Article Contents

Industry Insight: Led Light Control

The evolution of LED lighting control has fundamentally transformed energy management and operational efficiency across commercial and industrial facilities, moving far beyond simple on/off functionality. Today’s sophisticated control systems—encompassing occupancy and vacancy sensing, daylight harvesting, time scheduling, task tuning, and fully networked IoT platforms—are critical drivers for achieving significant energy savings, often exceeding 30-60% compared to legacy systems, while simultaneously enhancing occupant comfort, productivity, and space utilization. For facility managers and building owners, the strategic implementation of these controls is no longer a luxury but a necessity to meet stringent energy codes, reduce operational costs, and fulfill sustainability mandates. Crucially, deploying reliable and safe control solutions in demanding environments like warehouses, factories, offices, and retail spaces requires components that adhere to rigorous international safety and performance standards, with ETL certification for the North American market and CE marking for Europe serving as non-negotiable benchmarks for product legitimacy, electrical safety, and electromagnetic compatibility. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this transformation, leveraging over 25 years of specialized engineering expertise to design and manufacture high-performance, standards-compliant LED drivers, sensors, and control systems tailored precisely to the robust demands of commercial and industrial applications worldwide. Our deep understanding of real-world installation challenges and regulatory landscapes ensures our solutions deliver the durability, precision, and seamless integration essential for optimizing modern lighting infrastructure.

Technical Specs & Certifications

LED light control systems by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver superior performance, precision, and energy efficiency across a wide range of commercial, industrial, and architectural lighting applications. Central to our design philosophy is the integration of high-efficiency LED technology with intelligent control capabilities, ensuring optimal light output, color fidelity, and environmental resilience.

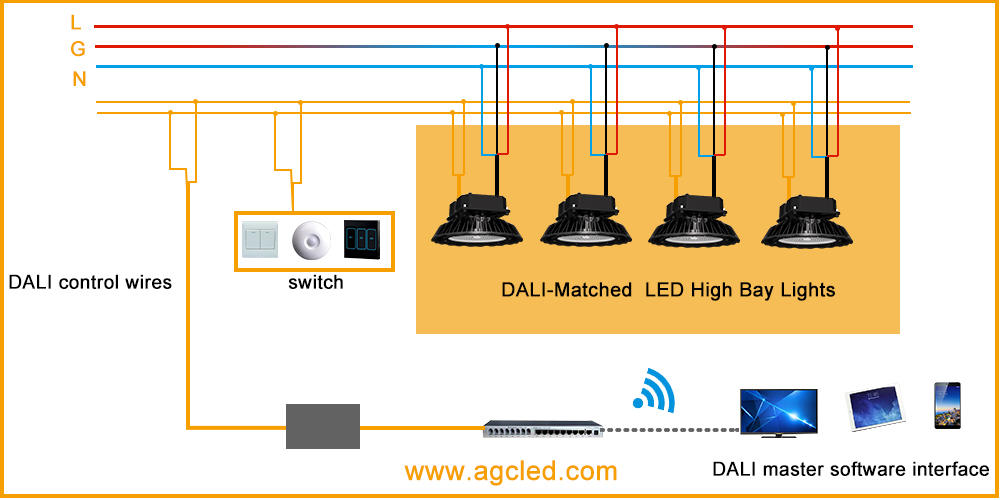

In terms of luminous efficacy, Beauty STC’s LED lighting solutions achieve industry-leading lumen-per-watt ratios, typically ranging from 130 to 180 lumens per watt depending on the fixture type and optical configuration. This high efficiency is attained through the use of premium-grade LED chips, advanced thermal management systems, and precision driver electronics that minimize energy loss while maintaining consistent light output over extended operational cycles. Our drivers support a variety of control protocols including 0-10V, DALI, PWM, and wireless systems (such as Zigbee and Bluetooth Mesh), enabling seamless integration into smart building ecosystems.

Color Rendering Index (CRI) is a critical benchmark in our product development, and all high-end fixtures are designed to deliver a CRI greater than 90, with select models exceeding 95. This ensures accurate color representation, making our lighting ideal for retail, healthcare, museum, and hospitality environments where visual clarity and color integrity are paramount. We achieve this through the use of multi-channel LED arrays and phosphor-converted white LEDs tuned to closely match natural daylight spectra.

Environmental durability is ensured through rigorous adherence to international protection marking standards. Beauty STC LED fixtures are available with IP ratings ranging from IP44 for indoor damp locations to IP65, IP66, and IP67 for outdoor and harsh industrial environments. These ratings reflect robust ingress protection against dust, moisture, and water jets, ensuring long-term reliability in demanding conditions. Sealed housings, corrosion-resistant materials, and gasketed optical compartments are standard in outdoor-rated products.

