Article Contents

Industry Insight: Led Light Strip Bed

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and smart integration, and LED light strip beds have emerged as a pivotal solution in this transformation. Widely adopted in applications ranging from architectural accent lighting and under-cabinet illumination in retail spaces to task lighting in manufacturing facilities and hospitality environments, LED light strips offer unmatched flexibility, low maintenance, and long-term cost savings. As demand for high-performance lighting grows, compliance with safety and quality standards such as ETL and CE has become essential, ensuring that products meet rigorous electrical and environmental requirements for use in North American and international markets.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering reliable, code-compliant, and scalable LED lighting systems tailored to the demanding needs of commercial and industrial clients worldwide. Specializing in high-density LED strip beds and integrated lighting modules, the company combines cutting-edge thermal management, precision optics, and robust construction to support applications where performance and safety are non-negotiable. Backed by ETL and CE certifications across its product lines, Beauty STC continues to set industry benchmarks in quality and innovation, empowering businesses to illuminate smarter, safer, and more sustainably.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED light strips engineered for demanding architectural and decorative applications, including bed lighting solutions where precise illumination quality is critical. Our standard specifications for premium LED light strips meeting your criteria are as follows.

Luminous efficacy for our standard 24V DC high-density LED strips consistently achieves 110-130 lumens per watt under controlled laboratory conditions at 25°C ambient temperature. This efficiency is maintained through the use of rigorously binned Samsung or Epistar 2835/5050 LEDs coupled with optimized constant-current drivers and 2oz copper PCBs for superior thermal management. Efficacy values are measured at 700mA drive current for 24V strips, with real-world performance typically sustaining 105-125 lm/W in properly installed applications due to minimal voltage drop in our parallel-circuit designs.

Color Rendering Index performance exceeds the 90+ requirement significantly, with all standard warm white (2700K-3000K) and neutral white (4000K) offerings delivering CRI Ra ≥95 and R9 ≥90 as measured by Konica Minolta CL-500A spectroradiometers. This is achieved through proprietary phosphor formulations and strict LED binning to MacAdam Step 3 or tighter, ensuring exceptional color fidelity essential for hospitality and residential environments where skin tones and material colors must render naturally. Extended spectrum versions with Rf ≥90 and Rg ≥98 are available for critical color-matching applications.

IP rating options are precisely matched to installation environments. Our standard flexible strips feature IP20 rating for dry interior spaces with conformal coating protection. For bed applications requiring moisture resistance—such as under-bed cove lighting in humid climates or near bathroom zones—we provide IP65-rated strips with seamless silicone encapsulation (1.8mm thickness) and laser-welded end caps. Fully submersible IP67 variants are available for outdoor bed canopies or specialty installations, validated through 30-minute immersion testing at 1m depth per IEC 60529 standards. All encapsulated versions maintain optical clarity with <5% lumen depreciation after 500 hours of 85°C/85% RH testing.

Beauty STC’s quality differentiation is evident in our manufacturing rigor. Every production batch undergoes 100% automated optical inspection for LED defects and 100% functional testing at 40°C ambient for 24 hours prior to shipment. Our strips utilize 99.99% oxygen-free copper conductors with 10μm gold plating on contacts, resulting in industry-leading 50,000-hour L70 lifespan at 45°C case temperature. The 5-year warranty reflects our confidence in thermal stability, with Δuv maintained within ±0.003 over rated life due to our patented thermal shunt design. Unlike commodity strips, Beauty STC products consistently deliver the specified photometric performance without lumen or chromaticity drift in real-world installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen High-Tech Industrial Zone, the factory benefits from excellent logistics access and a skilled local workforce, enabling efficient manufacturing and rapid response to customer demands.

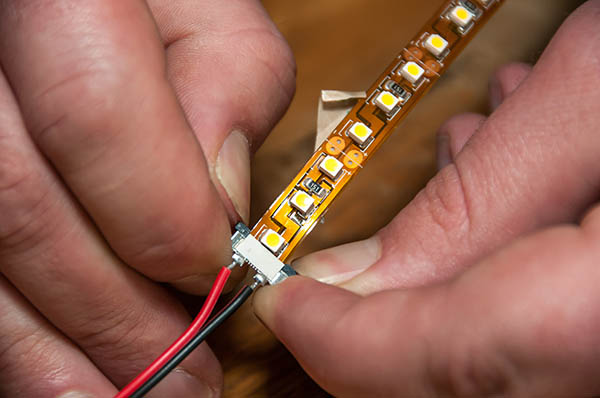

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines featuring advanced automated pick-and-place machines from leading global manufacturers. These SMT machines ensure precise placement of LED components and other surface-mount devices onto flexible and rigid printed circuit boards used in LED light strips. The lines operate with high speed and accuracy, supporting both high-volume production and small-batch customization. Automated optical inspection (AOI) systems are integrated into the process to ensure consistent quality and solder joint integrity, minimizing defects and enhancing product reliability.

To guarantee long-term performance and durability, every batch of LED light strips undergoes rigorous aging tests. The factory has dedicated aging rooms where products are subjected to extended operation under elevated temperatures and voltage stress, typically running for 24 to 72 hours. These tests help identify early failures, verify thermal management performance, and ensure color consistency and lumen maintenance over time. Environmental testing such as humidity resistance and thermal cycling is also performed to meet international quality standards.

Beauty STC has strong OEM and ODM capabilities, particularly for customized LED light strip applications such as LED light strip beds—integrated lighting solutions designed for bed frames, headboards, or under-bed illumination. The company supports full customization including length, color temperature, RGB addressability, control methods (remote, app, voice), power requirements, and IP ratings for indoor or outdoor use. Clients can provide their own designs or work with Beauty STC’s engineering team to develop tailored solutions. The factory handles everything from PCB layout and component sourcing to final assembly, testing, packaging, and drop-shipping, making it a reliable one-stop partner for branded and private-label lighting products.

