Article Contents

Industry Insight: Led Light Heat Sink

Thermal management remains the defining challenge in commercial and industrial LED lighting performance and longevity, where high-output fixtures operate continuously under demanding conditions. Unlike residential applications, these environments—spanning warehouses, manufacturing floors, parking structures, and retail spaces—demand lighting solutions that maintain lumen output and color stability for tens of thousands of hours. The heat sink is not merely a component; it is the critical thermal backbone ensuring LEDs operate within their optimal temperature range, directly impacting fixture efficacy, lifespan, and total cost of ownership. Failure to effectively dissipate heat accelerates lumen depreciation and risks premature failure, undermining the core value proposition of LED technology in professional settings. Crucially, adherence to rigorous safety and performance standards like ETL for the North American market and CE marking for Europe is non-negotiable for specifiers and facility managers. These certifications validate not only electrical safety but also the thermal design integrity of the entire fixture, including the heat sink’s ability to manage heat under real-world operational stress. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over two decades to mastering this thermal challenge. We engineer and manufacture high-performance LED lighting solutions specifically for the commercial and industrial sector, with thermal management expertise at our core. Our commitment to robust heat sink design, validated through stringent compliance with ETL, CE, and other global standards, ensures our fixtures deliver the reliability, efficiency, and durability professionals demand in mission-critical lighting applications. We are not just a manufacturer; we are a trusted partner in sustainable, high-performance illumination.

Technical Specs & Certifications

The LED light heat sink is a critical component in ensuring the performance, efficiency, and longevity of LED lighting systems. At Beauty (STC) Manufacturing Co., Ltd., our heat sinks are engineered to support high-performance LED fixtures that meet stringent technical and quality standards. When paired with our advanced LED modules, these heat sinks enable optimal thermal management, directly influencing key metrics such as lumens per watt, color rendering, and environmental resilience.

Lumens per watt (lm/W) is a measure of luminous efficacy, indicating how efficiently a light source produces visible light. Our LED lighting systems, designed with precision-matched heat sinks, consistently achieve luminous efficacies ranging from 130 to 180 lm/W, depending on the configuration and application. This high efficiency is made possible by the heat sink’s ability to maintain lower LED junction temperatures, minimizing lumen depreciation and ensuring sustained light output over time. The aluminum alloy construction—typically 6063-T5—with optimized fin design and surface anodization maximizes thermal conductivity and dissipation.

Color Rendering Index (CRI) is essential for applications requiring accurate color representation, such as retail, healthcare, and studios. Beauty STC’s LED fixtures, equipped with our high-efficiency heat sinks, support LED chips that deliver a CRI greater than 90. This is maintained over the product’s lifespan due to effective thermal regulation, which prevents color shift caused by overheating. We use high-quality phosphor-coated LEDs from trusted suppliers, ensuring consistency in chromaticity and long-term color stability.

Ingress Protection (IP) ratings indicate the fixture’s resistance to dust and moisture. Our integrated LED luminaire designs—featuring die-cast or extruded heat sinks—support IP ratings up to IP66 and IP67. This is achieved through seamless housing integration, gasket sealing, and corrosion-resistant finishes on the heat sink surface. These ratings make our products suitable for both indoor and outdoor environments, including wet locations, industrial settings, and coastal areas.

Beauty STC is committed to excellence in manufacturing and product reliability. Our heat sinks undergo rigorous quality control, including thermal performance testing, salt spray resistance tests, and material certification. We adhere to international standards such as ISO 9001 and IEC 62717, ensuring consistent performance and safety. Every heat sink is designed in-house using thermal simulation software to optimize airflow and heat transfer, reflecting our dedication to innovation and engineering precision.

In summary, Beauty STC’s LED light heat sinks are integral to delivering high-efficiency lighting solutions with exceptional lumens per watt, CRI above 90, and robust IP-rated protection. Our focus on thermal management and quality manufacturing ensures that our LED systems perform reliably in demanding applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production capacity. Strategically located within the Pearl River Delta manufacturing corridor, the Jiangmen factory occupies a purpose-built site of approximately 30,000 square meters. This facility is designed to stringent international manufacturing standards, featuring controlled environment zones for critical processes, comprehensive quality control laboratories, and dedicated areas for raw material storage, component assembly, and finished goods logistics. The layout emphasizes efficiency and traceability throughout the production flow, supporting both high-volume output and specialized project fulfillment.

The Surface Mount Technology (SMT) production lines form the core of our electronics assembly capability at the Jiangmen site. We operate multiple high-speed, high-precision Yamaha YSM20 and YSM10 placement machines, capable of handling components down to the ultra-fine 0201 package size. These machines feature advanced multi-vision systems for precise component recognition and placement, with placement accuracy consistently maintained within ±25 microns. The SMT lines are fully integrated with automated solder paste printers, reflow ovens with 10+ zone temperature profiling, and automated optical inspection (AOI) systems that perform 100% post-placement and post-reflow verification. This ensures exceptional solder joint quality and component placement integrity for LED drivers, control modules, and other critical circuitry, forming the reliable electronic foundation for our lighting products.

Rigorous aging and reliability testing are non-negotiable elements of our quality assurance protocol at the Jiangmen factory. We maintain a large-scale, dedicated aging test laboratory equipped with numerous environmental chambers capable of simulating extended operational life under controlled thermal and electrical stress. Typical aging tests run for durations of 500 to 1000 hours at elevated temperatures, significantly exceeding standard industry practice. During these tests, critical parameters such as lumen maintenance, chromaticity shift, forward voltage, and thermal performance are continuously monitored using calibrated spectroradiometers and data loggers. This comprehensive aging regime allows us to identify potential infant mortality failures, validate thermal management designs, and ensure the long-term performance and reliability our customers expect before any product leaves the factory.

