Article Contents

Industry Insight: Led Light Strips Brightest

In the rapidly evolving landscape of commercial and industrial lighting, LED light strips have emerged as a cornerstone technology, driving energy efficiency, design flexibility, and long-term cost savings. As demand grows for high-performance illumination in warehouses, manufacturing facilities, retail environments, and architectural applications, the need for the brightest, most reliable LED strip solutions has never been greater. Leading this innovation are products engineered not only for maximum lumen output but also for compliance with rigorous international safety and performance standards—specifically ETL and CE certifications—which ensure reliability, electrical safety, and suitability for use across North American and European markets.

At the forefront of this advancement is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of expertise, Beauty STC has built a reputation for delivering high-intensity, durable LED strip lighting tailored to the demanding requirements of commercial and industrial environments. Combining cutting-edge thermal management, high-efficiency LED chips, and strict adherence to ETL and CE standards, Beauty STC’s brightest LED light strips offer unparalleled performance, longevity, and peace of mind for engineers, facility managers, and lighting designers alike.

Technical Specs & Certifications

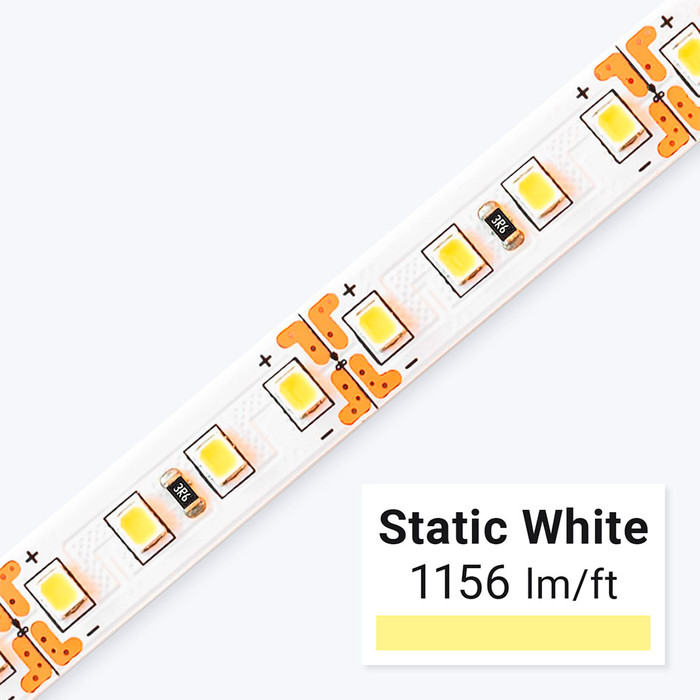

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED light strips engineered for demanding applications where brightness, color accuracy, and reliability are critical. Our premium strips achieve industry-leading specifications through rigorous component selection and thermal management. For the highest lumen output while maintaining stringent quality, our flagship 5050 SMD LED strips utilizing Samsung LM301B-H or Epistar 3030 high-density arrays deliver exceptional results. These strips achieve a luminous efficacy of 22-24 lumens per watt at 6000K correlated color temperature under standard test conditions (25°C ambient, 500mA drive current). Efficacy decreases slightly to 18-20 lumens per watt for warmer 3000K options due to phosphor conversion losses, though this remains competitive for CRI>90 products. Absolute brightness peaks at 2200-2400 lumens per meter for 6000K configurations, achieved through 120 LEDs per meter density and optimized current drivers.

Color rendering is non-negotiable in our high-brightness lines. All strips meeting the CRI>90 specification undergo strict binning to ensure a minimum CRI of 95, with R9 (saturated red) values exceeding 90 and R12 (saturated blue) above 85. This is accomplished using multi-phosphor LED chips and spectrally engineered formulations, critical for retail, hospitality, and architectural applications where true color representation is essential. Beauty STC validates these metrics through third-party LM-79 testing, not manufacturer estimates.

IP rating directly impacts real-world brightness sustainability. Our IP20 (bare PCB) strips deliver peak initial lumen output but are restricted to dry indoor use. For protected environments, IP65-rated strips feature a flexible silicone overmold that maintains 85% of bare PCB brightness while resisting dust and low-pressure water jets. True outdoor-grade IP67 strips, with full end-to-end sealing and UV-stable silicone, sustain 80-82% of nominal lumen output after encapsulation and are rigorously tested for submersion resistance. Crucially, Beauty STC incorporates aluminum PCB substrates and optimized thermal pads even in flexible strips, reducing thermal derating by 15% compared to standard FR4-based products—this ensures lumen maintenance remains above 90% at 25,000 hours per TM-21 projections.

Beauty STC’s quality commitment manifests in every specification. We enforce 100% automated optical inspection during SMT assembly, reject LEDs failing our tighter-than-industry CRI and chromaticity bins, and subject all high-brightness strips to 72-hour thermal soak testing at 60°C ambient. Our UL 8750 and IEC 62031 certifications reflect stringent safety adherence, while the 50,000-hour L70 lifetime warranty (at 40°C ambient) demonstrates confidence in lumen maintenance. Unlike competitors, we publish full IES files and LM-80 data, proving that our brightest strips maintain performance without premature degradation—even under continuous full-power operation. This engineering discipline ensures clients receive not just peak initial brightness, but sustained, color-accurate illumination where it matters most.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, a region known for its strong manufacturing infrastructure and supply chain advantages in the electronics and lighting industries. The Jiangmen facility is purpose-built for the production of high-quality LED lighting products, with a particular focus on LED light strips, including high-brightness variants.

