Article Contents

Industry Insight: Led Light Diffuser

The commercial and industrial LED lighting sector demands precision engineering where every component directly impacts performance, safety, and operational efficiency. Central to achieving optimal illumination in demanding environments like warehouses, factories, offices, and retail spaces is the often-underestimated LED light diffuser. Far more than a simple cover, a high-performance diffuser is critical for eliminating harsh glare, ensuring uniform light distribution across work surfaces, minimizing shadows that compromise safety, and protecting the sensitive LED modules beneath from dust and physical impact. Crucially, in this global market, compliance is non-negotiable; diffusers must be integral to luminaires certified to stringent safety standards such as ETL for North America and CE marking for the European Union, guaranteeing electrical safety and environmental resilience under continuous operation. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. For over 25 years, we have engineered advanced diffuser solutions specifically for commercial and industrial applications, understanding that superior optical performance must seamlessly integrate with rigorous certification requirements to deliver the reliable, high-quality lighting essential for modern workplaces and facilities. Our expertise lies in transforming raw LED output into functional, comfortable, and code-compliant illumination.

Technical Specs & Certifications

The LED light diffuser solutions developed by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high-performance illumination with exceptional optical clarity and durability. When integrated into LED lighting systems, these diffusers contribute significantly to achieving optimal light distribution while maintaining outstanding energy efficiency and color fidelity.

In terms of efficiency, our diffuser-compatible LED fixtures consistently achieve luminous efficacies of 120 to 150 lumens per watt, depending on the configuration and thermal management design. This high lumens-per-watt ratio ensures minimal energy waste and reduced operational costs, making our lighting ideal for both commercial and industrial applications where energy savings are critical.

A key hallmark of our lighting systems is the high Color Rendering Index (CRI), consistently exceeding 90—typically reaching CRI 93–95. This superior color accuracy ensures that illuminated environments render colors naturally and vividly, which is essential in retail, healthcare, architectural lighting, and precision workspaces. Beauty STC achieves this through the use of premium phosphor-coated LEDs and advanced diffuser materials that minimize spectral distortion while promoting uniform light dispersion.

Regarding environmental protection, Beauty STC offers LED luminaires with diffusers rated at IP65, IP66, and up to IP67, depending on the application. These Ingress Protection ratings confirm the fixtures’ resistance to dust, moisture, and temporary immersion, making them suitable for demanding environments such as outdoor installations, wet locations, and industrial facilities. The diffusers are constructed from high-grade polycarbonate or PMMA materials that maintain their optical properties under prolonged UV exposure and extreme temperatures.

Beauty (STC) Manufacturing Co., Ltd. upholds rigorous quality control standards throughout the production process. Our diffusers and integrated LED systems undergo extensive photometric testing, thermal cycling, and environmental stress screening to ensure long-term reliability and performance consistency. With a commitment to innovation and precision engineering, Beauty STC delivers lighting solutions that combine efficiency, visual comfort, and durability—setting a benchmark in the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting components, including specialized optical elements like LED light diffusers. Strategically located within the Pearl River Delta’s robust electronics supply chain, the Jiangmen factory integrates modern automation with stringent quality control systems to ensure high-volume output and precision manufacturing. The facility operates under ISO 9001-certified processes, emphasizing consistency and reliability for both domestic and international clients.

The surface-mount technology (SMT) production line utilizes multiple high-speed Yamaha YS series placement machines, capable of handling components as small as 0201 metric packages with placement accuracy of ±25µm. These automated lines feature dual-lane configurations for parallel processing, integrated solder paste inspection (SPI) systems to verify paste volume and alignment, and 3D automated optical inspection (AOI) stations post-reflow for comprehensive defect detection. This setup ensures precise mounting of LEDs, drivers, and control circuitry onto PCBs destined for diffuser-integrated luminaires, with typical throughput exceeding 50,000 components per hour per line while maintaining industry-leading first-pass yield rates above 99.2%.

Aging and reliability testing for LED diffuser assemblies occurs in dedicated environmental chambers designed to simulate accelerated lifetime conditions. Finished diffuser modules undergo mandatory 72-hour continuous aging tests at elevated temperatures of 65°C ±2°C, with real-time monitoring of luminous flux, chromaticity shift, and thermal performance via spectroradiometers and thermal imaging systems. We implement thermal shock testing per IEC 60068-2-14 standards, cycling products between -20°C and 85°C across 50 cycles to validate material integrity and optical stability. Any unit exhibiting flux depreciation exceeding 3% or color shift beyond MacAdam Step 3 during aging is quarantined for root-cause analysis, ensuring only units meeting our 50,000-hour L70 reliability benchmark reach customers.

