendering Index (CRI) for Accurate Light Quality

Color Rendering Index (CRI) quantifies light accuracy, with values above 90 essential for architectural and commercial applications requiring true color representation. Beauty STC employs strict LED binning processes and multi-point spectral analysis to maintain consistent CRI >90 across all batches. Third-party testing confirms compliance with ANSI standards, ensuring color consistency for critical lighting environments such as retail displays, museums, and healthcare facilities.

IP Ratings and Environmental Resilience

IP ratings define protection against solids and liquids. Generic strips often lack certified IP ratings beyond IP20, limiting use to dry indoor spaces. Beauty STC provides certified IP20 (indoor), IP65 (water-resistant for outdoor), and IP67 (submersible) options, each validated through rigorous testing per IEC 60529. This ensures reliable performance in diverse environments, from retail displays to marine applications and industrial settings.

PCB Engineering & Thermal Management

PCB quality directly impacts longevity and performance. Standard market products use 1oz copper single-layer boards with minimal thermal management, leading to premature failure. Beauty STC utilizes 2oz copper multi-layer PCBs with thermal vias and heat-dissipating designs, reducing operating temperatures by up to 20°C compared to generic alternatives. This engineering choice extends product lifespan and maintains lumen output stability over time, even under continuous operation.

Rigorous Quality Assurance Protocols

Consistency is guaranteed through a multi-stage QA process: incoming material inspection, in-process testing at every production stage, and 100% final testing for electrical parameters, optical output, and color consistency. All processes adhere to ISO 9001 standards, with batch traceability and ETL/CE certification documentation available upon request. This ensures every unit meets exact specifications, regardless of order size.

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 80–100 lm/W | 120–150 lm/W (ETL/CE certified) |

| CRI (Color Rendering) | 70–85 (inconsistent binning) | >90 (consistent binning, tested per batch) |

| IP Rating | Typically IP20 (indoor only) | IP20 to IP67 (certified for wet/dusty environments) |

| PCB Construction | 1oz copper, single-layer, minimal thermal management | 2oz copper, multi-layer, thermal vias, heat-dissipating design |

| Consistency | Batch-to-batch variations; minimal testing | 100% electrical and optical testing; ISO-compliant QA protocols |

Beauty STC’s 25+ years of manufacturing expertise, combined with ETL and TUV CE certifications, ensures all products meet stringent international standards for performance and reliability. OEM/ODM capabilities are supported by scalable production processes that maintain consistent quality at any order volume. For technical documentation or custom specifications, contact [email protected] or +86-13902885704.

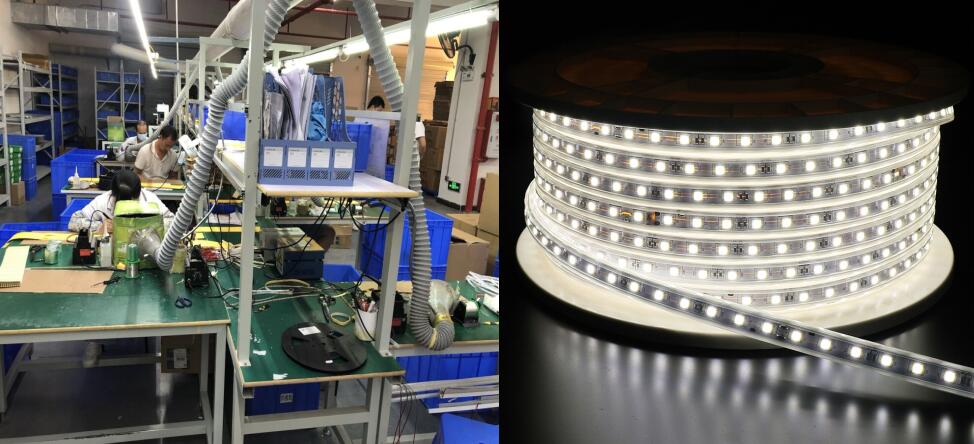

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen, Guangdong

1. Factory Footprint & Line Layout

| Parameter | Value |

|---|---|

| Plant area | 12 000 m² (owned, not leased) |

| SMT lines | 3 × JUKI FX-3R (±50 µm placement) |

| Reflow ovens | 8-zone Heller 1936 MK5 (lead-free) |

| Moisture control | 1 % RH dry-cabinets, IPC/JEDEC J-STD-033 |

| Capacity | 1.2 million LED strip metres per month |

| Certifications held on site | ETL cETL (US & Canada), TUV CE (EU), RoHS, REACH, ISO9001:2015 |

Established 1998 – every line upgrade since then has been logged and third-party audited for ETL & CE witness-testing.