Quality is embedded in every stage of production at Beauty STC. Our manufacturing processes comply with ISO 9001 standards, and all products undergo extensive photometric testing, thermal cycling, and electrical safety verification. We utilize automated surface-mount technology (SMT) lines and in-line quality control systems to ensure consistency and reliability. The result is a portfolio of LED lighting controls and fixtures known for longevity, stable performance, and compliance with global safety and efficiency certifications including CE, UL, and RoHS.

By combining high lumens per watt, exceptional color rendering, and robust IP-rated construction, Beauty STC delivers LED light control solutions that meet the most demanding technical and aesthetic requirements.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern, purpose-built manufacturing facility in Jiangmen, Guangdong Province, China. This factory serves as our primary production hub for LED lighting solutions and related electronic components, featuring a comprehensive infrastructure designed for high-volume, precision manufacturing with stringent quality control. The facility spans over 10,000 square meters and is equipped with advanced automation to support global supply chain demands.

The Surface Mount Technology (SMT) production lines form the core of our electronics assembly capability. We utilize multiple high-speed, precision SMT machines from leading brands such as Yamaha and Panasonic, configured for efficient component placement across a wide range of PCB sizes. These lines include fully automated solder paste printers, reflow soldering ovens with nitrogen capabilities for optimal joint quality, and sophisticated Automated Optical Inspection (AOI) systems for real-time defect detection. This integrated SMT setup ensures high placement accuracy, repeatability, and throughput for complex LED driver and control circuit boards, handling components down to 0201 package sizes.

Rigorous aging and reliability testing is a mandatory step for all products before shipment. Our dedicated aging test area subjects finished LED drivers, modules, and control systems to extended operational stress under controlled conditions. Products undergo a minimum 72-hour continuous burn-in test at elevated temperatures (typically 60-70°C) and full load to identify early-life failures. Additionally, we conduct environmental stress screening including thermal cycling, humidity exposure, and input voltage variation tests. This comprehensive aging protocol, combined with final functional verification, ensures a field failure rate consistently below 0.3% and meets international reliability standards such as IEC 62384.

Beauty STC possesses extensive OEM capabilities specifically for LED light control systems. We offer full turnkey solutions from initial concept through to mass production, including custom circuit design, firmware development, and mechanical integration for a wide array of control products. Our expertise covers standard protocols such as 0-10V, DALI, PWM, and wireless systems including Bluetooth Mesh, Zigbee, and proprietary RF solutions. Clients can leverage our engineering team for tailored modifications to existing platforms or completely new developments, supported by in-house PCB design, prototyping, and certification assistance for major global markets (CE, UL, TUV, CCC). The factory’s flexibility allows for low to high-volume production runs with dedicated lines for specialized control products, ensuring confidentiality and adherence to client-specific quality benchmarks under strict ISO 9001 and ISO 14001 certified processes.

Application Scenarios

LED light control systems are highly effective in environments such as hotels, malls, and offices, where energy efficiency, ambiance, and operational control are critical. In hotels, LED lighting controls are ideal for guest rooms, lobbies, corridors, and banquet halls. They allow for customizable lighting scenes—such as wake-up, relaxation, or cleaning modes—enhancing guest comfort while reducing energy consumption through occupancy sensing and scheduled dimming. In malls, LED controls are best applied in retail spaces, atriums, and parking areas. Motion sensors and daylight harvesting systems help maintain optimal illumination while cutting electricity costs during low-traffic hours. For offices, LED controls improve productivity and comfort in open workspaces, private offices, meeting rooms, and common areas. Features like task tuning, personal dimming controls, and automated on/off based on occupancy support both energy savings and occupant well-being.

When installing LED light control systems, begin by conducting a detailed lighting audit to determine the appropriate control strategy for each zone. Ensure compatibility between LED drivers, dimmers, sensors, and control panels—mismatched components can cause flickering or reduced lifespan. Use low-voltage wiring for control signals and follow electrical codes strictly, especially in commercial installations. Position occupancy and daylight sensors carefully to avoid false triggers or blocked detection; for example, avoid placing motion sensors behind obstacles or in direct sunlight. In larger facilities, consider a centralized lighting management system that allows remote monitoring and scheduling via software. Finally, label all circuits and control zones clearly during installation to simplify maintenance and future upgrades. Proper commissioning and staff training are essential to ensure the system operates as intended and delivers long-term performance.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I emphasize that precise light control is fundamental to achieving exceptional lighting experiences in modern architectural and commercial environments. Our engineering team specializes in developing advanced, reliable, and seamlessly integrated LED control solutions that deliver unparalleled performance, energy efficiency, and user-friendly operation. Partner with Beauty STC to leverage our technical expertise and innovative approach, ensuring your projects benefit from lighting systems that are not only visually stunning but also technically robust and future-proof.

To explore a collaborative partnership and discuss how our tailored LED light control solutions can meet your specific requirements, reach out directly to our dedicated management team. Contact us at [email protected] to initiate a technical consultation and discover the Beauty STC advantage for your next lighting project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.