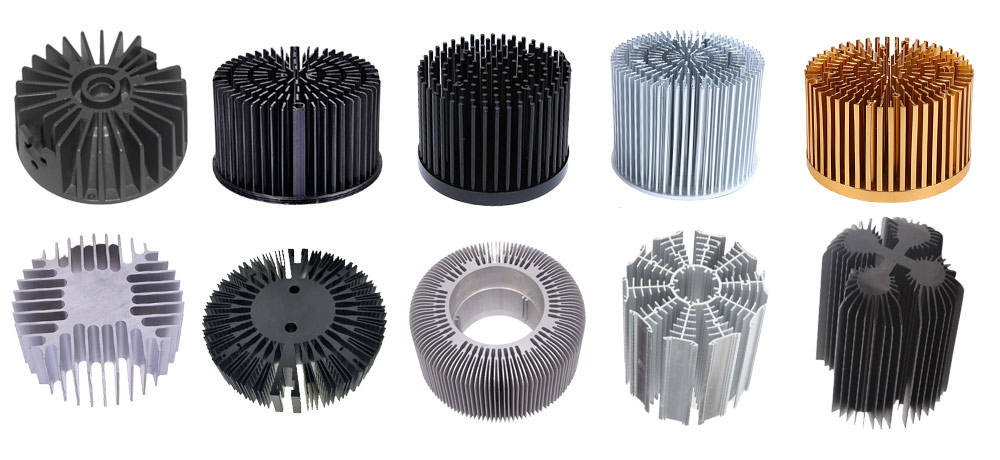

Our OEM capability for LED light heat sinks is a particular strength developed at the Jiangmen facility. We offer a complete turnkey solution for custom heat sink production, beginning with thermal simulation and mechanical design support using industry-standard software like SolidWorks Flow Simulation. The factory houses in-house aluminum extrusion tooling capabilities, allowing us to develop and maintain custom profiles optimized for specific thermal and aesthetic requirements. Post-extrusion, we perform precision CNC machining for mounting features, threading, and critical tolerances, followed by a range of surface finishing options including anodizing (clear, black, colored), powder coating, and chromate conversion. Crucially, our integration within the full LED lighting assembly process means these custom heat sinks are seamlessly incorporated into final luminaires, with rigorous thermal validation performed during the aging tests mentioned previously. This ensures the heat sink design not only meets manufacturing specifications but also delivers the required thermal performance within the complete product under real-world operating conditions, all while adhering to international safety and compliance standards.

Application Scenarios

LED light heat sinks are essential components in any LED lighting system where thermal management is critical to ensure performance longevity and reliability. They are commonly used across commercial and industrial environments such as hotels, malls, and offices, particularly in high-output or enclosed lighting fixtures.

In hotels, LED heat sinks are used in recessed downlights, corridor lighting, lobby chandeliers, and outdoor landscape lighting. These areas often require continuous operation, and effective heat dissipation helps maintain light output and color consistency while preventing premature failure. High-end guest rooms and banquet halls with dimmable or decorative LED fixtures also benefit from integrated heat sinks to handle variable loads and maintain aesthetic integrity.

In malls, where lighting is typically on for extended periods and high lumen output is required, heat sinks are crucial in track lighting, high bays, and spotlight displays. The large open spaces demand powerful LED fixtures that generate significant heat. Without proper thermal management, light efficacy drops and LED drivers may fail prematurely. Heat sinks ensure stable operation under high ambient temperatures and heavy usage.

In offices, LED heat sinks are used in panel lights, troffers, and under-cabinet lighting. These fixtures are often installed in ceiling grids with limited airflow, making heat buildup a concern. Efficient heat sinks help maintain cooler operating temperatures, which supports long service life and reduces maintenance costs—important factors in corporate environments with large-scale lighting installations.

When installing LED lights with heat sinks, several best practices should be followed. Ensure the fixture is mounted in a location with adequate ventilation. Avoid enclosing the fixture in tight, non-ventilated spaces unless it is specifically rated for enclosed use. Always follow the manufacturer’s clearance guidelines around the heat sink to allow for proper airflow.

Mount the fixture securely to a stable surface to ensure consistent thermal contact between the LED module and the heat sink. Avoid applying external coatings or paint to the heat sink, as this can insulate and reduce its effectiveness. Regularly inspect for dust accumulation, especially in malls or industrial office environments, and clean the heat sink fins gently with compressed air or a soft brush during maintenance cycles.

Lastly, always verify that the heat sink is correctly matched to the LED’s power rating and thermal requirements. Using undersized or inadequate heat sinks can lead to thermal runaway and early failure. Proper selection and installation ensure optimal performance and reliability across all commercial applications.

Why Choose Beauty STC Lighting

Partner with Beauty STC Manufacturing Co., Ltd. for engineered excellence in LED light heat sink solutions. As your dedicated thermal management partner, we leverage decades of specialized expertise to deliver heat sinks that ensure optimal LED performance, longevity, and reliability under demanding conditions. Our rigorous engineering process focuses on maximizing thermal dissipation while maintaining sleek, cost-effective designs tailored to your specific luminaire requirements.

Eliminate thermal bottlenecks and elevate your product quality by integrating Beauty STC’s precision-engineered heat sinks into your lighting systems. We collaborate closely with clients from initial concept through production, providing thermal analysis, material optimization, and scalable manufacturing to meet your volume and performance targets. Trust our engineering team to solve your most complex thermal challenges and enhance your product’s market competitiveness.

Reach out to our technical management team today to discuss your next LED lighting project. Contact us directly at [email protected] to initiate a partnership focused on innovation, quality, and measurable results in thermal management.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.