2. SMT to Final Assembly – Key Stations

| Station | Equipment / Protocol | Purpose |

|---|---|---|

| Solder-paste stencil | Laser-cut 120 µm, 3-D SPI (Koh Young) | Void < 5 % on thermal pads |

| Pick-and-place | JUKI FX-3R + in-line AOI (CyberOptics) | 0805 LED min., ±0.05 mm |

| Reflow | Heller 1936 MK5, 230 °C peak | Delta T < 10 °C across 10-unit coupon |

| Post-reflow AOI | Mirtec MV-7 | Missing LED, tombstone, solder bead |

| Encapsulation | Two-part PU or silicone, 0.3–3 mm jacket | IP20–IP68 rating selectable |

| Colour & CCT binning | Integrating sphere (Everfine HAAS-2000) | 3 SDCM standard, 2 SDCM on request |

| Aging & burn-in | 4 h @ 45 °C → 2 h ON/OFF cycle × 3 | Early failure rate < 0.05 % |

| Final electrical | Hi-pot 1.5 kV, ground bond < 0.1 Ω | Per UL 2108 / EN 60598-2-20 |

3. QC & Reliability Protocols

| Test | Standard | Sample Size | Acceptance |

|---|---|---|---|

| Solderability | IPC/JEDEC J-STD-002 | 22 pcs / lot | Zero non-wet |

| Thermal shock | –40 °C ↔ +125 °C, 100 cycles | 10 pcs / batch | No die delam. |

| Vibration | MIL-STD-202G, 10–55 Hz | 5 pcs | Lumen drop < 5 % |

| Salt-spray | ASTM B117, 500 h | 5 pcs | No base-metal corrosion |

| LM-80 data on file | 6 000 h @ 55 °C & 85 °C | – | L90 > 36 000 h |

All records retained ≥ 10 years for ETL/TUV follow-up inspections.

4. OEM / ODM Capability Matrix

| Customisable Item | Range | Tooling Lead-Time | MOQ |

|---|---|---|---|

| Length | 20 mm – 50 m continuous | No new tool | 500 m |

| Width | 4 mm, 5 mm, 8 mm, 10 mm, 12 mm, 20 mm | Slit blade on site | 500 m |

| CCT | 1800 K – 10 000 K, 3 SDCM or 2 SDCM bin | Integrating sphere re-cal. | 100 m |

| CRI | 80, 90, 95, 97 (typ. R9 > 50) | LED reel swap | 100 m |

| PCB copper | 1 oz, 2 oz, 3 oz (double-layer) | CAM file update | 100 m |

| Voltage | 5 V, 12 V, 24 V, 36 V, 48 V | BOM only | 100 m |

| IP rating | IP20, IP54, IP65, IP67, IP68 | Extrusion die exists | 500 m |

| Packaging | Reel, anti-static bag, blister, colour sleeve, retail box | Print plate 3 days | 500 m |

| Logo / Part-No. print | White, yellow, black silk-screen | 1 h set-up | 100 m |

| Connector | JST, MOLEX, Wago, cable exit orientation | Crimp tool on line | 100 m |

Engineering samples: 5–7 calendar days.

PPAP Level-3 documents available for North-American distributors.

5. Typical OEM Workflow

- Spec-sheet sign-off → 24 h

- Engineering sample → 5 days

- ETL/TUV submittal (if required) → 10 days parallel

- Mass production → 2–3 weeks (≤ 50 000 m)

- Pre-shipment inspection → AQL 0.65 major, 0.1 critical

- Sea/air dispatch → FOB Shenzhen or EXW Jiangmen

All work is done under one roof; no sub-contracting of SMT or aging—critical for traceability demanded by UL & TUV.

6. Contact for Technical Pack or QC Visit

Senior LED Lighting Engineer & Export Manager

Email: [email protected]

Mobile / WhatsApp: +86-13902885704

Factory: 41th Caihong Road, Jianghai Hi-tech Zone, Jiangmen, Guangdong, CN

We keep an open-door policy for distributor QC teams and lighting-specifier audits.