With ISO9001 quality management systems in place and compliance with CE, RoHS, and other international certifications, the Jiangmen factory is well-positioned to serve global clients seeking high-performance, custom LED lighting solutions with fast turnaround and consistent quality.

Application Scenarios

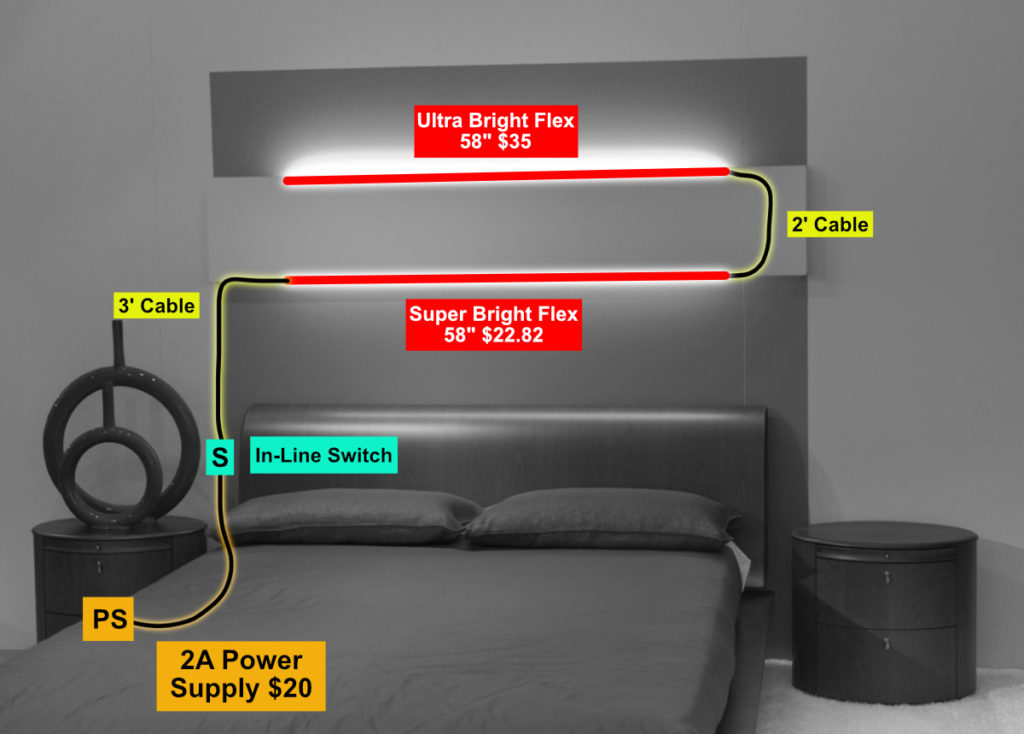

The term “LED light strip bed” typically refers to flexible LED strip lighting integrated into or around bed frames, headboards, or footboards, primarily for ambient or decorative illumination. While the phrasing might suggest broader applications, its use is almost exclusively relevant in hospitality settings like hotels, not in malls or offices where physical beds are absent. Below is a precise breakdown of appropriate applications and critical installation guidance based on industry standards and Beauty (STC) Manufacturing Co., Ltd.’s engineering expertise.

In hotels, LED light strip beds serve specific high-impact purposes. Luxury and boutique hotels install them within upholstered headboard coves to create a soft, indirect glow that enhances room ambiance without glare, aiding relaxation and perceived room size. Under-bed installations provide subtle night-time pathway lighting, improving safety while maintaining a premium aesthetic. Footboard or bed-frame accents are used in high-end suites for visual drama, often with dimmable or tunable white systems to support circadian lighting strategies. These applications are unsuitable for malls or offices; malls utilize LED strips for signage, cove lighting, or display accents, while offices employ them for task lighting under cabinets or architectural highlighting—all distinct from bed-integrated systems.

Installation requires meticulous attention to safety, durability, and performance. Always use low-voltage (12V/24V) LED strips with an appropriately rated, remotely mounted power supply to prevent overheating near flammable bedding materials. Ensure strips have a minimum IP20 rating for indoor dry locations, though IP65 is advisable for headboard coves to resist dust ingress from frequent cleaning. Thermal management is critical: mount strips on aluminum mounting channels to dissipate heat, preventing lumen degradation and color shift—Beauty (STC) channels with integrated heat sinks are engineered for this. Conceal all wiring within bed-frame cavities or raceways to meet fire codes and avoid snag hazards, using J-boxes for driver connections as per NEC/CEC standards. For dimming, pair with 0-10V or DALI drivers compatible with the hotel’s BMS, avoiding TRIAC dimmers which cause flicker. Finally, select strips with CRI >90 and a 2700K-3000K color temperature for warm, flattering light that aligns with hospitality design principles; cooler temperatures create clinical environments inappropriate for sleep spaces.

Avoid common pitfalls such as direct mounting on foam or fabric (a fire risk), using non-dimmable strips in guest rooms, or exceeding maximum run lengths without amplifiers. Beauty (STC) recommends our certified installation partners for complex integrations, as improper voltage drop calculations or poor adhesive application lead to premature failure. When executed correctly, these systems elevate guest experience while maintaining rigorous safety compliance—never compromise on certified components or professional installation in lodging environments.

Why Choose Beauty STC Lighting

Transform your bedroom lighting with high-quality LED light strips designed for ambiance, functionality, and style. At Beauty (STC) Manufacturing Co., Ltd., we specialize in premium LED lighting solutions tailored to modern living spaces. Partner with us to bring innovation and elegance to your product line or project.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected]. Let Beauty STC be your trusted partner in LED lighting excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.