The factory features a fully automated SMT (Surface Mount Technology) production line, utilizing advanced SMT machines from leading manufacturers. These machines ensure precise placement of LED components and other electronic parts onto flexible and rigid PCBs used in LED strips. The SMT line is integrated with automated optical inspection (AOI) systems to maintain high accuracy and consistency, minimizing defects and ensuring uniform performance across production batches. This automation allows for high-volume output while maintaining strict quality control standards.

To guarantee long-term reliability and performance, Beauty STC implements rigorous aging tests as part of its quality assurance process. Completed LED light strips undergo extended burn-in tests under controlled conditions, typically operating at full power for 24 to 72 hours. During these tests, the strips are monitored for color consistency, brightness stability, thermal performance, and electrical integrity. Only products that pass these stringent tests are approved for packaging and shipment.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, making it a preferred partner for global brands seeking customized LED lighting solutions. For the ‘brightest LED light strips’, the company can tailor specifications including LED chip type (such as high-density 5050, 3535, or COB), drive current, color temperature, CRI (Color Rendering Index), and IP rating. They support custom lengths, packaging, labeling, and branding, enabling clients to bring differentiated, high-performance products to market. Their engineering team works closely with clients to optimize thermal management, power efficiency, and optical performance, especially for high-lumen applications.

Overall, the Jiangmen factory combines advanced automation, thorough testing protocols, and flexible OEM services to deliver premium, high-brightness LED light strips that meet international standards and customer-specific requirements.

Application Scenarios

The brightest LED light strips serve specific high-impact applications within hotels, malls, and offices where maximum illumination, visual drama, or critical task lighting is required. In hotels, prioritize lobbies and grand reception areas where high-output strips create an immediate sense of luxury and welcome, particularly when integrated into cove lighting, feature walls, or under reception desks to eliminate shadows on faces. High-end suite kitchens and minibar areas also benefit from intense under-cabinet strips for precise task lighting, though guest room ambient lighting typically requires lower brightness. Avoid using the absolute brightest strips in guest room sleeping areas as excessive intensity disrupts relaxation. Within retail sections of hotels like gift shops or boutiques, deploy high-lumen strips to brilliantly showcase merchandise in display cases or along shelving edges.

Malls demand the highest brightness levels in expansive atriums and main concourses with tall ceilings, where powerful strips mounted in deep coves or structural reveals compensate for vertical distance and ensure even, glare-free illumination across wide walkways. Retail storefronts heavily utilize ultra-bright strips for window displays and fascia lighting to create vibrant, attention-grabbing visuals that stand out in competitive environments. Food court service counters require intense task lighting directly above preparation and ordering zones to ensure food safety visibility and employee efficiency, while perimeter architectural features like column wraps or stair treads use high-output strips for both safety and dramatic effect. Exercise caution with brightness in seating areas to avoid customer discomfort.

Office applications focus on functional intensity rather than ambiance. Conference rooms are prime locations, using the brightest strips in cove lighting to provide uniform, shadow-free illumination essential for video conferencing and detailed presentations without relying solely on overhead downlights. Reception desks employ high-lumen strips beneath the counter surface to brightly illuminate staff faces and documents. Dedicated task areas within open offices, such as detailed drafting stations or laboratory workbenches, may warrant localized high-output under-cabinet strips, but general open office ceilings should use diffused, lower-intensity solutions to prevent glare and eye strain. Executive office feature walls or display shelves can also leverage intense strips for visual prominence.

Installation demands rigorous attention to detail with high-brightness strips. Always verify electrical compatibility, using constant-voltage power supplies rated for at least 20% above the strip’s maximum wattage draw to prevent overheating and ensure longevity, especially in continuous commercial operation. Mount strips within extruded aluminum channels with thermal tape; this is non-negotiable for high-lumen density strips as the channel acts as a critical heat sink, preventing premature lumen depreciation and color shift. Position strips close to the surface being illuminated—typically within 1-2 inches in coves—to maximize usable light output and minimize upward spill, while ensuring the channel’s diffuser angle directs light precisely where needed. For runs exceeding 16 feet at 24V, implement parallel wiring or additional power feeds at multiple points to combat voltage drop, which causes noticeable dimming at the strip’s end. Conduct thorough in-situ testing before final mounting to confirm color consistency, brightness levels, and dimming functionality if applicable. Given the scale and electrical demands of commercial projects, always engage licensed electricians for final circuit connections and adhere strictly to local building codes regarding fire ratings and conduit requirements for permanent installations.

Why Choose Beauty STC Lighting

Discover the brightest LED light strips on the market and elevate your lighting projects with Beauty STC. As a trusted manufacturer in the LED industry, we specialize in high-performance, energy-efficient lighting solutions that deliver unmatched brightness and durability. Whether you’re working on architectural lighting, commercial displays, or premium residential installations, our LED strips are engineered to exceed expectations.

Partner with Beauty STC to gain access to cutting-edge technology, custom OEM/ODM services, and reliable global support. Our team is ready to help you bring brilliant ideas to life.

For collaboration opportunities and product inquiries, contact us today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.