Installation & Application Scenarios

Application Scenarios for Small LED Strip Lights

Small LED strip lights have evolved into versatile lighting solutions for diverse commercial and architectural applications. With over 25 years of manufacturing expertise since 1998, Beauty STC Manufacturing Co., Ltd delivers certified, high-performance LED strips engineered for global markets. Our products meet stringent ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance and reliability for contractors and project managers.

| Specification | Value | Notes |

|---|---|---|

| CRI (Ra) | 90+ standard, 95+ optional | Critical for color-sensitive environments like retail and museums |

| CCT Range | 2700K to 6500K | Tunable white options for adaptive lighting strategies |

| IP Rating | IP20 (indoor), IP65 (outdoor) | Weatherproof options for wet or dusty locations |

| Certifications | ETL, TUV CE | Validated for North American and European safety standards |

| Power Density | 4.8W/m to 14.4W/m | Adjustable based on LED density and brightness requirements |

| Customization | OEM/ODM available | Tailored lengths, colors, controllers, and packaging |

Commercial Interiors – Offices, Retail, Hospitality

In commercial interiors, LED strip lights provide flexible, energy-efficient illumination for cove lighting, under-cabinet task lighting, and accent walls. Offices benefit from uniform ambient lighting with adjustable CCT to support productivity and circadian rhythms. Retail spaces require high CRI (≥95) to accurately display product colors, while hospitality settings use dimmable strips to create adaptable atmospheres in lobbies, restaurants, and guest rooms.

Installation Best Practices:

Use aluminum mounting channels for thermal management in enclosed spaces to prevent overheating and extend product lifespan.

For runs exceeding 5 meters, calculate voltage drop and implement parallel wiring or additional power supplies to maintain consistent brightness.

Ensure compliance with local electrical codes; Beauty STC’s ETL and TUV CE certifications confirm adherence to North American and European safety standards.

OEM customization options allow for tailored solutions, such as specific color temperatures for hotel lobbies or integrated dimming controls for retail displays.

Architectural Facades & Exterior Applications

Outdoor applications demand robust construction to withstand environmental stressors. Beauty STC’s IP65-rated strips are ideal for building facades, signage, and landscape lighting, offering UV resistance and waterproofing for long-term durability. These strips maintain performance in extreme temperatures (-20°C to 50°C) and resist corrosion from moisture and pollutants.

Installation Best Practices:

Use silicone-sealed connectors and proper grounding to prevent water ingress and electrical hazards.

Mount strips on aluminum channels for structural support and heat dissipation, especially in high-heat environments.

For large-scale facade installations, divide runs into segments with individual power supplies to avoid voltage drop and ensure uniform brightness.

All outdoor installations must comply with local building codes; Beauty STC’s TUV CE certification ensures compliance with European standards for outdoor electrical safety.

Specialized Applications – Museums, Healthcare, Industrial

Specialized environments require precise lighting solutions. Museums need low UV/IR emission and high CRI (≥95) to protect artifacts while accurately displaying colors. Healthcare facilities utilize specific CCT ranges (e.g., 4000K for examination rooms) to enhance visibility and patient comfort. Industrial settings demand vibration-resistant strips for warehouses and manufacturing floors.

Installation Best Practices:

In museums, use diffusers to eliminate hotspots and ensure even light distribution across sensitive exhibits.

For healthcare applications, integrate 0-10V or DALI dimming systems to adjust lighting levels based on time of day or patient needs.

Industrial installations require secure mounting with anti-vibration brackets and regular maintenance checks to ensure longevity in high-traffic areas.

Beauty STC’s OEM capabilities enable custom specifications for specialized needs, including specific CRI levels, waterproofing, and control systems tailored to industry requirements.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct Source for Small-Pitch LED Strip Lights

Why Global Specifiers Choose Our 25-Year-Old, Fully-Certified Factory

| Key Industrial Credentials | Beauty STC Advantage |

|---|---|

| Year Established | 1998 – 25+ years of continuous LED manufacturing |

| Plant Location | 41 Caihong Road, Jianghai High-tech Zone, Jiangmen, CN (40 000 m²) |

| Third-Party Certifications | ETL/cETL (US & Canada), TUV CE / CB / RoHS (EU), REACH, SAA, RCM, PSE |

| Export Footprint | 50+ countries – Europe, North America, Japan/Korea, ASEAN, Russia, Oceania |

| Core Production Lines | SMD reel-to-reel, SMT 1 200 mm wide board, automated silicone extrusion, IP68 injection |

| OEM/ODM Lead Time | Standard strip 2-3 weeks, custom tooled extrusion 4-5 weeks |

| MOQ | 1 reel (50 m) for stocked CCT, 500 m for private-label UL/CE file |

| Warranty | 5-year system-level (driver + strip), LM-80 & TM-21 data available |