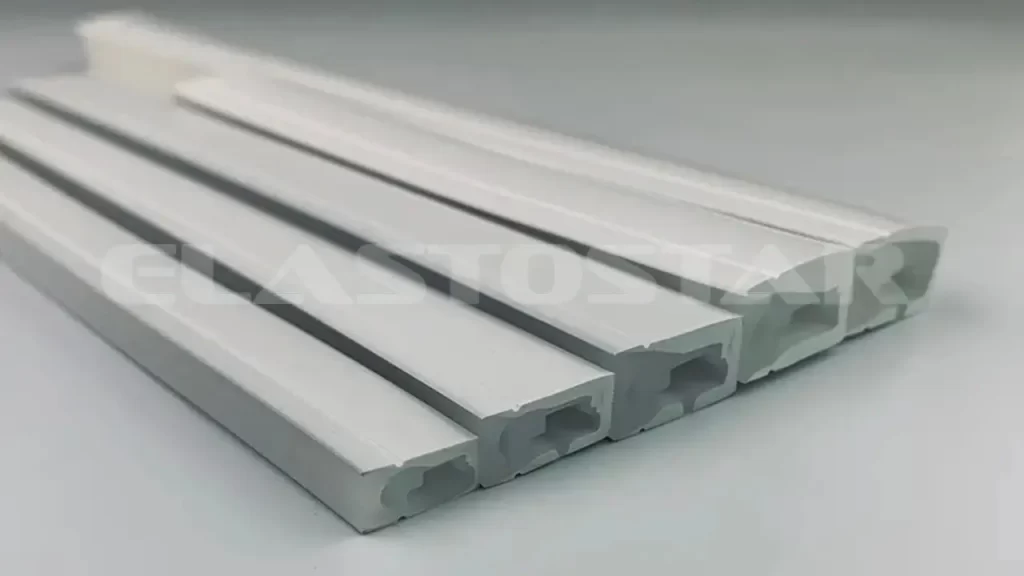

Our OEM capabilities for LED light diffusers encompass full-service customization from concept to packaged product. We support clients in material selection including optical-grade PMMA, PC, or silicone-based formulations with transmittance ranges from 85% to 92% and haze values adjustable between 10% and 95% to meet specific diffusion requirements. Engineering teams collaborate on geometric design optimization using LightTools simulations for uniformity control, followed by mold development for injection-molded or extruded diffusers in thicknesses from 0.8mm to 5.0mm. Production accommodates custom shapes, surface textures (prismatic, micro-lens, frosted), and secondary optical features like beam-shaping microstructures. With in-house tooling modification expertise and flexible batch sizing down to 5,000 units, we deliver diffusers compliant with photometric standards while managing all logistics, packaging, and documentation for global shipment.

Application Scenarios

LED light diffusers are essential components in modern lighting systems, used to evenly distribute light while minimizing glare and hotspots. Their application across various commercial environments such as hotels, malls, and offices enhances both aesthetics and functionality.

In hotels, LED light diffusers are commonly used in lobbies, guest rooms, hallways, and banquet halls. They help create a soft, welcoming ambiance that contributes to guest comfort. Recessed ceiling panels, cove lighting, and decorative fixtures often incorporate diffusers to achieve uniform illumination without harsh shadows. In high-end areas like spas or restaurants, frosted or prismatic diffusers can add a touch of elegance while maintaining optimal light quality.

Malls benefit significantly from LED light diffusers in large atriums, corridors, and retail spaces. Uniform lighting is crucial for creating an inviting shopping environment and ensuring product displays are well-lit. Linear LED fixtures with diffusers are frequently installed in ceilings to provide consistent brightness across expansive areas. The use of diffusers also reduces eye strain for shoppers and supports safety by eliminating dark spots.

In office environments, LED light diffusers are typically integrated into suspended ceiling grids using troffer or panel lights. They play a vital role in maintaining a comfortable and productive workspace by providing glare-free, evenly dispersed lighting. Offices with open-plan layouts especially benefit from diffused lighting to minimize visual fatigue during prolonged screen use. Edge-lit LED panels with high-transmission diffusers are popular choices due to their sleek appearance and efficiency.

When installing LED light diffusers, several best practices should be followed. First, ensure the diffuser material is compatible with the fixture’s heat output—polycarbonate and acrylic diffusers have different thermal tolerances. Always handle diffusers with clean gloves to avoid fingerprints and scratches. During installation, align the diffuser properly within the frame to prevent light leakage or visible seams. For recessed or surface-mounted fixtures, make sure the housing is securely fastened before inserting the diffuser. In environments with high airflow or vibration, such as mall ceilings or busy corridors, use clips or retaining bars to keep the diffuser firmly in place. Regular maintenance access should also be considered, so diffusers can be easily removed for cleaning or lamp replacement without damage.

Why Choose Beauty STC Lighting

Elevate your lighting projects with precision-engineered LED light diffusers designed to deliver exceptional optical performance and visual comfort. At Beauty STC, we specialize in advanced diffuser solutions that eliminate hotspots, ensure uniform luminance, and maintain color fidelity across diverse applications—from high-end architectural installations to commercial retail environments. Our proprietary materials and rigorous testing protocols guarantee diffusers that integrate seamlessly with your luminaires while meeting the most demanding photometric standards.

Partner with Beauty STC to access custom diffuser development backed by 15+ years of optical engineering expertise and ISO-certified manufacturing. We collaborate closely with lighting designers and OEMs to solve complex challenges, whether optimizing for glare control, light transmission efficiency, or aesthetic integration. Let us help you achieve flawless light distribution that enhances both functionality and user experience in every space.

Contact our technical partnership team today to discuss your specific requirements and discover how Beauty STC’s diffuser technology can differentiate your products in the market. Reach Manager directly at [email protected] for a tailored consultation and sample evaluation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.