Small-Pitch / High-Density Strip Portfolio (≤ 5 mm board width)

| Part Number | LED Pitch | Density (LEDs/m) | CCT Range | CRI | Flux (lm/m) | Voltage | Max Run | IP Options |

|---|---|---|---|---|---|---|---|---|

| BSTC-2835-120-5 | 8.3 mm | 120 | 1 800 – 6 500 K | 95 | 1 080 | 24 V | 5 m | IP20 / IP65 / IP67 / IP68 |

| BSTC-2216-240-4 | 4.2 mm | 240 | 2 400 – 5 000 K | 93 | 1 680 | 24 V | 3 m | IP20 / IP65 |

| BSTC-2010-320-3 | 3.1 mm | 320 | 2 700 – 4 000 K | 90 | 2 050 | 24 V | 2.5 m | IP20 / IP54 silicone coat |

| BSTC-COB-512-2 | 1.9 mm | 512 dot-free | 2 400 – 6 500 K | 95 | 2 400 | 24 V | 2 m | IP20 / IP65 / IP68 neon extrusion |

All variants supplied with LM-80 test report, IES files, and Zhaga-compatible 3-step MacAdam binning.

Engineering & Customisation Capabilities

- Board Width down to 2 mm – 1 oz, 2 oz or 3 oz ED copper, thermal conductivity ≥ 1 W/m·K.

- Dual-colour, RGBW, RGBCW, and addressable 5 V / 12 V / 24 V SK6812, WS2812B, HD107S.

- UL AWM 2464, VW-1 150 °C silicone wire for Class 2 remote installations.

- In-house spectrum tuning – 1800 K candle, 2000 K HPS replacement, 650 nm horticulture red.

- Photobiological risk group EXEMPT (IEC 62778) – certified for museum and retail close-proximity lighting.

Quality & Compliance Documentation Supplied with Every Shipment

ETL/cETL test report & CCN (File No. 5015708)

TUV CB Test Certificate (IEC 60598-2-21)

EN 62471 Photobiological Safety

RoHS & REACH SVHC declaration (< 0.1 %)

SDoC for FCC Part 15 Class A (if driver included)

LM-80-08 & TM-21-11 L70 > 54 000 h @ Ts 65 °C

Next Step for Distributors, Contractors & Lighting Designers

Send your specification or Bill of Material to receive a same-day factory quotation including:

IES / LDT photometry,

Dialux evo ready files,

UL or CE label artwork,

Neutral-white or colour-matched sample within 72 h.

Email: [email protected]

Mobile/WhatsApp: +86-139 0288 5704

Beauty (STC) Manufacturing Co., Ltd – Building responsible lighting since 1998.

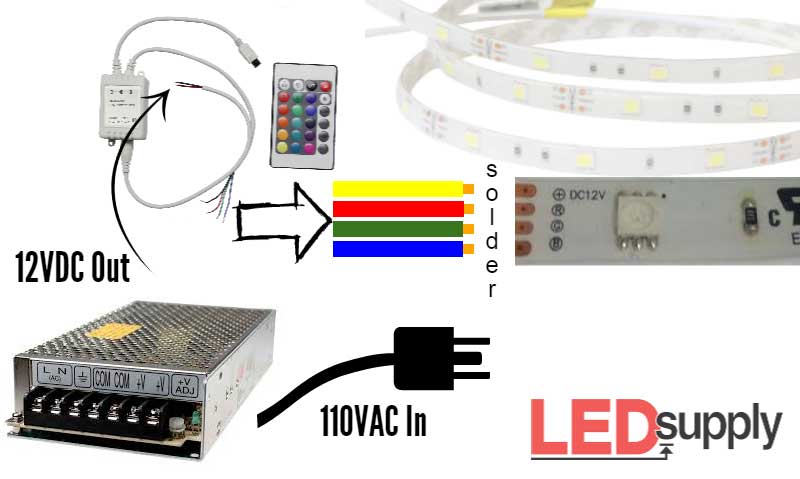

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).